Double-channel exhaust pipe for taking gas from channel closest to supercharger through EGR

A technology closest to the supercharger, applied in the exhaust device, exhaust gas recirculation, machine/engine, etc., can solve the problem of high EGR rate demand, inability to meet, etc., to achieve the effect of smooth airflow and high EGR rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

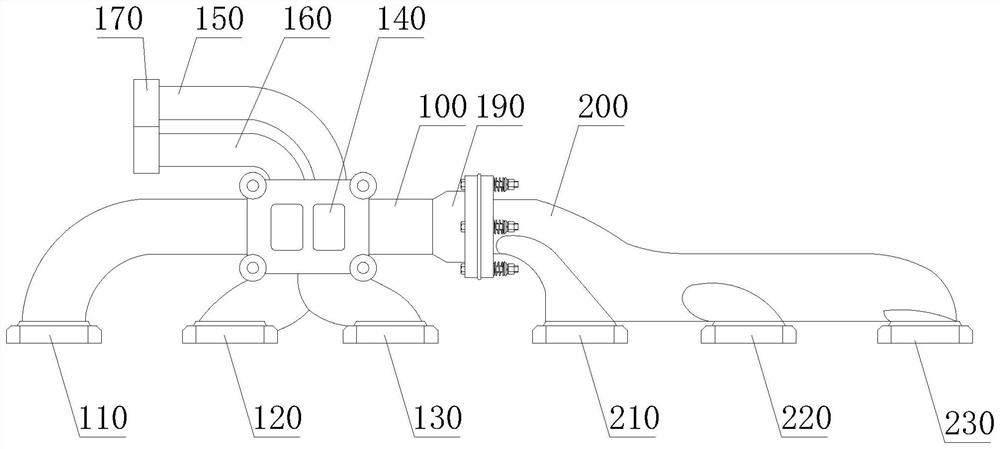

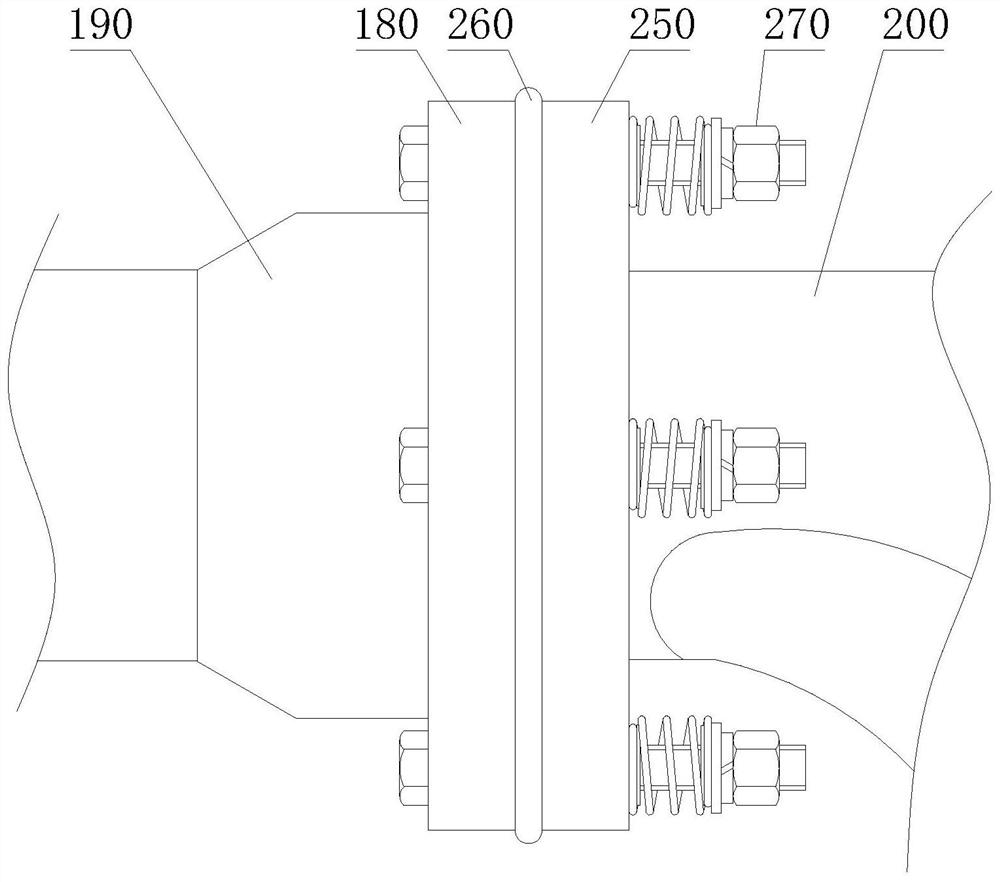

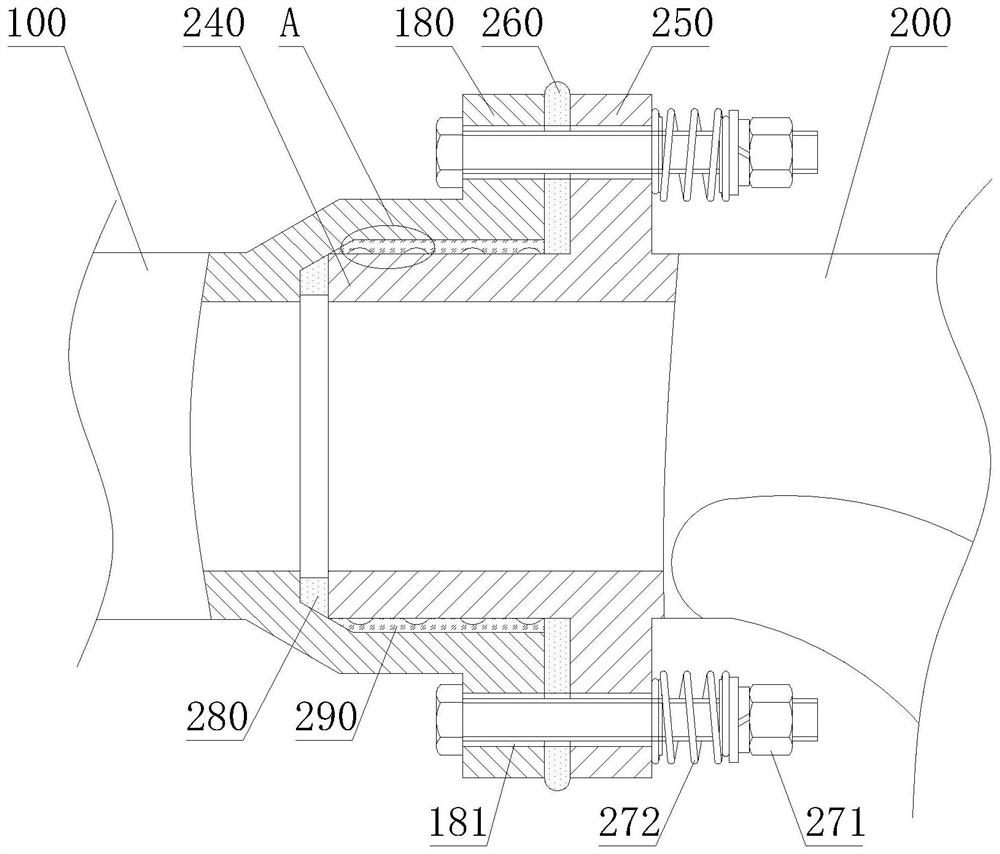

[0032] See Figure 1-4 The present invention provides a dual flow channel exhaust pipe that is closest to the supercharger, including the first exhaust manifold 100 and the second exhaust manifold 200.

[0033] Wherein, the first exhaust manifold 100 and the second exhaust manifold 200 are connected to each other, and the top of the first exhaust manifold 100 employs a dual-channel EGR system. In order to match the dual channel EGR valve, the engine exhaust pipe is from 1 to 1 ~ The 3-cylinder duct manifold and 4 ~ 6-cylinder-free manifold composition, each having 1 EGR air supply port corresponding to the inlet of the dual-channel EGR valve. The EGR air-opening position is arranged in the inlet position of the supercharger, the airflow is more smooth, the EGR rate is as high as 20%, meets the Summer Six emissions.

[0034] See figure 1, A first bottom manifold 100 are respectively provided with a first intake port 110, a second intake port 120 and the third intake port 130. The to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com