Method for removing dust and oil from wastewater and dust and oil removing system

An oil system and waste water technology, applied in the field of dust removal and oil removal system, waste water dust removal and oil removal, can solve the problems of not being able to remove dust and oil at the same time, and oil pollution treatment is difficult to meet the discharge standard, so as to be beneficial to comprehensive application and not cause secondary pollution , strong filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

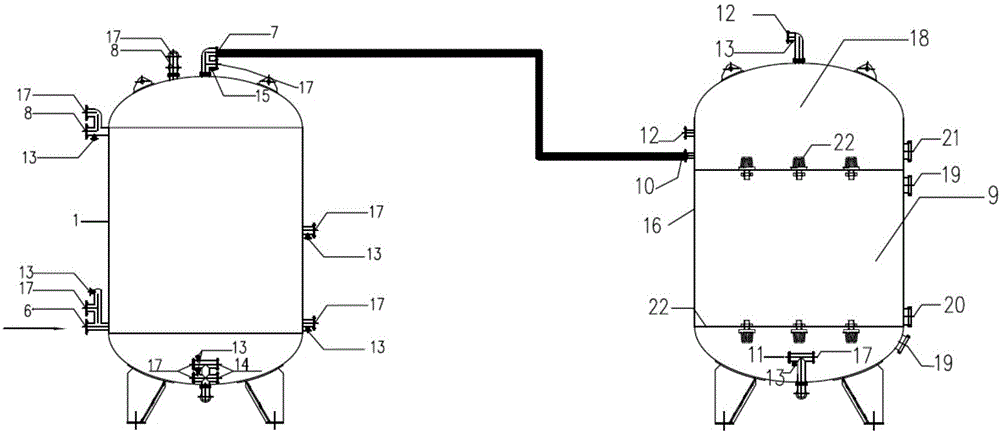

[0050] Example: see figure 1 , the present embodiment provides a method for dedusting and degreasing waste water, which comprises the following steps:

[0051] (1) Dust removal:

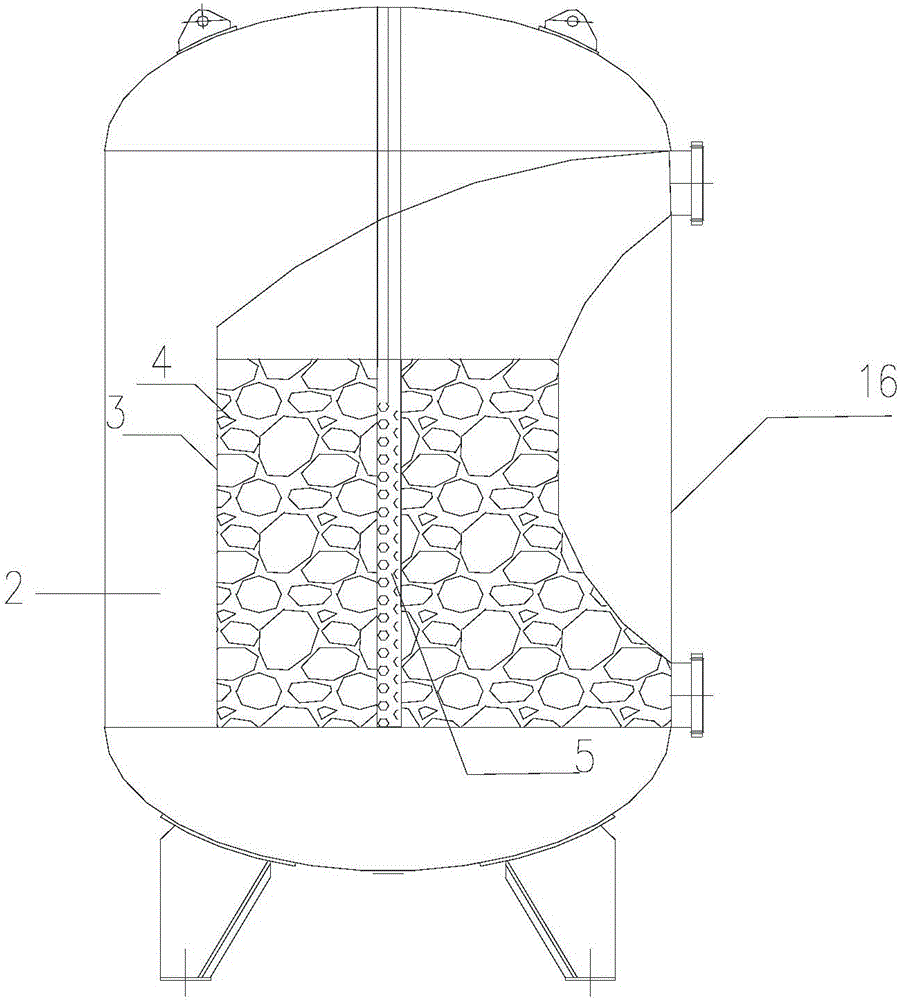

[0052] (1.1) Prepare a dust removal mechanical filter, which includes a cylinder shell 1, a water passage 2, a grid 3, a dust removal filter material 4 and a central water distributor 5, and the dust removal filter material 4 is arranged in the grid 3, and the The water channel 2 is set between the grid 3 and the inner wall of the cylinder shell 1, and the central water distributor 5 is set in the middle of the inside of the cylinder shell 1;

[0053] (1.2) Set a dust removal water inlet valve 6 at the lower part of one side of the cylinder shell 1, set a dust removal water outlet valve 7 at the upper end of the cylinder shell 1, and set a dust discharge valve 8 at the upper end of the cylinder shell 1;

[0054] (1.3) The waste water enters the water passage 2 through the dust removal water inlet val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com