Recycling and regeneration method of alkaline etching liquid

A technology of cyclic regeneration and etching solution, applied in the improvement of process efficiency, photography process, instruments, etc., can solve the problems of waste etching solution treatment troubled enterprises and other problems, so as to meet the needs of etching production, reduce production and operation costs, and realize automatic control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The recycling device for alkaline etching solution provided by the present invention will be described in detail below.

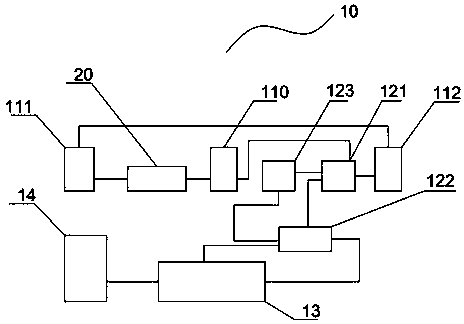

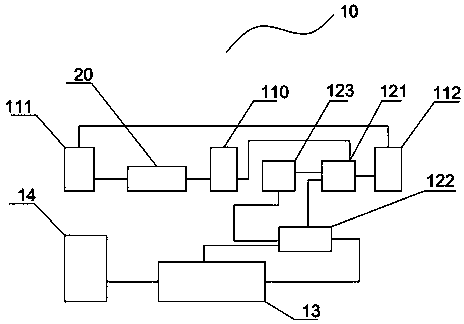

[0032] refer to figure 1 , a recycling device 10 for alkaline etching solution, including a connected circulating storage system and an extraction system, the circulating storage system includes an etching waste solution tank 110, a regeneration solution tank 111 and a regeneration solution preparation tank 112 for temporary storage and circulating alkaline etching waste liquid and alkaline etching regeneration liquid; the regeneration liquid tank 111 communicates with the alkaline etching line (SES line) 20, uses the regeneration liquid for the etching process, and connects the SES line 20 with the etching waste The liquid tank 110 is communicated, and the etching waste liquid that produces is collected in the etching waste liquid tank 110; The extraction system includes a connected copper extraction separator 121 and a stripping separator 122, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com