Sludge aerobic fermentation system

An aerobic fermentation and sludge technology, applied in biological sludge treatment, gas treatment, dispersed particle separation, etc., can solve the problem that aerobic fermentation cannot be carried out continuously, the sludge accumulation height should not be too high, and bacteria provide oxygen environment, etc. problems, to achieve the effect of convenient installation, high degree of automation, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

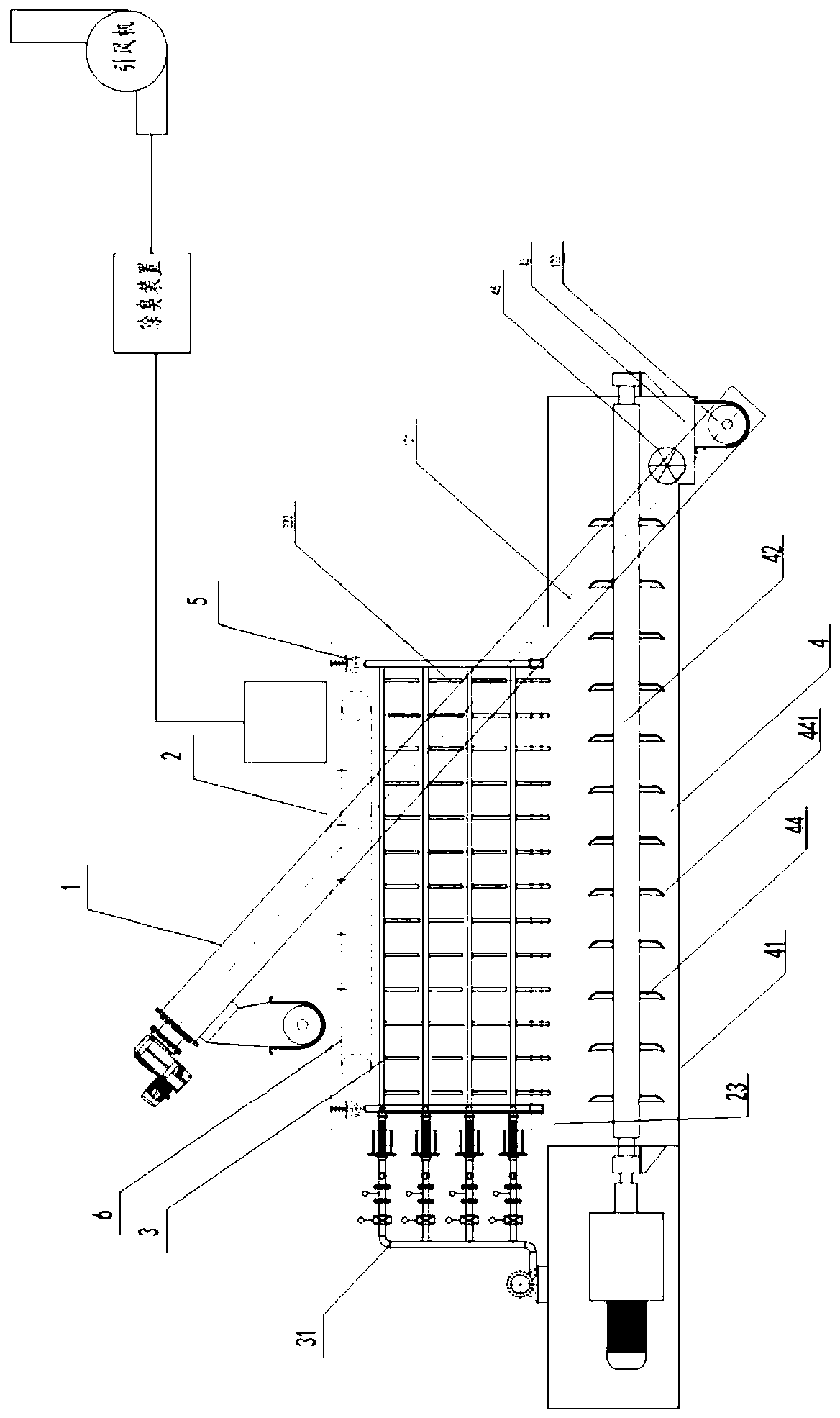

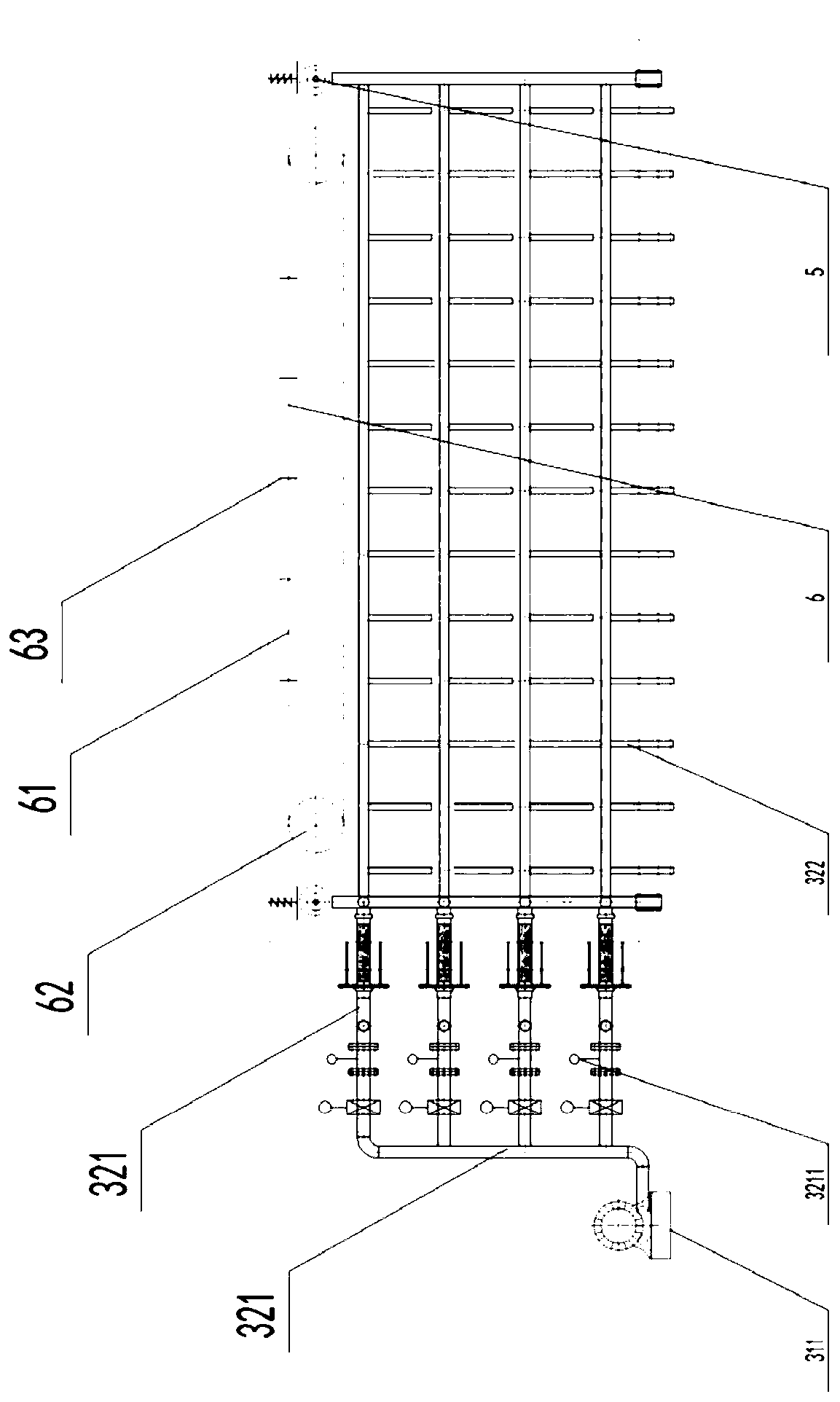

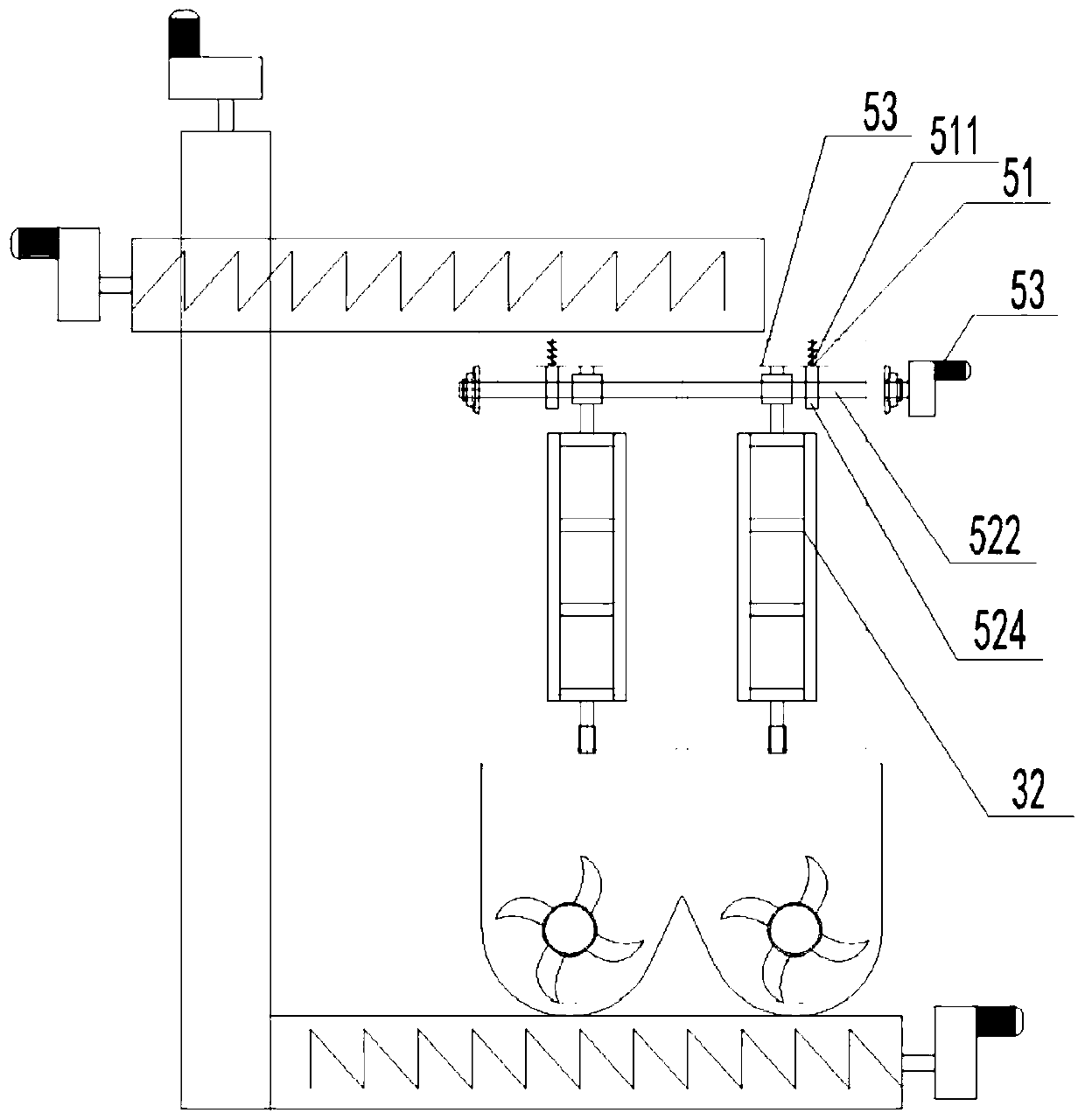

[0050] like Figure 1-12 As shown, a kind of sludge aerobic fermentation system of the present invention comprises a feeding device 1, a fermentation tank 2, an aeration device 3 and a discharge device 4, and the feeding device 1 transports the sludge material to the upper end of the fermentation tank 2, And thrown from the upper end, the sludge material is sent into the fermentation tank 2 for fermentation, and after the sludge material is fermented with oxygen provided by the aeration device, it is sent away from the fermentation tank 2 through the discharge device 4; wherein, the aeration device 3 includes an air intake pipe 31 Aeration units 32 connected with a plurality of inlet pipes 31 are distributed in the fermentation tank 2 to provide oxygen for the sludge to fully ferment.

[0051] This system utilizes the fermenting box to ferment, which solves the problem that the fermentation device of the pit filling type fermentation in the prior art center cannot be moved and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com