Automatic etching and cleaning device for PCB

A technology for PCB boards and cleaning devices, which is applied in the cleaning/polishing of conductive patterns, secondary processing of printed circuits, electrical components, etc., can solve the problems of high labor intensity, worker hazards, corrosion of etching liquid, etc., and reduce labor intensity. , High degree of automation, ensure the effect of cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

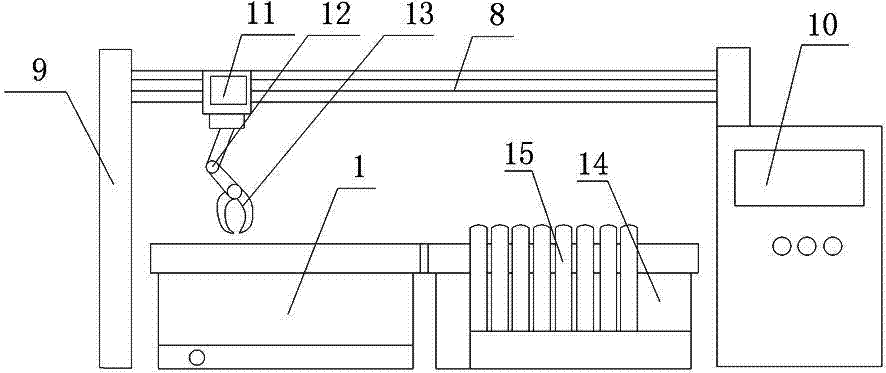

[0014] Such as figure 1 Shown, a kind of PCB board automatic etching cleaning device, it comprises etching tank 1, cleaning tank 14, grasping mechanism, cross bar 8, support 9 and control box 10, described grasping mechanism comprises manipulator controller 11, mechanical Arm 12 and manipulator 13, described manipulator controller 11 and manipulator 12 are flexibly connected, and lead wire is connected between manipulator controller 11 and manipulator 13, and manipulator controller 11 is movably installed on cross bar 8, and described cross bar 8 is installed on the bracket 9, and the control box 10 is connected with the manipulator controller 11. In this embodiment, the control box 10 controls the manipulator 13 to move laterally, and the manipulator controller 11 controls the manipulator 13 to grab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com