Femtosecond laser processing device and method for rapid deep etching of silicon carbide

A kind of femtosecond laser processing and femtosecond laser technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of undercutting, samples that are difficult to etch masks, and needs, etc., and achieve etching processing parameters The setting is fine, avoiding adverse effects, and improving the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0134] Example 1: Etching circular blind holes

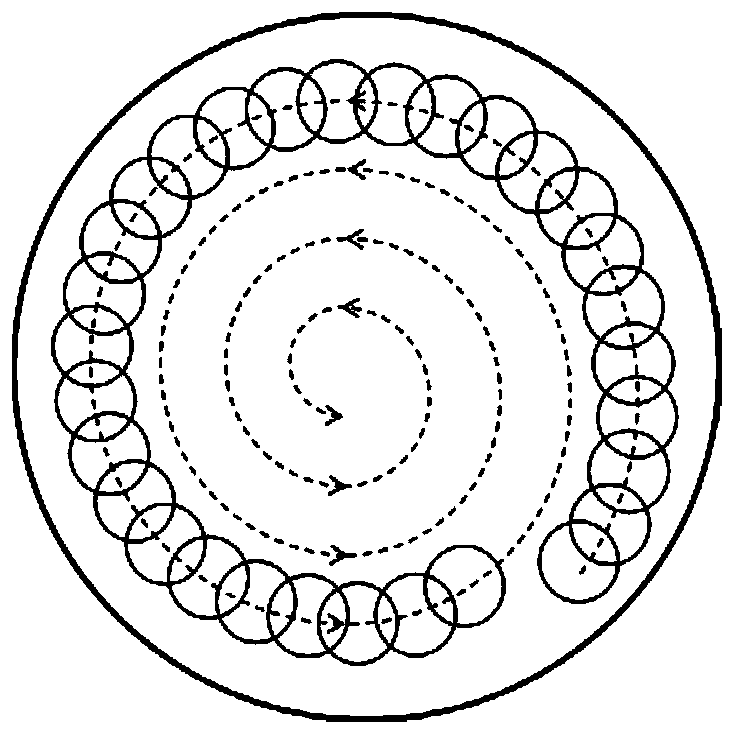

[0135] Etch circular blind holes, design blind hole depth 250μm, diameter 1200μm. High-quality, fast deep etching with femtosecond laser processing equipment. Femtosecond laser processing equipment such as Figure 10 As shown, the aperture of the adjustable aperture 108 is adjusted to 1.4 mm, the focal length of the shaping mirror 109 is 100 mm, the focal length of the plano-convex lens 1010 is 100 mm, and the clamping table 1014 is a vacuum adsorption clamping table. Etching process such as Figure 14 shown.

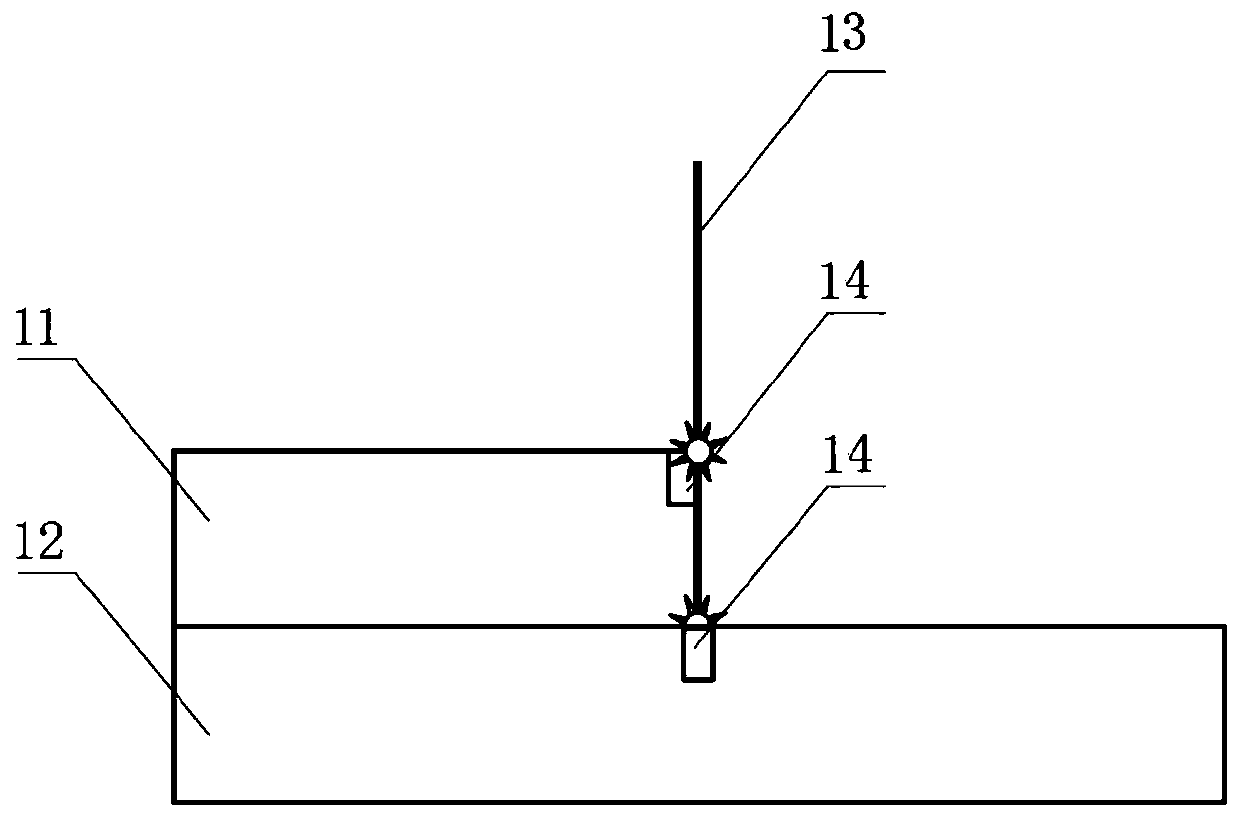

[0136] (1) According to figure 1 In this method, a femtosecond laser beam is used to ablate two superimposed borosilicate glass sheets for focal plane calibration. The thickness of each borosilicate glass sheet is 350 μm.

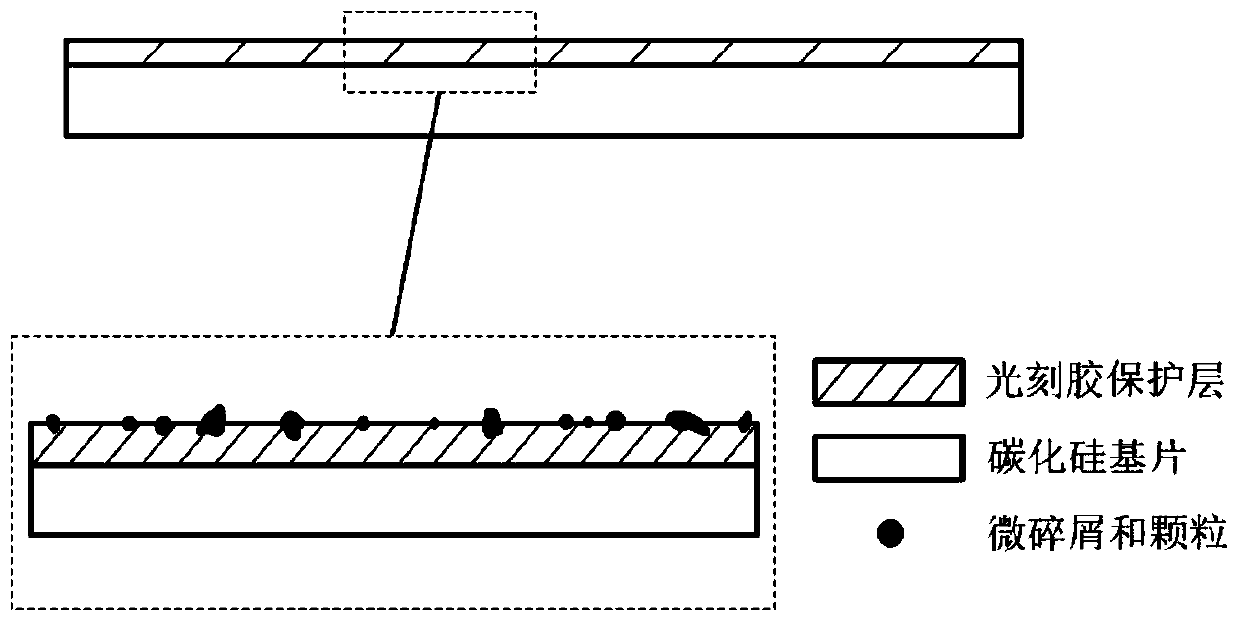

[0137] (2) Select a 4H-SiC substrate with a thickness of 350 μm as the etching object to prepare a photoresist protective layer: wash the 4H-SiC substrate with deionized water for 10 minutes and ...

example 2

[0146] Example 2: Etching square vias

[0147] Etch a square through hole, design the depth of the square hole to be 300 μm, and the side length to be 500 μm. High-quality, fast deep etching with femtosecond laser processing equipment. Femtosecond laser processing equipment such as Figure 10 As shown, the aperture of the adjustable aperture 108 is adjusted to 1.4 mm, the focal length of the shaping mirror 109 is 50 mm, the focal length of the plano-convex lens 1010 is 50 mm, and the clamping table 1014 is a clip-type clamping table. Etching process such as Figure 16 shown.

[0148] (1) According to figure 1 In this method, a femtosecond laser beam is used to ablate two superimposed borosilicate glass sheets for focal plane calibration. The thickness of each borosilicate glass sheet is 300 μm.

[0149] (2) A 6H-SiC substrate with a thickness of 300 μm was selected as an etching object to prepare a photoresist protective layer: the 6H-SiC substrate was cleaned with deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com