Copper etching liquid composition as well as preparation method and application thereof

A technology of copper etching and composition, which is applied in the field of copper etching liquid composition and its preparation, can solve the problems affecting the quality of the etching process, loss of critical dimensions, slow etching speed, etc., and achieve small CD-loss variation and small critical dimensions Loss, Effect of Small Taper Angle Variations

Active Publication Date: 2021-05-14

江苏和达电子科技有限公司 +1

View PDF8 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

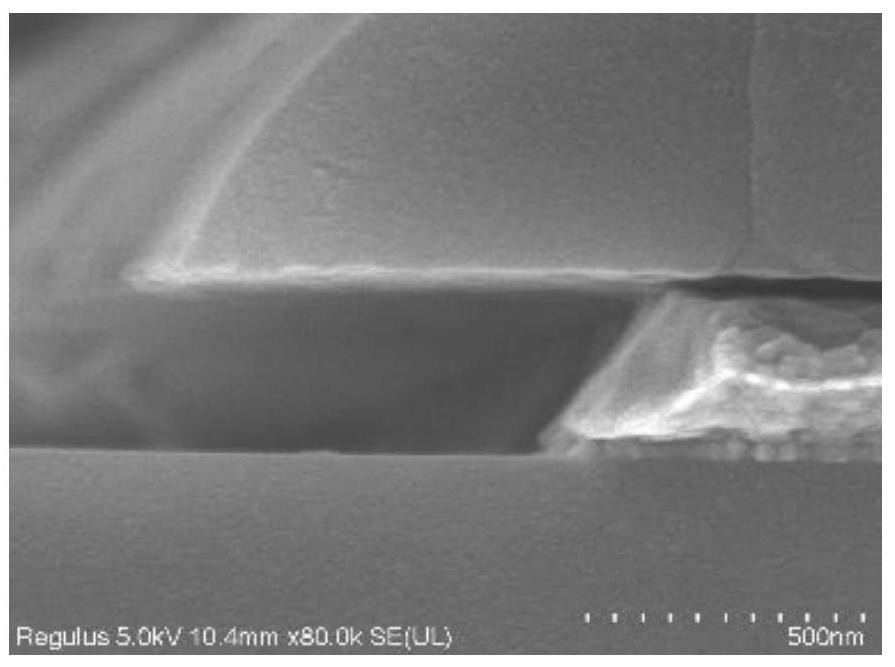

[0005] Because molybdenum is not easy to be etched by general etching solution, or the etching speed is slow, there are often molybdenum residues when the etching is completed. Prolonging the etching time to avoid molybdenum residues will lead to a large critical dimension loss (CD- loss, critical dimension-loss, that is, the difference between the border of the PR photoresist and the border of the metal film)

In the prior art, fluorine-containing etching solutions are often used to improve the etching effect on metal molybdenum, but fluorine-containing etching solutions will increase the cost of waste liquid treatment and cause pollution to the environment

In addition, the existing etching solution is a

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

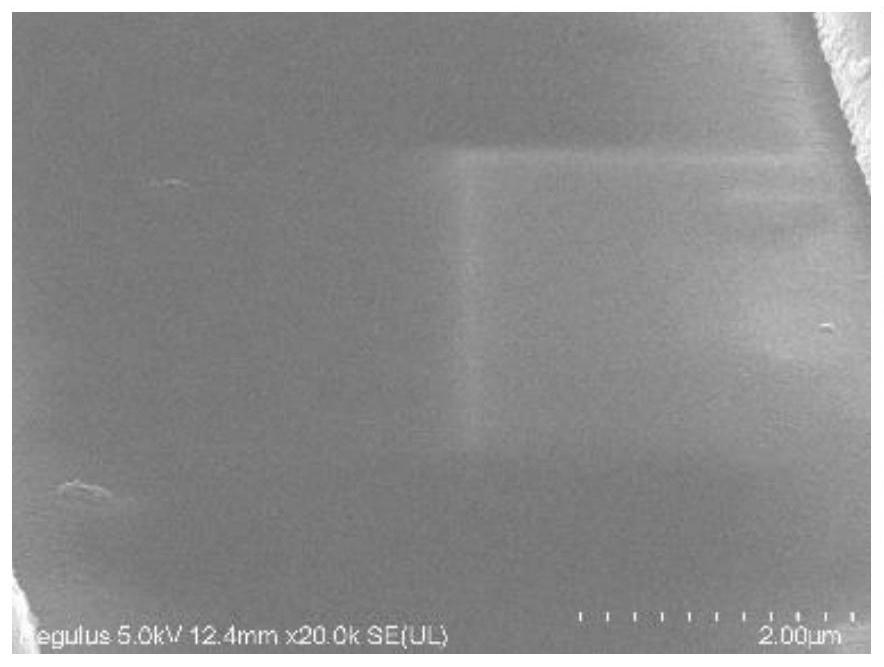

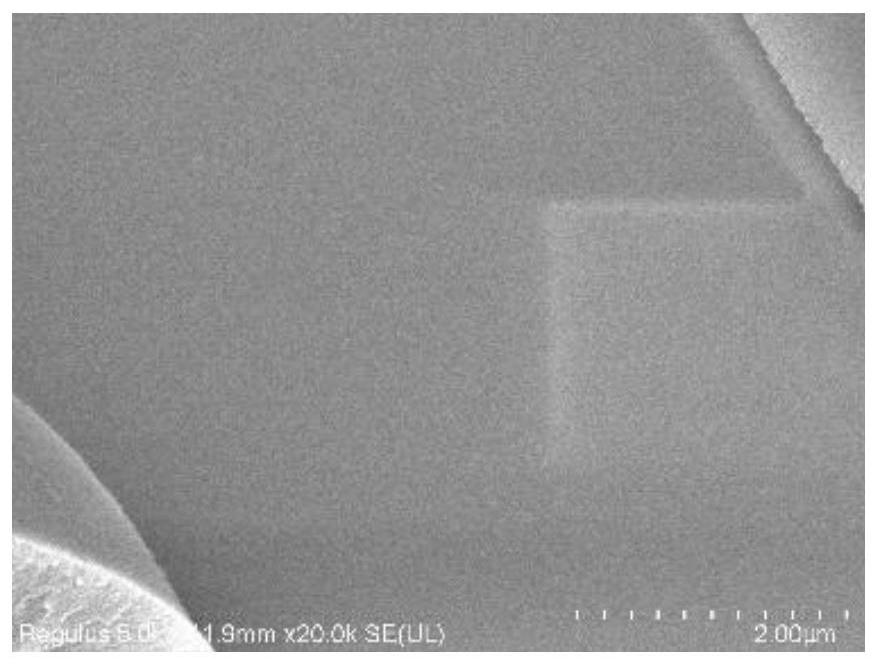

The invention provides a copper etching liquid composition as well as a preparation method and application thereof. The copper etching liquid comprises a main agent and an auxiliary agent, and at least one of the main agent and the auxiliary agent contains melamine and/or a derivative thereof. The copper etching liquid composition is low in price, the surface of a copper/molybdenum film layer treated by the copper etching liquid is free of metal residues, chamfers and cracks, and the copper/molybdenum film layer has relatively small critical dimension loss (CD-loss), relatively proper taper angle, relatively high copper loading capacity, relatively small CD-loss variable quantity and relatively small taper angle variable quantity.

Description

technical field [0001] The invention belongs to the field of etching liquid, and relates to a copper etching liquid composition, a preparation method and application thereof. Background technique [0002] A liquid crystal display device (LCD, Liquid Crystal Display) includes a liquid crystal display panel and a backlight module. Generally, a liquid crystal display panel includes a CF (Color Filter) substrate, a TFT (Thin Film Transistor) array substrate, and a liquid crystal (LC, Liquid Crystal) disposed between the CF substrate and the TFT array substrate. By supplying power to the TFT array substrate or not, the direction of the liquid crystal molecules is controlled, and the light from the backlight module is projected onto the CF substrate to generate a picture. [0003] When manufacturing microcircuits such as TFT-LCD, conductive metal films such as aluminum, aluminum alloy, copper and copper alloys or insulating films such as silicon dioxide and silicon nitride are fo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23F1/14

CPCC23F1/14

Inventor 徐帅张红伟李闯胡天齐钱铁民

Owner 江苏和达电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com