Etchant composition for glass of flat panel display

A technology for flat panel displays and compositions, applied in the direction of surface etching compositions, chemical instruments and methods, etc., can solve the problems of difficulty in applying large-scale production, decreased cleaning ability, poor oxidation ability, etc., and achieve good etching quality and etching sheet The effect of increasing the number and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

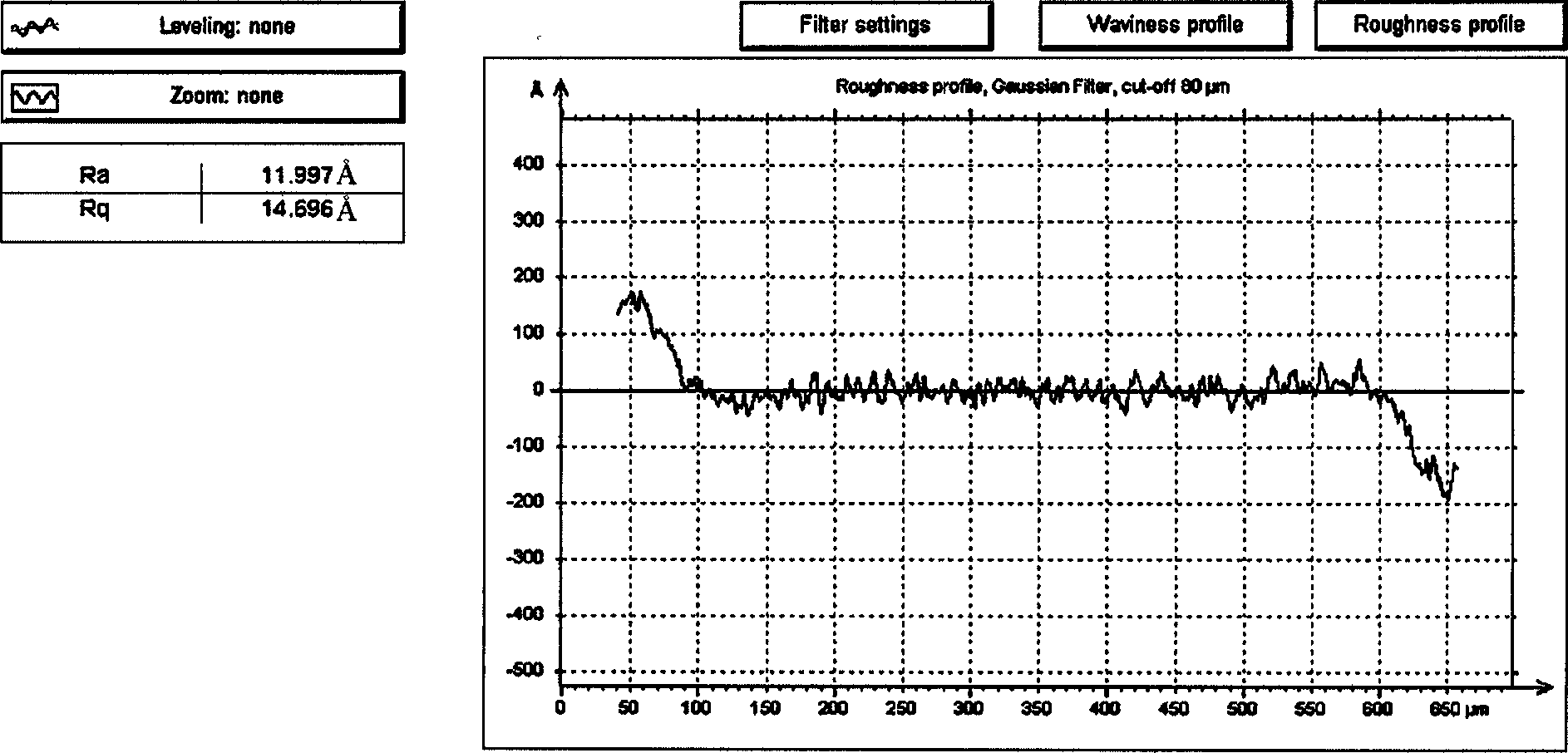

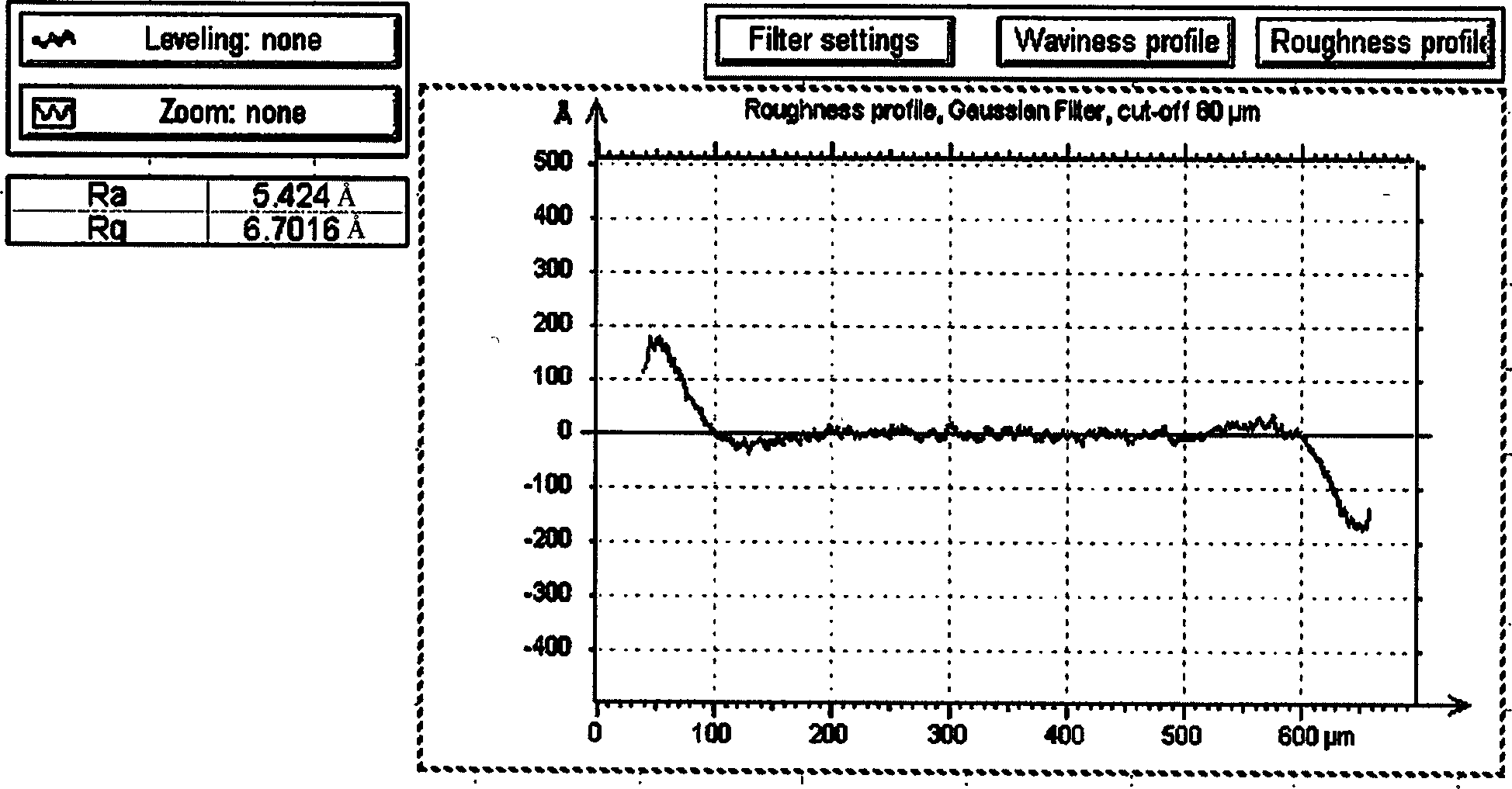

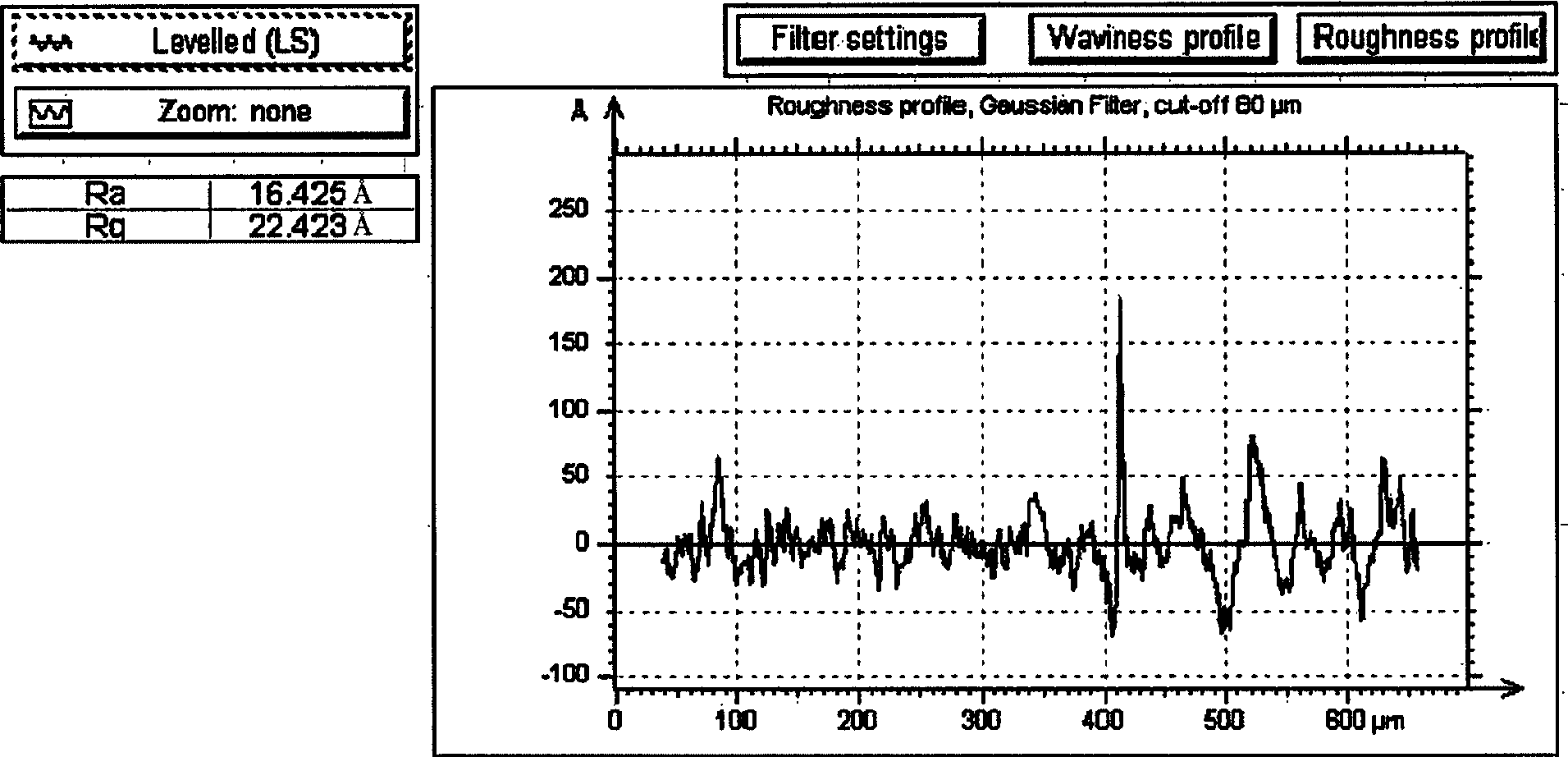

Image

Examples

Embodiment 1~6

[0024] Etching method

[0025] An etching solution composition prepared by mixing HF / sodium nitrate / inorganic acid (sulfuric acid, phosphoric acid, hydrochloric acid) / glycolic acid / fluorine-based surfactant / deionized water in the ratio shown in Table 1 below was prepared and maintained at 30°C. In order to remove contaminants, in the LCD process, the upper and lower plates are tightly combined and liquid crystal-infused etched alkali-free glass (NEG OA-21 of NEG Glass Co., Ltd., size: 370×470, thickness: 1.26t (1260μm)), and measured The thickness of each predetermined part is put into the etching solution. The etching amount is set as follows: pre-spray for about 10 minutes in advance to measure the etching ability, and then spray for a time corresponding to the required etching amount (1.26t→0.8t, ie 460μm) to perform etching.

[0026] In the spraying device used in the present invention, a storage tank is arranged at the lower part. The storage tank is made of acid-resistant (T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com