Quenching and tempering device for cooling high-temperature fume

A technology of high-temperature flue gas, conditioning equipment, applied in heat exchange equipment, high-efficiency regulation technology, lighting and heating equipment, etc., can solve the problems of low efficiency of high-pressure pump, affecting dust removal effect, dust emission, etc., and achieve high equipment failure rate , The effect of reducing the volume of flue gas and reducing environmental protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Example 1 of the high temperature flue gas cooling and tempering equipment is used in the production of cement plants. The flue gas emission requires the outlet temperature of the humidification tower to be maintained within the temperature range of 130°C to 150°C.

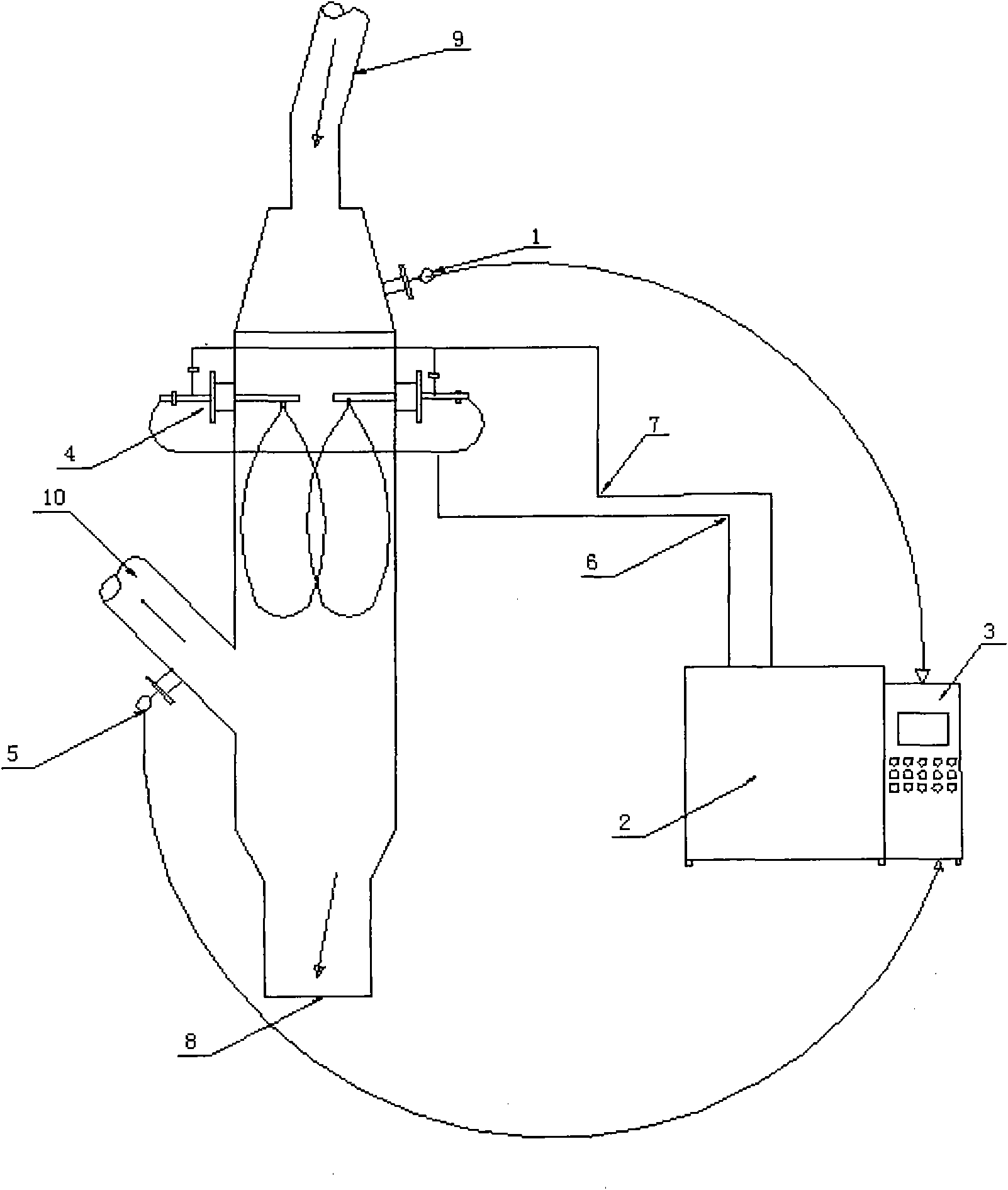

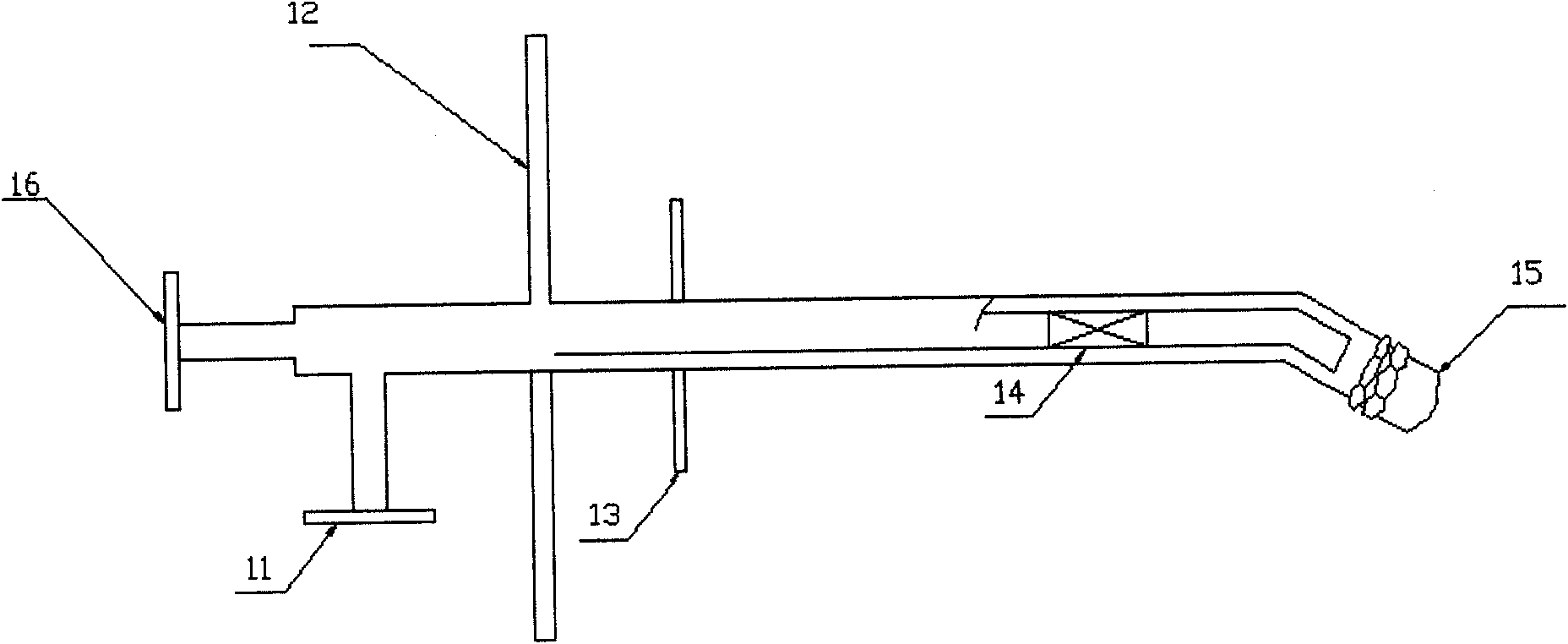

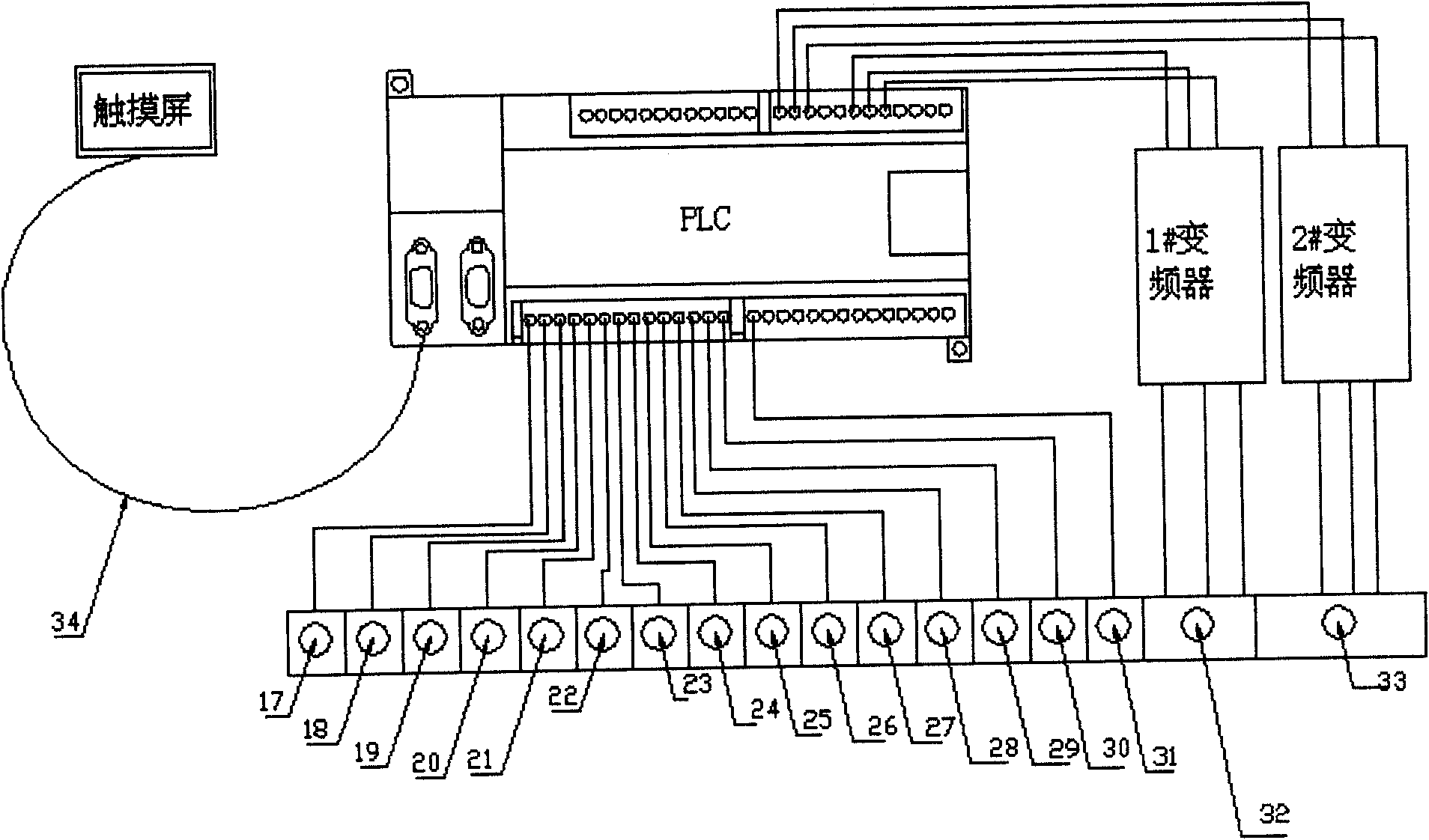

[0018] see figure 1 : The technology of the present invention is the water pipeline 6 and the gas pipeline 7 set between the high temperature flue gas inlet 9 and the outlet 10 of the humidification tower, and the inlet temperature sensor 1 and the outlet temperature sensor 5 are set in the humidification tower, which is characterized in that the gas pipe Set low pressure pump in way 7, see Figure 4 : Gas outlet valve 36, gas shut-off valve 42, gas pressure sensor 41, electromagnetic flowmeter 40, gas hand valve 43 and solenoid valve 44, detection instrument with water pressure sensor 37, control system PLC and inverter are installed in dual The fluid spray cooling control cabinet 39 implements the progr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com