Technology for preparing amoxicillin by straight-through method

A technology of amoxicillin and straight-through method, applied in the pharmaceutical field, can solve the problems of affecting the health of production personnel, 6-APA is prone to flying, and the labor intensity of production personnel is high, so as to strengthen the health protection of employees, reduce the allergy rate, reduce the The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

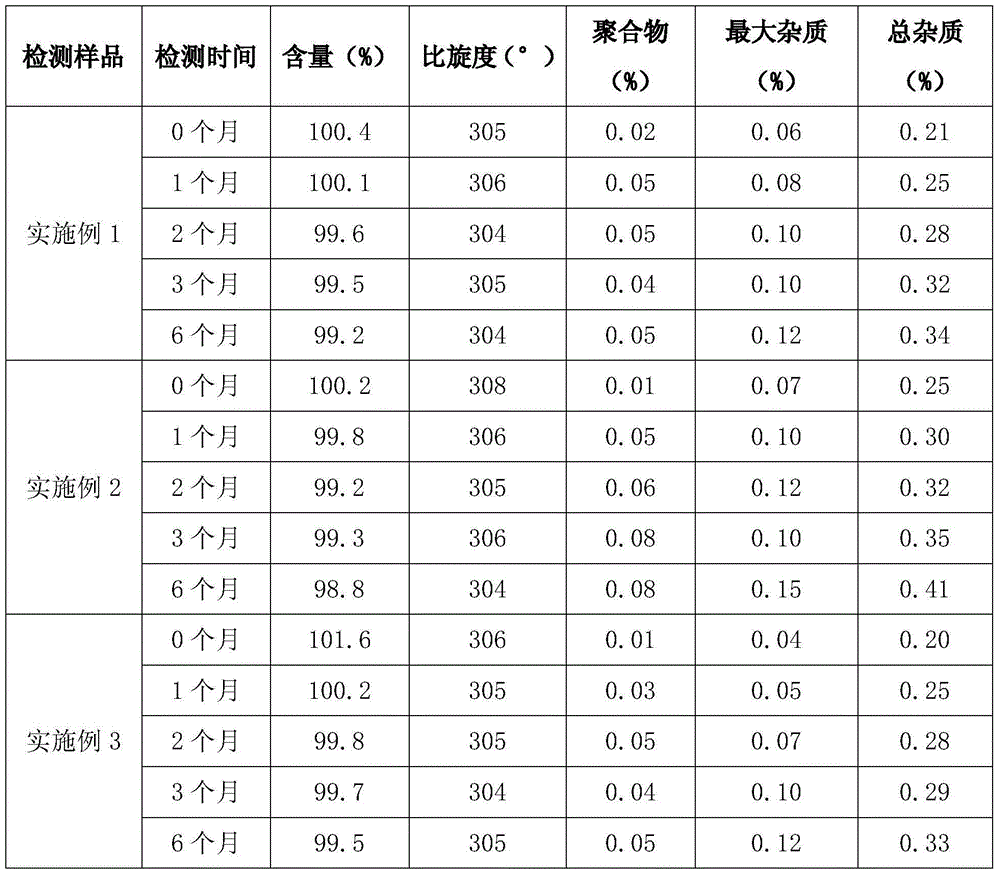

Embodiment 1

[0029] Embodiment 1 straight-through method prepares amoxicillin

[0030]a. Take 20L of penicillin degreasing solution with a penicillin concentration of 6%, add it to a reactor equipped with 200KU penicillin acylase, control the pH value to 8.0, control the reaction temperature to 28±1°C, and detect the content of penicillin during the reaction , calculate the conversion rate of penicillin, when the result is 97.4%, release the feed liquid, intercept the penicillin acylase by the screen mesh at the bottom of the reactor, transfer the obtained filtrate to the nanofiltration system with a membrane molecular weight of 120nm for concentration, and obtain a concentration of 70g / L 6-APA solution;

[0031] b. Add 18% hydrochloric acid aqueous solution to the 6-APA solution obtained in step a, adjust the pH value to 1.0, then add 50% butanol by volume of the 6-APA solution for extraction, and separate the aqueous phase;

[0032] c. Take the aqueous phase obtained in step b and pass ...

Embodiment 2

[0035] Embodiment 2 straight-through method prepares amoxicillin

[0036] a. Take 20L of penicillin degreasing solution with a penicillin concentration of 10%, add it to a reactor equipped with 200KU penicillin acylase, control the pH value to 8.5, control the reaction temperature to 37±1°C, and detect the content of penicillin during the reaction , calculate the conversion rate of penicillin, when the result is 98.1%, discharge feed liquid, intercept penicillin acylase by screen cloth at the bottom of the reactor, transfer the gained filtrate to the nanofiltration system and concentrate, and obtain concentration is 120g / L 6- APA solution;

[0037] b. Add 30% hydrochloric acid aqueous solution to the 6-APA solution obtained in step a, adjust the pH value to 2.0, then add 70% butyl ester of 6-APA solution volume for extraction, and separate the aqueous phase;

[0038] c. Take the aqueous phase obtained in step b and pass it through the LXT-057 macroporous resin column, control...

Embodiment 3

[0041] Embodiment 3 straight-through method prepares amoxicillin

[0042] a. Take 20L of penicillin degreasing solution with a penicillin concentration of 8%, add it to a reactor equipped with 200KU penicillin acylase, control the pH value to 8.2, control the reaction temperature to 32±1°C, and detect the content of penicillin during the reaction , calculate the transformation rate of penicillin, when the result is 97.8%, discharge feed liquid, intercept penicillin acylase by screen cloth at the bottom of the reactor, transfer the gained filtrate to the nanofiltration system and concentrate, and obtain concentration is 100g / L 6- APA solution;

[0043] b. add 25% hydrochloric acid aqueous solution in the 6-APA solution that step a obtains, adjust pH value to be 1.5, then add the butanol butyl ester mixture of 6-APA solution volume 60% (the volume ratio of butanol and butyl ester is 2:3) extract and separate the aqueous phase;

[0044] c. Take the aqueous phase obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com