Method for preparing ketose by utilizing aldose

A technology of aldose and ketose, applied in the field of preparing ketose from aldose, achieving important application value, easy industrialization, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

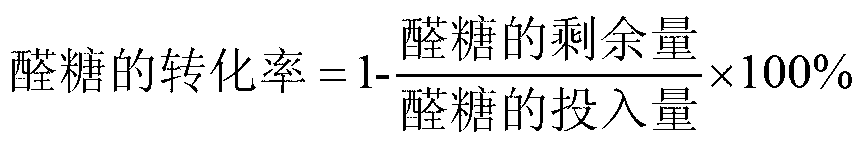

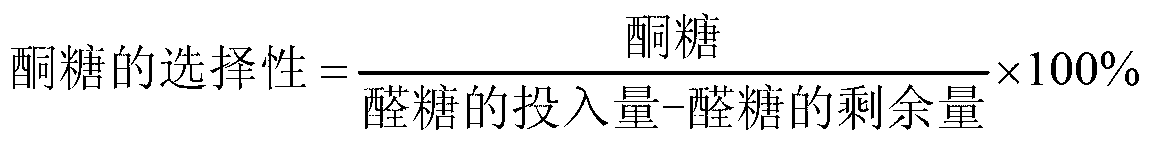

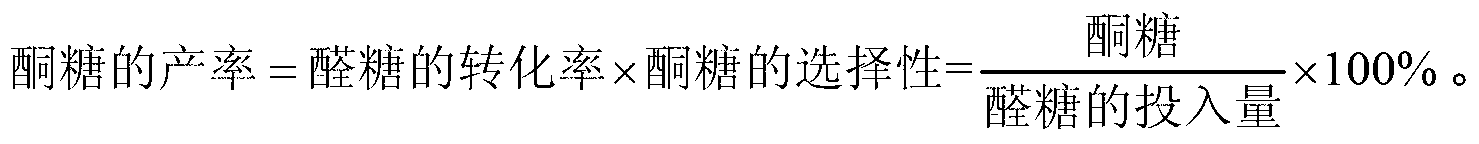

Image

Examples

Embodiment 1

[0045] Embodiment 1, prepare fructose by glucose

[0046] Add 0.5g of glucose, 1.0g of H-Beta (silicon-alumina ratio of 50) and 50mL of methanol in sequence into a 350mL pressure-resistant tube, seal the pressure-resistant tube, stir and rapidly heat to 90°C for 15 hours to obtain fructoside. Cool the pressure tube, change it to a condensing device and add 100ml of water, stir and rapidly heat to 90°C, recover the methanol solvent, and perform in-situ hydrolysis to generate fructoside. After hydrolysis for 12 hours, cool to room temperature and filter. The conversion rate of glucose in the filtrate is 95% and the yield of fructose is 81%.

[0047] The catalyst used in this example was washed 3 times with water, dried overnight in an oven at 140°C, and reused without further treatment. Experiments were carried out according to the above-mentioned steps, and the conversion rate of glucose was 90%, and the yield of fructose was 76%.

Embodiment 2

[0048] Embodiment 2, fructose is prepared by glucose

[0049] Add 0.5g of glucose, 0.5g of H-Beta (silicon-aluminum ratio of 50) and 50mL of acetonitrile in sequence into a 350mL pressure-resistant tube, seal the pressure-resistant tube, stir and rapidly heat to 90°C for 15 hours to obtain fructoside. Cool the pressure tube, change it to a condensing device and add 100ml of water, stir and rapidly heat to 90°C, recover the solvent, and perform in-situ hydrolysis to generate fructoside. After hydrolysis for 6 hours, it was cooled to room temperature and filtered. The conversion rate of glucose and fructose in the filtrate was detected to be 87% and 66% respectively.

[0050] The catalyst used in this example was washed 3 times with water, dried overnight in an oven at 140°C, and then reused without any other treatment. Experiments were carried out according to the above-mentioned steps, and the conversion rate of glucose was 84%, and the yield of fructose was 62%.

Embodiment 3

[0051] Embodiment 3, fructose is prepared by glucose

[0052] Add 0.5g of glucose, 2.5g of H-Beta (silicon-aluminum ratio of 50) and 50mL of acetone in sequence into a 350mL pressure-resistant tube, seal the pressure-resistant tube, stir and rapidly heat to 90°C for 15 hours to obtain fructoside. Cool the pressure tube, change it to a condensing device and add 100ml of water, stir and rapidly heat to 90°C, recover the solvent, and perform in-situ hydrolysis to generate fructoside. After hydrolysis for 24 hours, cool to room temperature and filter. The conversion rate of glucose in the filtrate is 93% and the yield of fructose is 55%.

[0053] The catalyst used in this example was washed 3 times with water, dried overnight in an oven at 140°C, and reused without any other treatment. Experiments were carried out according to the above-mentioned steps, and the conversion rate of glucose was 89%, and the yield of fructose was 53%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com