Method for preparing high-purity manganese sulfate solution with low cost

A manganese sulfate solution, low-cost technology, applied in the preparation of manganese sulfate, manganese compounds, etc., can solve problems such as vacancy of technical achievements, achieve the effects of reducing production costs, improving resource utilization, and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

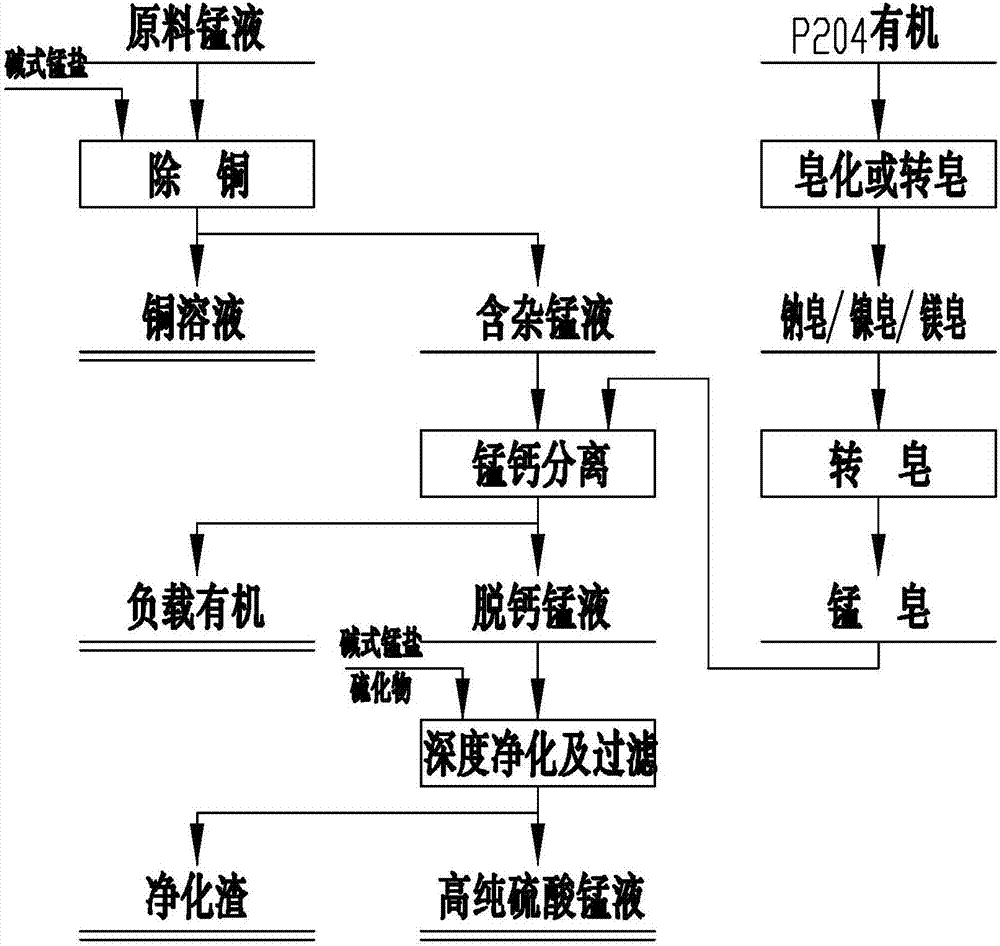

[0039] A method for preparing high-purity manganese sulfate solution at low cost, comprising the steps of:

[0040] (1) Copper removal: Carry out copper extraction to raw material manganese liquid, obtain the raw material manganese liquid after copper removal of Cu≤0.2g / L;

[0041] (2) adjust the pH value, adopt manganese carbonate slurry to adjust the raw material manganese liquid pH value after copper removal to be 1.5~5.0;

[0042] (3) Saponification: Saponify the extractant P204 with NaOH to obtain the P204 sodium soap organic after saponification;

[0043] (4) transfer manganese soap: the obtained P204 sodium soap is organically mixed with MnSO 4 Liquid is carried out to manganese saponification, obtains the P204 manganese soap organic after saponification;

[0044] (5) Extraction and separation of Mn and Ca: the manganese soap that will obtain P204 is organically carried out multi-stage countercurrent extraction to the raw material manganese liquid obtained in step (2)...

Embodiment 2

[0047] A method for preparing high-purity manganese sulfate solution at low cost, comprising the steps of:

[0048] (1) Copper removal: Carry out copper extraction to raw material manganese liquid, obtain the raw material manganese liquid after copper removal of Cu≤0.2g / L;

[0049] (2) adjust the pH value, adopt the manganese hydroxide slurry to adjust the raw material manganese liquid pH value after copper removal to be 1.5~5.0;

[0050] (3) Saponification: use Na 2 CO 3 The liquid carries out saponification to extractant P204, obtains the P204 sodium soap organic after saponification;

[0051] (4) transfer manganese soap: the obtained P204 sodium soap is organically mixed with MnCl 2 Solution is carried out to manganese saponification, obtains the P204 manganese soap organic after saponification;

[0052] (5) Extraction and separation of Mn and Ca: the obtained P204 manganese soap is organically carried out to multistage countercurrent extraction of the raw material mang...

Embodiment 3

[0055] A method for preparing high-purity manganese sulfate solution at low cost, comprising the steps of:

[0056] (1) Copper removal: Carry out copper extraction to raw material manganese liquid, obtain the raw material manganese liquid after copper removal of Cu≤0.2g / L;

[0057] (2) adjust the pH value, adopt manganese carbonate to adjust the raw material manganese liquid pH value after copper removal to be 1.5~5.0;

[0058] (3) Saponification: use KOH or K 2 CO 3 Carry out saponification to extractant P204, obtain the P204 potassium soap organic after saponification;

[0059] (4) transfer manganese soap: the potassium soap of the obtained P204 is organically mixed with MnSO 4 Liquid is carried out to manganese saponification, obtains the P204 manganese soap organic after saponification;

[0060] (5) Extraction and separation of Mn and Ca: the obtained P204 manganese soap is organically carried out to multistage countercurrent extraction of the raw material manganese li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com