High-boron, iron-based and abrasion-resistant alloy material and production method thereof

A wear-resistant alloy and production method technology, applied in the field of wear-resistant materials, can solve the problems of high operating cost, strong modification agent dependence, coarse matrix structure, etc., to achieve low cost of modification treatment technology, improve comprehensive use performance, metamorphic Simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

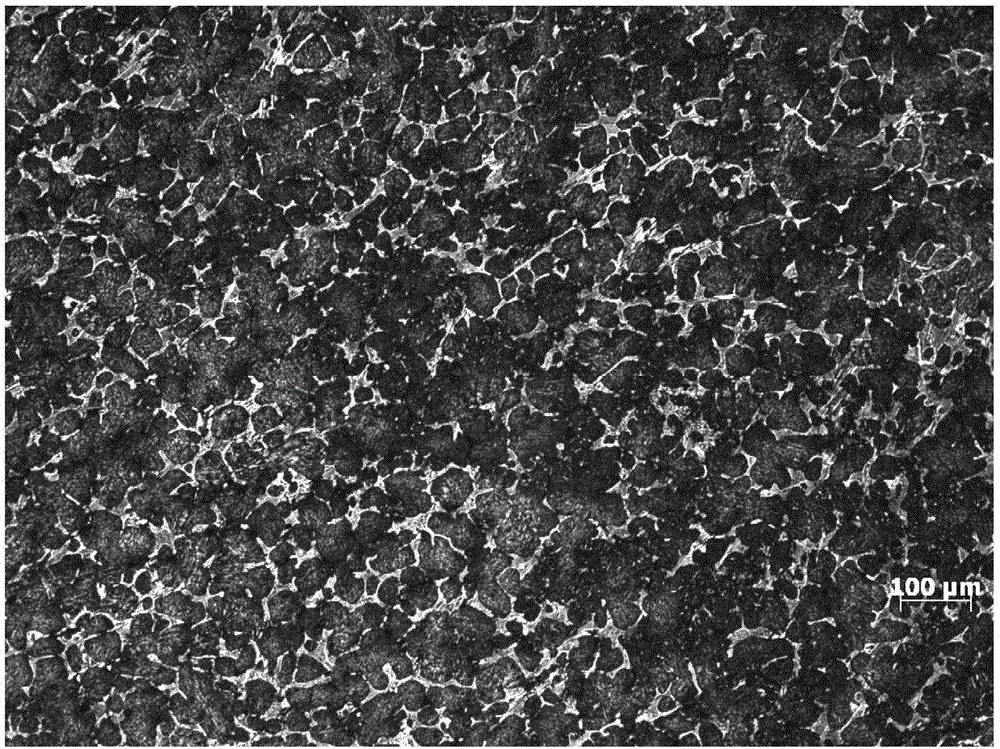

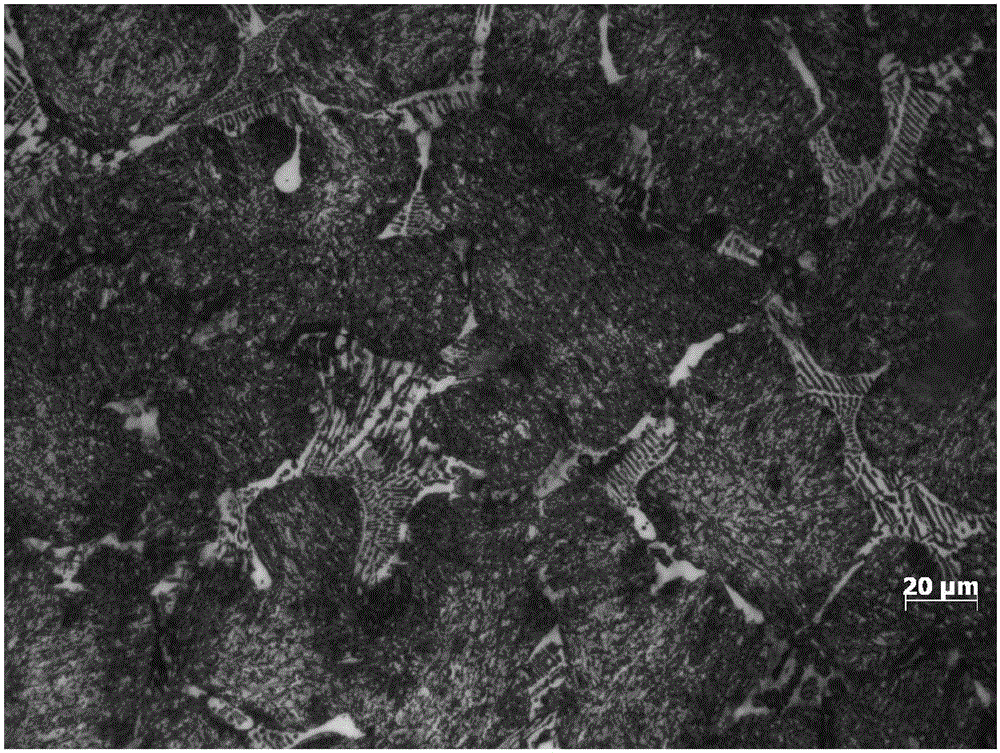

[0032] The mass percentage of the chemical composition of the high boron wear-resistant alloy material of the present invention is: C: 0.4--0.5%, B: 2.0--2.5%, Si: ≤1.5%, Mn: 0.8--1.5%, Cr: 0.6--0.8 %, Mo: 0.1--0.3%, Ti: 0.5--1.0%, S: ≤0.04%, P: ≤0.04%, and the balance is iron. Among them, silicon element comes from scrap steel.

[0033] In the present invention, each element is as follows:

[0034] C: Carbon is very important to the structure and performance of high-boron composite wear-resistant alloy materials. It is mainly dissolved in the matrix to play a role in solid solution strengthening, and can also promote the transformation of matrix martensite, improving the matrix of composite wear-resistant alloy materials. hardenability. If the carbon content is too high, it will increase the brittleness of the matrix material, and if it is too low, it will affect the hardenability of the matrix and reduce its wear resistance. Therefore, the C content should be controlled b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com