Manufacturing method of non-woven dedusting filter material

A technology of non-woven fabrics and manufacturing methods, applied in the field of textile manufacturing, can solve the problems of increasing production process costs, environmental hazards, material costs, labor costs, and high energy consumption, so as to shorten the production process and reduce production Process cost, the effect of reducing water and heat energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for manufacturing a nonwoven dust filter material, comprising the steps of:

[0032] A. The polyester staple fibers with a diameter of 2.5mm and a length of 51mm are sequentially pre-opened, finely opened, and cotton box beating processes to form opened cotton;

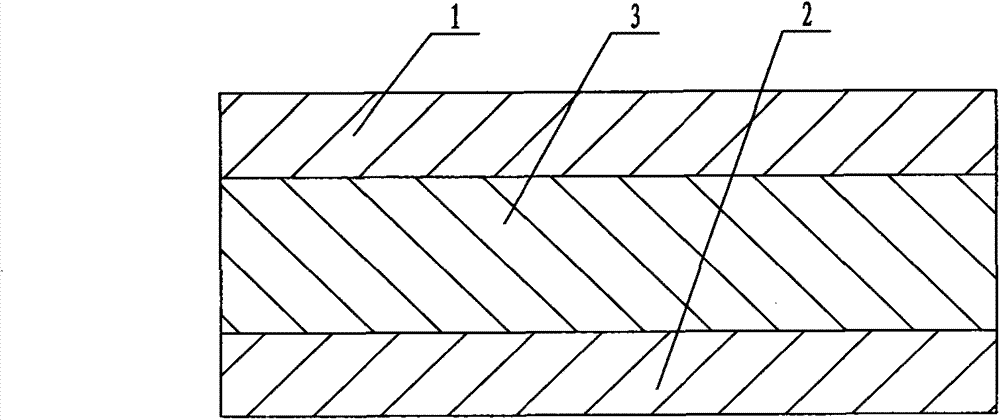

[0033] B. Use the mist spray humidification device to spray and humidify the opened cotton made in step A, and then use the carding machine to card, so that the opened cotton moves forward in parallel and evenly and falls on the laying net Machine surface, carry out laying net, prepuncture to form the fluffy and uniform non-woven floc layer 1, and described prepuncture needle depth is 11mm; In the humidification liquid that described mist spray humidification device uses, mix elemental surfactant, The blending ratio of elemental surfactant and water is 1.8:100, spray 15g of humidifying liquid per square meter of non-woven dust filter material; elemental surfactant contains fluorine element and hydrophi...

Embodiment 2

[0040] A method for manufacturing a nonwoven dust filter material, comprising the steps of:

[0041] A. The polyester staple fibers with a diameter of 2.5mm and a length of 51mm are sequentially pre-opened, finely opened, and cotton box beating processes to form opened cotton;

[0042]B. Use the mist spray humidification device to spray and humidify the opened cotton made in step A, and then use the carding machine to card, so that the opened cotton moves forward in parallel and evenly and falls on the laying net Machine surface, carry out netting, prepuncture to form fluffy and uniform non-woven floc layer 1, and described prepuncture needle depth is 13mm; In the humidification liquid that described mist spray humidification device uses, mix elemental surfactant, The blending ratio of elemental surfactant and water is 3:100, spray 10g of humidifying liquid per square meter of non-woven dust filter material; elemental surfactant contains fluorine element and hydrophilic segmen...

Embodiment 3

[0049] A method for manufacturing a nonwoven dust filter material, comprising the steps of:

[0050] A. The polyester staple fibers with a diameter of 2.5mm and a length of 51mm are sequentially pre-opened, finely opened, and cotton box beating processes to form opened cotton;

[0051] B. Use the mist spray humidification device to spray and humidify the opened cotton made in step A, and then use the carding machine to card, so that the opened cotton moves forward in parallel and evenly and falls on the laying net Machine surface, carry out netting, prepuncture to form fluffy and uniform non-woven floc layer 1, and described prepuncture needle depth is 14mm; In the humidification liquid that described mist spray humidification device uses, mix elemental surfactant, The blending ratio of elemental surfactant and water is 4.5:100, spray 5g of humidifying liquid per square meter of non-woven fabric dust removal filter material; elemental surfactant contains fluorine element and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com