Transparent plastic with antibacterial and mouldproof capacity and preparing method thereof

A transparent plastic, antibacterial and mildew-proof technology, which is applied in the field of functional polymer materials and inorganic-organic nanocomposites, can solve the problem of poor chemical resistance and impact strength of polystyrene resin, poor impact strength and chemical resistance, and Poor chemical properties and other problems, to achieve the effect of easy implementation, strong processing adaptability, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

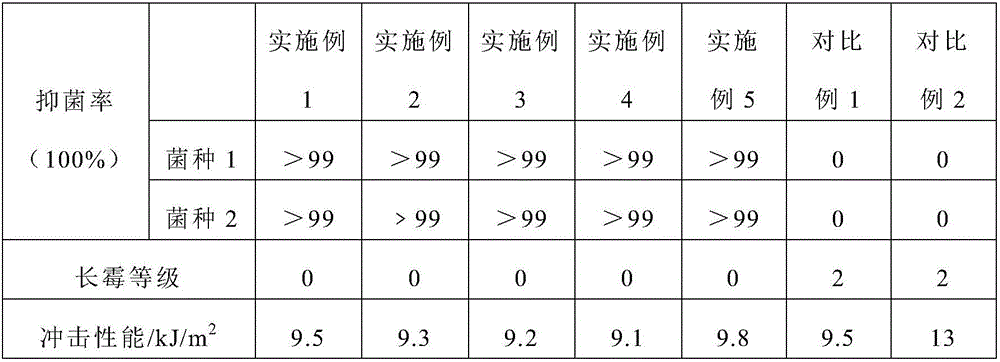

Examples

Embodiment 1

[0036] A transparent plastic with antibacterial and antifungal ability, the components and mass percentage of the transparent plastic are: methyl methacrylate-acrylonitrile-butadiene-styrene copolymer: 90.7%, nano-zinc oxide: 4.5%, Nano-titanium dioxide: 4.5%, composite antioxidant: 0.1%, stearic acid: 0.2%, and the composite antioxidant is tetrakis[β-(3,5-di-tert-butyl-4- A mixture of hydroxyphenyl) propionate] pentaerythritol ester and tris [2.4-di-tert-butylphenyl] phosphite; the average particle size of nano-zinc oxide and nano-titanium dioxide is 20nm.

[0037]The method of preparing the transparent plastic with antibacterial and antifungal ability is to put the above-mentioned nano-zinc oxide, nano-titanium dioxide, composite antioxidant, and stearic acid into a high-speed mixer and heat it to 70°C for 3 minutes, and keep mixing at a high speed. The rotating speed of the mixer is 800r / min to obtain a mixed system, then add methyl methacrylate-acrylonitrile-butadiene-styr...

Embodiment 2

[0040] A kind of transparent plastic with antibacterial and antifungal ability. The components and mass percentage of the transparent plastic are: methyl methacrylate-acrylonitrile-butadiene-styrene copolymer: 90.7%, methacrylic acid-butadiene -Styrene copolymer: 2.0%, nano-zinc oxide: 2.5%, nano-titanium dioxide: 4.5%, composite antioxidant: 0.1%, aluminum stearate: 0.2%, and the mass ratio of composite antioxidant is 1.2:1 A mixture of tetra[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester and tris[2.4-di-tert-butylphenyl]phosphite; nano-zinc oxide and nano-titanium dioxide The average particle size is 10nm.

[0041] The method for preparing the transparent plastic with antibacterial and antifungal ability is to put the nano-zinc oxide, nano-titanium dioxide, composite antioxidant, and aluminum stearate in the above mass percentage into a high-speed mixer and heat it to 40°C for 5 minutes. The rotating speed of the mixer is 500r / min to obtain a mixed sy...

Embodiment 3

[0044] A kind of transparent plastic with antibacterial and antifungal ability. The components and mass percentage of the transparent plastic are: methyl methacrylate-acrylonitrile-butadiene-styrene copolymer: 90.7%, methyl methacrylate-benzene Ethylene copolymer: 4.0%, nano-zinc oxide: 2.5%, nano-titanium dioxide: 2.5%, composite antioxidant: 0.1%, calcium stearate: 0.2%, and the composite antioxidant is four Mixture of [β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester and tris[2.4-di-tert-butylphenyl]phosphite; the average of nano-zinc oxide and nano-titanium dioxide The particle size is 50nm.

[0045] The method for preparing the transparent plastic with antibacterial and mildew-proof ability is to put the above-mentioned nano-zinc oxide, nano-titanium dioxide, composite antioxidant, and calcium stearate into a high-speed mixer and heat it to 70°C for 3 minutes. The rotating speed of the mixer is 800r / min to obtain a mixed system, and then add meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com