Textile material

A textile material and chitin fiber technology, applied in textiles, papermaking, clothing, clothing, etc., can solve the problems of affecting comfort, high bursting strength, poor air permeability, etc., and achieve the effect of improving bursting strength and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

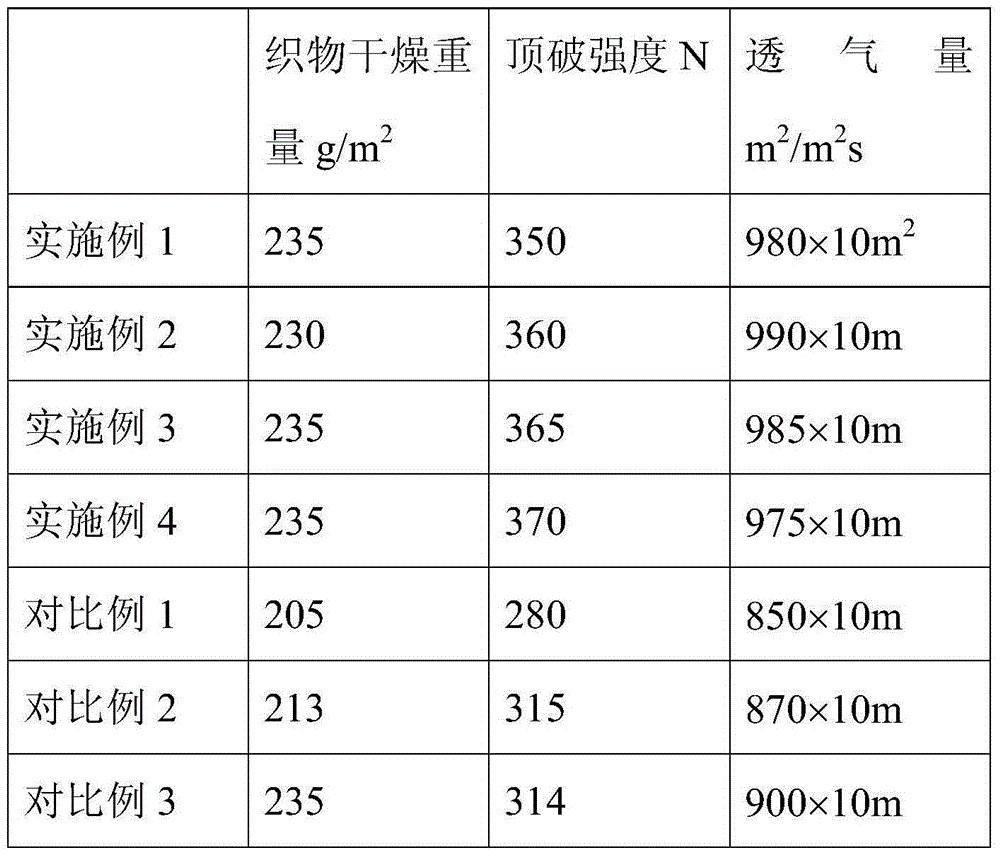

Embodiment 1

[0015] The Prime Minister mixed chitin fiber and milk fiber in proportion to make strips, then mixed them with nano-microcrystalline cellulose and tencel fibers in proportion to make strips, spun into yarn through multiple processes, and made fabrics from this yarn fabric, and the fabric fabric is finished by nano microcapsule finishing agent. Wherein, the weight percentage of chitin fiber, milk protein fiber, tencel fiber and nano-microcrystalline cellulose is 42:10:10:5.

Embodiment 2

[0017] The Prime Minister mixed chitin fiber and milk fiber in proportion to make strips, then mixed them with nano-microcrystalline cellulose and tencel fibers in proportion to make strips, spun into yarn through multiple processes, and made fabrics from this yarn fabric, and the fabric fabric is finished by nano microcapsule finishing agent. Wherein, the weight percentage of chitin fiber, milk protein fiber, tencel fiber and nano-microcrystalline cellulose is 60:50:40:10.

Embodiment 3

[0019] The Prime Minister mixed chitin fiber and milk fiber in proportion to make strips, then mixed them with nano-microcrystalline cellulose and tencel fibers in proportion to make strips, spun into yarn through multiple processes, and made fabrics from this yarn fabric, and the fabric fabric is finished by nano microcapsule finishing agent. Wherein, the weight percentage of chitin fiber, milk protein fiber, tencel fiber and nano-microcrystalline cellulose is 45:20:30:5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com