Device and method for preparing hydrogen by the electrocatalysis water vapour recapitalization biological oil

A hydrogen production device and water vapor technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of difficult separation of hydrogen and carrier gas, high reforming reaction temperature, and increase of hydrogen production cost, so as to improve the heavy The effect of adjusting the reaction speed, improving the life of the catalyst, and improving the efficiency of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

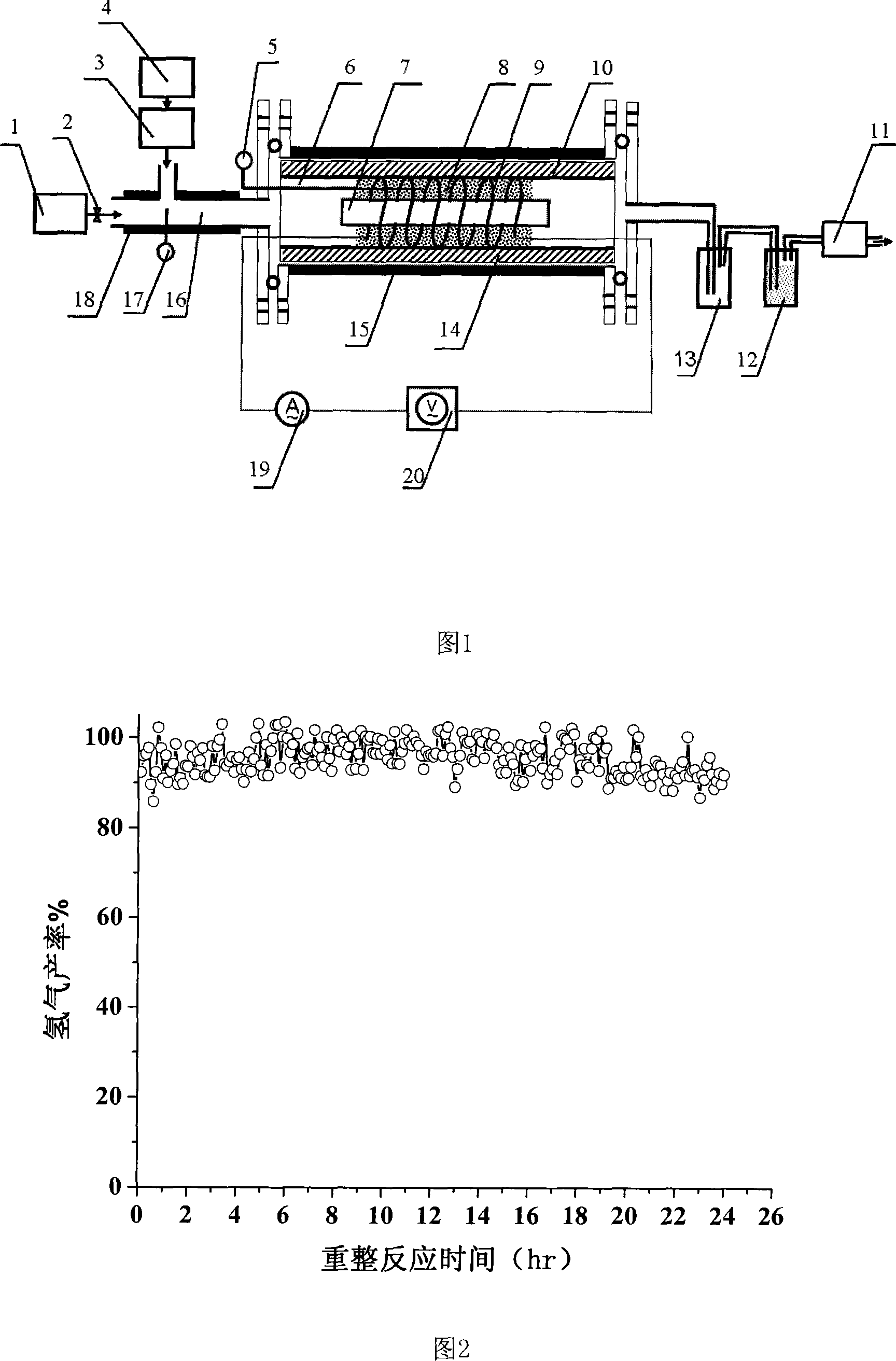

[0021] Example 1: Using the hydrogen production device shown in Figure 1 and using the bio-oil obtained from the rapid pyrolysis of wood chips as raw material to produce hydrogen

[0022] 1. The bio-oil raw material obtained by fast pyrolysis of sawdust is packed in the bio-oil raw material storage tank 4 .

[0023] 2. Turn on the power supply of the electric heating belt in the preheating zone, and turn on the power supply of the Ni-Cr electric furnace wire for internal heating to heat the catalyst: control and adjust the reforming reactor by turning on or off the external heating furnace by means of heating or heat dissipation 6. The temperature in the inner cavity is within the range of 400-600°C at medium temperature, and the AC current passing through the built-in electric furnace wire is within the range of 0-5A; the temperature in the preheating zone is within 180-200°C; reforming reactor 6 The catalyst used in the inner cavity is Ni-Al 2 o 3 Catalyst, consumption is ...

Embodiment 2

[0030] The structure of the device used and the bio-oil raw material are the same as in Example 1, except that the Ni-Cr electric furnace wire is replaced by Fe-Cr-Al electric furnace wire, and the catalyst is replaced by Ni-MgO-Al 2 o 3 Microparticles, the test conditions are 550±5°C, current 0-5A, water vapor flow rate 45g / h, bio-oil flow rate 15g / h, corresponding molar ratio is 8 / 1, catalyst dosage is 15g, particle size is 0.2mm. After operating according to the procedures described in Example 1, the influence of current strength on hydrogen production rate and bio-oil conversion rate is shown in Table 3.

[0031] Table 1

[0032] serial number

[0033] Table 2

[0034] serial number

[0035] table 3

[0036] serial number

[0037] (In tables 1, 2, and 3, the data of hydrogen production rate and raw material bio-oil conversion rate are the average value of three experiments)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com