Patents

Literature

31results about How to "Ensure uniformity of light emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LED (Light Emitting Diode) lamp filament and manufacturing method thereof

ActiveCN104600174AImprove thermal reliabilityMaximum Thermal ReliabilitySemiconductor devicesFluorescenceConductive coating

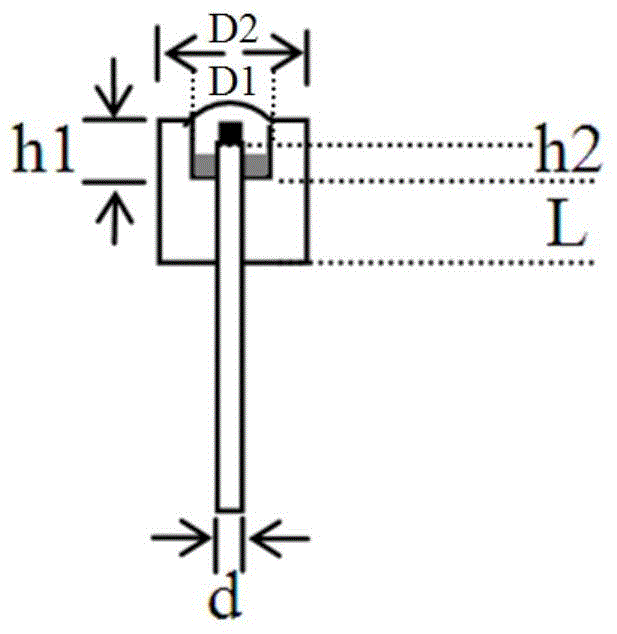

The invention provides an LED (Light Emitting Diode) lamp filament and a manufacturing method thereof. An LED chip is encapsulated on the edge top surface of a thin and long sheet metal support of the LED filament innovatively, meanwhile the sheet metal is inserted into a preformed transparent plastic model frame to produce a light source, and accordingly the automated continuous production of the LED lamp filament is implemented and the problem of the facing direction strength caused by the too thin and too long metal support is solved due to the transparent plastic model frame; meanwhile the lateral direction strength of the metal support is effectively utilized and accordingly the integral mechanical strength of the LED lamp filament is ensured; the heat dissipation characteristics of the metal is directly utilized, meanwhile the heat dissipation efficiency of the LED chip is maximized through the innovative encapsulation of thermal conductive coatings, and accordingly the problem of a heat dissipation bottleneck of the LED lamp filament is effectively solved, the LED lamp filament can work at the rated power for a long time, and the cost is reduced; the LED light extraction efficiency is improved, the light attenuation is reduced, the high lighting effect and ambient light of lamp filament light emission is implemented, and the market vacancy of the existing LED lamp filament is filled through innovative fluorescence encapsulation materials.

Owner:DONGGUAN RIWEI ELECTRONICS

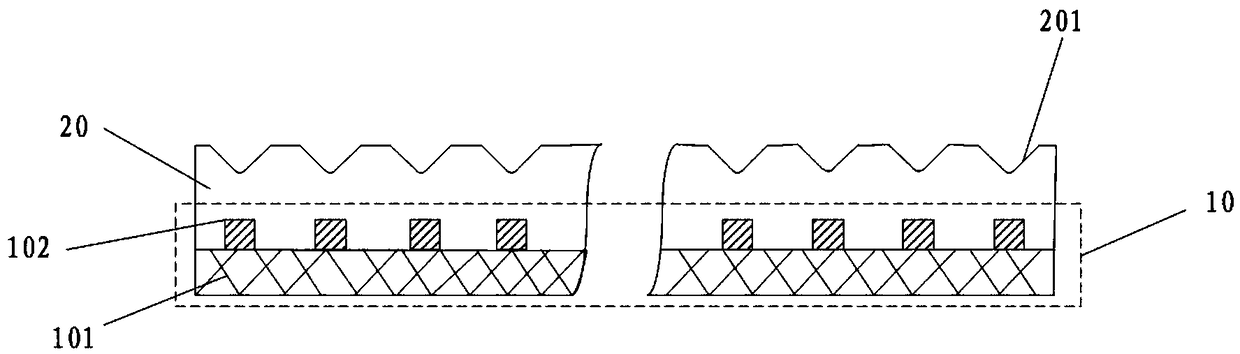

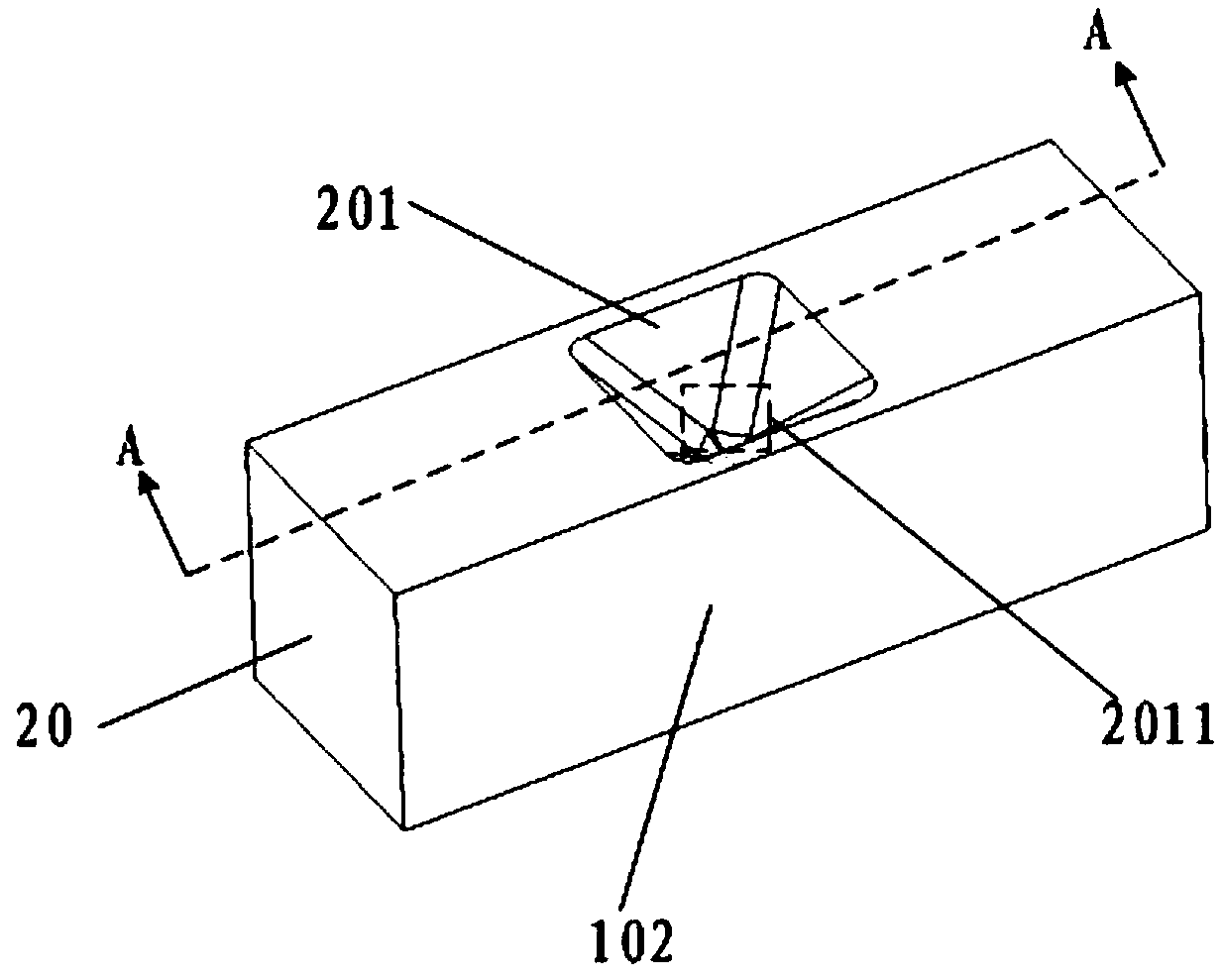

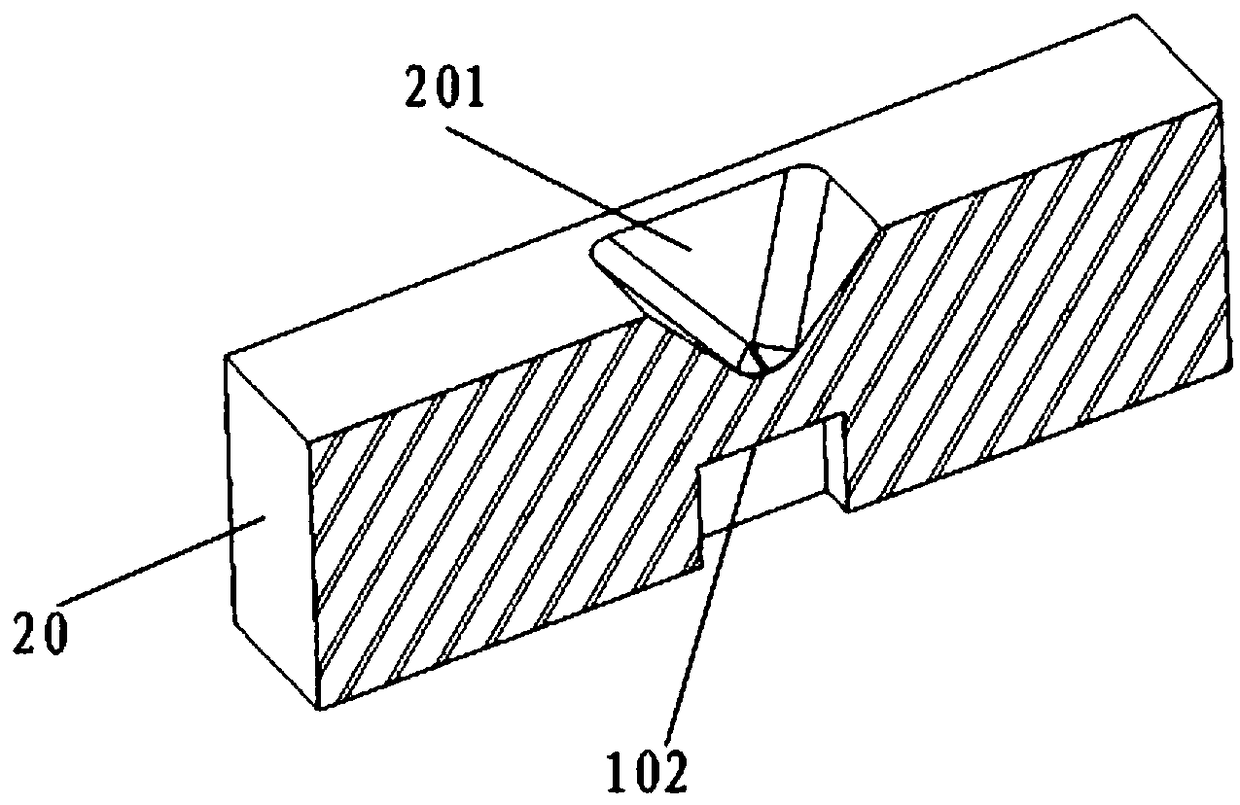

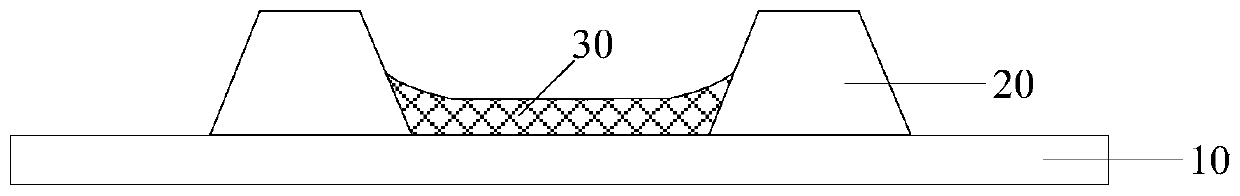

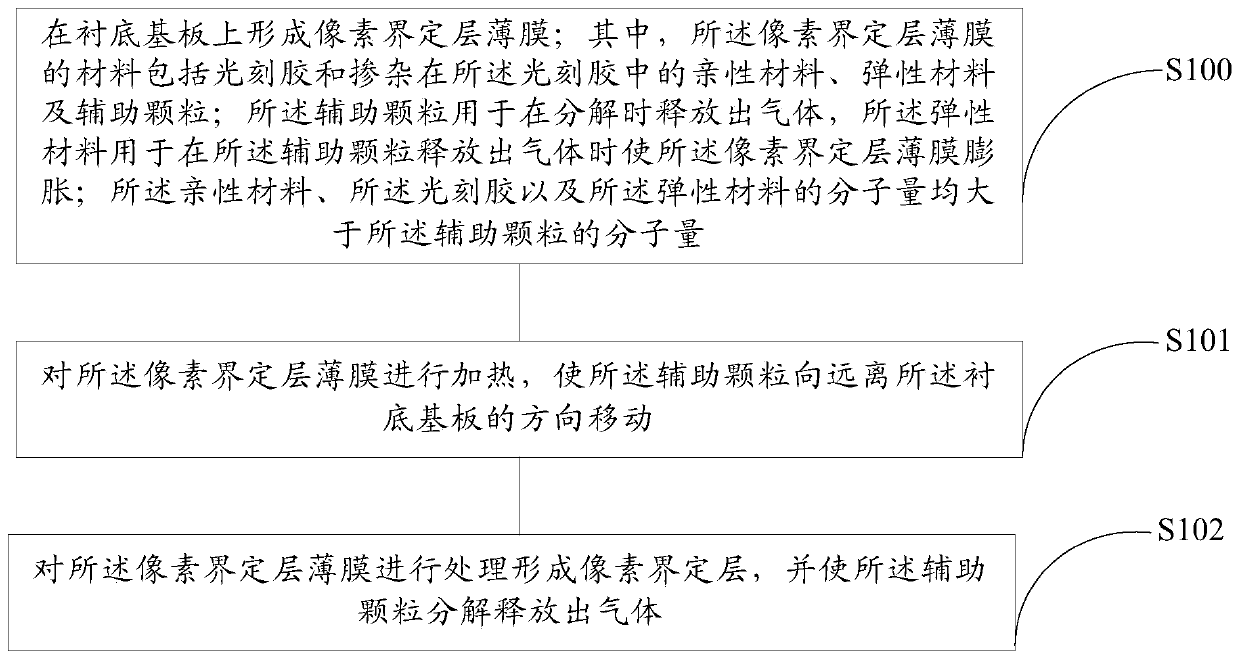

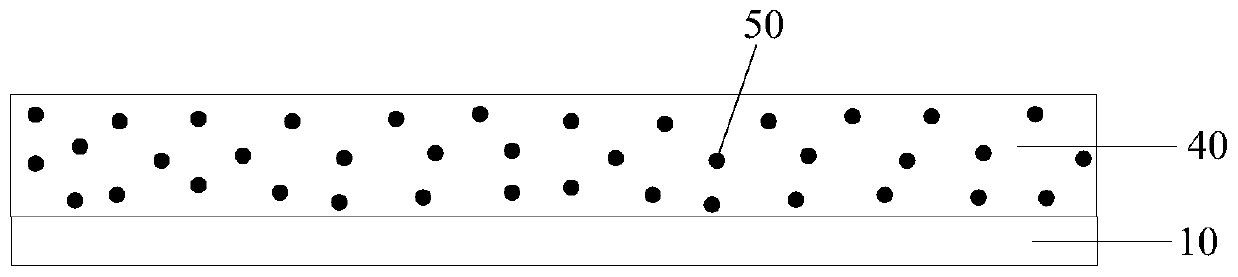

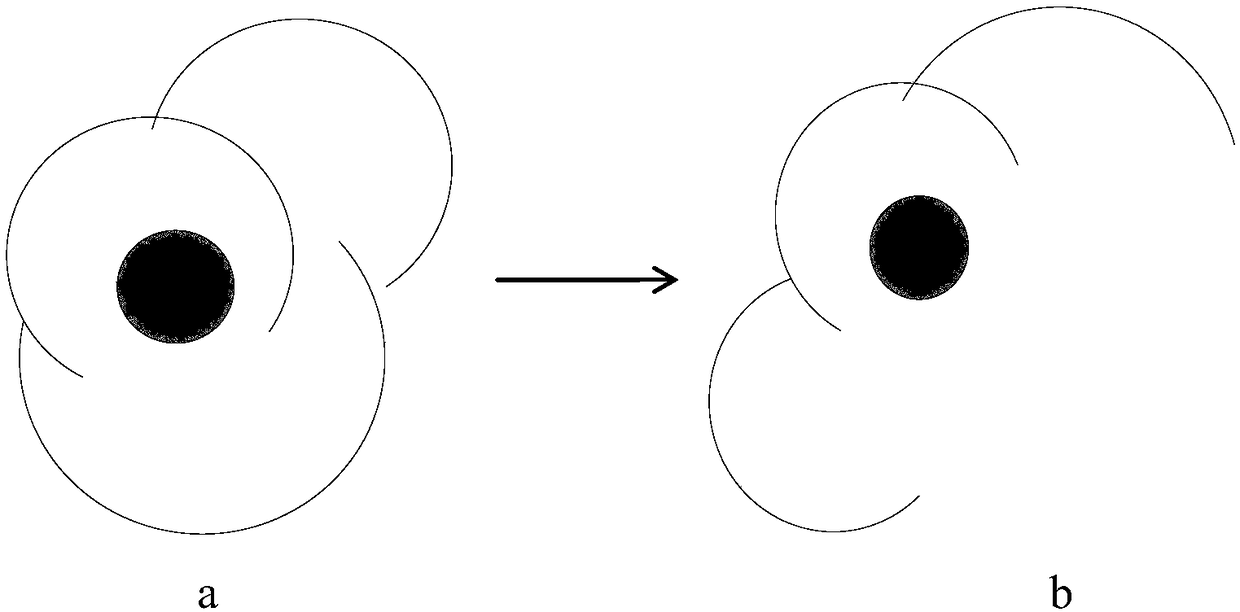

Substrate, preparation method of substrate and display device

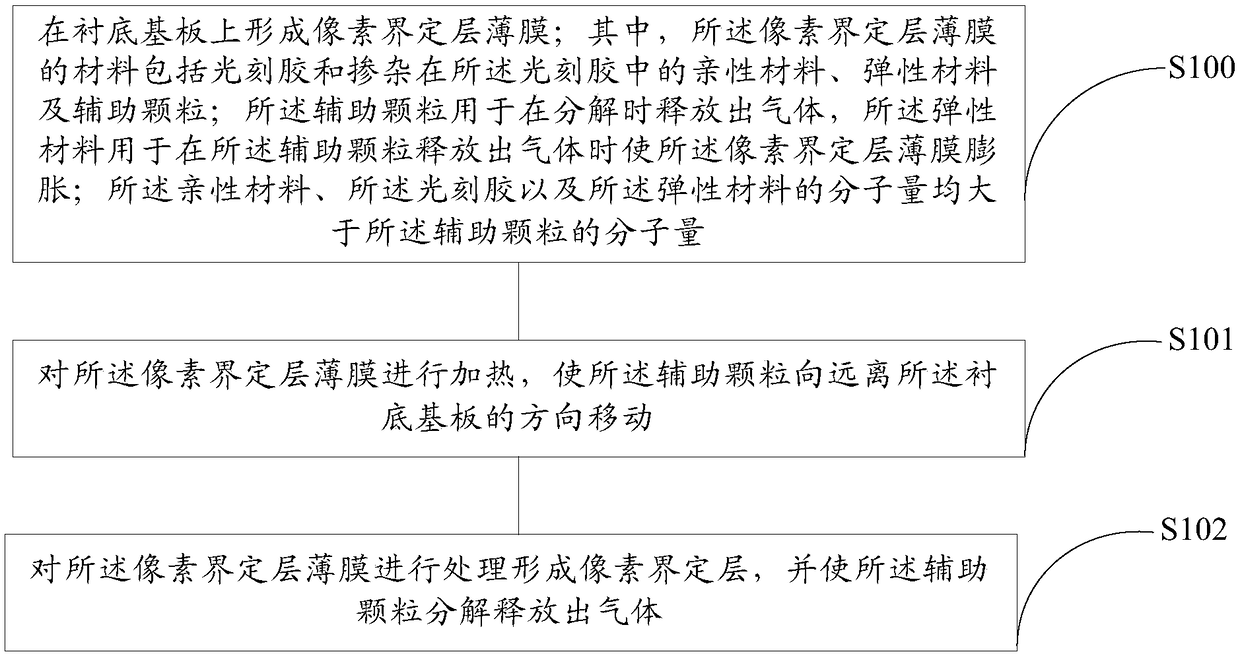

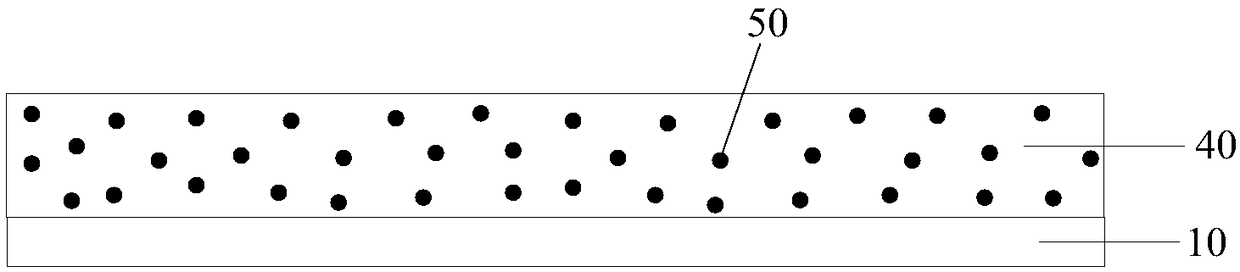

ActiveCN108878689AAvoid climbingEnsure uniformity of light emissionSolid-state devicesSemiconductor/solid-state device manufacturingPhotoresistDecomposition

Embodiments of the invention provide a substrate, a preparation method of the substrate and a display device, relate to the technical field of display, and can solve the problem that the thickness ofa light-emitting functional layer formed in an opening region of an existing pixel definition layer is not uniform. The preparation method of the substrate comprises the following steps of forming a pixel definition layer thin film on a substrate, wherein the material of the pixel definition layer thin film comprises a photoresist, and a hydrophilic material, elastic materials and auxiliary particles doped in the photoresist; the auxiliary particles are used for releasing gas during decomposition, and the elastic material is used for expanding the pixel definition layer thin film when the auxiliary particles release the gas; the molecular weight of the hydrophilic material, the photoresist and the elastic material is larger than that of the auxiliary particles; heating the pixel definitionlayer thin film, and enabling the auxiliary particles to move in the direction far away from the substrate; and processing the pixel definition layer thin film to form a pixel definition layer, and enabling the auxiliary particles to be decomposed to release gas. The preparation method is used for preparing the pixel definition layer.

Owner:BOE TECH GRP CO LTD +1

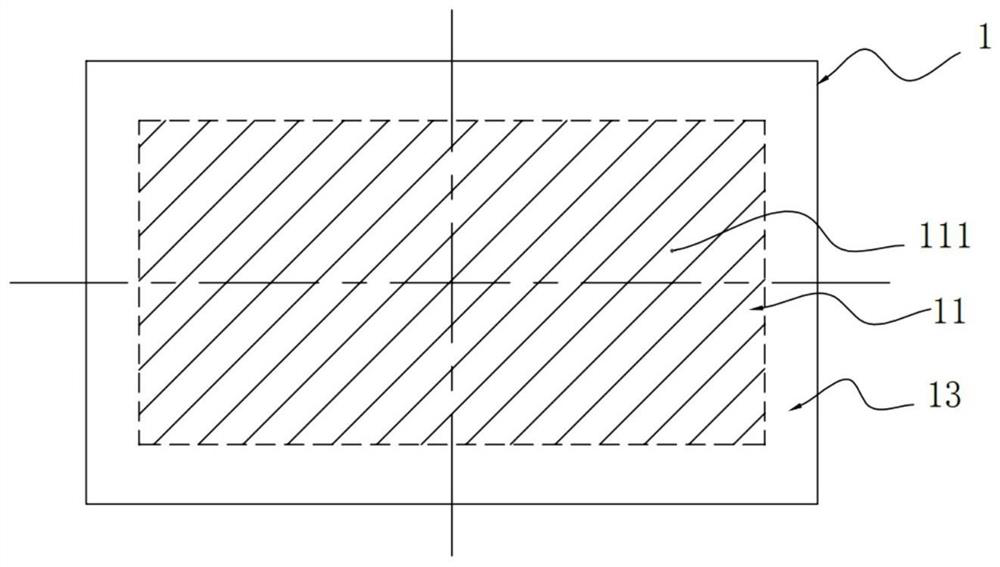

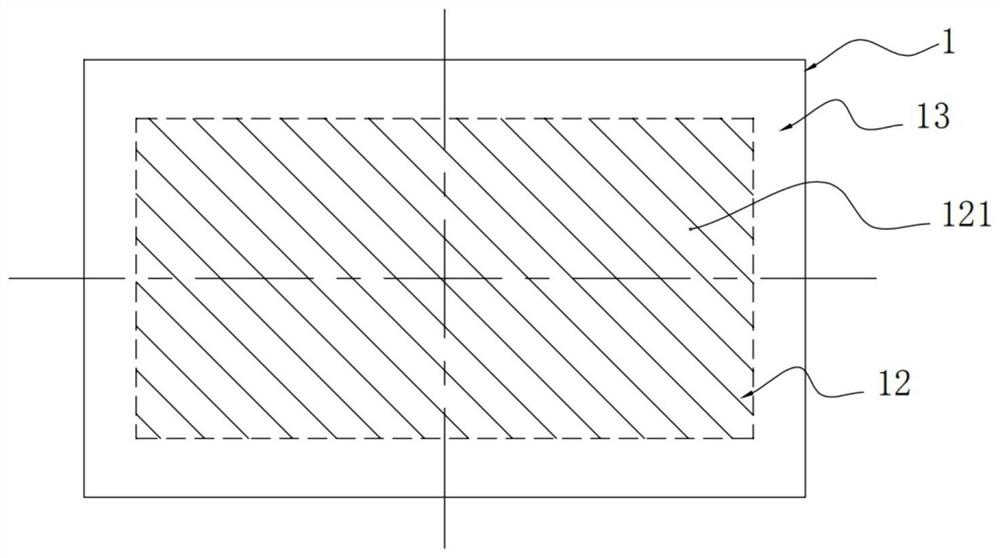

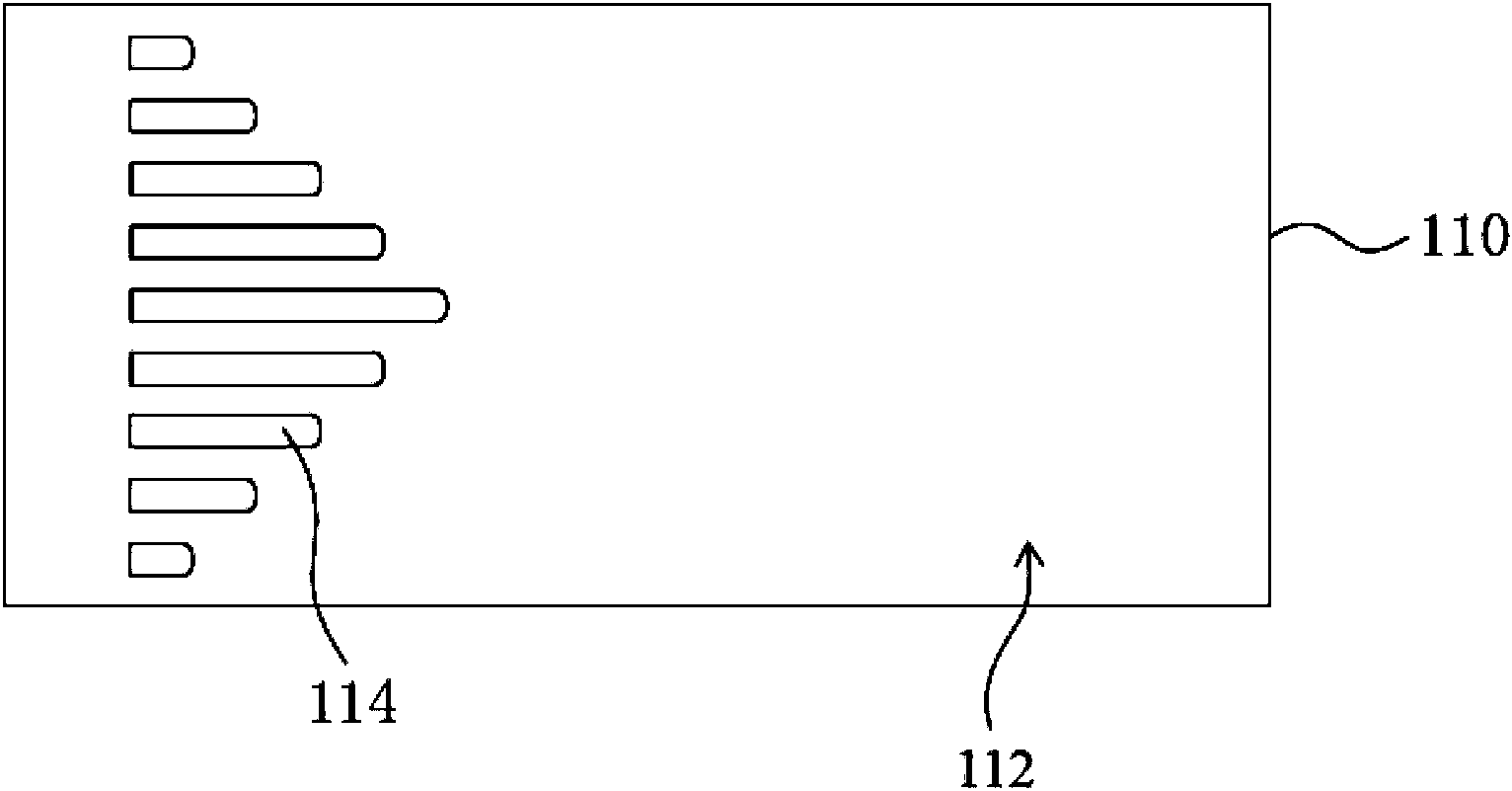

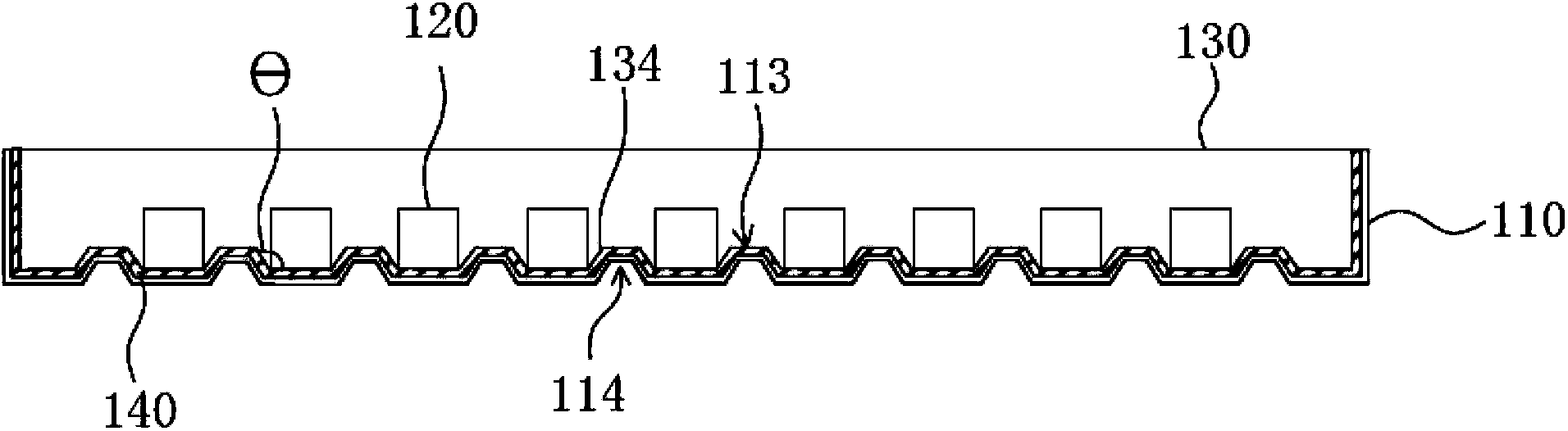

Backlight module and display device

InactiveCN102679243AImprove uniformity of light emissionEnsure uniformity of light emissionMechanical apparatusLight guides for lighting systemsLight guideDisplay device

The invention provides a backlight module and a display device. The display device comprises a backlight module and a display panel. The backlight module comprises a backplane, a light guide plate and a light source, wherein the backplane comprises a plurality of backplane bulges and corresponding backplane pits thereof, the light guide plate comprises a plurality of pits, the backplane bulges of the backplane are embedded into the pits of the light guide plate, and the light source is arranged on at least one side of the light guide plate. According to the invention, the heat dissipation effect can be improved by using the backplane pits of the backplane.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

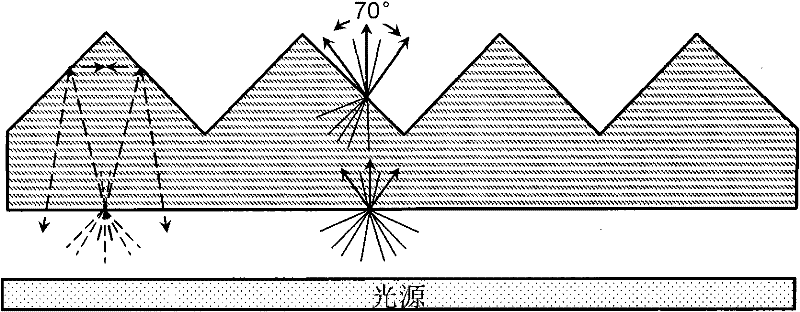

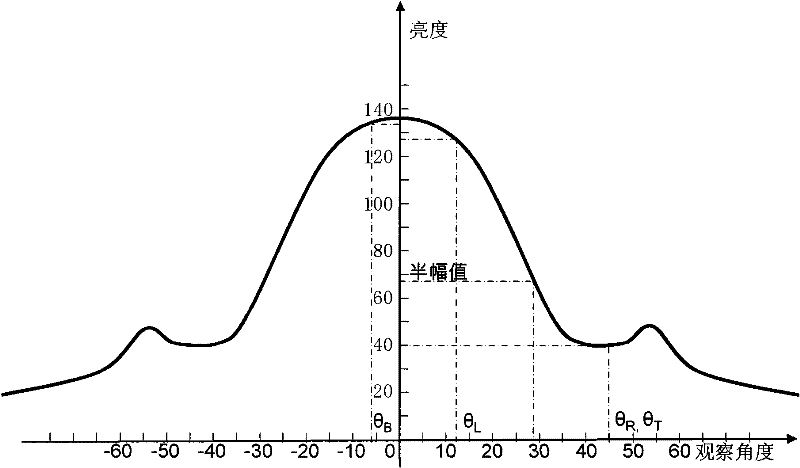

Light-focusing module and backlight module

ActiveCN101706081AHigh central luminance valueEnsure uniformity of light emissionNon-linear opticsRefractorsLiquid-crystal displayLight-emitting diode

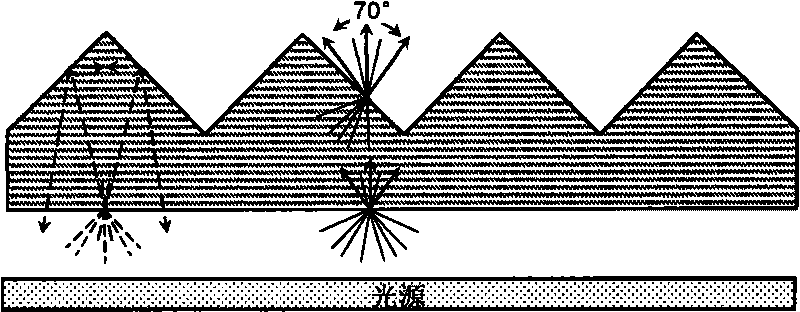

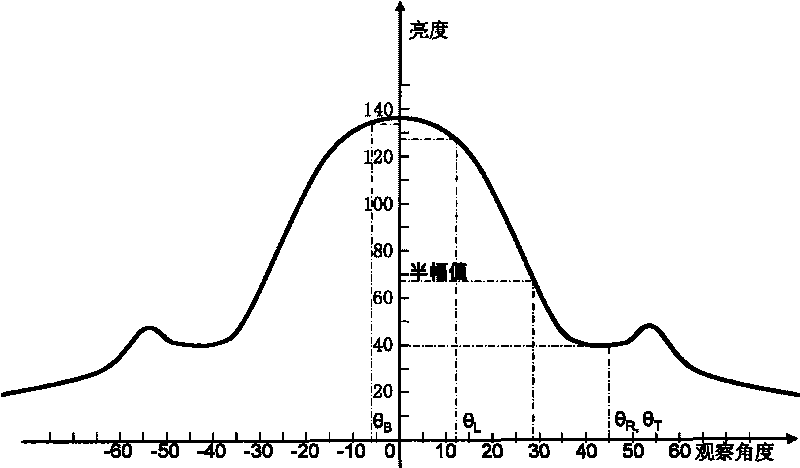

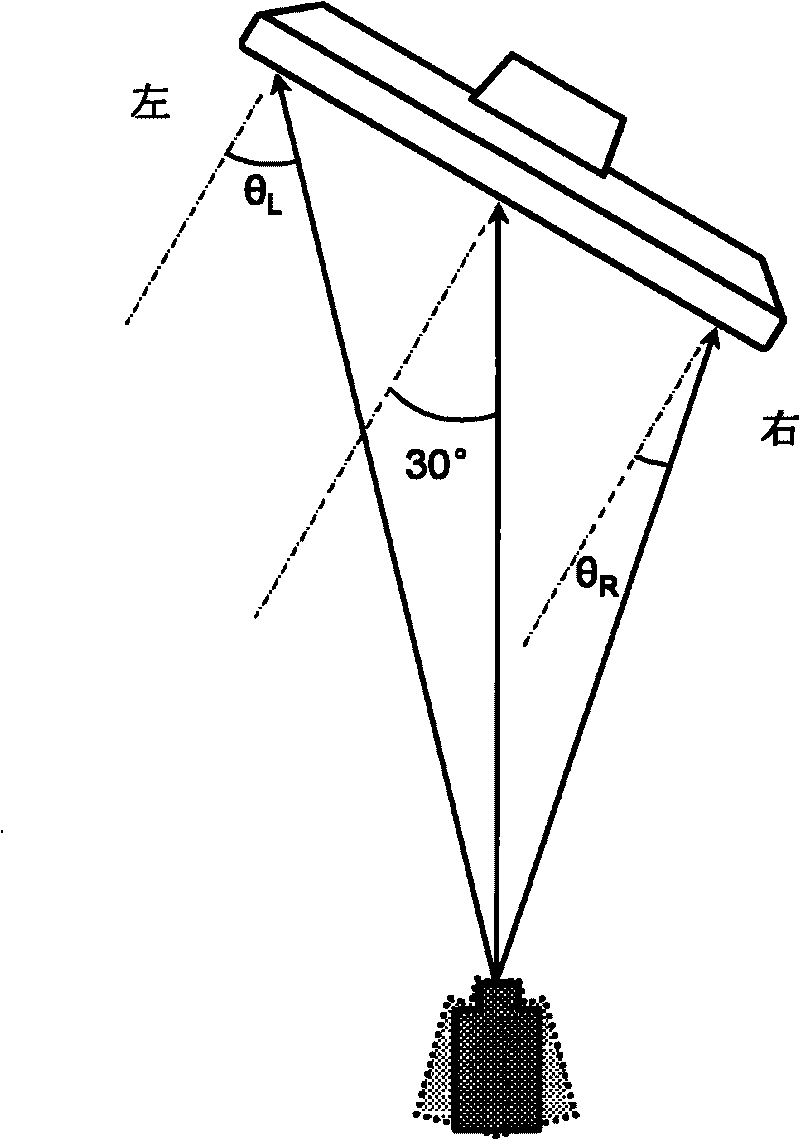

The invention provides a light-focusing module and a backlight module using the light-focusing module. The light-focusing module comprises a light emitting face and a plurality of light-focusing microstructures; the light emitting face has a geometric center; the light of each light-focusing microstructure has the maximum emitting brightness in certain direction; when the inclined angle between the light emitting direction and the certain direction is a brilliance semi-range angle, the brightness decreases to half the maximum emitting brightness; the light-focusing microstructures change gradually from the geometric center of the light emitting face towards the direction far away from the geometric center, the farer from the geometric center of the light emitting face, the larger the brilliance semi-range angle of the light-focusing microstructures. A liquid crystal display using the light-focusing module and the backlight module seems to have more uniform brightness.

Owner:KUSN INFOVISION OPTOELECTRONICS

Backlight module and display device

The invention discloses a backlight module and a display device. The backlight module comprises an LED light source and a fluorescent glue layer, wherein the LED light source comprises a substrate andmini LED lamp beads arranged on the substrate in an array; the fluorescent glue layer is arranged in the light emitting direction of the LED light source, and the portions, away from the LED light source, of the fluorescent glue layer are provided with rectangular pyramid structures; the mini LED lamp beads correspond to the rectangular pyramid structures one to one. The technical problem that anexisting mini LED backlight module is thick is solved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

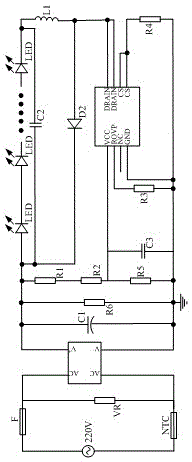

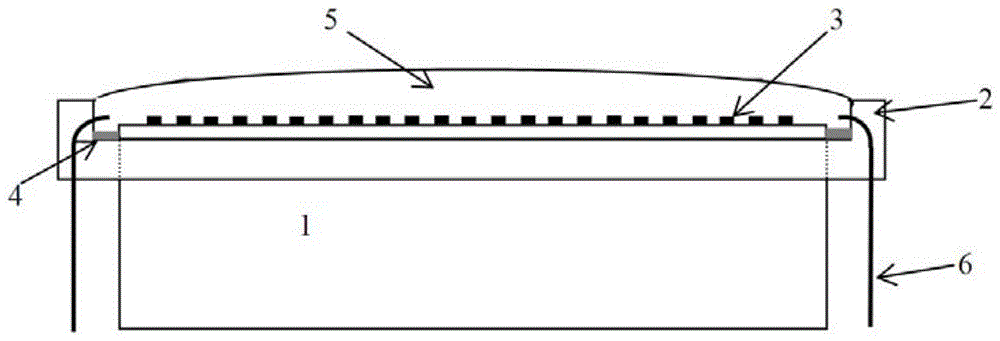

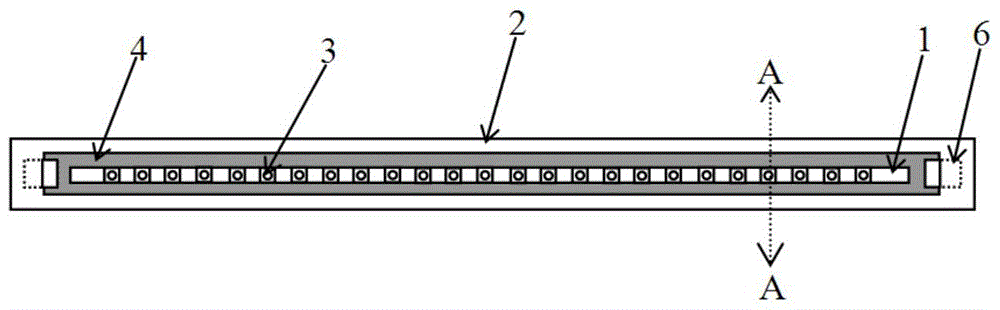

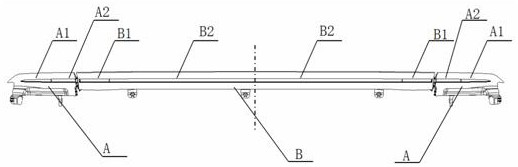

AC (alternating current) high-voltage double-side LED lamp bar

InactiveCN103822134AReduce installation difficultyConvenient power supplyElectric lightingElectric light circuit arrangementEpoxyEngineering

The invention discloses an AC (alternating current) high-voltage double-side LED lamp bar. The AC high-voltage double-side lamp bar comprises an elongated bar-shaped transparent cover, protecting caps and an LED lamp bar body, wherein the protecting caps are fixed at two ends of the transparent cover, and the LED lamp bar body is fixed in the transparent cover. The LED lamp bar body comprises an FR-4 epoxy resin circuit board and LED lamps, wherein the FR-4 epoxy resin circuit board is provided with an alternating-current and direct-current conversion circuit, and the LED lamps are arranged on the front side and the back side of the FR-4 epoxy resin circuit boards. Meanwhile, waterproof heat-conduction silica gel is filled in the protecting caps. The AC high-voltage double-side LED lamp bar is skillful in design, simple in structure, convenient to realize and low in cost, is remarkably higher in comprehensive performance as compared with the prior art, and has good market prospect.

Owner:李忠训

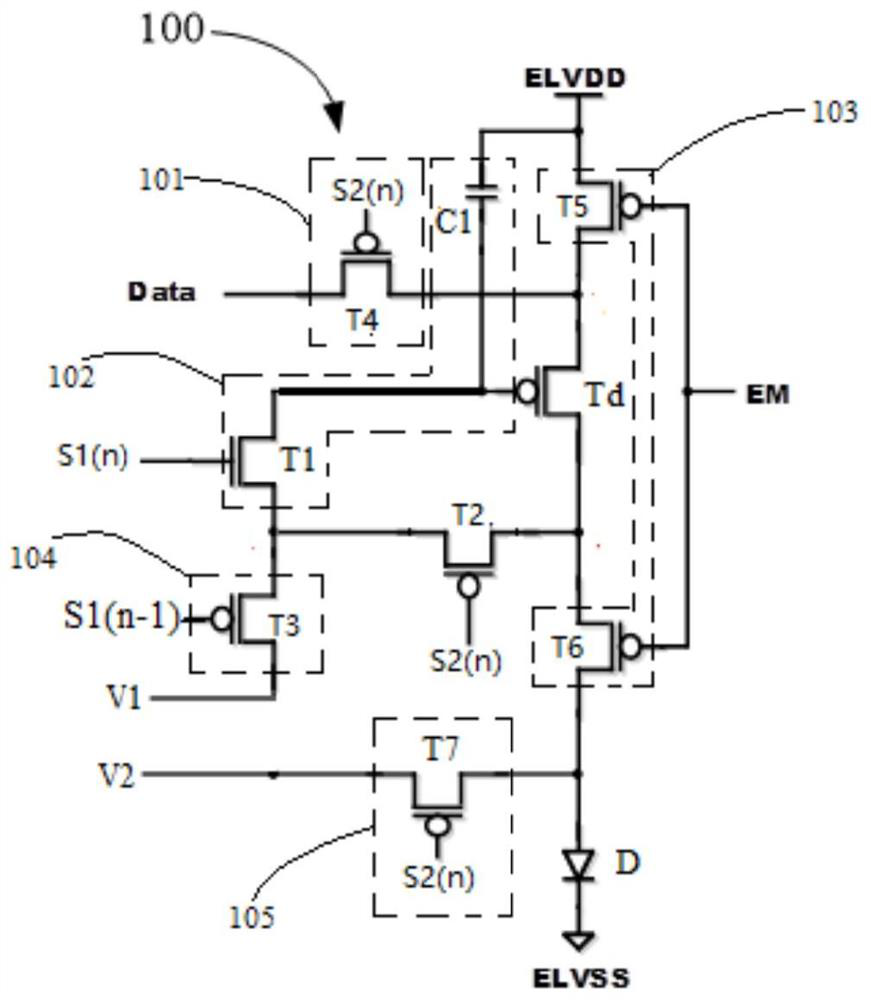

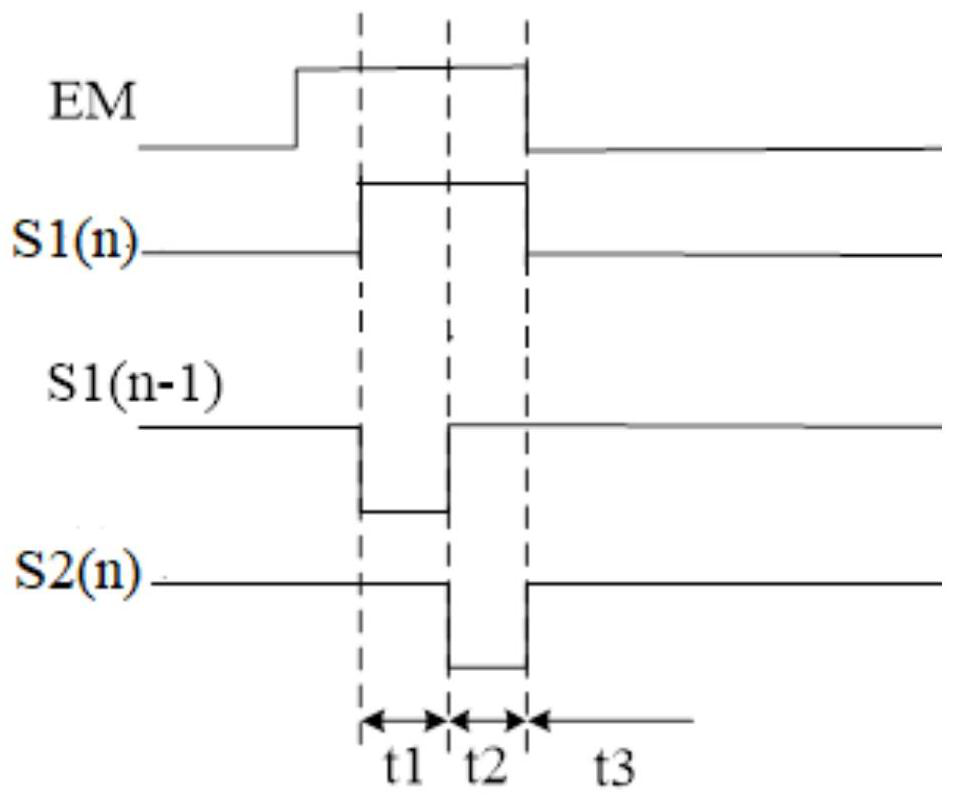

Display panel

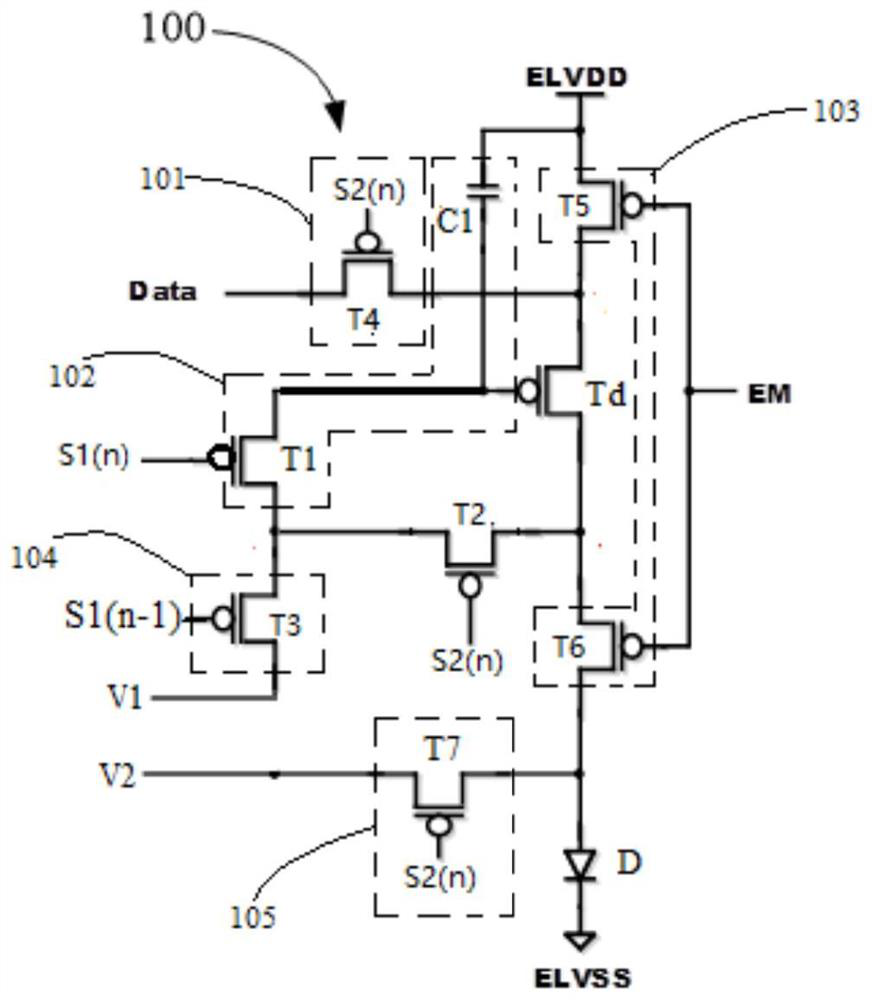

ActiveCN114220839AEnsure uniformity of light emissionImprove potential stabilityStatic indicating devicesSolid-state devicesCapacitanceDriver circuit

The invention discloses a display panel. The display panel comprises a plurality of sub-pixels, each sub-pixel comprises a driving circuit, and each driving circuit comprises a light-emitting device, a driving transistor, a first transistor, a first capacitor, a second transistor and a third transistor. A drain electrode of a first transistor is electrically connected with a grid electrode of a driving transistor, a source electrode of a third transistor is electrically connected with a source electrode of the first transistor, the first transistor is an oxide thin film transistor, and after the first transistor is closed, a light-emitting device is turned on to emit light. And after the first transistor is closed, the low leakage characteristic of the oxide thin film transistor is utilized to suppress the grid potential change of the driving transistor within one frame time, the potential stability of the grid of the driving transistor is improved, and the light emitting uniformity of the light emitting device is further ensured, so that leakage is controlled through the oxide thin film transistor, and high-quality display is realized. And low frequency and low power consumption are achieved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

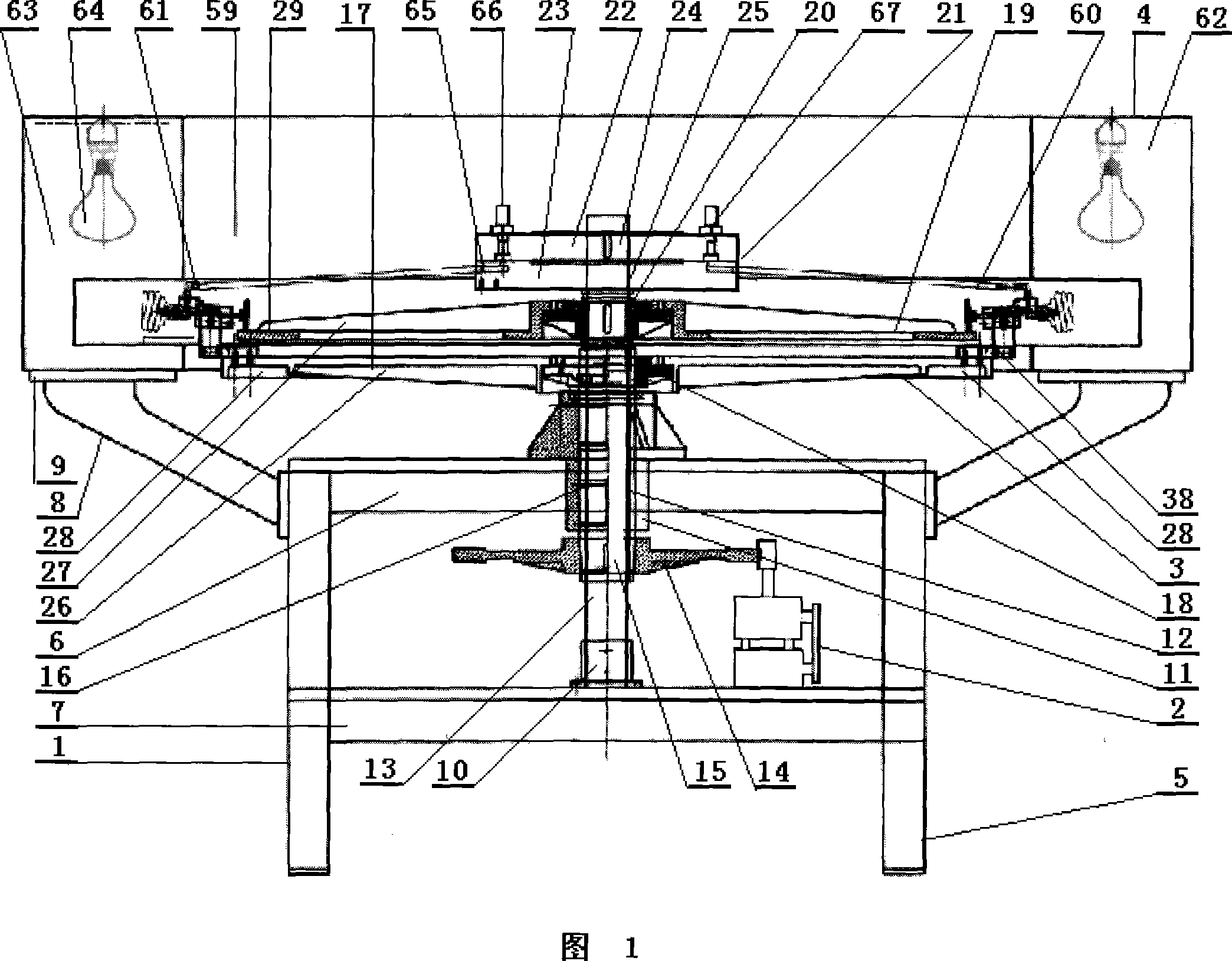

Method and apparatus for coating fluorescent powder on screw type fluorescent lamp tube

InactiveCN101042965AUniform thicknessEnsure luminous brightnessLuminescent coatings applicationState of artDesiccant

The invention relates to a method and device of smearing fluorescence powder to screw type fluorescence lamp, it adopts the device with function of rotation and revolution to make the fluorescence powder slurry layer smeared evenly and solidified slowly in screw bent glass pipe, and the normal temperature air is as the moisture absorption agent, and combining the infrared radiation, firing in oven and desiccation of flowed circled air, technics of reinforcing coat, the fluorescence powder layer is insured not to be thick, and the thickness is even, it fits for insuring the quality of screw type fluorescence lamp, and can increase at least 3% or above of the luminescence efficiency, save 10% or above of fluorescence powder, and the device can set many screw bent glass pipe mounting rack, it can move slowly, work as sequence, operate circularly, the work efficiency can be increased greatly, and without technics that it adopts the definite 90deg.C hot air desiccant which is used in current technique, the production cost is decreased, it possesses advantages of reliability, convenient to use, evident saving energy, and possesses marked economy and strong practicability.

Owner:上海川石光电科技有限公司

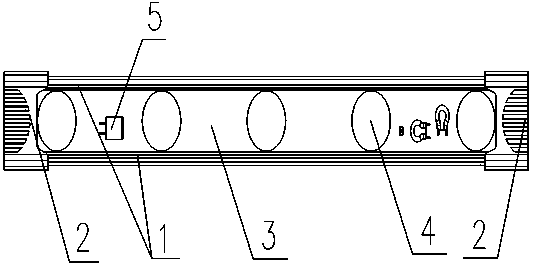

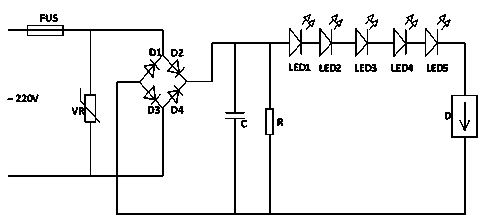

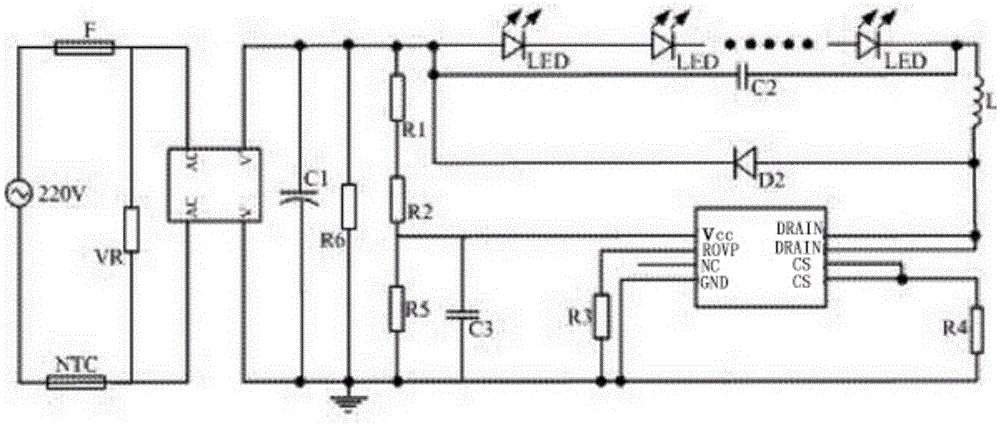

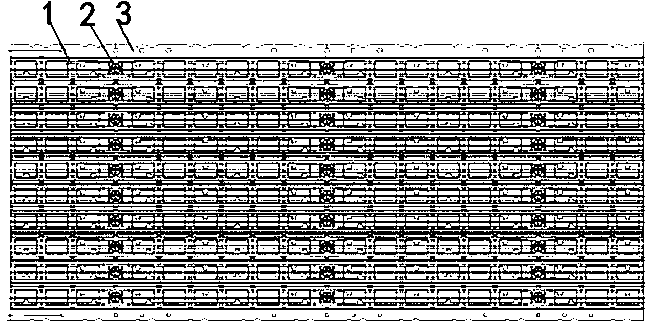

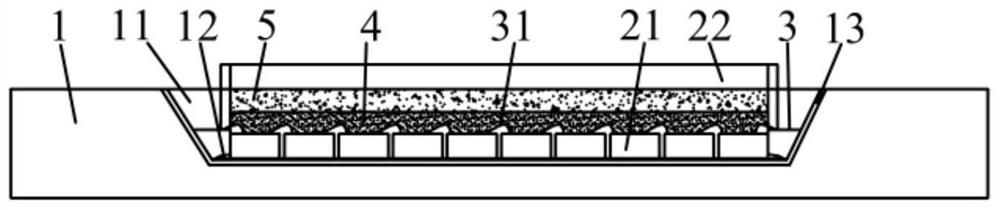

LED advertisement light box side lighting light bar based on 220V alternating current

InactiveCN103712113ASave processSave costPoint-like light sourceElectric circuit arrangementsEffect lightEngineering

The invention discloses an LED advertisement light box side lighting light bar based on the 220V alternating current, and belongs to the technical field of electronics. The LED advertisement light box side lighting light bar based on the 220V alternating current comprises a light bar outer shell and LED light beads (4), wherein the light bar outer shell is composed of an anti-flaming PC clamping groove (1) and a PC lampshade (3) arranged at the top of the anti-flaming PC clamping groove (1); a circuit board is embedded into the anti-flaming PC clamping groove (1); the LED light beads (4) are fixed to the light bar outer shell; a rectifier (5) and an LED working circuit connected with the rectifier are integrated on the circuit board. By means of the structure, the LED advertisement light box side lighting light bar based on the 220V alternating current solves the problems that as an existing light bar can be connected with the electric supply by being provided with a direct current power source independently or being matched with an adapter, installation is inconvenient and cost is high, and has higher practical value.

Owner:李忠训

Direct type backlight module comprising perforated layer

PendingCN110543048AGuaranteed uniformityImprove the display effectNon-linear opticsOptoelectronicsMaterial Perforation

The invention discloses a direct type backlight module comprising a perforated layer. The backlight module comprises a lower shell, a direct type light source, a reflecting cover, the perforated layer, a light scattering assembly and an upper frame. The direct type light source is fixed in the lower shell; the reflecting cover is arranged on the direct type light source; the perforated layer and the light scattering assembly are sequentially stacked on the reflecting cover; and the reflecting cover, the perforated layer and the light scattering assembly are pressed and fixed in the lower shellthrough the upper frame. A plurality of LED light sources are arranged on the direct type light source; a plurality of reflection cups are arranged on the reflecting cover; a plurality of perforationunits are arranged on the perforated layer; a plurality of perforations are formed in each perforation unit; each LED light source is arranged on the bottom of one corresponding reflection cup; and each perforation unit is arranged right above the corresponding reflection cup. The method is used for optimizing light emitting uniformity of the backlight module.

Owner:HUIZHOU WAI CHI ELECTRONICS CO LTD

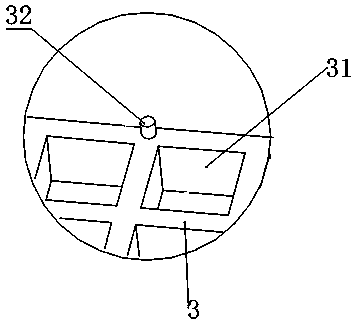

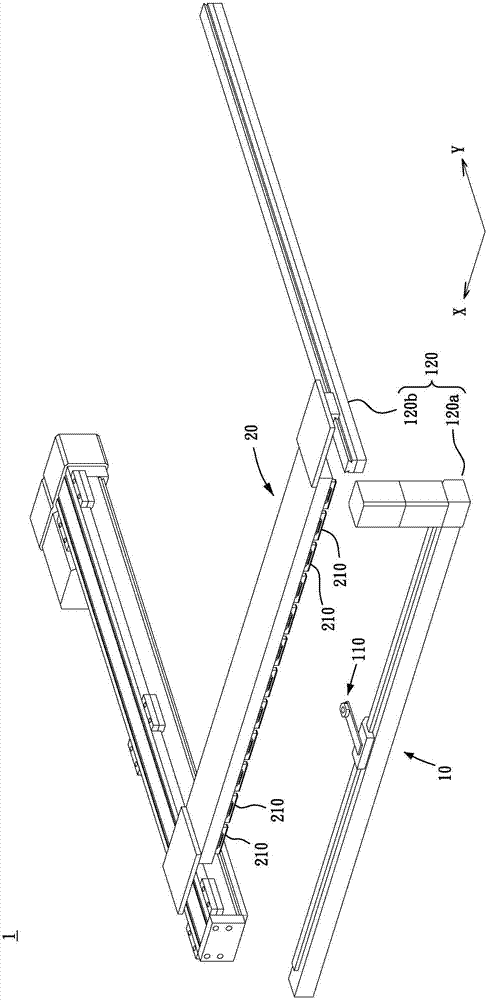

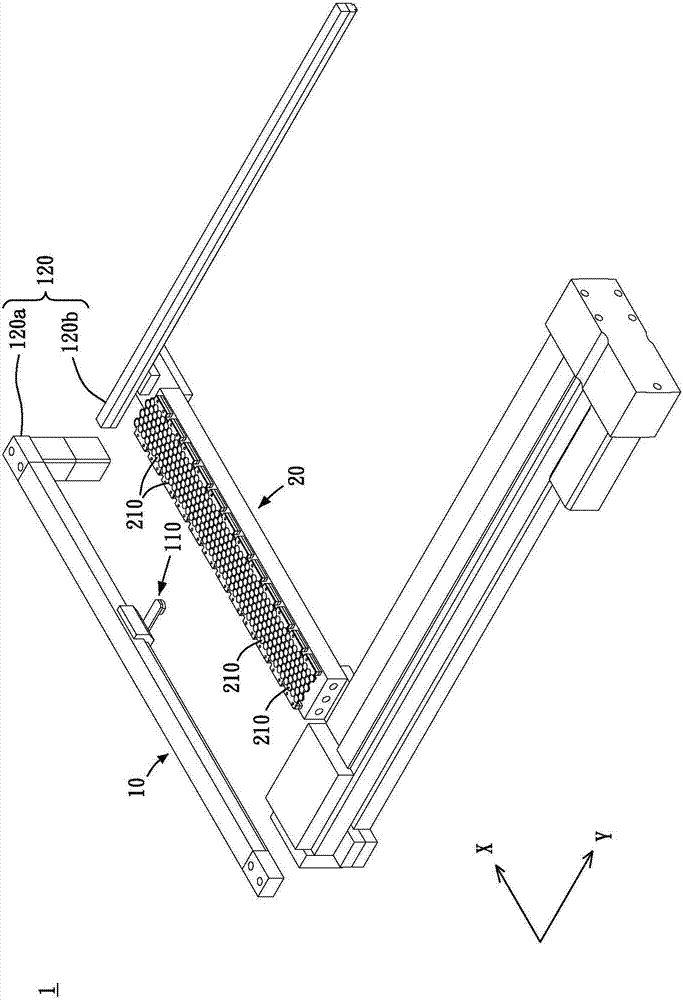

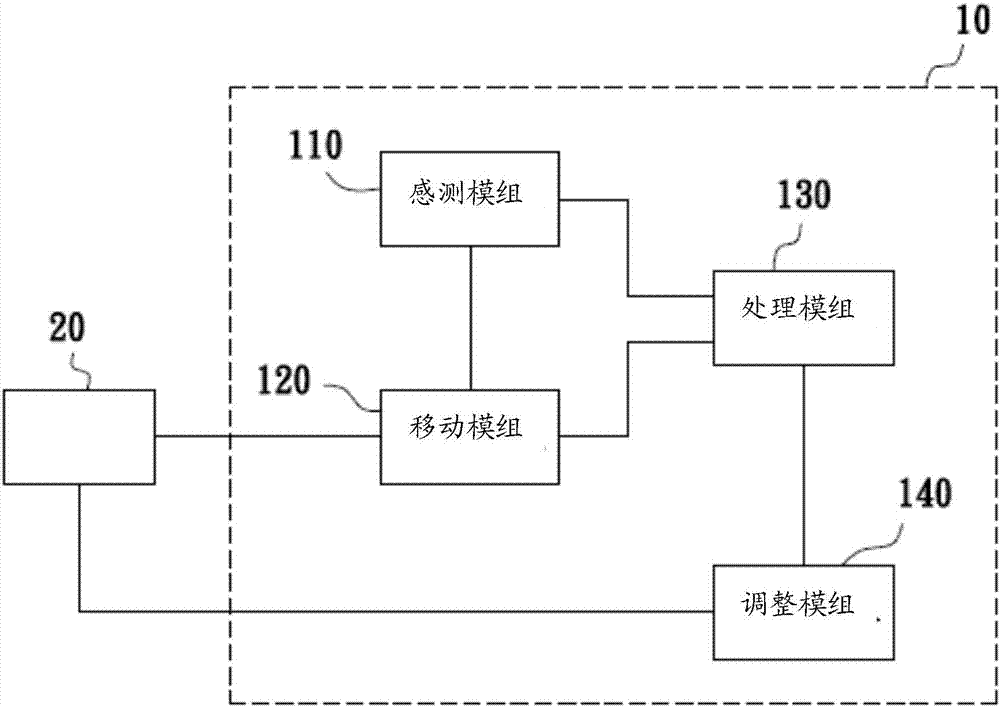

Correcting equipment and correcting method for luminous uniformity

InactiveCN107315319AEnsure uniformity of light emissionEasy to adjustPhotomechanical exposure apparatusMicrolithography exposure apparatusLuminous intensityLight exposure

The invention discloses a luminous uniformity correction device, which is suitable for correcting the luminous uniformity of a light emitting module of an exposure machine. The light intensity signals are generated by the sensing module at each sampling position corresponding to the distribution of the light emitting module, and the processing module analyzes the light emitting uniformity of the light emitting module according to these light intensity signals, and when the light emitting uniformity of the light emitting module does not meet the A corresponding calibration signal is generated when a uniformity standard is used, and the adjustment module correspondingly adjusts the luminous intensity of at least one of the light emitting units of the light emitting module according to the calibration signal. Therefore, by using automatic equipment to correct the uniformity of the light emitting module, it is possible to quickly and conveniently adjust the areas with abnormal light intensity to ensure uniformity of light emission, thereby improving the manufacturing yield of the circuit board.

Owner:CHIME BALL TECH

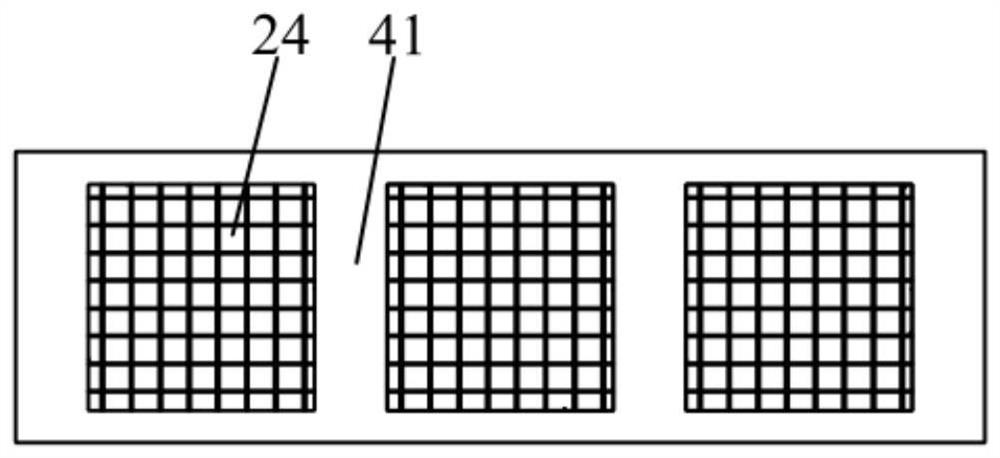

Manufacturing method of LED display module for splicing

The invention provides a manufacturing method of an LED display module for splicing, which comprises the following steps of: providing a substrate, arranging a process edge around the substrate, and defining a display area for mounting a light-emitting unit on the front surface of the substrate; defining a drive mounting area for mounting an electronic drive element on the back surface of the substrate; a groove which does not penetrate through the substrate is formed in the process edge, and the depth of the groove is larger than the thickness of the part, not penetrating through the substrate, of the substrate; mounting a light-emitting unit array on the display area; a light-transmitting packaging adhesive layer covering the display area is molded on the substrate, and the groove is filled with the light-transmitting packaging adhesive layer; and cutting off part of the process edge and part of the light-transmitting packaging adhesive layer along one side of the process edge to form a cutting surface on the outer side of the LED display module, and enabling the distance from the central point of the light-emitting unit closest to the cutting surface on the plane where the display area is located to the cutting surface to be smaller than or equal to 1 / 2 of the line spacing value between two rows of light-emitting units parallel to the cutting surface. The spliced display screen has the beneficial effects that water vapor invasion is prevented, and the spliced display screen is uniform in light emitting.

Owner:SHENZHEN JUFEI OPTOELECTRONICS CO LTD

AC high-pressure dual-face LED lamp bar

InactiveCN105627177AReduce installation difficultyConvenient power supplyElectric circuit arrangementsLighting heating/cooling arrangementsEpoxyEngineering

The invention discloses an AC high-pressure dual-face LED lamp bar. The AC high-pressure dual-face LED lamp bar comprises a long-strip-shaped tubular transparent cover, protection covers fixed to the two ends of the transparent cover and an LED lamp bar body fixed in the transparent cover. The LED lamp bar body comprises an FR-4 epoxy resin circuit board with an alternating current and direct current conversion circuit and LED lamps arranged on the front face and the back face of the FR-4 epoxy resin circuit board. Meanwhile, the protection covers are filled with waterproof heat conduction silica gel. The AC high-pressure dual-face LED lamp bar is ingenious in design, simple in structure, convenient to implement and low in cost; the comprehensive performance is remarkably improved compared with the prior art; and the good market prospects are achieved.

Owner:YANYANG LAMP SET TIANCHANG CITY

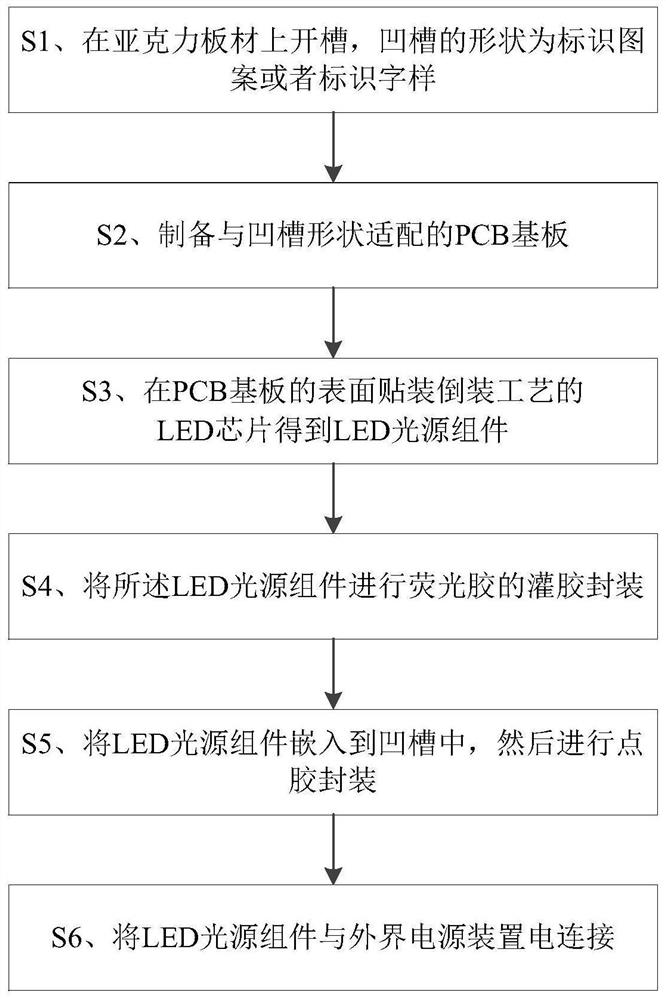

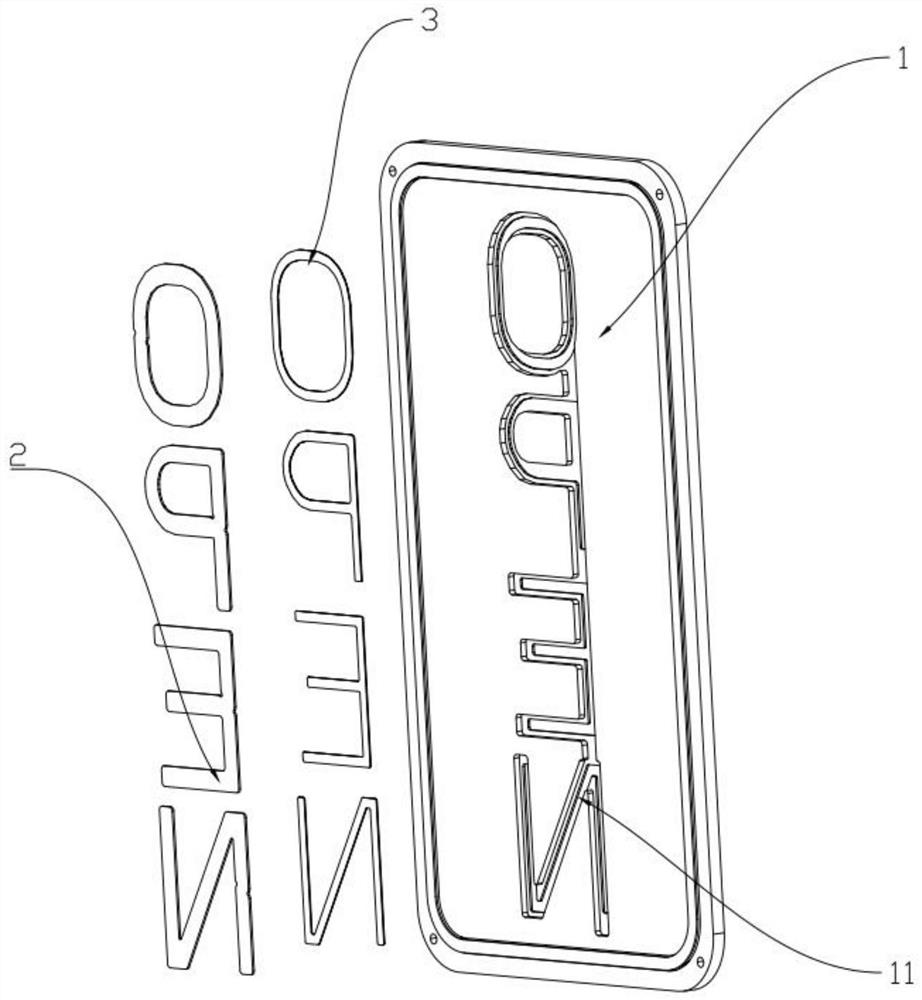

LED signboard preparation process

InactiveCN111883016AEnsure uniformity of light emissionGlow is not affectedIlluminated signsSurface mountingEngineering

The preparation process of the LED signboard comprises the following steps: S1, forming a groove in an acrylic plate, wherein the shape of the groove is an identification pattern or an identificationcharacter; s2, preparing a PCB substrate matched with the groove in shape; s3, mounting an LED chip on the surface of the PCB substrate to obtain an LED light source assembly; s4, enabling the LED light source assembly to be subjected to glue pouring packaging; s5, enabling the LED light source assembly to be embedded into the groove, and then carrying out dispensing packaging; s6, electrically connecting the LED light source assembly with an external power supply device. The PCB substrate is prepared into a whole block, then the LED chips are mounted, the light emitting uniformity can be guaranteed, and after the LED chips at a certain point position break down, due to the fact that the mounting density of the LED chips is large, it can be guaranteed that light emitting of the whole signboard is not affected, meanwhile, the deformation resistance is enhanced, and the signboard manufactured through the technology is ingenious in structure and good in light emitting effect.

Owner:SHENZHEN HUAKA LIGHT ELECTRONICS CO LTD

Method and device for coating fluorescent powder on spiral fluorescent lamp tube

InactiveCN101042965BUniform thicknessEnsure uniformity of light emissionLuminescent coatings applicationLaboratory ovenFluorescent lamp

Owner:上海川石光电科技有限公司

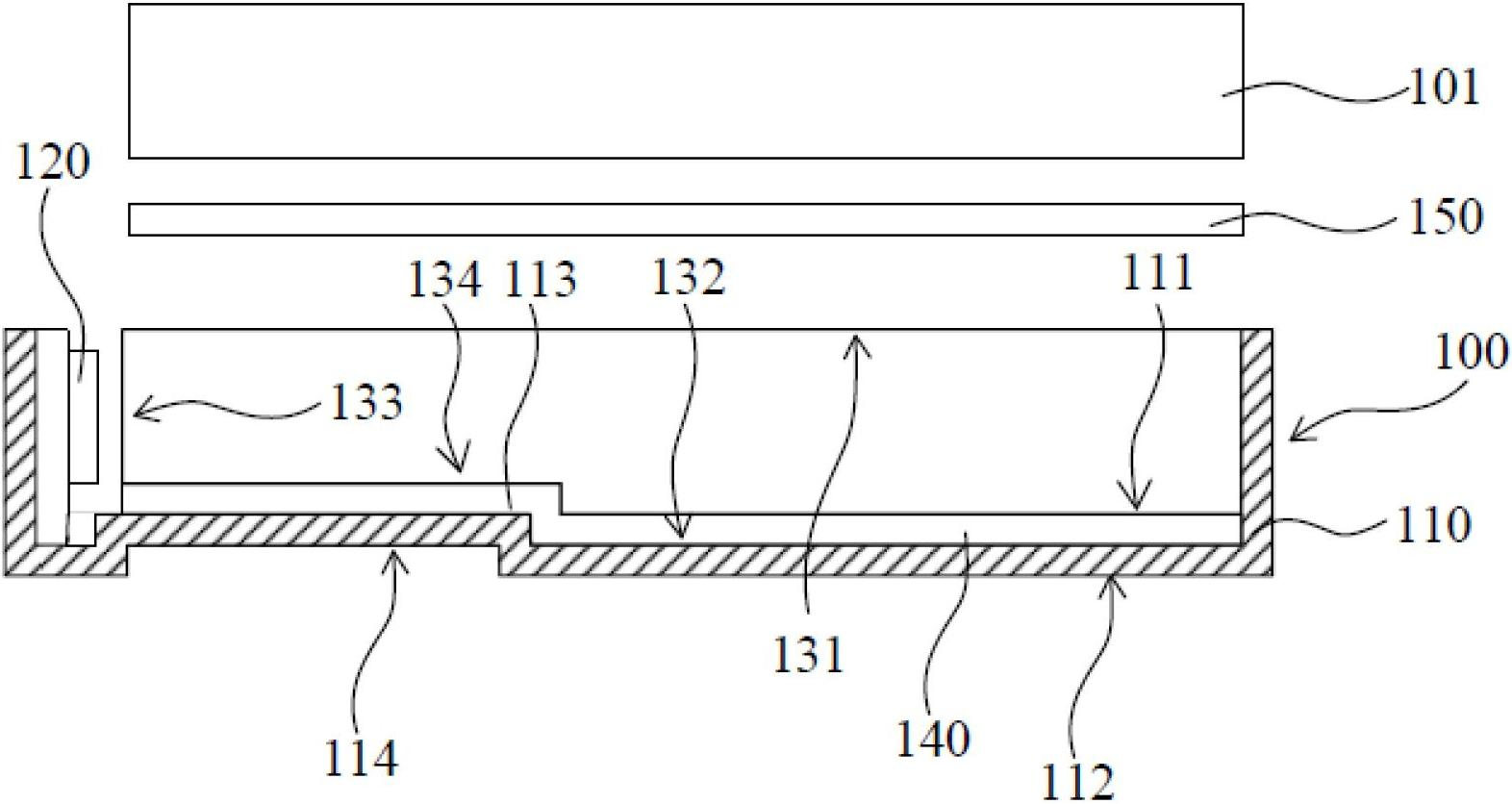

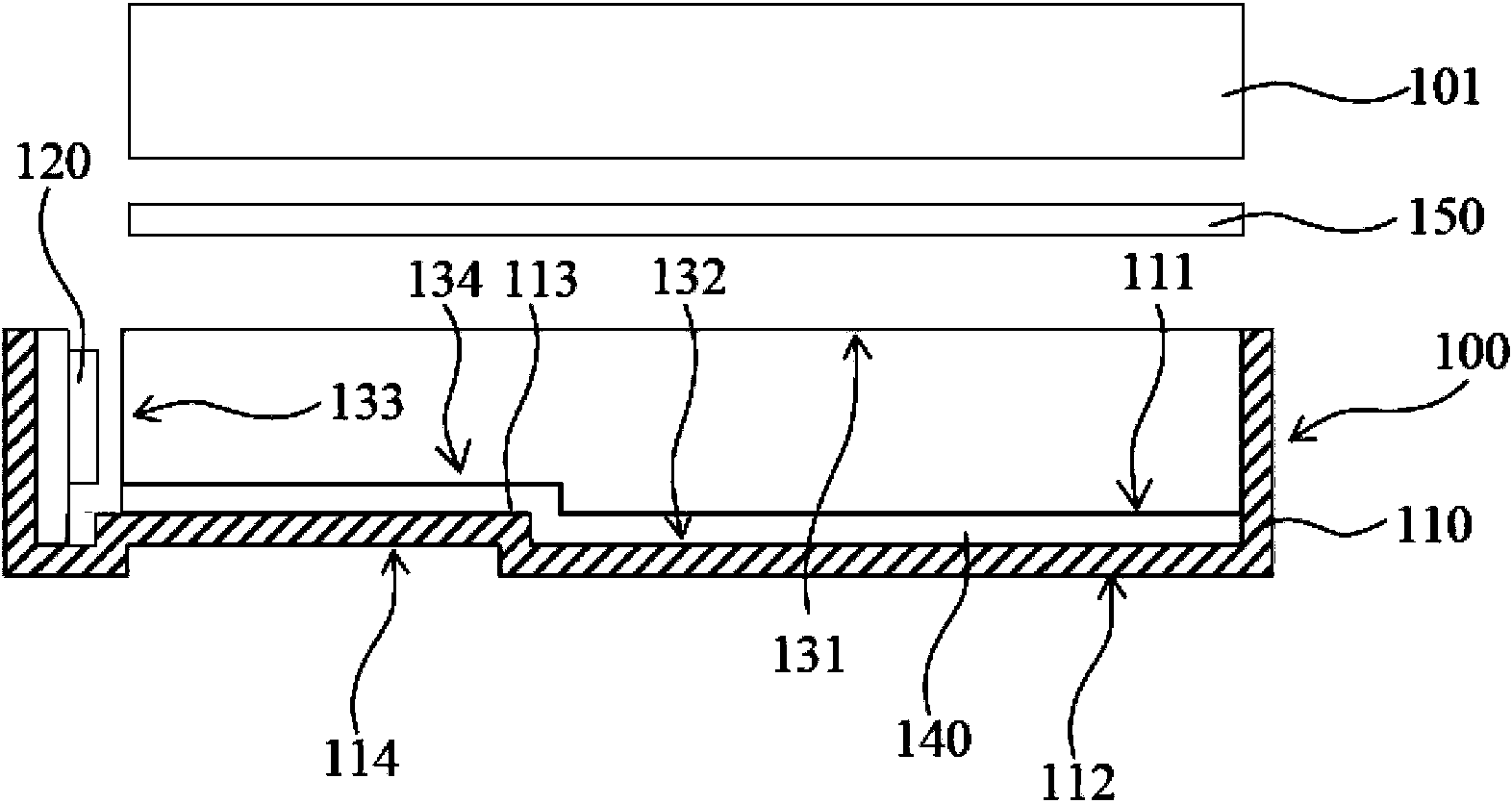

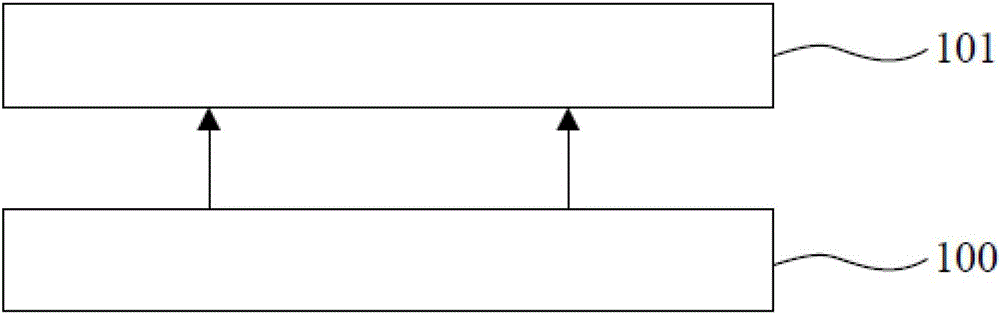

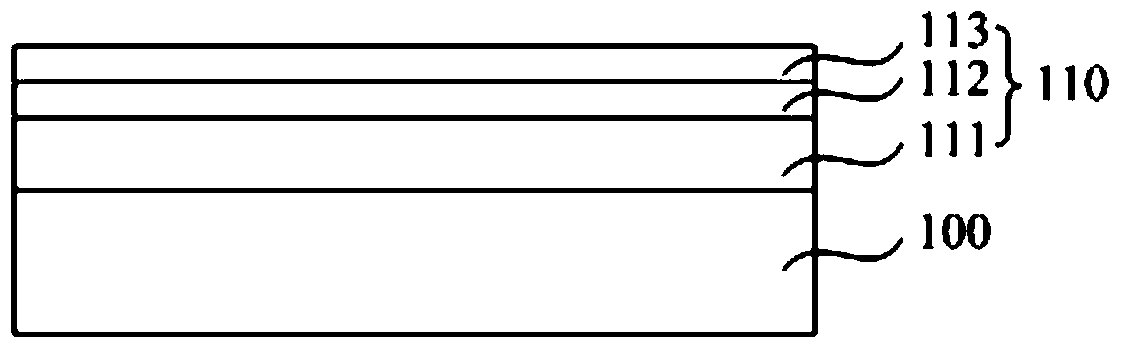

Backlight module and display device

InactiveCN102679243BImprove uniformity of light emissionEnsure uniformity of light emissionMechanical apparatusLight guides for lighting systemsLight guideDisplay device

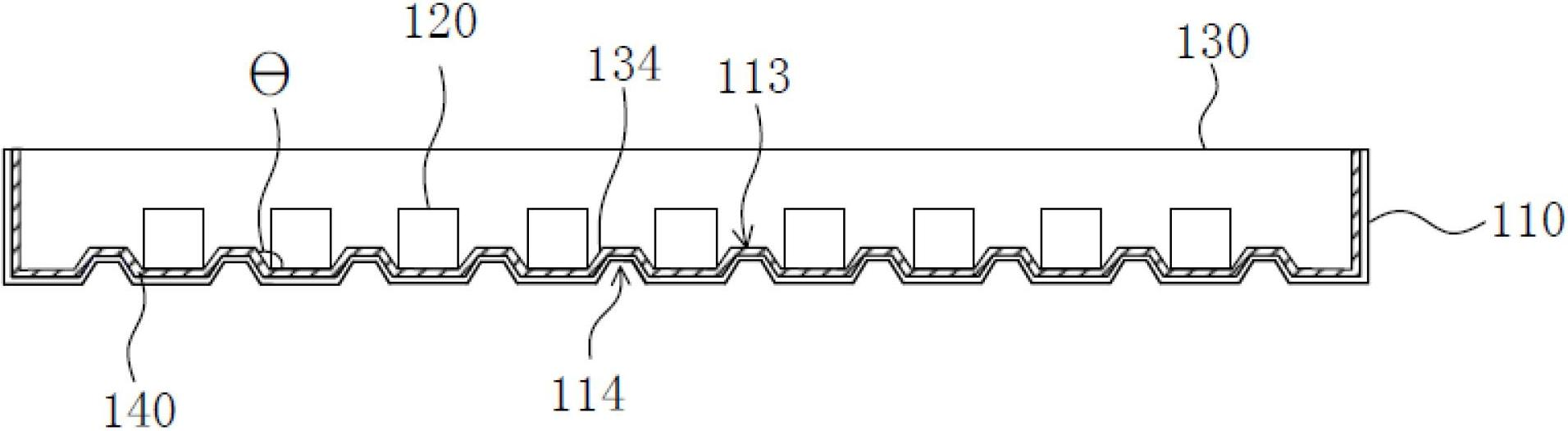

A backlight module (100) and a display device comprising the backlight module (100) and a display panel (101). The backlight module (100) comprises a back panel (110), a light guide plate (130), and a light source (120). The back panel (110) comprises multiple back panel protrusions (113) and back panel indentations (114) corresponding thereto. The light guide plate (130) comprises multiple indentations (134). The back panel protrusions (113) of the back panel (110) are embedded into the indentations (134) of the light guide plate (130). The light source (120) is arranged on at least one side of the light guide plate (130). The back panel indentations (114) can be utilized to improve heat-dissipation effects.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

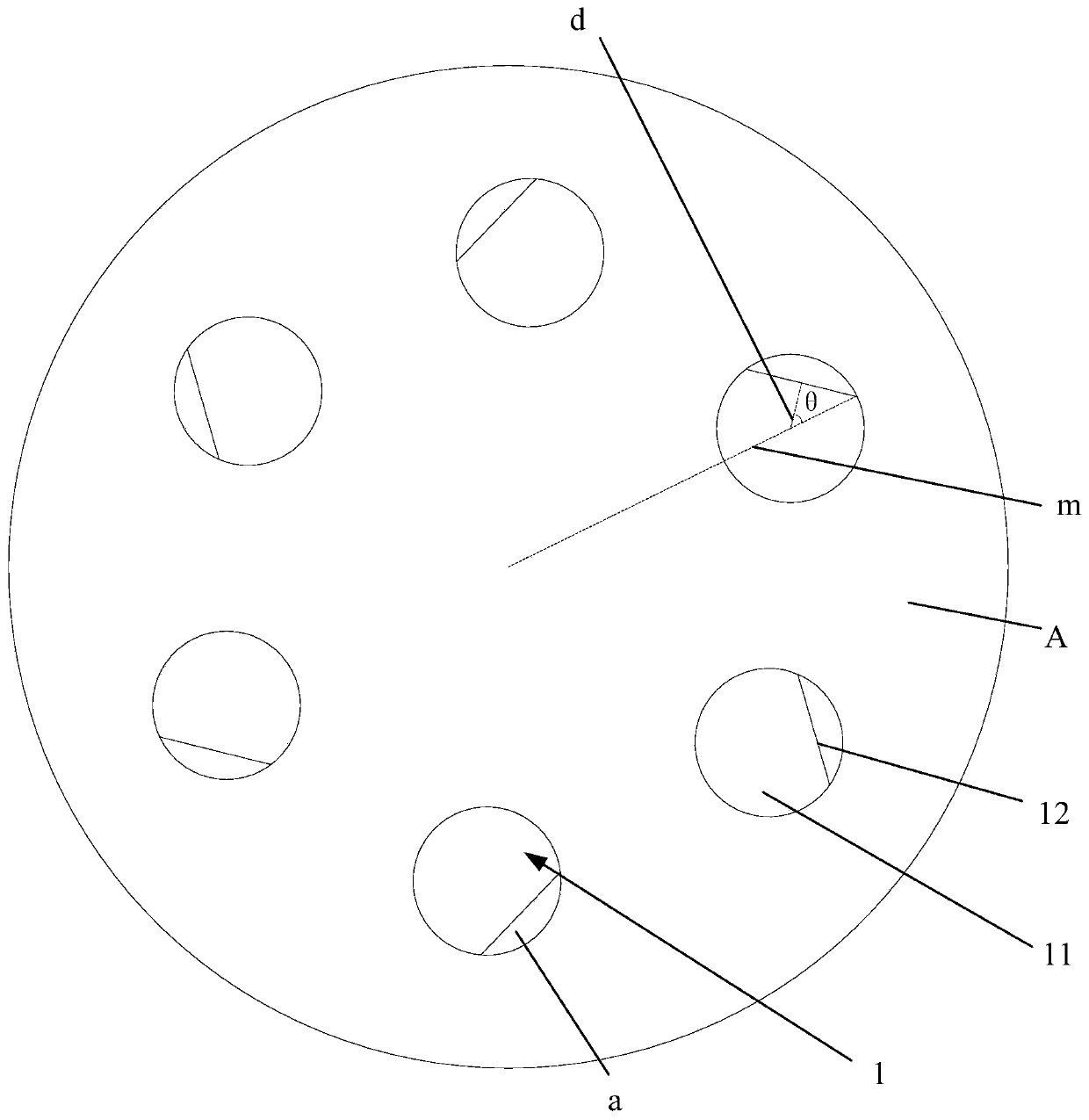

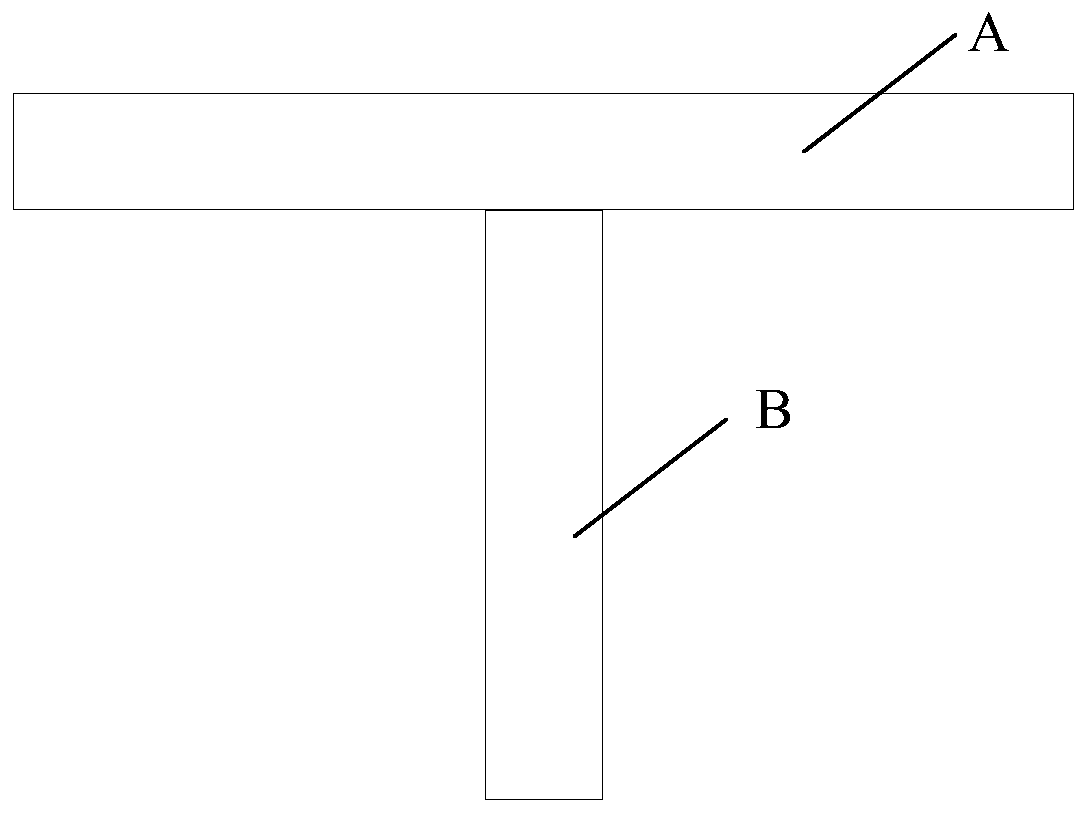

A kind of preparation method of light-emitting diode epitaxial wafer

ActiveCN109087979BIncrease temperatureEnsure uniformity of light emissionChemical vapor deposition coatingSemiconductor devicesEdge surfaceChemical vapor deposition

The invention discloses a preparation method of a light emitting diode epitaxial wafer, belonging to the field of light emitting diode manufacture. When the substrate is placed into the turntable of the organic chemical vapor deposition apparatus, the distance between the midpoint of the chord of the arcuate rounded edge surface and the axis of rotation is greater than the distance between the midpoint of the arc of the arcuate rounded edge surface and the axis of rotation, such an arrangement that the flat edge surface of the substrate faces the side away from the axis of rotation of the turntable. At this time, under the centrifugal force of the tray, the rounded edge surface portion of the substrate moves away from the flat edge surface, the friction between the peripheral portion of the epitaxial layer on the round edge surface and the sidewall of the circular groove is reduced, so that the temperature of the epitaxial layer of the part is not too high, the In in the InGaN well layer in the peripheral part is not excessively lost, the wavelength difference between the central part of the epitaxial layer grown on the round edge surface and the wavelength of the light wave emitted from the peripheral part is not too large, and the light emitting uniformity of the light emitting diode is further ensured.

Owner:HC SEMITEK ZHEJIANG CO LTD

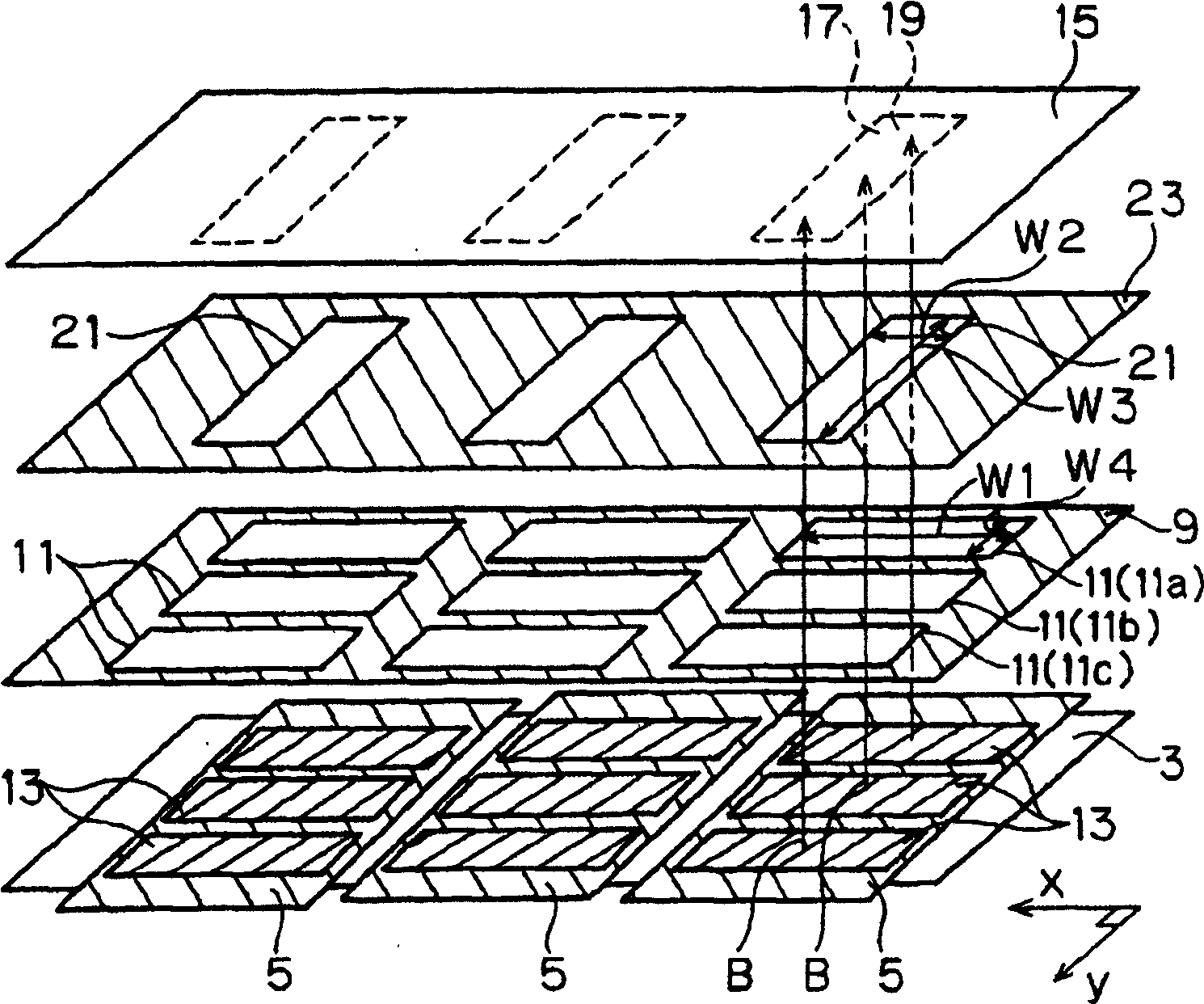

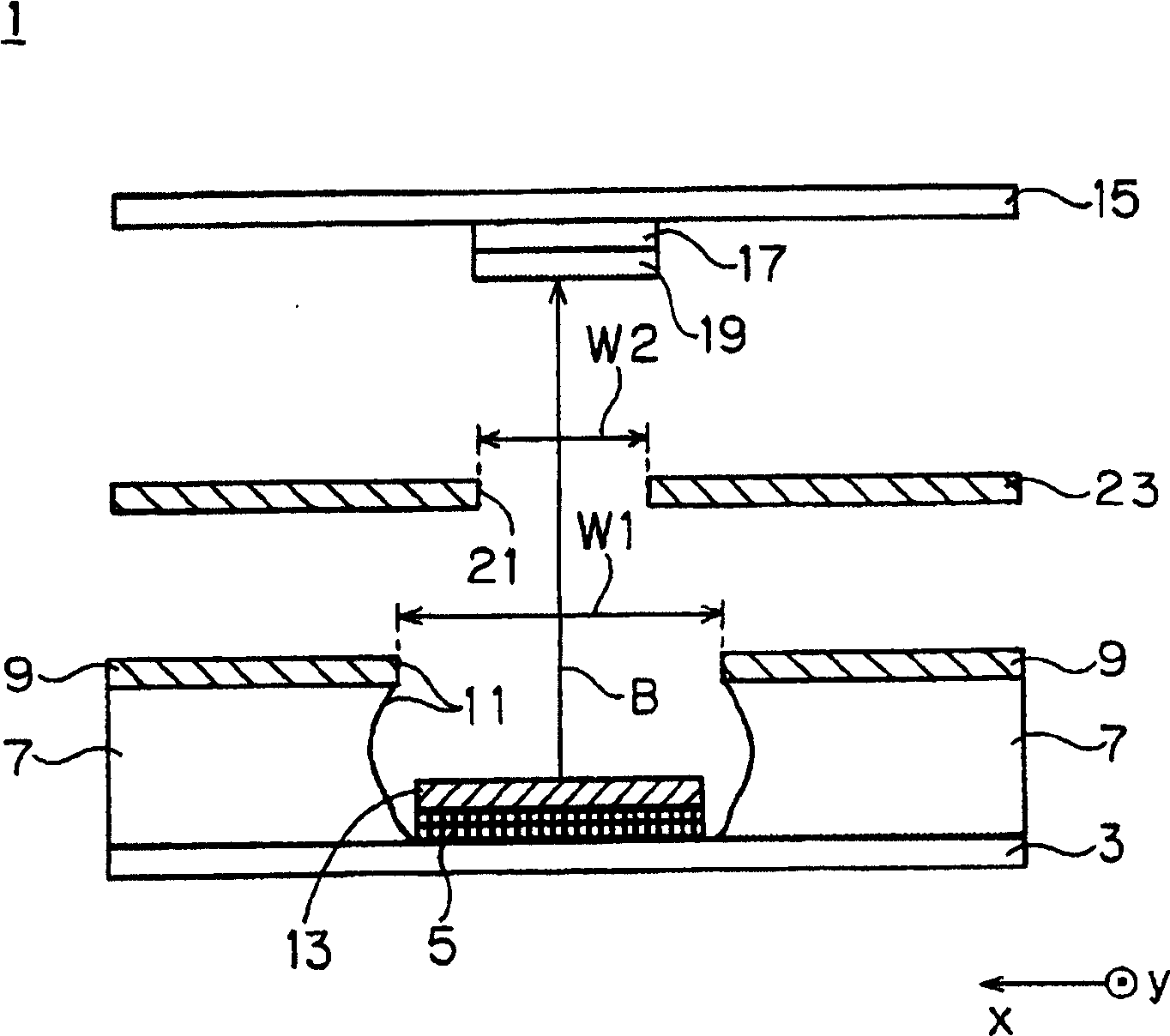

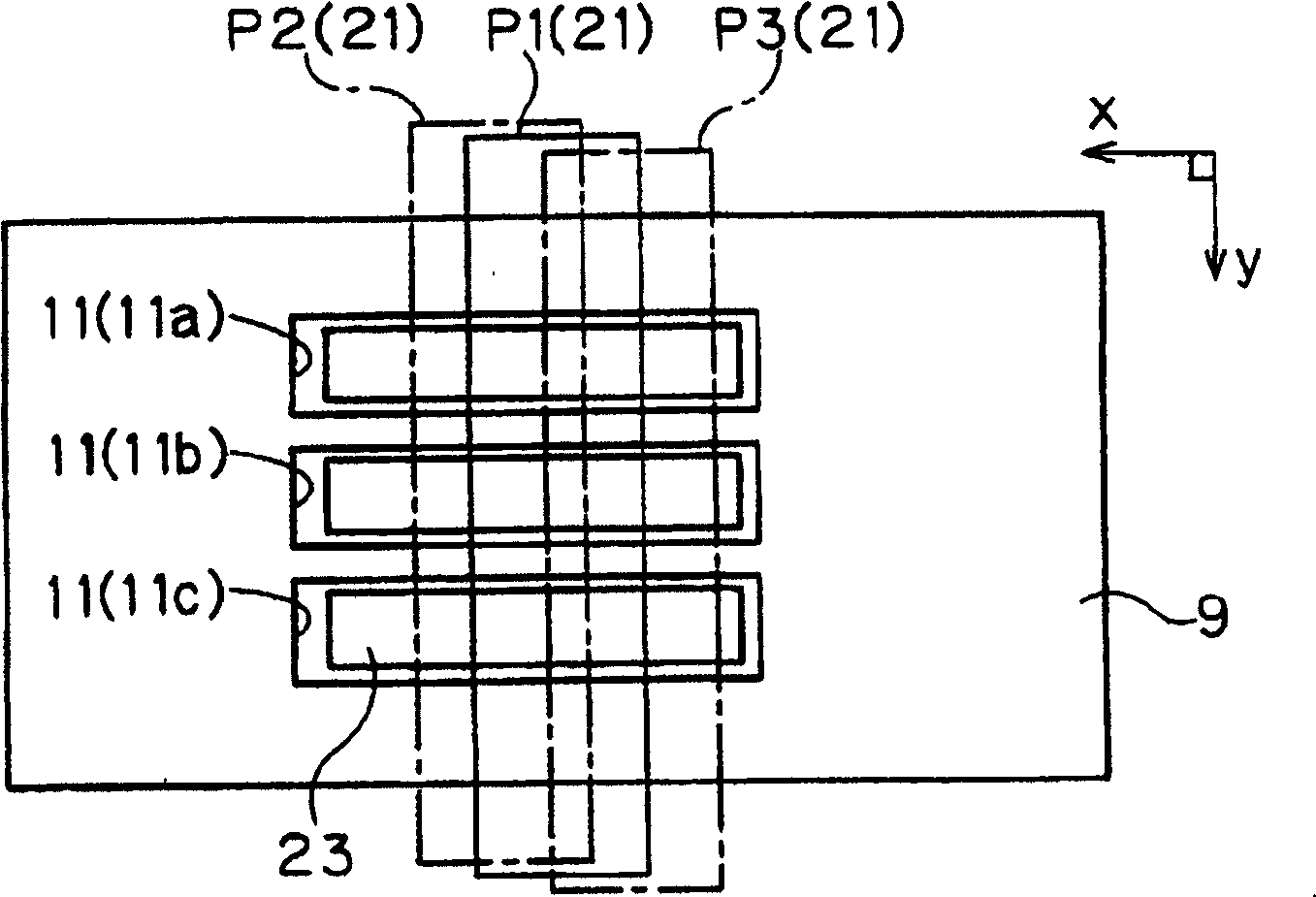

Field emission display device and method of manufacturing same

InactiveCN100521060CEnsure uniformity of light emissionDischarge tube luminescnet screensLamp detailsField emission displayDisplay device

Provided are an electric field emission display device and a method of manufacturing the same, capable of assembling a shielding electrode in such a manner that uniformity of light emission on a fluorescent surface (display surface) can be maintained without requiring high assembling accuracy. In this field emission display device (1), the opening width (W1) of the opening (11) of the control electrode (9) in a predetermined direction (x direction) is formed to be larger than the electron passing hole (W1) of the shielding electrode (23). 21) The opening width (W2) in the above-mentioned predetermined direction is large, and the entire range of the opening width (W2) in the above-mentioned predetermined direction of the electron passing hole (21) of the shielding electrode (23) overlaps the opening of the control electrode (9) (11) The shielding electrode (23) is arranged on the front side of the control electrode (9) so as to be within the range of the opening width (W1) in the predetermined direction.

Owner:MITSUBISHI ELECTRIC CORP

A kind of substrate and its preparation method, display device

ActiveCN108878689BAvoid climbingEnsure uniformity of light emissionSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceThin membrane

Embodiments of the present invention provide a substrate, a preparation method thereof, and a display device, which relate to the field of display technology and can solve the problem of uneven thickness of a light-emitting functional layer formed in an opening area of an existing pixel defining layer. The preparation method of the substrate includes: forming a pixel defining layer thin film on a base substrate; wherein, the material of the pixel defining layer thin film includes photoresist, an affinity material doped in the photoresist, an elastic material and auxiliary particles; The particles are used to release gas when decomposed, and the elastic material is used to expand the pixel defining layer film when the auxiliary particles release the gas; the molecular weight of the affinity material, photoresist and elastic material is greater than the molecular weight of the auxiliary particles; the pixel definition The layer film is heated to make the auxiliary particles move away from the substrate; the pixel defining layer film is processed to form a pixel defining layer, and the auxiliary particles are decomposed to release gas. For the preparation of the pixel definition layer.

Owner:BOE TECH GRP CO LTD +1

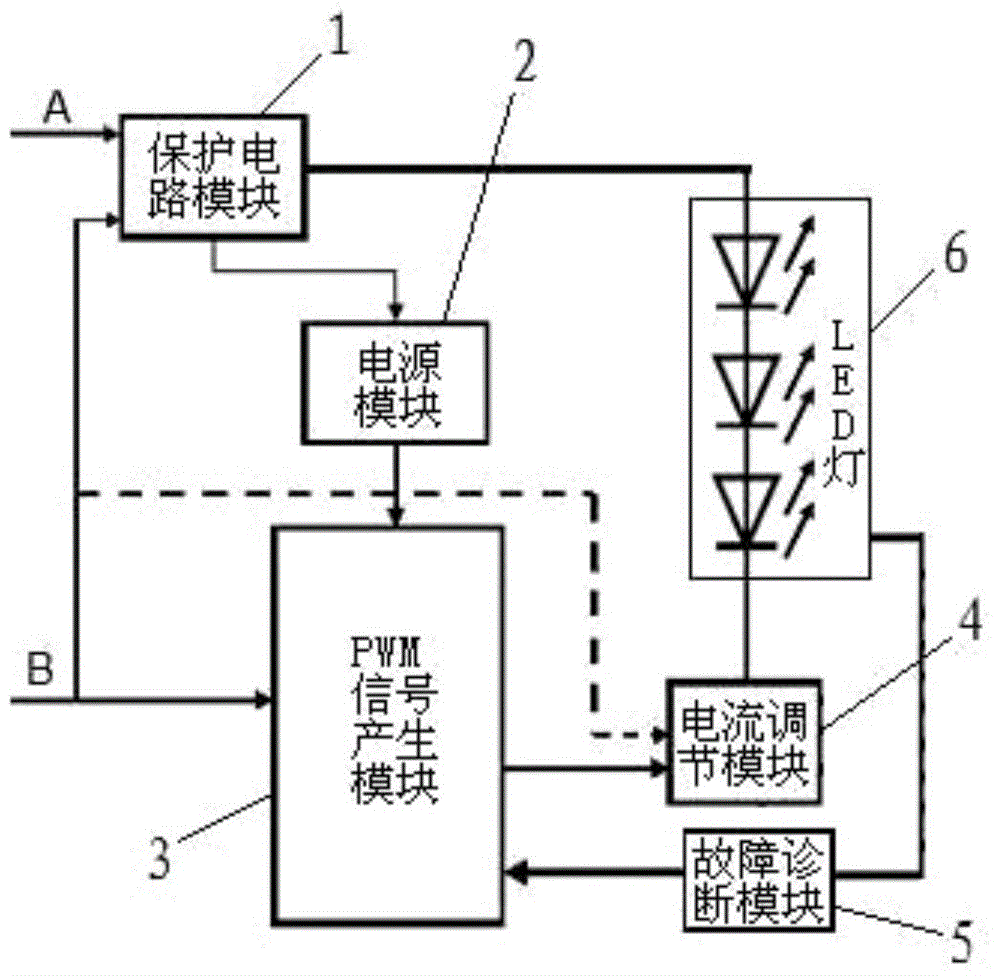

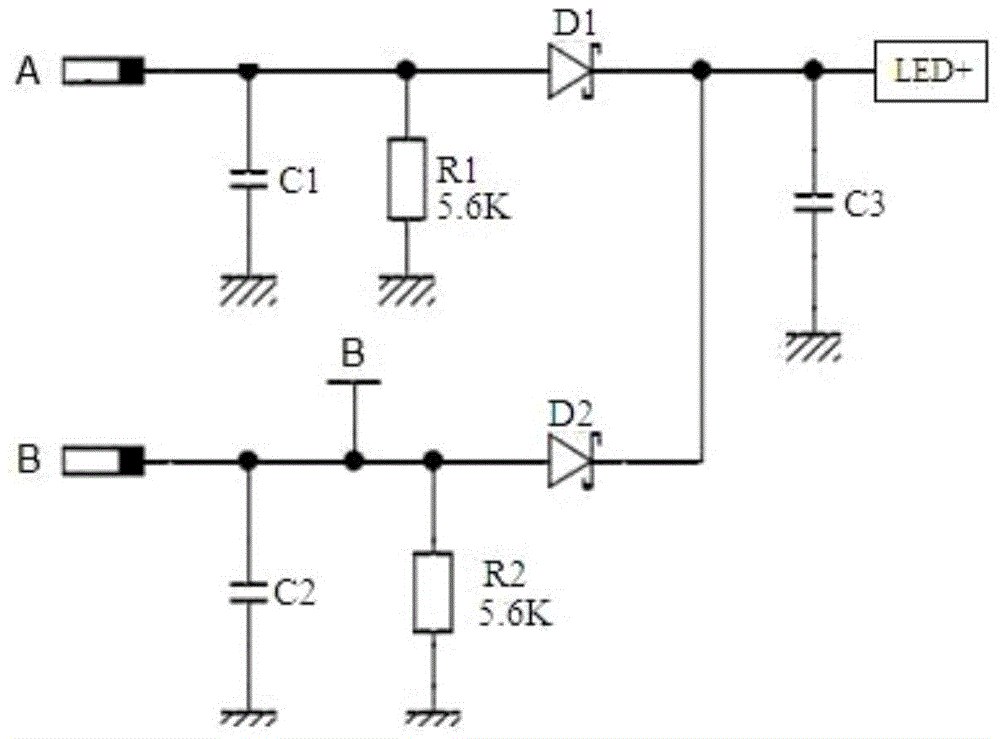

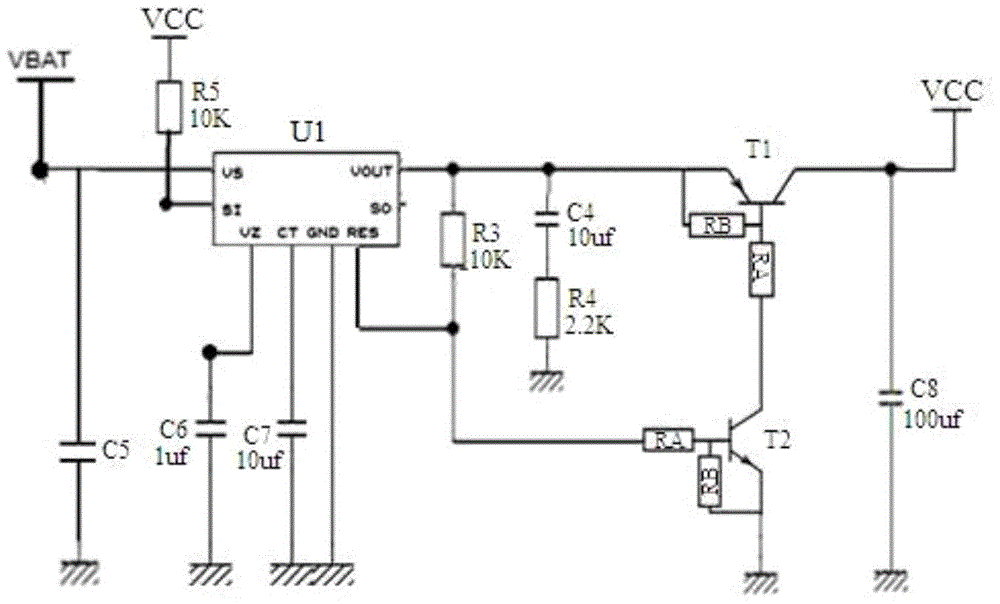

A dual-function led drive circuit

ActiveCN103561527BGuaranteed uniformityGuaranteed stabilityElectric light circuit arrangementElectricityPower flow

The invention belongs to the technical field of automobile lamps, and particularly relates to a dual-function LED drive circuit. The dual-function LED drive circuit comprises a protective circuit module, a power supply module, a PWM signal generating module, a current adjusting module, a fault diagnosis module and an LED lamp. The protective circuit module, the power supply module, the PWM signal generating module and the current adjusting module are electrically connected in sequence. The output end of the protective circuit module and the output end of the current adjusting module are connected with the anode and the cathode of the LED lamp respectively, the input end of the fault diagnosis module is connected with the cathode of the LED lamp, and the output end of the fault diagnosis module is connected with the PWM signal generating module. The LED drive circuit is controlled by PWM, a constant flow source is adopted to control a field effect transistor in the LED drive circuit to enable the current flowing through the LED lamp to be constant, the uniformity and stability of LED brightness are ensured, two kinds of light with different kinds of brightness can be emitted by a series of LED lamps through the drive circuit, the number of the LED light sources on an automobile body is effectively reduced, and the space utilization rate of the automobile body is improved.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

A kind of LED filament and manufacturing method thereof

ActiveCN104600174BImprove thermal reliabilityMaximum Thermal ReliabilitySemiconductor devicesFluorescenceConductive coating

The invention provides an LED (Light Emitting Diode) lamp filament and a manufacturing method thereof. An LED chip is encapsulated on the edge top surface of a thin and long sheet metal support of the LED filament innovatively, meanwhile the sheet metal is inserted into a preformed transparent plastic model frame to produce a light source, and accordingly the automated continuous production of the LED lamp filament is implemented and the problem of the facing direction strength caused by the too thin and too long metal support is solved due to the transparent plastic model frame; meanwhile the lateral direction strength of the metal support is effectively utilized and accordingly the integral mechanical strength of the LED lamp filament is ensured; the heat dissipation characteristics of the metal is directly utilized, meanwhile the heat dissipation efficiency of the LED chip is maximized through the innovative encapsulation of thermal conductive coatings, and accordingly the problem of a heat dissipation bottleneck of the LED lamp filament is effectively solved, the LED lamp filament can work at the rated power for a long time, and the cost is reduced; the LED light extraction efficiency is improved, the light attenuation is reduced, the high lighting effect and ambient light of lamp filament light emission is implemented, and the market vacancy of the existing LED lamp filament is filled through innovative fluorescence encapsulation materials.

Owner:广东佳光电子有限公司

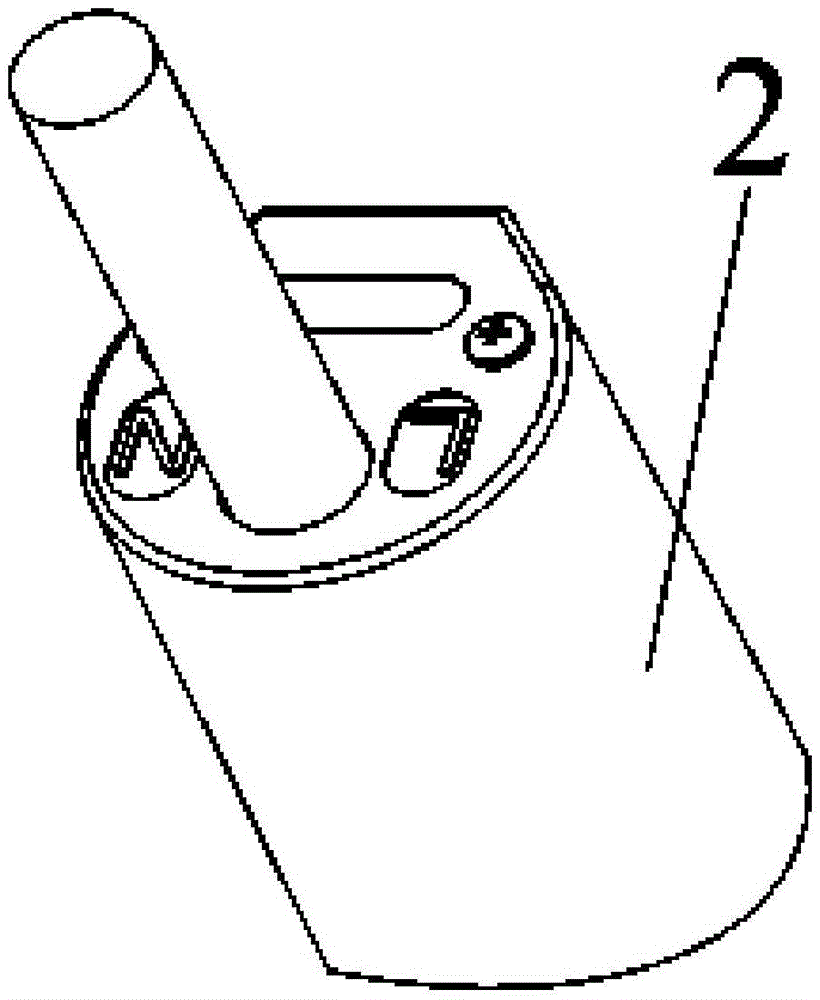

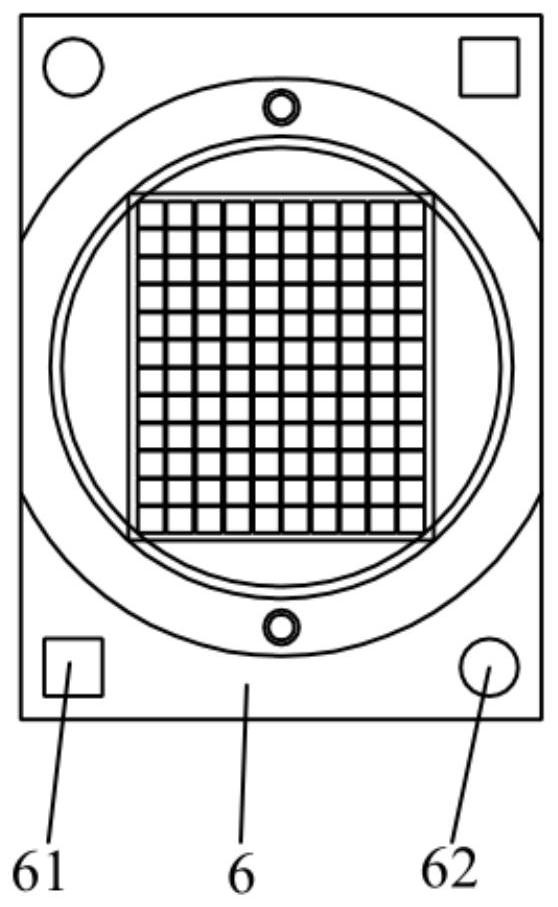

High-heat-conductivity LED (light-emitting diode) high-power packaging bracket

InactiveCN102683569ALow costSimple production processSemiconductor devicesThermodynamicsMetallic materials

The invention discloses a high-heat-conductivity LED (light-emitting diode) high-power packaging bracket, comprising a radiating substrate, an insulating heat conduction layer and a dielectric layer, wherein the radiating substrate is made of high-heat-conductivity metal materials, the surface of the radiating substrate is provided with a circuit, the surface of the radiating substrate is covered by the insulating heat conduction layer and the dielectric layer, and the radiating substrate is made of aluminum copper carbon alloy materials. The technical problem to be solved is to improve the radiating performance of LED packaging. According to the high-heat-conductivity LED high-power packaging bracket, the heat conductivity performance of the packaging bracket is improved, and meanwhile, the material cost of the packaging bracket is controlled; the radiating performance of the packaging bracket is improved, and meanwhile, the production cost of products is effectively reduced, the luminous efficiency and the light color uniformity of LED lamps are ensured, and the controllability of luminous color temperature is increased.

Owner:JIANGSU WINAD LIGHTING TECH

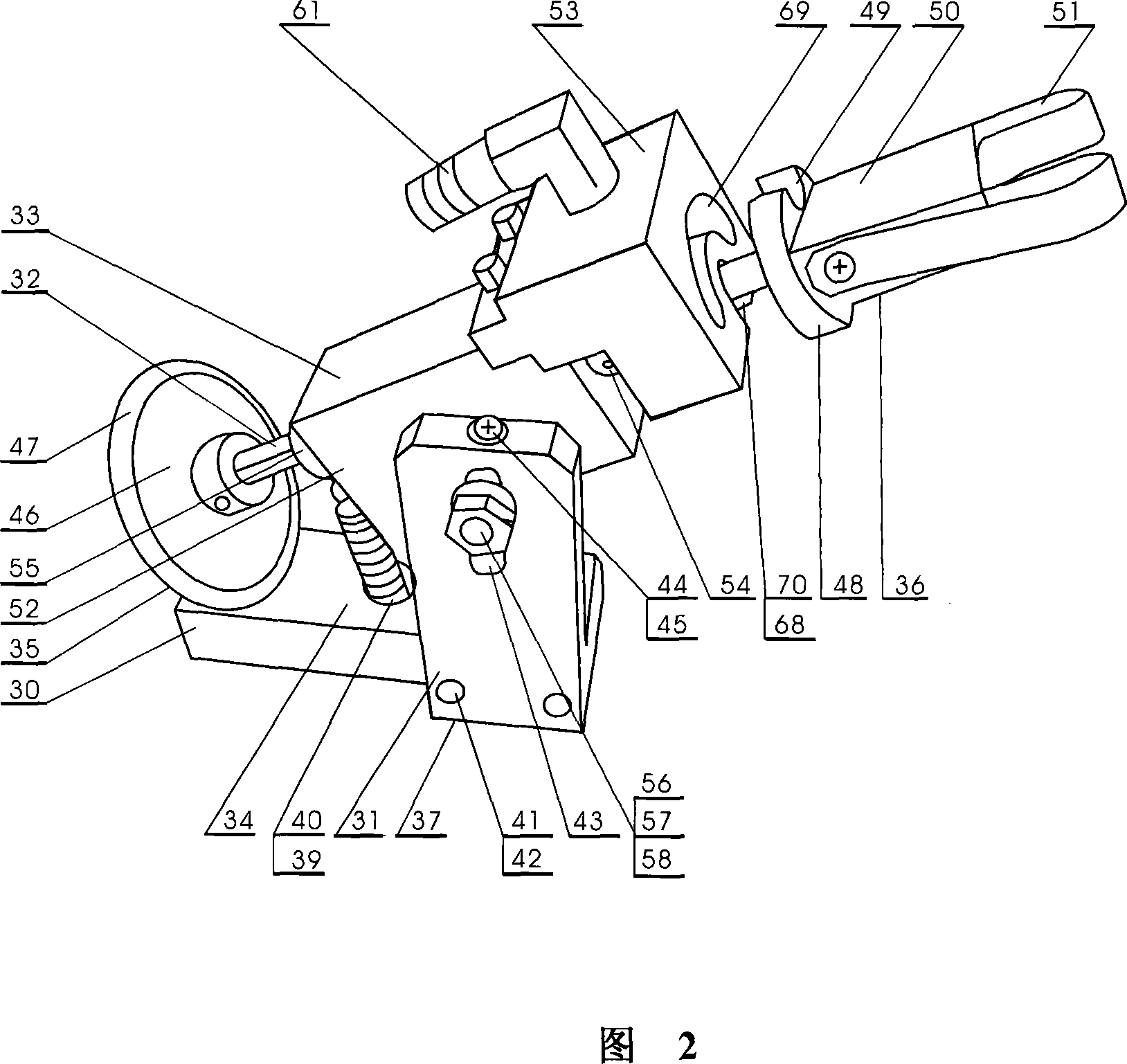

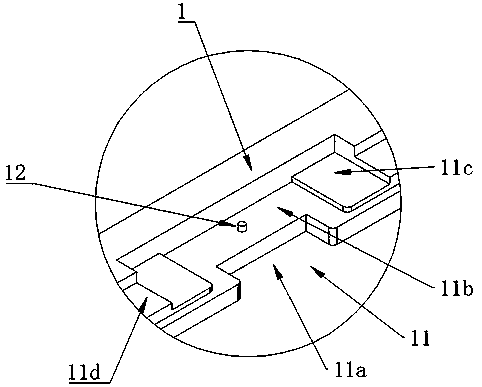

Integrated LED light bar

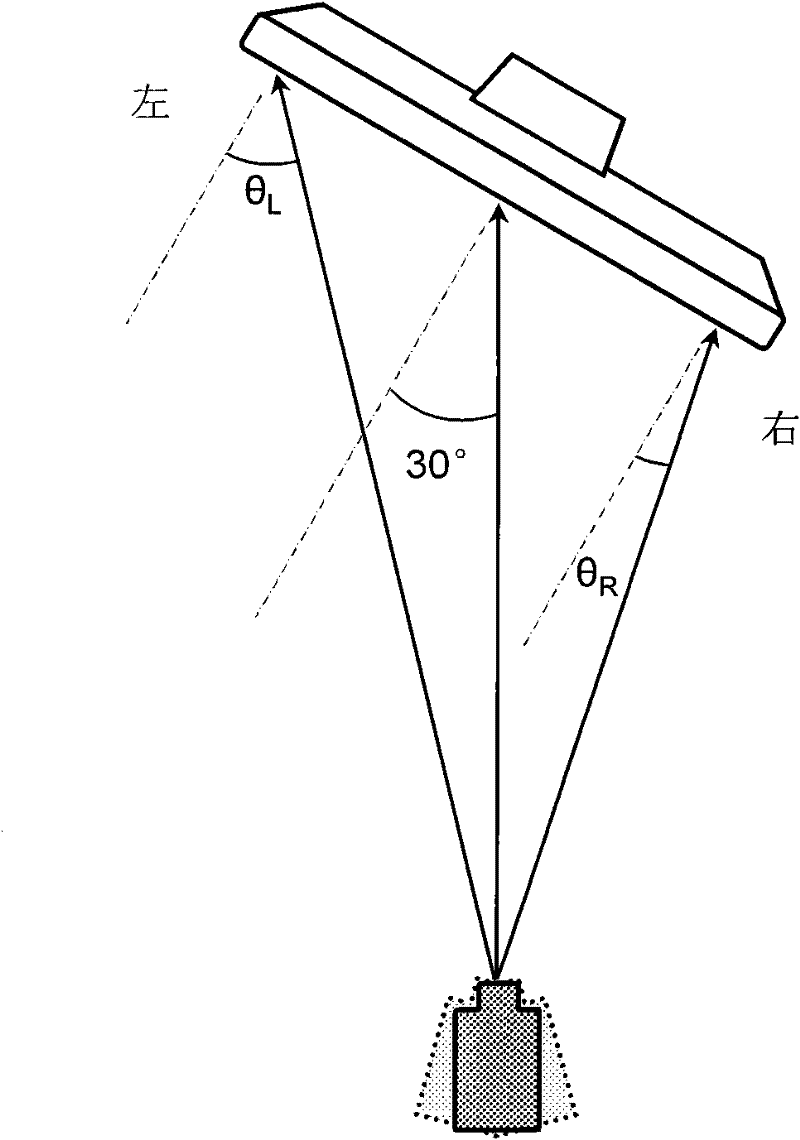

PendingCN111189005AAutomatically and quickly export and dissipate heatEnsure uniformity of light emissionElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringLight emission

The invention is applicable to the technical field of light bars, and provides an integrated LED light bar. The integrated LED light bar comprises a base material mechanism for mounting light-emittingmechanisms, arranging a power line, and radiating the light-emitting mechanisms; and the light-emitting mechanisms which are embedded in the base material mechanism and are used for realizing the superposition of light-emitting angles through the combination of multiple groups of light-emitting mechanisms to form the comprehensive and uniform light emission. In the present invention, when the light emitting mechanisms operate, the reasonability of the light-emitting angle is realized through the structural design, the light source angle is utilized to the maximum extent, and the light emitting uniformity is ensured, so that the light emitting mechanisms can be efficiently used while the light emitting mechanisms are most economical, the heat generated during the operation of the light emitting mechanisms is automatically and quickly guided out and dissipated through the cooperation of the base material mechanism and the light emitting mechanisms, and the service life of the whole integrated LED light bar is prolonged.

Owner:谢明君

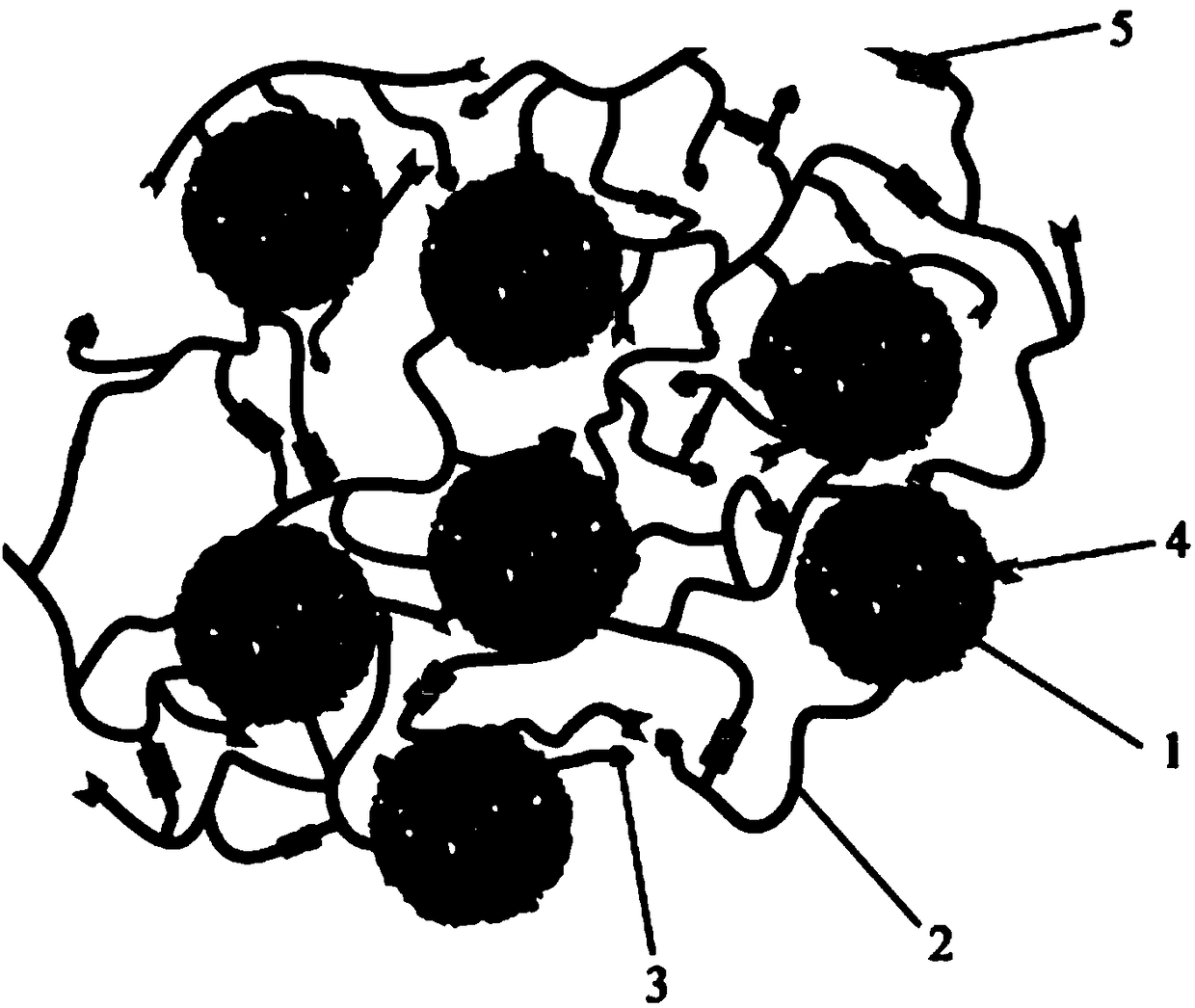

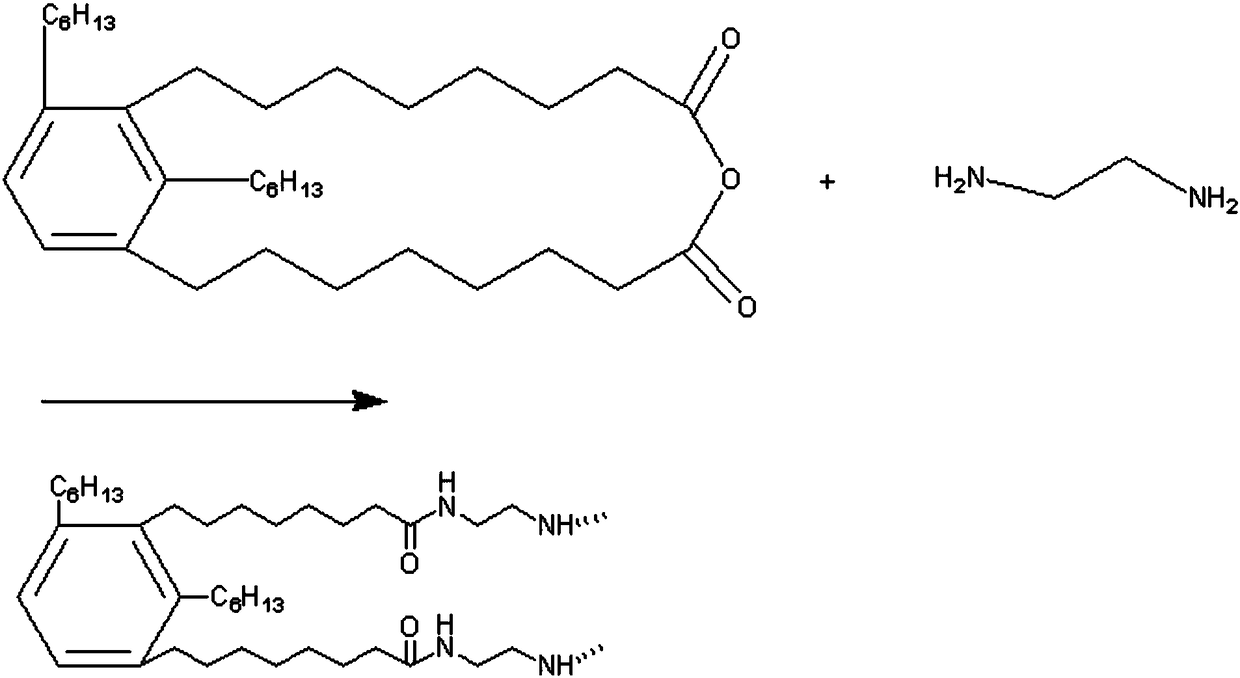

Graphical flexible electrode, preparation method and flexible display device

ActiveCN108232027AEliminate display defectsEnsure the uniformity of light emissionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic moleculesChemistry

The invention relates to the technical field of display, in particular to a graphical flexible electrode, a preparation method and a flexible display device. The flexible electrode comprises a graphical line, wherein the graphical line comprises a metal electrode material and further comprises fiber and micro-metallic particle; long-chain polymer is connected with the surface of the micro-metallicparticle; organic molecule is covered on the surface of the fiber; the organic molecule is connected with the long-chain polymer through a hydrogen bond; the fiber wraps the micro-metallic particle.The graphical flexible electrode has dynamic self-repairing capability, can dynamically repair bending fatigue damage during disconnection, rapidly recover path and eliminate display defect after being applied to the flexible display device, guarantees the uniformity of luminance, and improves the deflection resistance capacity and increases the service life of a product.

Owner:HISENSE VISUAL TECH CO LTD

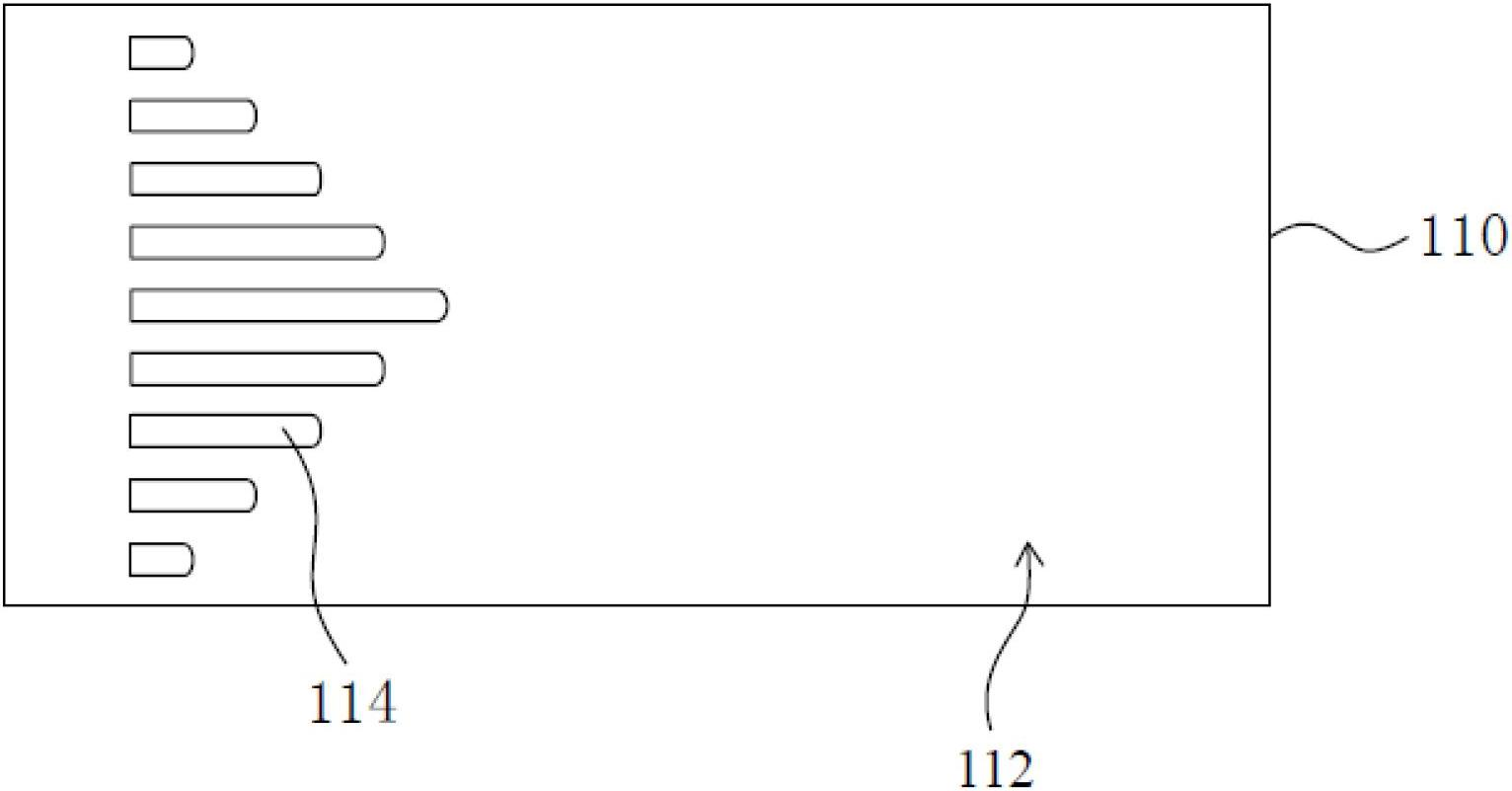

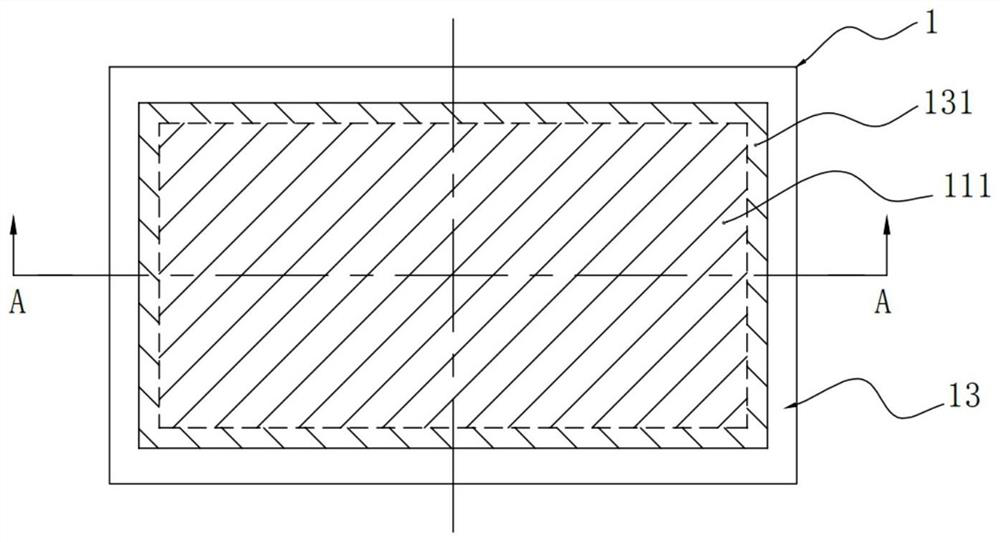

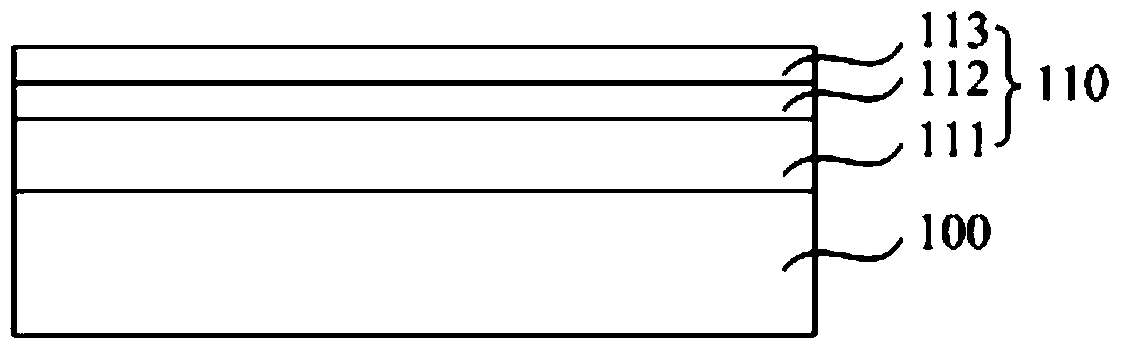

Backlight module and display device

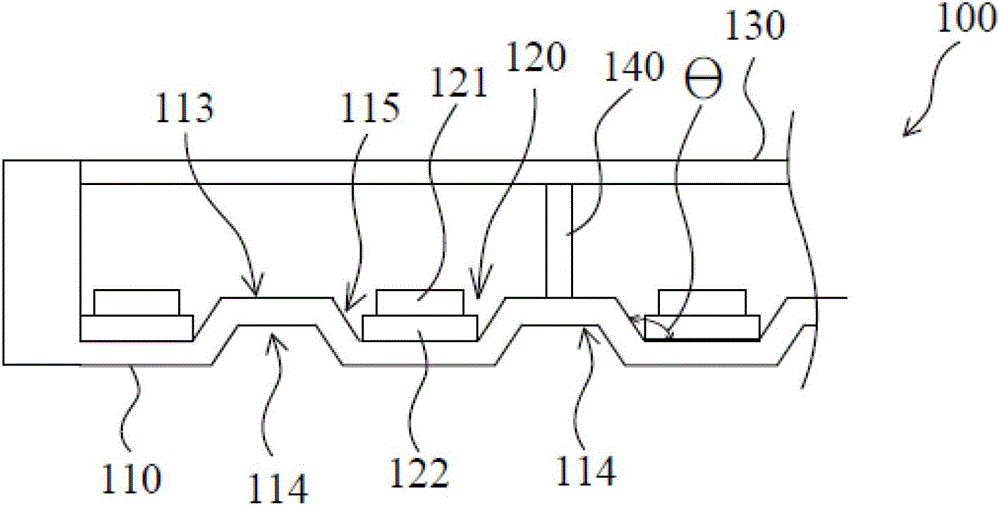

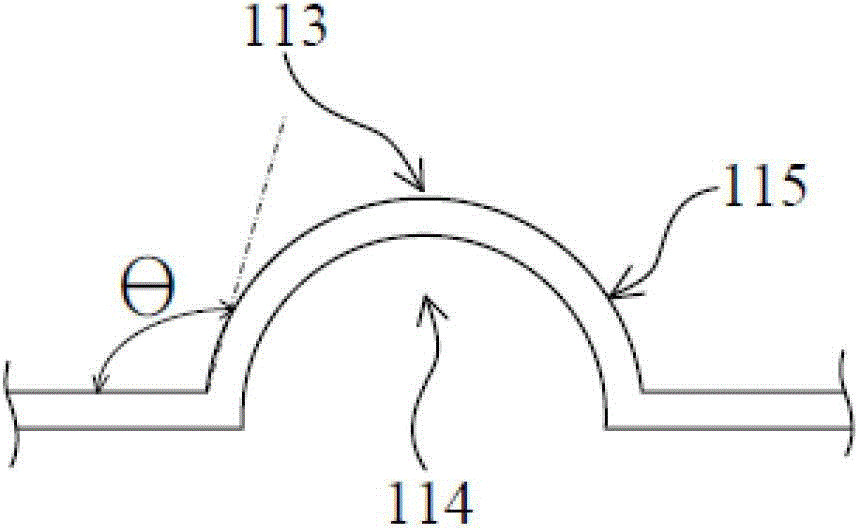

InactiveCN102705755BImprove uniformity of light emissionEnsure uniformity of light emissionLighting heating/cooling arrangementsNon-linear opticsDisplay deviceComputer science

A backlight module (100) comprising a back panel (110) and a light source (120). The back panel (110) comprises multiple back panel protrusions (113) and back panel indentations (114) corresponding thereto. The light source (120) is arranged on the back panel (110) and among the back panel protrusions (113). Also disclosed is a display device. The display device comprises the backlight module (100) and a display panel (101). The backlight module (100) and the display device are capable of utilizing the back panel indentations (114) to improve heat-dissipation effects.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

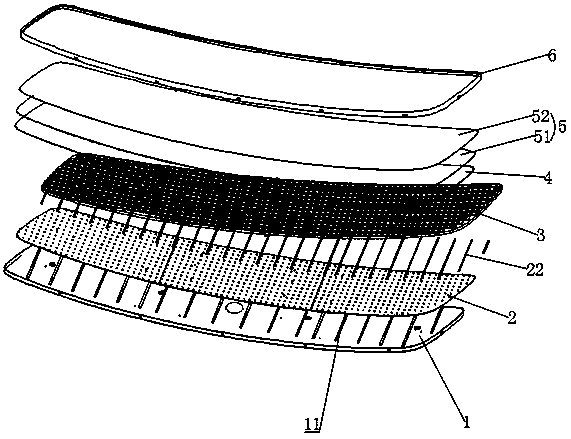

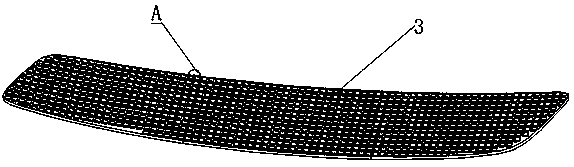

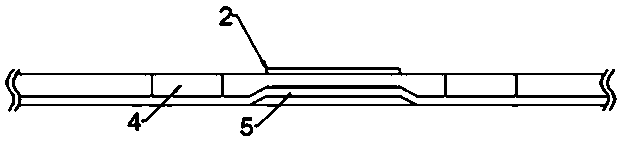

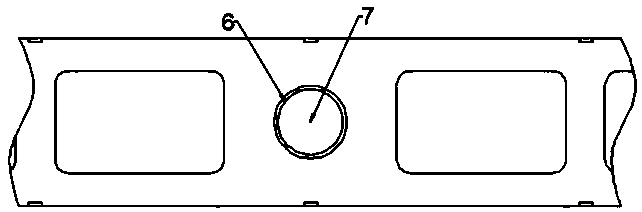

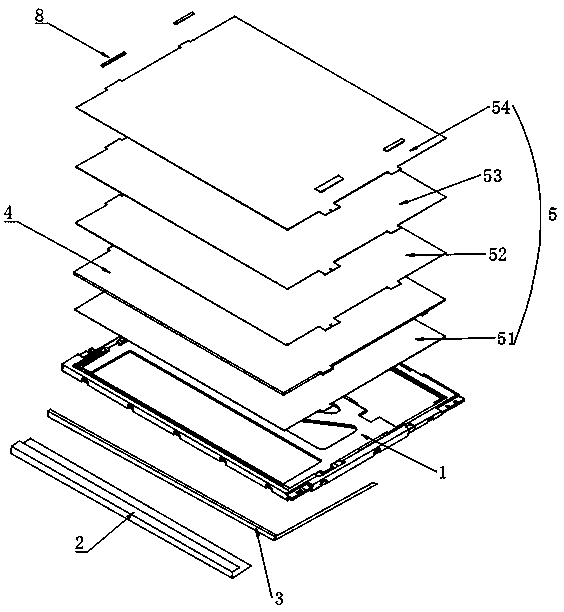

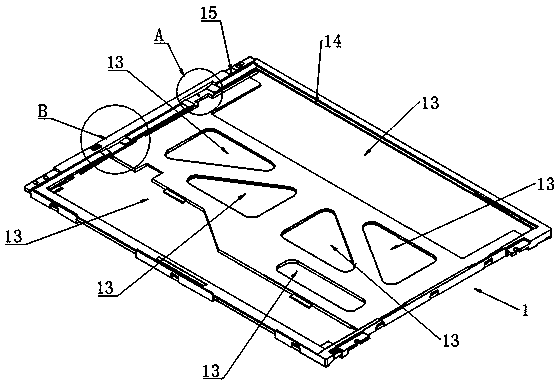

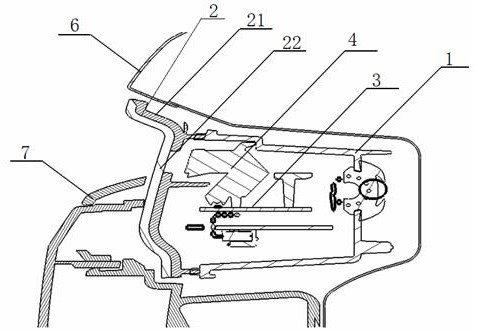

Side-entry backlight module with light and thin structure

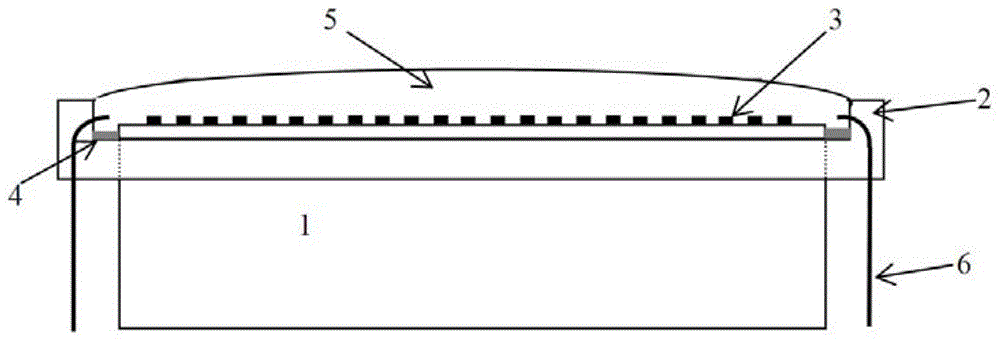

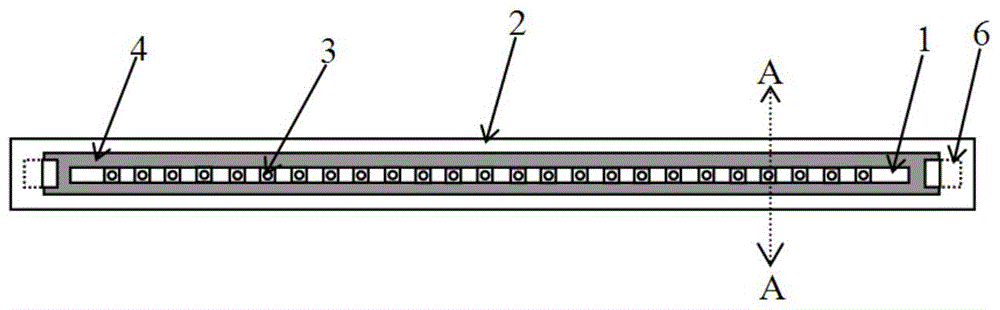

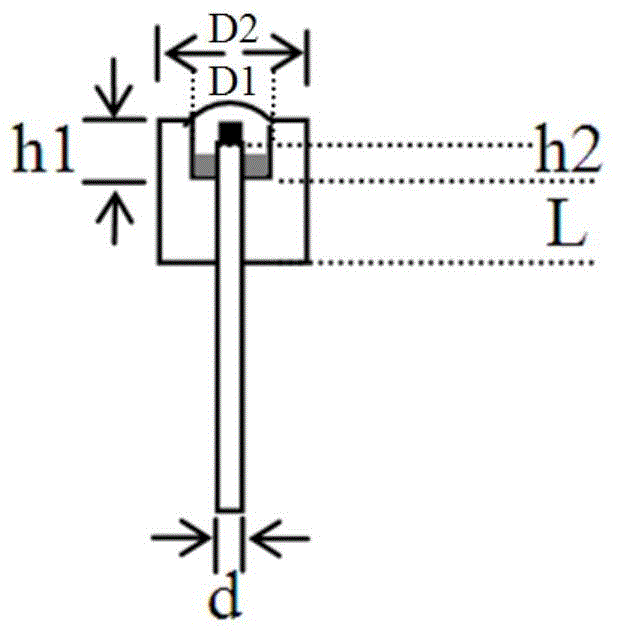

PendingCN110082962ARealize thinner and lighterGuaranteed cooling effectOptical light guidesNon-linear opticsDiaphragm structureLight guide

The invention discloses a side-entry backlight module with a light and thin structure. The backlight module comprises a lower shell (1), a lamp shade (2), a lamp strip (3), a light guide plate (4) anda diaphragm structure (5). The lamp strip (3) is arranged in the lamp shade (2); the lamp shade (2) is fixedly arranged on the lower shell (1); the light guide plate (4) and the diaphragm structure (5) fixedly arranged in the lower shell (1); the lower shell (1) is a plastic component, and the bottom portion of the lower shell (1) is of a hollow structure; the lamp shade (2) is a metal piece; thelight guide plate (4) is of a wedge structure; the lamp strip (3) enters light from the thicker side of the light guide plate (4); and a mesh point structure is arranged on the light guide plate (4),and mesh points on the light guide plate realize gradual transition from thin to dense from the thicker side to the thinner side. The weight of the backlight module is reduced, and size of the backlight module is thinned.

Owner:WAI CHI OPTO TECH (SHENZHEN) LTD

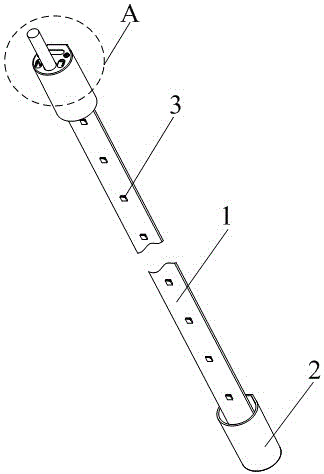

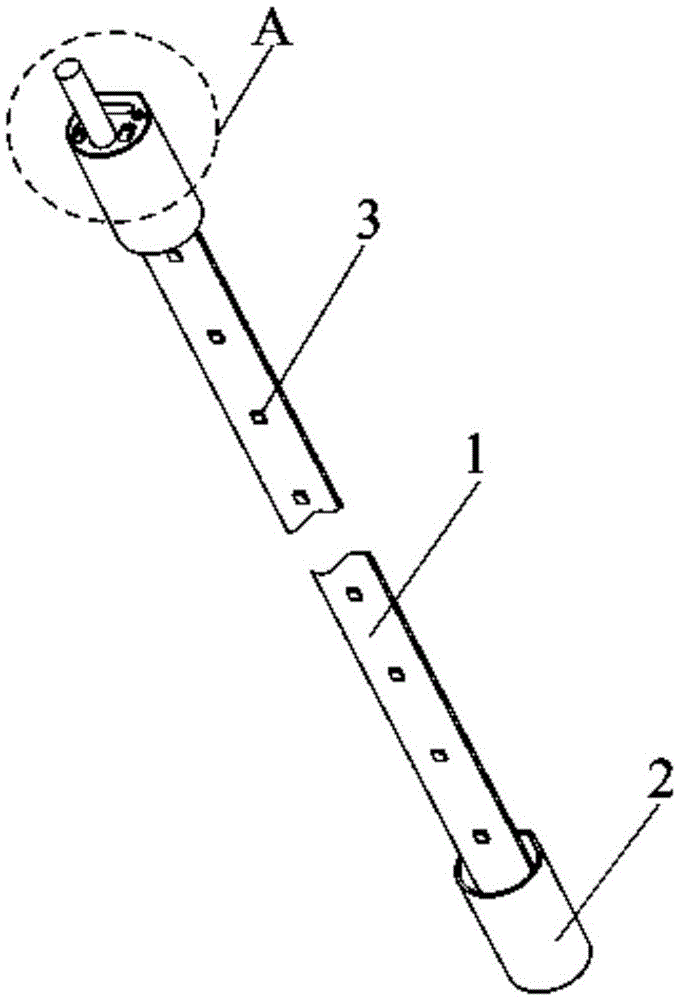

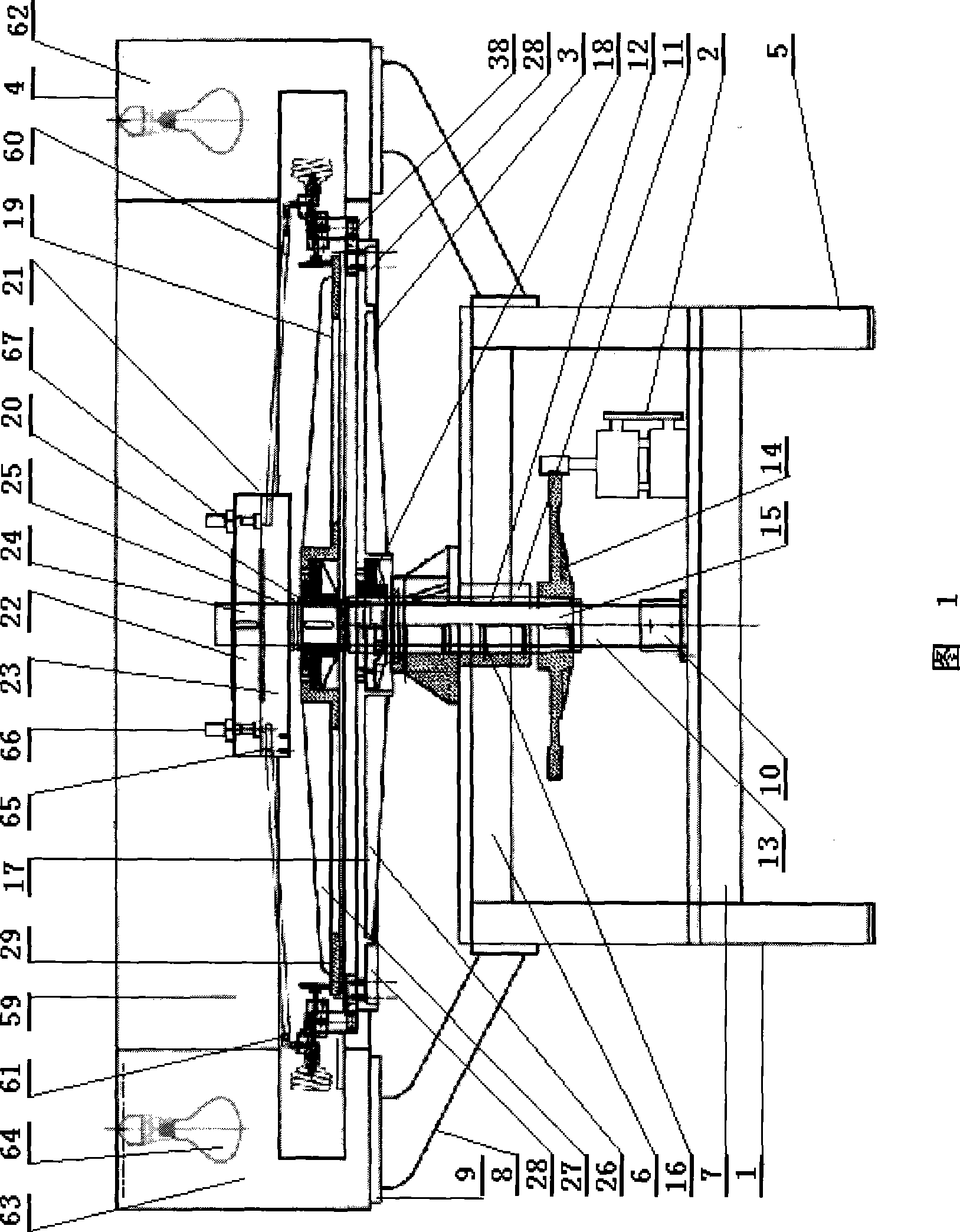

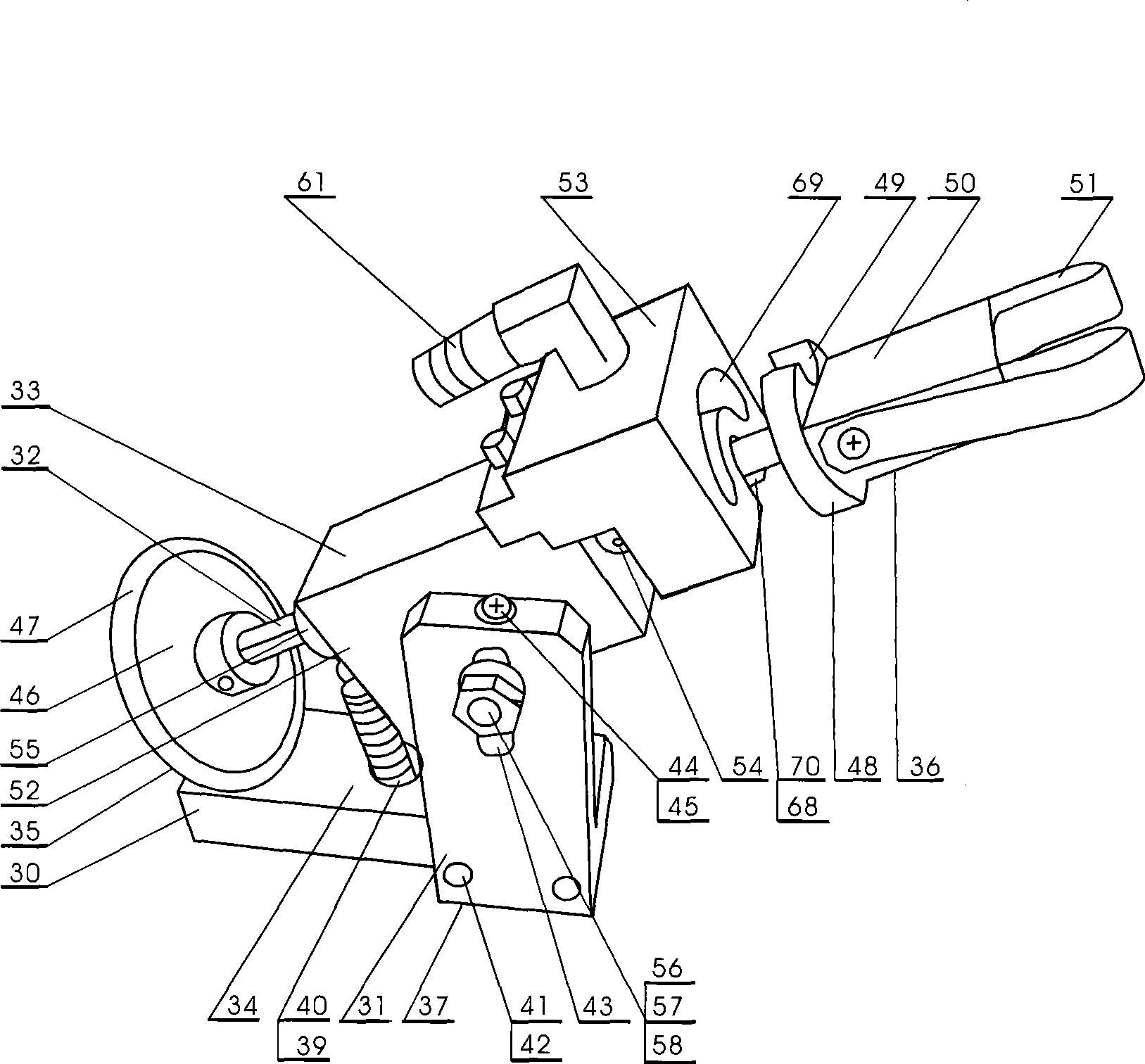

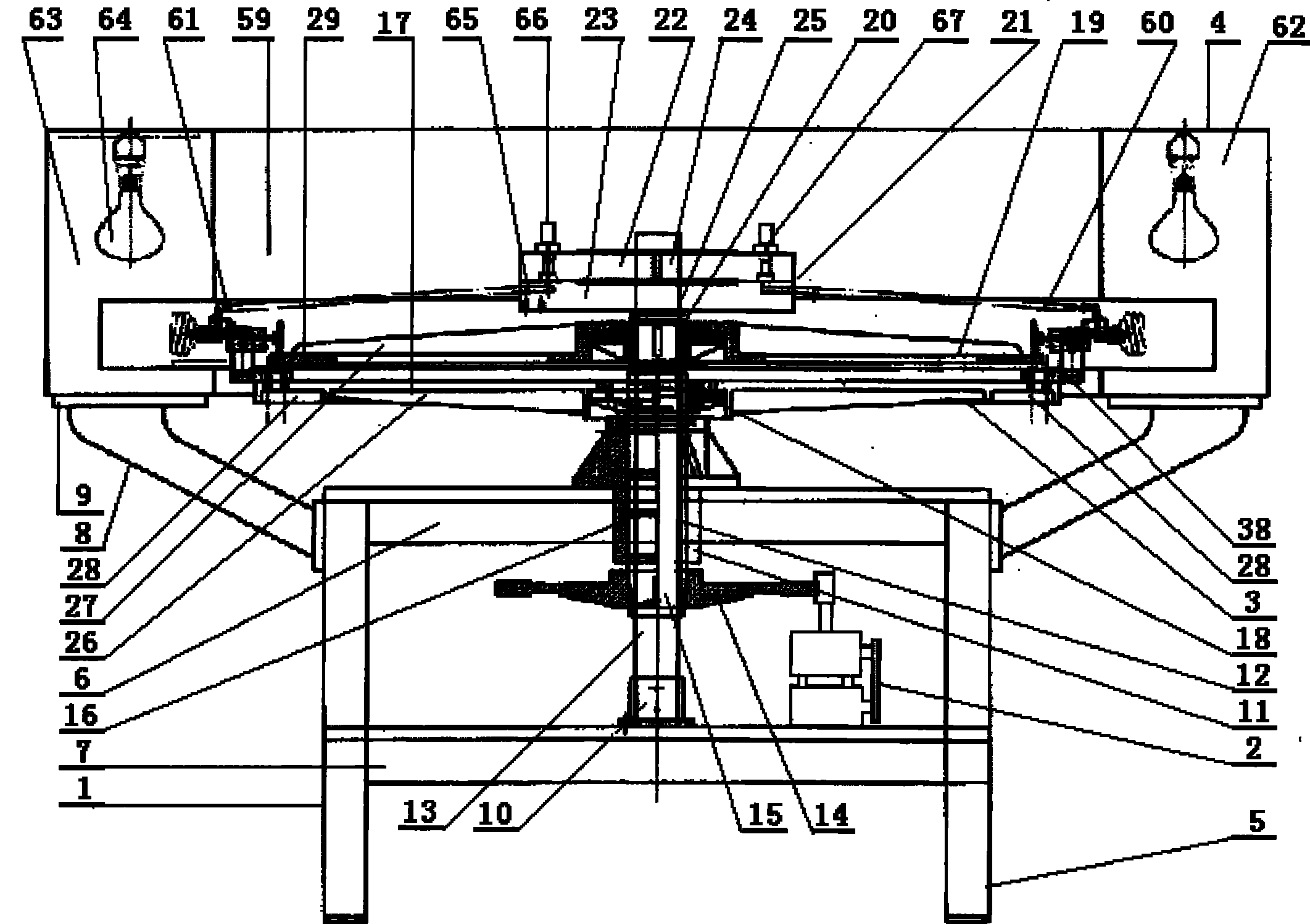

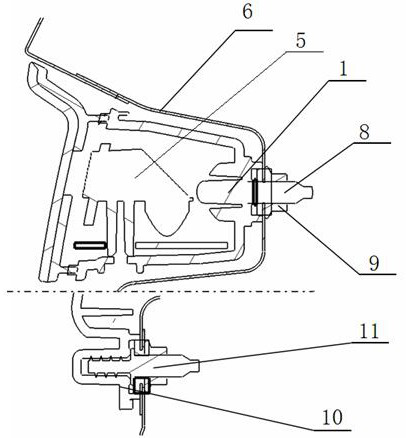

Multifunctional reusable slender through lamp and mounting structure thereof

ActiveCN114383109ARealize functionRealize functional reuseLighting support devicesEnergy saving control techniquesMechanical engineeringMaterials science

The invention discloses a multifunctional reusable slender through lamp and a mounting structure thereof. The slender through lamp comprises a movable rear lamp and fixed rear lamps symmetrically arranged on the left side and the right side of the movable rear lamp. The light-emitting module of the fixed rear lamp is composed of a first light-emitting module and a second light-emitting module, the first light-emitting module is composed of a plurality of brake lamp light sources and a plurality of position lamp light sources, and the second light-emitting module is composed of a plurality of steering lamp light sources and a plurality of position lamp light sources. The movable rear lamp comprises a fourth light-emitting module and third light-emitting modules arranged on the two sides of the fourth light-emitting module, each third light-emitting module is composed of a plurality of functional light sources and a plurality of position light sources, and the fourth light-emitting module is composed of a plurality of position light sources. A first thick-wall condenser is arranged above the first light-emitting module, the second light-emitting module and the third light-emitting module; and a second thick-wall condenser is arranged above the fourth light-emitting module. The slender through lamp can realize the function multiplexing of a position lamp, a steering lamp and a brake lamp, and can form a slender characteristic at the rear part of an automobile.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Flip-chip led chip and manufacturing method thereof

ActiveCN104835891BImprove internal quantum efficiencyImprove light extraction efficiencySemiconductor devicesQuantum efficiencyCrystal structure

The invention provides a flip LED chip and a manufacturing method thereof. The flip LED chip comprises a substrate structure, an epitaxial layer, a contact layer, a first connecting electrode, a second connecting electrode, an insulating reflective layer, a first bonding pad, and a second bonding pad. The substrate structure of the flip LED chip comprises a support substrate, a lattice matching layer and a connecting dielectric layer which are sequentially formed, wherein the connecting dielectric layer is provided with periodically arranged columnar structures, the connecting dielectric layer provided with periodically arranged columnar structures exposes part of the lattice matching layer, and the crystal structure of the lattice matching layer is the same with the crystal structure of an N-type semiconductor layer. The internal quantum efficiency and the external quantum efficiency of the flip LED chip are improved.

Owner:HANGZHOU SILAN AZURE

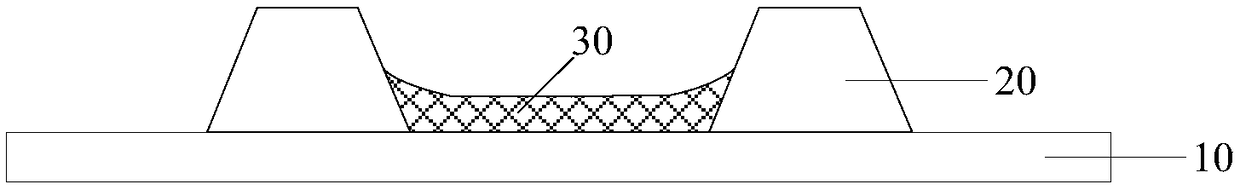

LED integrated light source manufacturing process and LED integrated light source

InactiveCN112071972AGuaranteed uniformityReduce the risk of crackingSolid-state devicesPretreated surfacesPhysicsFluorescence

The invention relates to the technical field of LED integrated light sources, and discloses an LED integrated light source manufacturing process and an LED integrated light source. The manufacturing process of the LED integrated light source comprises the following steps: S10, adhering a plurality of chips into counter bores of a substrate through an adhesive, and baking to form a chip layer; S20,conducting the plurality of chips, and reserving lead layers conducted with the chips; S30, placing an edge shielding frame, mixed fluorescent powder, fluorescent glue and a diluent on the peripheryof the chip layer, spray-covering the chip layer, taking down the edge shielding frame, baking to form a fluorescent layer, and placing the chip layer in the fluorescent layer; and S40, dispensing a packaging adhesive on the fluorescent layer, baking to form a packaging layer, and placing the chip layer in the packaging layer. According to the invention, by adding the diluent, the viscosity of thepowder glue mixed solution is reduced, the content of fluorescent powder is increased, and the brightness of light generated after excitation is ensured to be higher; and the spraying mode enables the excitation efficiency of each position of the chip to be the same, guarantees the light-emitting uniformity, reduces the risk of glue cracking, and prolongs the service life of the LED integrated light source.

Owner:GUANGDONG GMA OPTOELECTRONICS TECH +3

Light-focusing module and backlight module

ActiveCN101706081BHigh central luminance valueEnsure uniformity of light emissionNon-linear opticsRefractorsLiquid-crystal displayLight-emitting diode

Owner:KUSN INFOVISION OPTOELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com