Correcting equipment and correcting method for luminous uniformity

A technology for uniform luminescence and equipment correction, applied in optomechanical equipment, microlithography exposure equipment, optics, etc., can solve the problems of time-consuming cost, inconvenient use, scrapped photosensitive circuit boards, etc., to ensure luminous uniformity, improve The effect of manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to fully understand the purpose, features and effects of the present invention, now through the following specific embodiments, and in conjunction with the accompanying drawings, the present invention is described in detail, as follows:

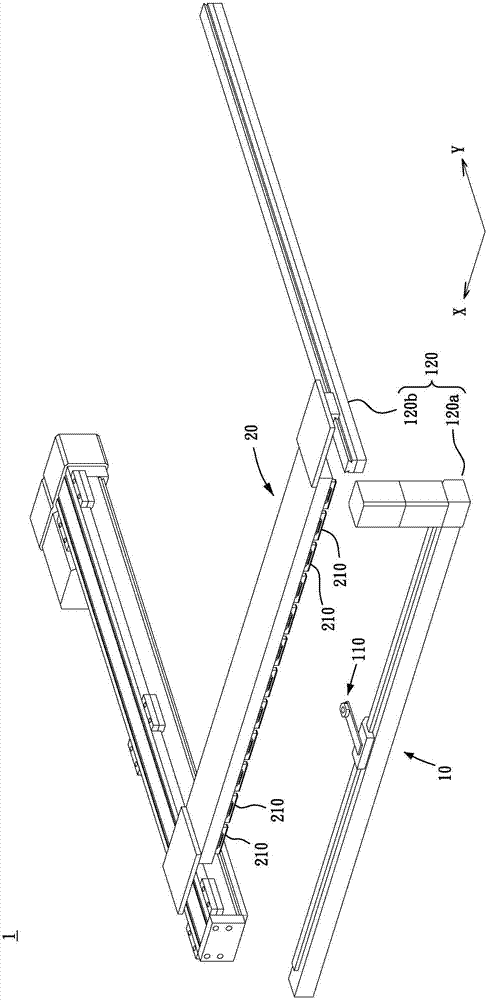

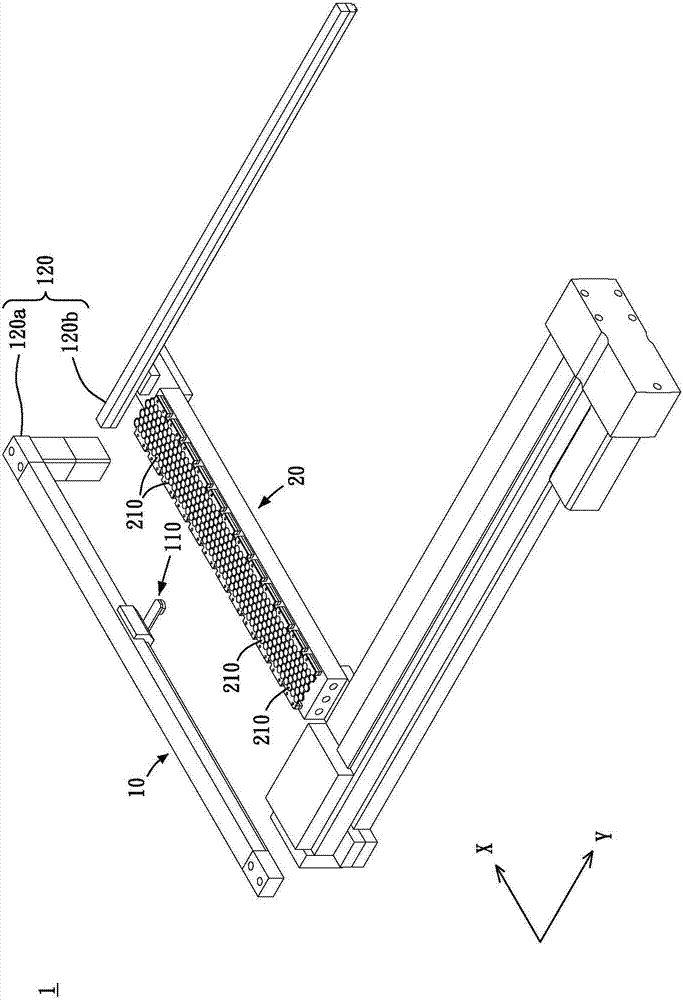

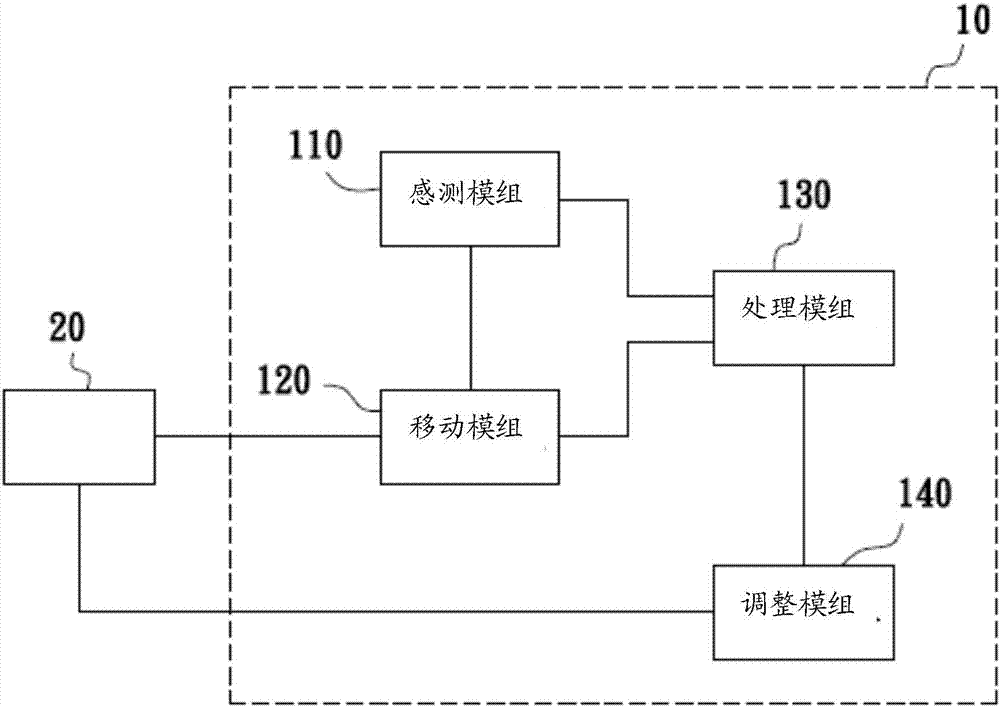

[0035] see Figure 1a and Figure 1b , is a perspective view of an exposure machine provided with the luminescence uniformity correction device of the present invention at different viewing angles. One side of the exposure machine 1 is provided with the luminous uniformity correction device 10 , and the luminous uniformity correction device 10 uses a sensing module 110 to target a plurality of light-emitting units of the light-emitting module 20 of the exposure machine 1 210 for detection, and for the light intensity adjustment operation of the light emitting unit 210 to ensure that the light intensity produced by each light emitting unit 210 is consistent, so that the exposure machine 1 can uniformly perform an exposure on an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com