Manufacturing method of LED display module for splicing

A technology for display modules and manufacturing methods, which is applied in the direction of instruments, identification devices, etc., and can solve the problems affecting the uniformity of the Mini-LED display, the display effect of the Mini-LED display, the stability and service life of the Mini-LED, and the Mini-LED display airtightness and other issues to achieve the effect of ensuring the uniformity of light emission, improving the bonding force, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The invention provides a method for making a LED display module for splicing, which includes the following steps,

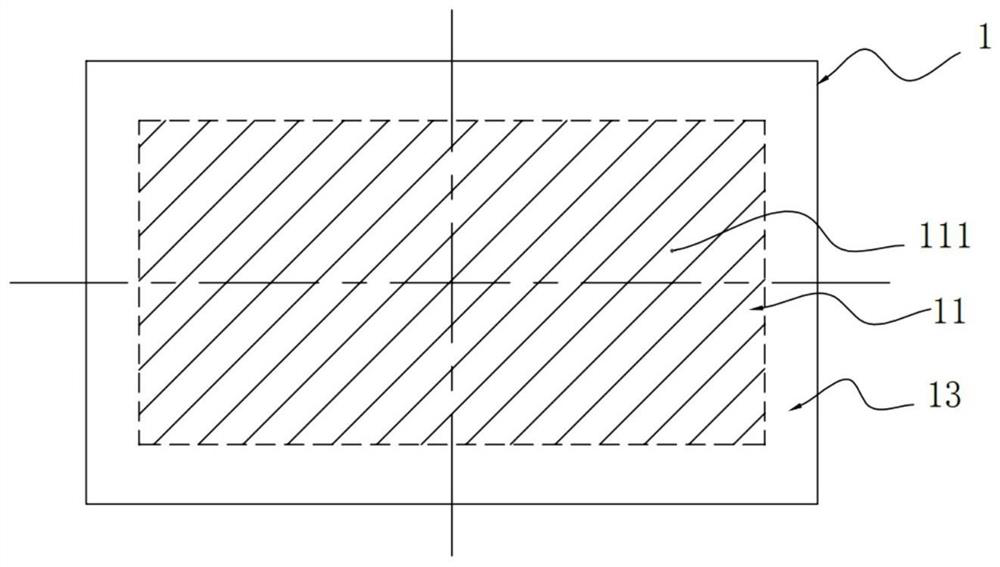

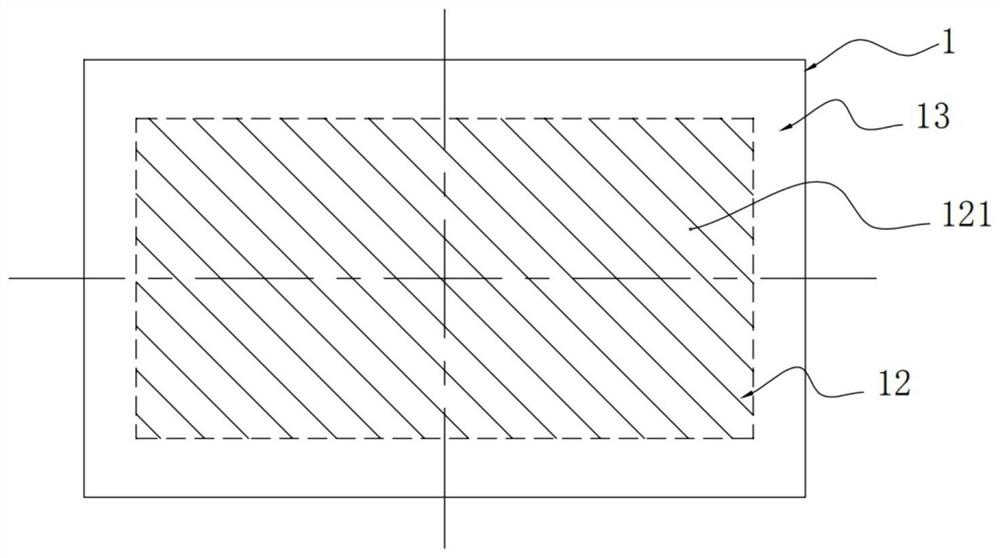

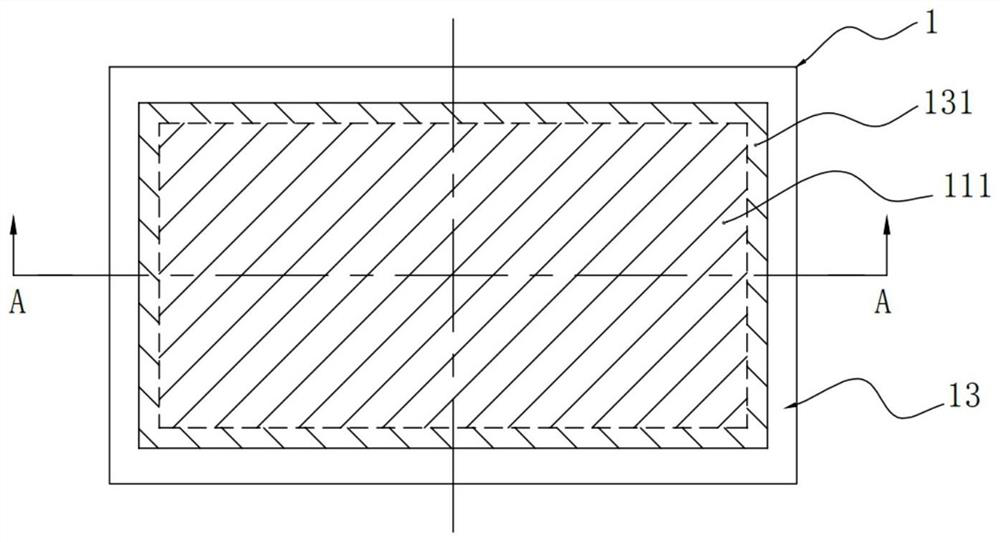

[0057] Step a: provide a substrate 1, the substrate 1 includes a front surface 11 ( figure 1 shown) and the back side 12 opposite to the front side ( figure 2 shown) and the process edge 13 located around the substrate, the display area 111 ( figure 1 The area covered by the oblique line framed by the dotted line in the center). In this embodiment, the substrate 1 is a rectangular substrate, and the front side 11 and the back side 12 are both flat. figure 1 The middle process side surrounds the four sides of the display area 111. In other embodiments, according to actual conditions and processing requirements, the process side 13 can also surround one or two opposite or adjacent sides of the display area 111. The present invention There is no limitation here. In other embodiments, the substrate 1 can also be other polygonal substrates, such as triangl...

Embodiment 2

[0071] Embodiment 2 of the present invention provides another method for manufacturing an LED display module for splicing, including the following steps:

[0072] Step A: provide a substrate, the substrate includes a front surface, a back surface opposite to the front surface, and a process edge located around the substrate, and a display area for installing a light-emitting unit is defined on the front surface; in this embodiment Step A is the same as Step a in Embodiment 1. You can refer to the description of Step a in Embodiment 1 above, and this embodiment will not repeat it here.

[0073] Step B: opening a groove around the process edge adjacent to the display area, wherein the groove does not penetrate the substrate, and the depth of the groove is greater than the thickness of the substrate that does not penetrate; Step B in this embodiment is the same as step b in Embodiment 1, and reference may be made to the description of Step b in Embodiment 1 above, and details wil...

Embodiment 3

[0082] refer to Figure 21 , in this embodiment, different from the second embodiment, in step B of the second embodiment, the groove is opened around the display area 111 (refer to image 3 shown), that is, the groove 131 is opened on the front surface 11 of the substrate. In this embodiment, the groove 134 is opened on the back surface 12 of the substrate. refer to Figure 22 After molding the first transparent encapsulation layer, part of the process edge is cut off from the groove 134 , and then the second transparent encapsulation layer 153 is molded. In this embodiment, the water vapor path is extended to be flush with the back surface 12 of the substrate 1 , which is longer than the water vapor path of the LED display module provided in Embodiment 1, and the second light-transmitting encapsulant 152 is more closely bonded to the substrate 1 .

[0083] Since there is no light-emitting unit 141 installed on the back 12 of the substrate 1, and if the driving electronic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com