Direct type backlight module comprising perforated layer

A backlight module, direct type technology, applied in the field of backlight, to ensure uniformity and good display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

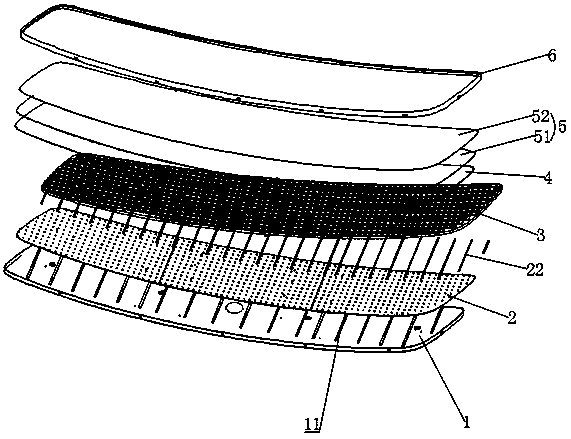

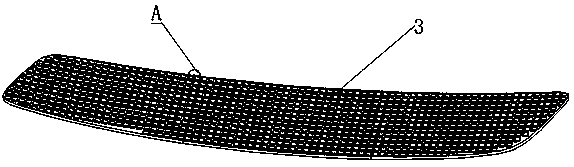

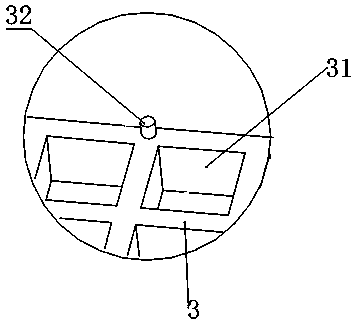

[0034] refer to Figure 1~16 The invention discloses a direct-type backlight module including a perforated layer, which is used to improve the uniformity of light emission of the backlight module, and can also be used as a backlight module of a display with regional light control. What is shown in the figure of this embodiment is a special-shaped backlight module similar to a parallelogram structure, but in practice, it can also be a normal quadrilateral module or a backlight module with other special-shaped structures. The backlight module includes a lower shell 1 , a direct-type light source 2 , a reflector 3 , a perforated layer 4 , a diffuser assembly 5 and an upper frame 6 .

[0035] refer to Figure 15 , the lower shell 1 is a structure with a flat bottom and sides around it. Generally, a metal shell is used to enhance the heat dissipation performance, and it can be formed by stamping. refer to Figure 14 , the direct-type light source 2 can use a whole piece of light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com