Field emission display device and method of manufacturing same

A display device and electric field emission technology, applied in the direction of electrode device and related components, electrode system manufacturing, non-luminescent electrode manufacturing, etc., can solve the problem of not being able to densely form openings, difficulty in forming openings, deviation of the total amount of electron beams, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

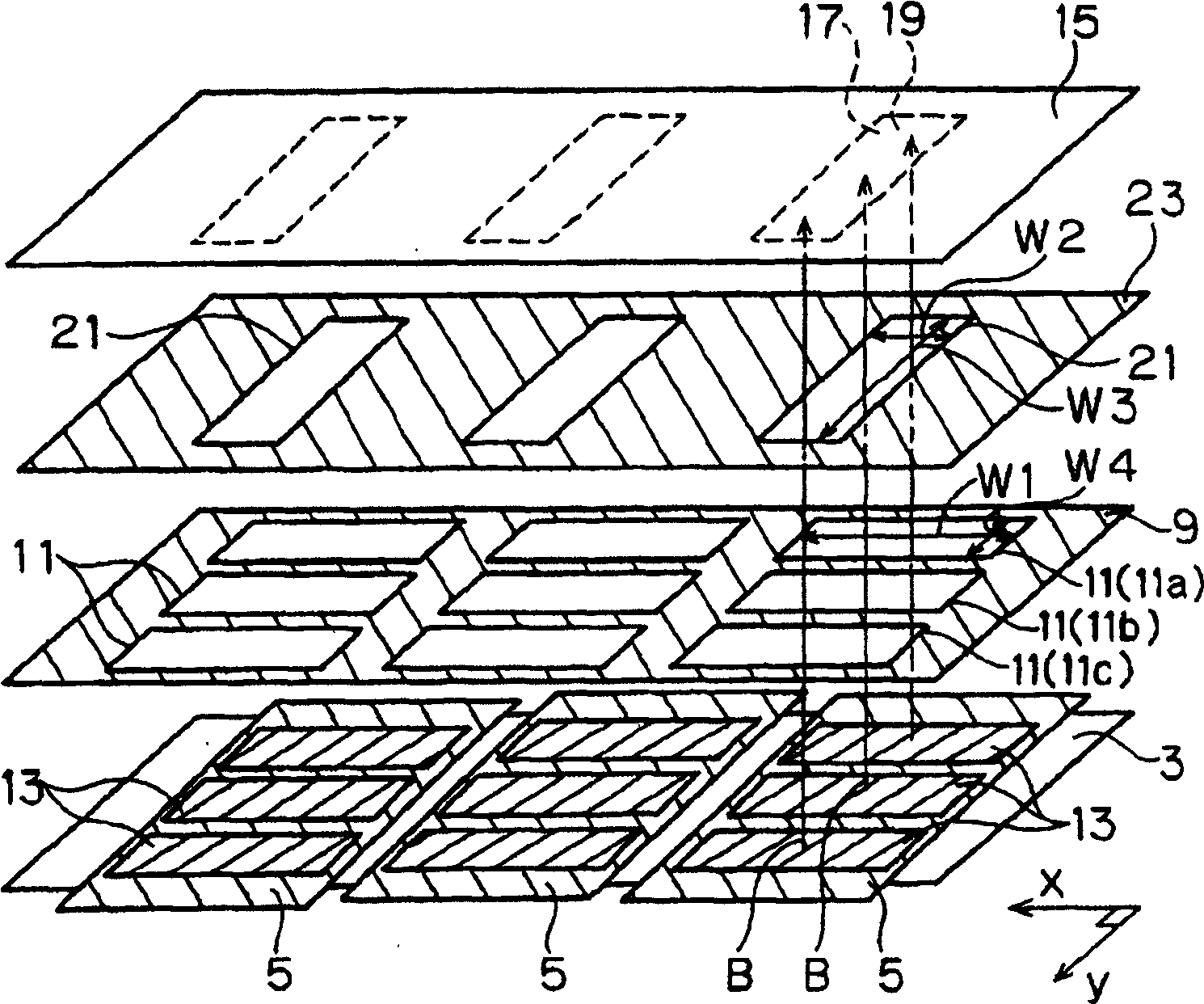

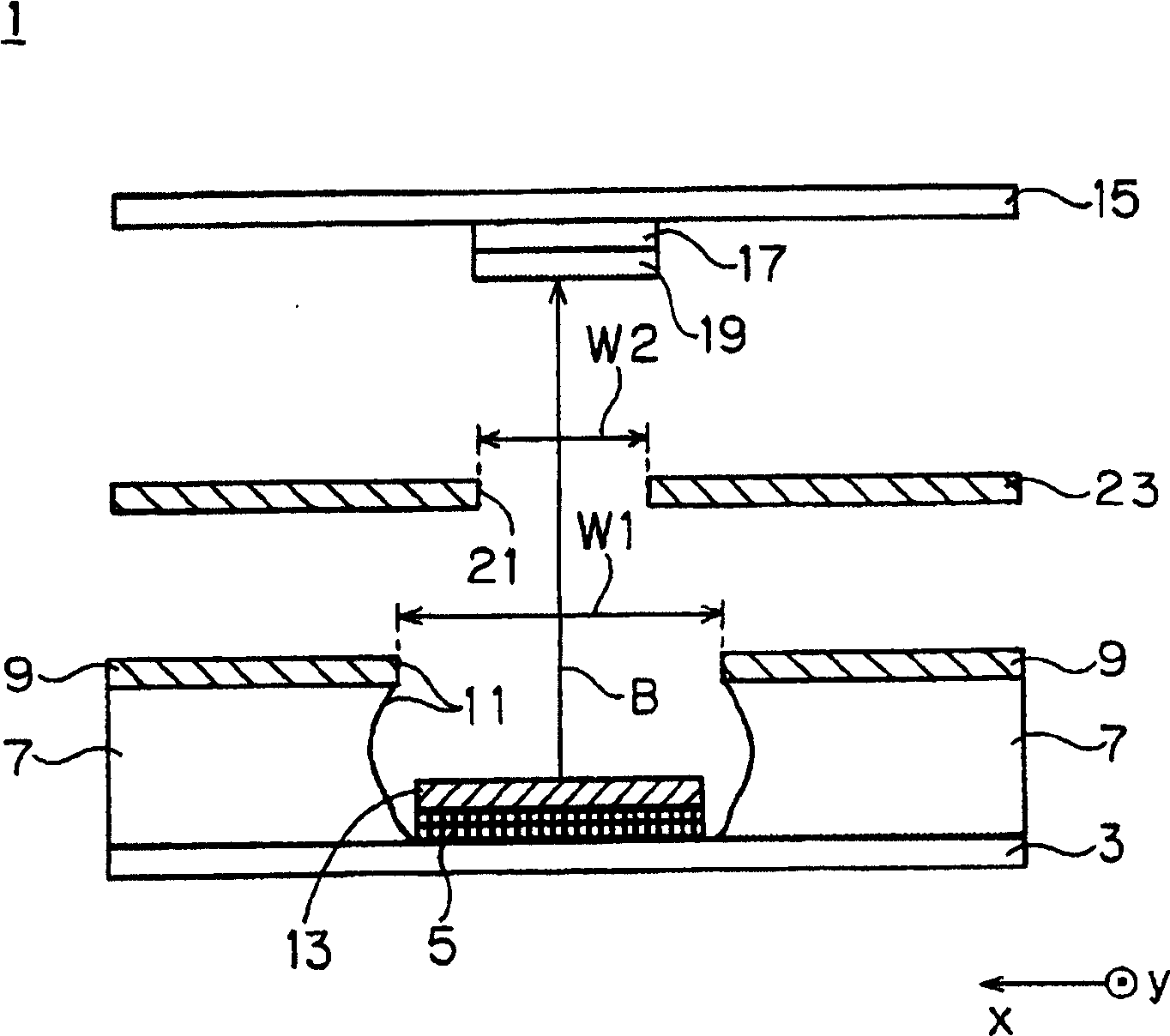

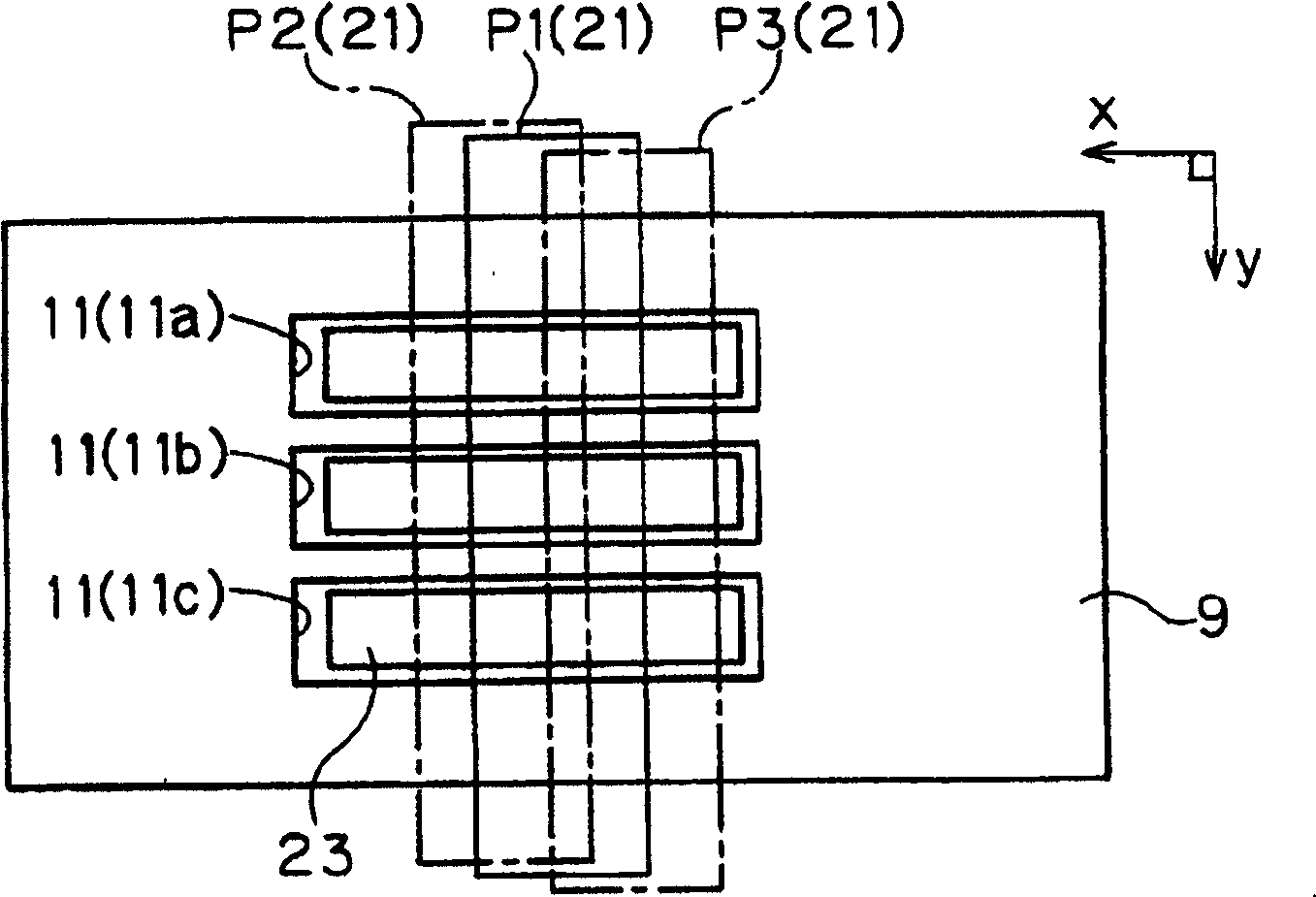

[0022] like figure 1 and figure 2 As shown, the field emission display device 1 of this embodiment includes: a cathode substrate 3; a cathode 5 formed on the cathode substrate 3; The same flat type electron emission material layer 13; the control electrode 9 which is arranged on the front side of the electron emission material layer 13 and has an opening 11 formed on the part opposite to the electron emission material layer 13; A transparent anode substrate 15 arranged in the front; a transparent anode 17 formed on the back side of the anode substrate 15; a phosphor 19 formed on the anode 17; The shielding electrode 23 of the electron passing hole 21 passes the electron beam B flowing from the electron emission material layer 13 into the phosphor 19 through the opening 11 of the control electrode 9 .

[0023] Here, an insulator layer 7 is formed on the cathode substrate 3 and the cathode 5 , and a control electrode 9 is formed on the insulator layer 7 . Opening 11 is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com