Graphical flexible electrode, preparation method and flexible display device

A flexible electrode and patterning technology, which is applied in the direction of circuits, electrical components, and electrical solid devices, can solve problems affecting product quality and life, electrode damage, and depletion of microsphere wrappings, so as to improve flexural resistance and Product life, ensuring the uniformity of luminescence, and improving product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] According to another aspect of the present invention, a method for preparing a patterned flexible electrode is provided, comprising the following steps:

[0060] (1) connecting long-chain polymers on the surface of micro-metal particles;

[0061] (2) The surface of the fiber is coated with organic molecules;

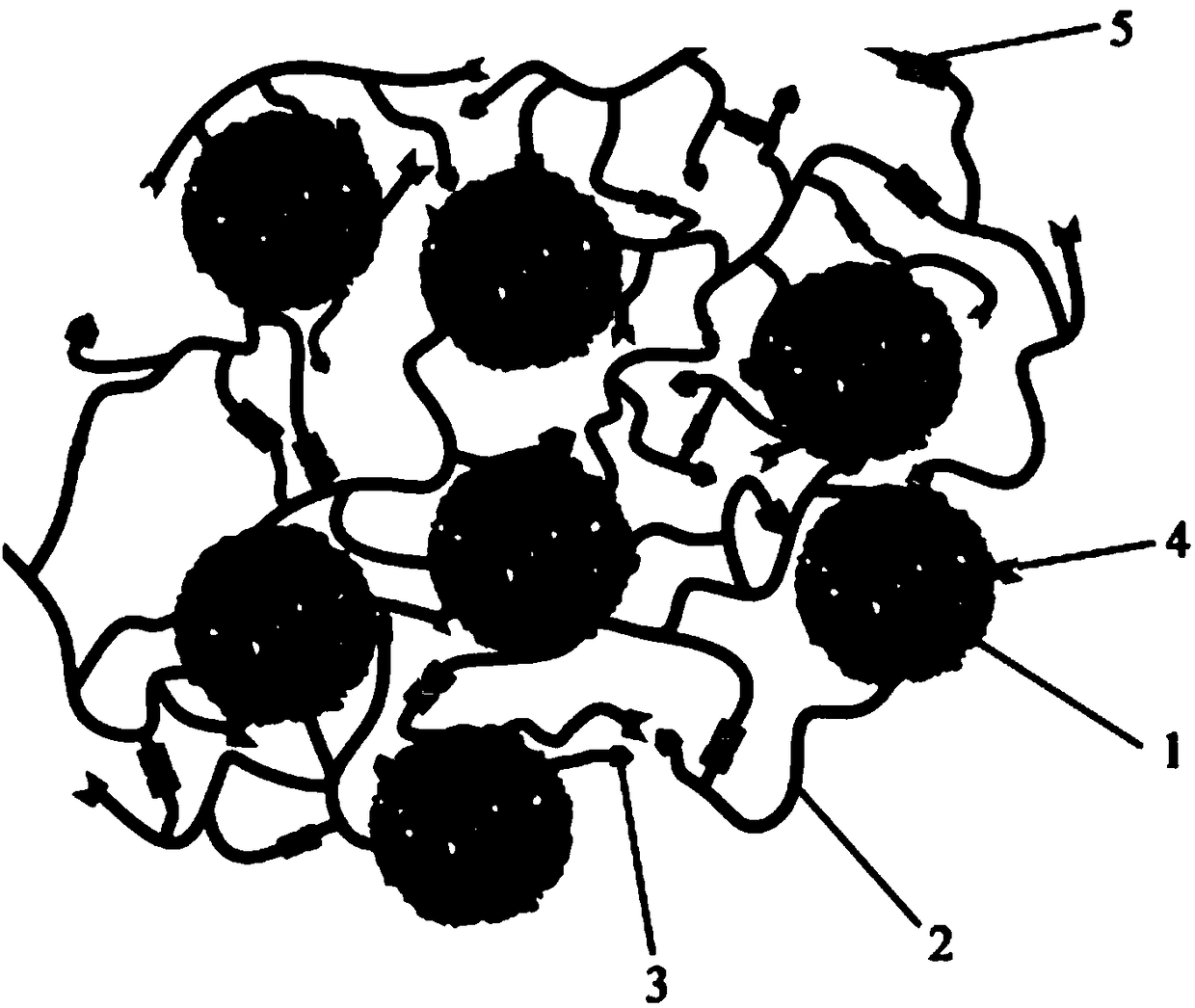

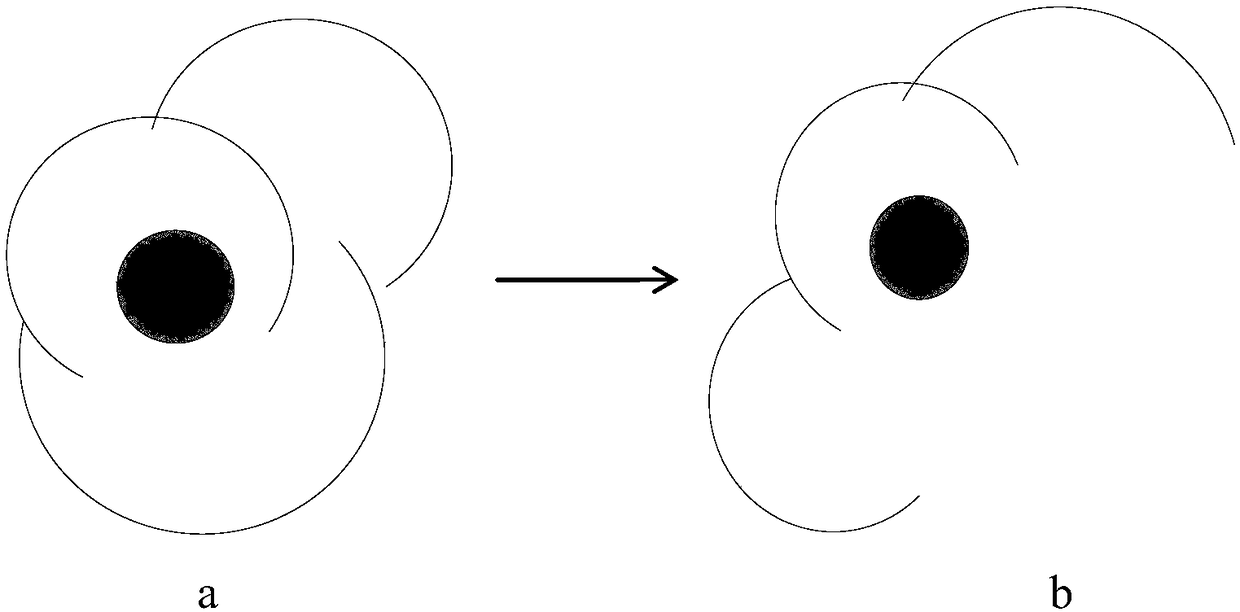

[0062] (3) Mixing the fine metal particles treated in step (1), the fibers treated in step (2) and the metal electrode material slurry to obtain a flexible electrode material, wherein the organic molecule and the long-chain polymer pass hydrogen bond connection, the fiber wraps the micro metal particles;

[0063] (4) Patterning the flexible electrode slurry to obtain the patterned flexible electrode.

[0064] According to one embodiment of the present invention, in step (2), the fibers and the organic molecules are mixed in a mass ratio of (4-5):1.

[0065] According to one embodiment of the present invention, the organic molecule is 4-vinylpyridine; the long-c...

preparation Embodiment 1

[0067] In this embodiment, the preparation method of the flexible electrode comprises the following steps:

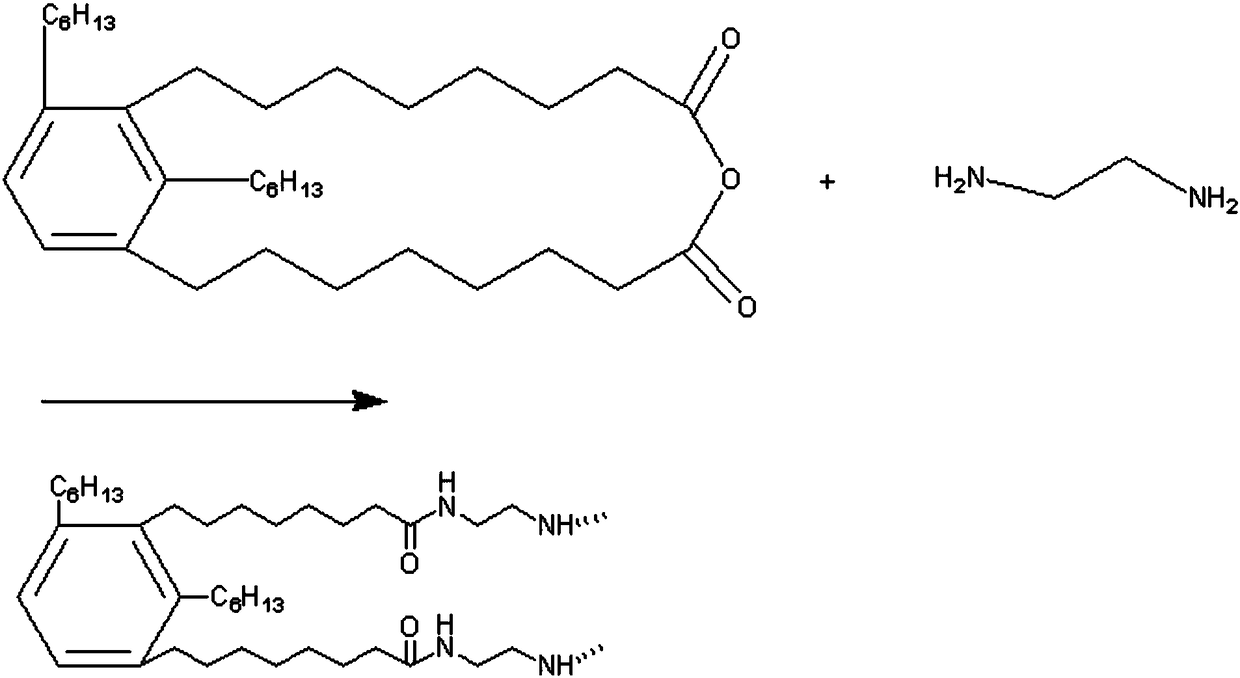

[0068] a. Dissolve 1mol m-phenylalkyl anhydride in an organic solvent (such as acetone, methanol, ethanol, etc.), add 2mol alkyl hydrazine solution, mix well, stir in an ice-water bath, and quickly add powdered micro-metal particles (such as micro-silver, micro-nickel, etc.); after 20 minutes of reaction, transfer the above mixed solution to a 60°C water bath to continue the reaction until the end, and obtain a viscous liquid, which is a micro-metal particle with a long-chain polymer attached to the surface; The reaction formula of the reaction of an acid anhydride with an alkyl hydrazine to generate a long-chain polymer is as follows image 3 shown. One of the amino groups of the alkyl hydrazine reacts with the m-phenylene anhydride to form an amide bond, and the other amino group can continue to react with the anhydride to form a polymer.

[0069] b. Add 4-picoline,...

preparation Embodiment 2

[0076] The flexible electrode of this embodiment is prepared according to a method similar to that of Preparation Example 2, wherein the organic molecule is selected from isocyanate; the long-chain polymer is a long chain polymers; long chain polymers are hydrogen bonded to the isocyanate.

[0077] According to yet another aspect of the present invention, a flexible display device is provided, comprising the above-mentioned patterned flexible electrode and the patterned flexible electrode obtained by the above-mentioned preparation method.

[0078] According to an embodiment of the present invention, the patterned flexible electrode is used as a cathode electrode layer of a flexible display.

[0079] The flexible display device according to the present invention also includes an electron transport layer, a light emitting layer, a hole transport layer, and a flexible transparent anode. According to the flexible display device of the present invention such as Figure 5 shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com