Vertical back light module

A backlight module, direct type technology, applied in the direction of optics, optical components, nonlinear optics, etc., can solve the problems of display defects, increased distance, uneven brightness of liquid crystal panel display, etc., to eliminate display defects and avoid excessive brightness , the effect of increasing the spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

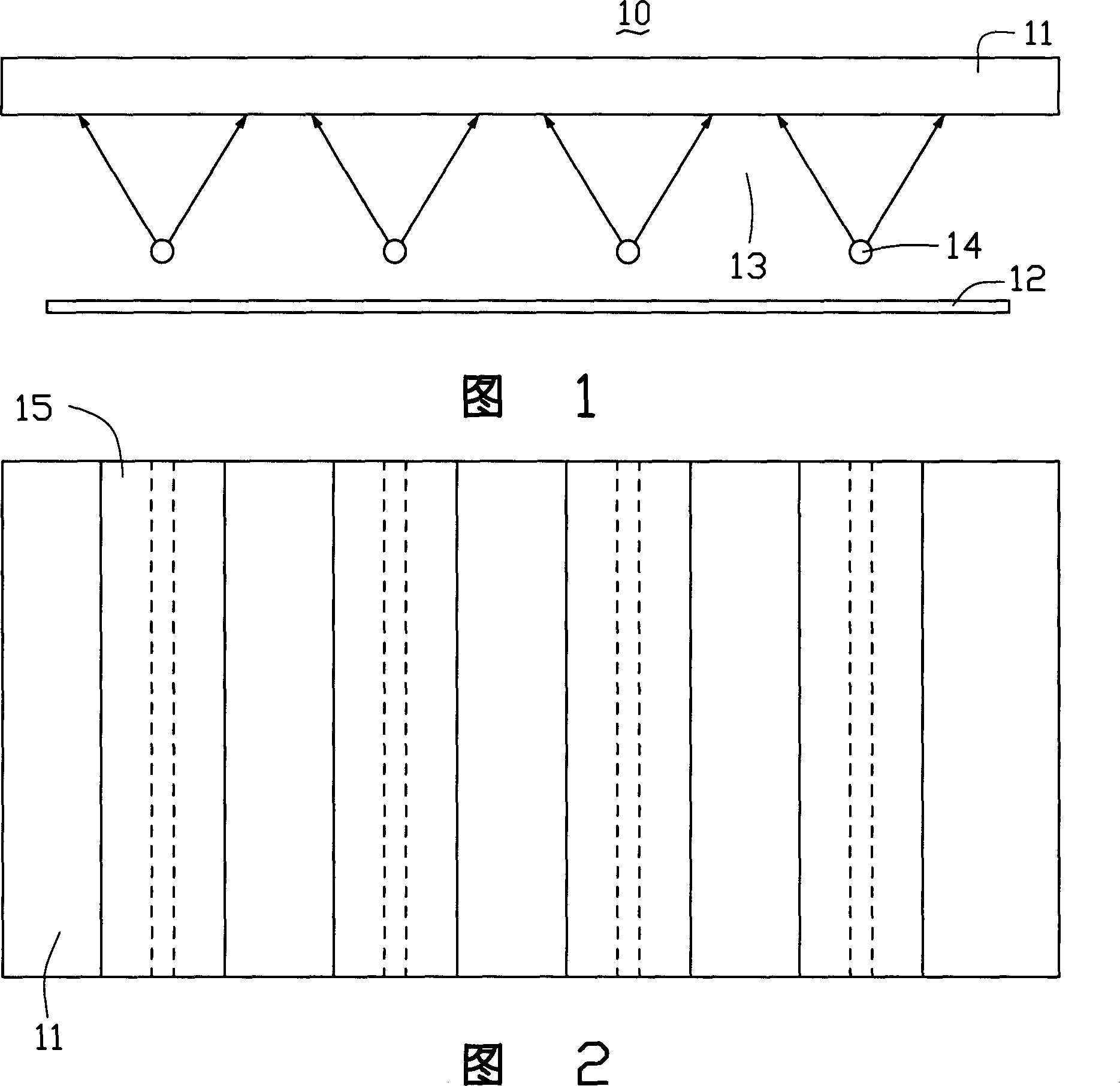

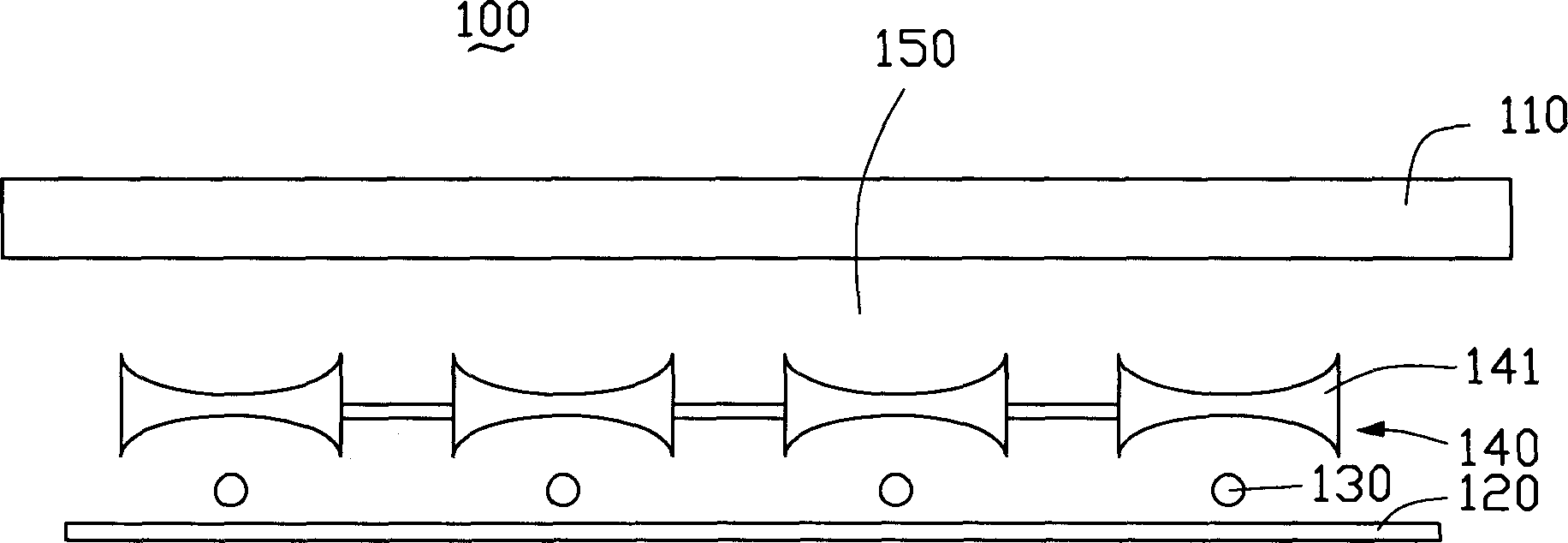

[0025] see image 3 , is a schematic diagram of the structure of the direct type backlight module according to the first embodiment of the present invention. The direct type backlight module 100 includes a diffuser plate 110 , a reflector plate 120 , a plurality of lamp tubes 130 and a diffuser 140 . The diffuser 110 is disposed on the reflector 120 and forms a chamber 150 with the reflector 120 . The lamp 130 is located in the chamber 150 and is a cold cathode fluorescent lamp or a light emitting diode.

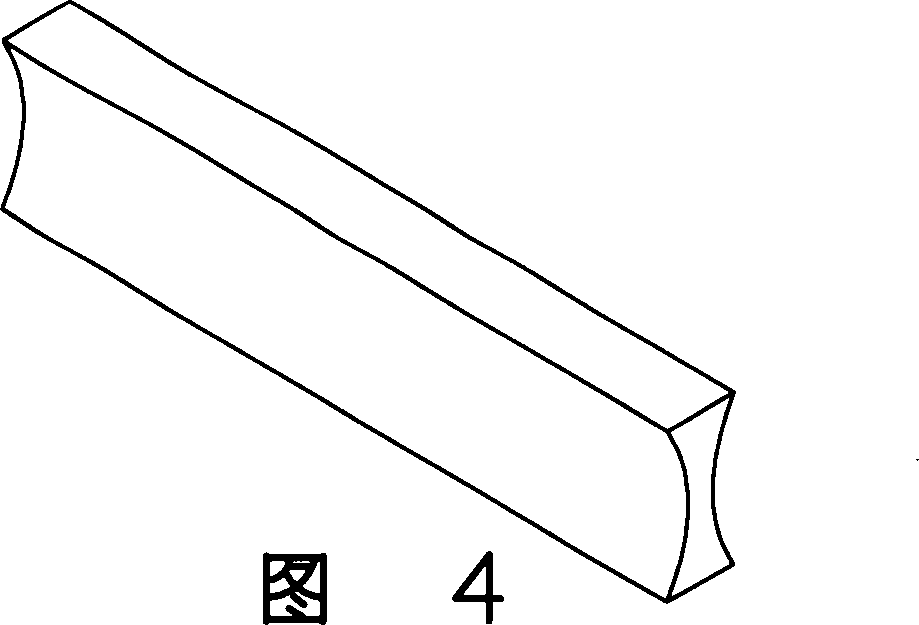

[0026] The astigmatism device 140 is located between the lamp tube 130 and the diffuser plate 110, which is a lens module, including a plurality of concave lenses 141, and each concave lens 141 corresponds to a lamp tube 130, because the concave lens 141 has the effect of astigmatism, each The light emitted by a lamp tube 130 is refracted by the concave lens 141 and diffused to increase, so that the area of the light incident on the diffuser plate 110 can be increased. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com