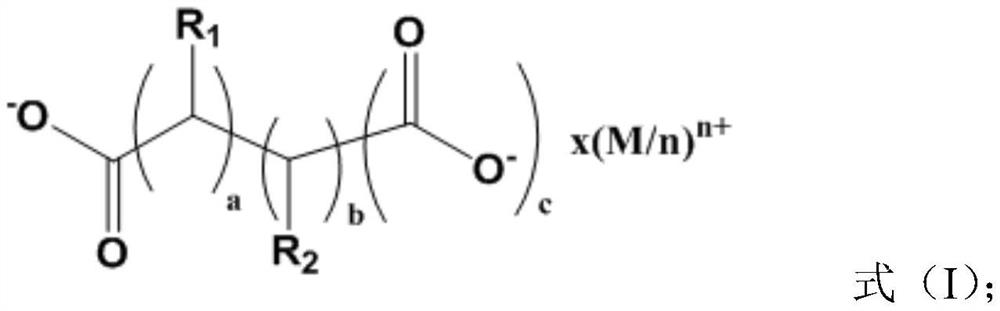

Viscoelastic surfactant composition and preparation method and application thereof

A surfactant and composition technology, applied in the field of viscoelastic surfactant composition and its preparation, can solve the problems of large adsorption capacity, low apparent viscosity at low concentration, etc., and achieve low adsorption capacity and improved ability to solubilize crude oil , the ability to emulsify crude oil and the effect of interface efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

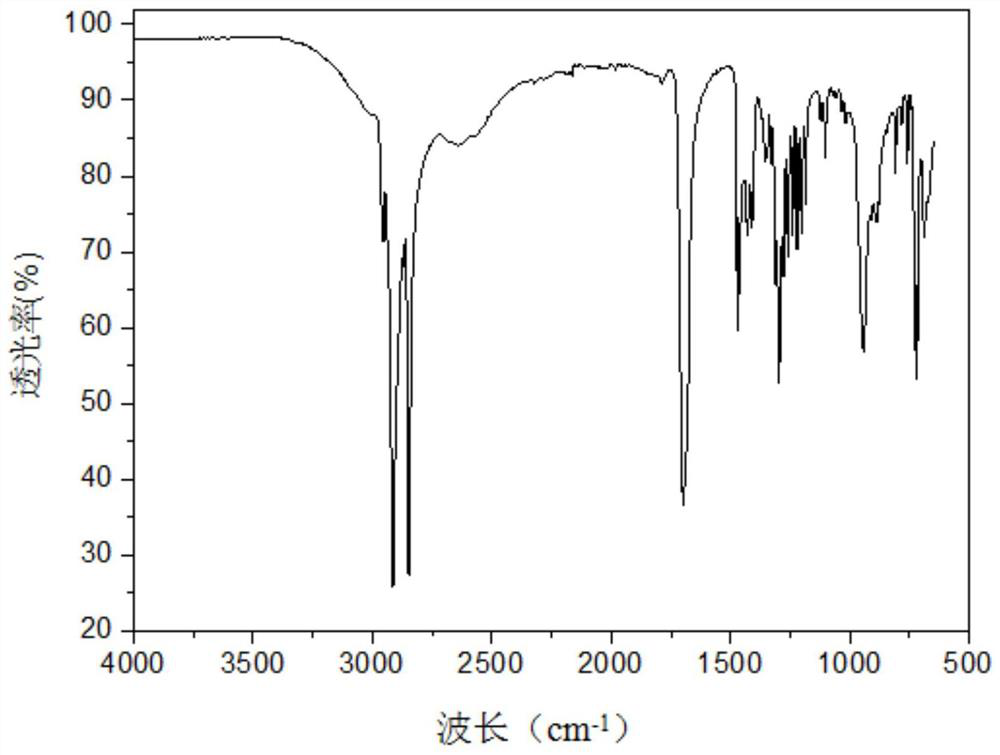

Embodiment 1

[0086] (a) Preparation of 1,1,2-potassium octadecyltricarboxylate:

[0087] ①Under nitrogen protection, cut 16.1 grams (0.7 moles) of fresh sodium metal into shreds and carefully add it to 150 ml of absolute ethanol several times. After the reaction of sodium metal is completed, add 112.2 grams (0.7 moles) of diethyl malonate , M=160), 195.6 g (0.5 mol, M=391) of ethyl α-bromostearate, heated to reflux, stopped heating when the pH of the reaction solution was nearly neutral, and cooled to room temperature.

[0088] 2. Add 750 grams of 15wt% potassium hydroxide aqueous ethanol solution (volume ratio of ethanol to water is 4 to 6) in the above reaction solution, heat and reflux for 5 to 6 hours to obtain 1,1,2-octadecyl potassium tricarboxylate ethanol in water. Take 20 grams of the uniform reaction solution to acidify with 10wt% hydrochloric acid, evaporate ethanol, add 50 grams of benzene, separate the water layer, wash 3 times with saturated saline, evaporate the benzene, an...

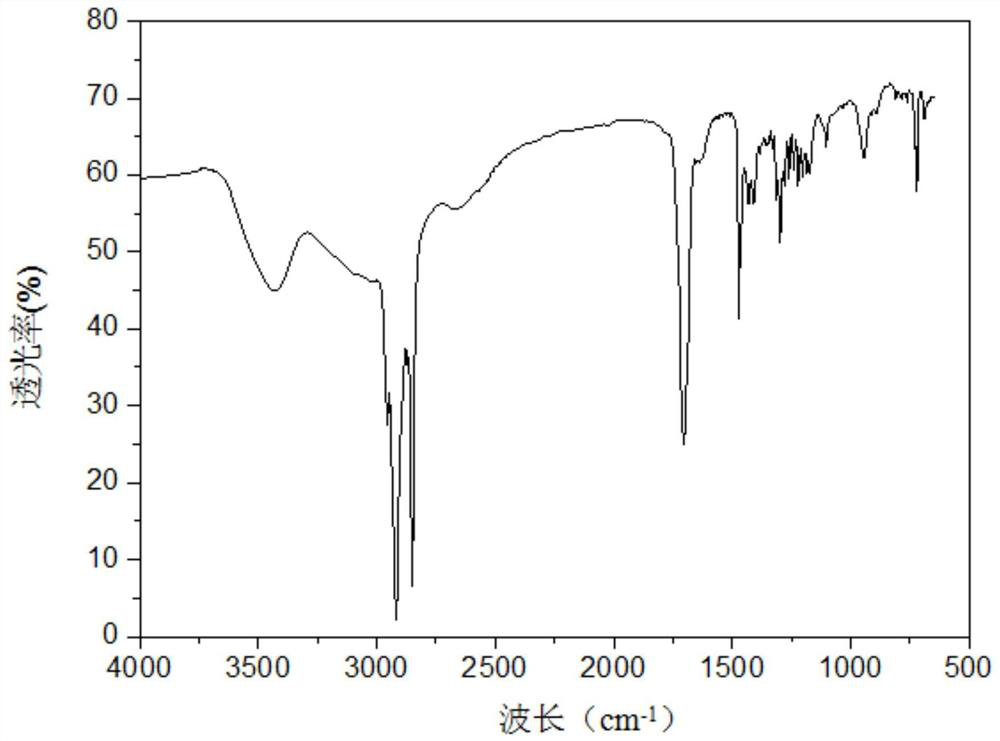

Embodiment 2

[0092] (a) Preparation of 1,1,2-docosyl potassium tricarboxylate:

[0093] ① Under the protection of nitrogen, cut 23.0 grams (1.0 moles) of fresh sodium metal into shreds and carefully add it to 200 ml of absolute ethanol several times. After the reaction of sodium metal is completed, add 160.1 grams (1.0 moles) of diethyl malonate , M=160), 223.5 g (0.5 mol, M=447) of ethyl α-bromobehenic acid, heated to reflux, stopped heating when the pH of the reaction solution was near neutral, and cooled to room temperature.

[0094] ②Add 750 grams of 20 wt% potassium hydroxide ethanol aqueous solution (the volume ratio of ethanol to water is 4 to 6) to the above reaction solution, and heat to reflux for 7 hours to obtain the ethanol of 1,1,2-docosyl potassium tricarboxylate aqueous solution. Take 20 grams of the uniform reaction solution to acidify with 10wt% hydrochloric acid, evaporate ethanol, add 50 grams of benzene, separate the water layer, wash 3 times with saturated saline, ev...

Embodiment 3

[0098] (a) Preparation of 1,1,2-(9-ene octadecyl)potassium tricarboxylate:

[0099] ① Under the protection of nitrogen, cut 13.8 grams (0.6 moles) of fresh sodium metal into shreds and carefully add it to 120 ml of absolute ethanol several times. After the reaction of sodium metal is completed, add 96.1 grams (0.6 moles) of diethyl malonate , M=160), 194.6 g (0.5 mol, M=389) of ethyl α-bromo-9-octadecanoate, heated to reflux, stopped heating when the pH of the reaction solution reached nearly neutral, and cooled to room temperature.

[0100] ②Add 1000 g of 10 wt% potassium hydroxide ethanol aqueous solution (the volume ratio of ethanol to water is 5 to 5) to the above reaction solution, and heat to reflux for 5 hours to obtain 1,1,2-(9-octadecyl)tricarboxylic acid Aqueous solution of potassium phosphate in ethanol. Take 20 grams of the uniform reaction solution to acidify with 10wt% hydrochloric acid, evaporate ethanol, add 50 grams of benzene, separate the water layer, wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com