Effective production process for shallow medium-high permeability super heavy oil reservoir

A medium-to-high-permeability, super-heavy oil technology, applied in the direction of production of fluids, wellbore/well components, drilling composition, etc., can solve the problems of high economic cost, low oil-steam ratio, poor production effect, etc. The effect of ripple and treatment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Example of effective production of shallow medium-high permeability ultra-heavy oil reservoirs

[0026] A block 1: The oil reservoir is buried 654 meters deep, 9.5 meters thick, and has a permeability of 529×10 -3 μm 2 , the reservoir temperature is 27°C, the viscosity of degassed crude oil at formation temperature is 112000mPa·s, and the oil saturation is S O = 53%. It belongs to the shallow medium-high permeability ultra-heavy oil reservoir, which is difficult to produce.

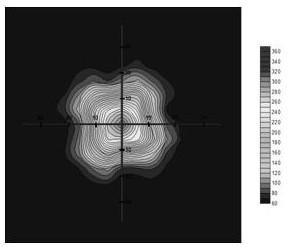

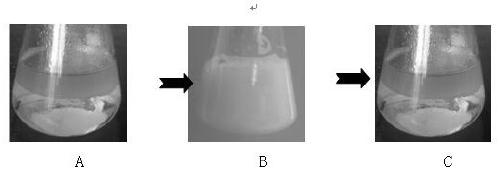

[0027] First, the oil-soluble viscosity reducer (C9 aromatics) with a mass concentration of 3% was used to conduct a viscosity reduction experiment on the crude oil in this block, and the viscosity of the crude oil after viscosity reduction was 21280 mPa·s. Using digital simulation software, the steam injection volume is optimized according to the parameters such as the viscosity of degassed crude oil at the formation temperature of 21280mPa·s, and the steam injection volume is obtaine...

Embodiment 2

[0031] Example 2 Example of effective production of shallow medium-high permeability ultra-heavy oil reservoirs

[0032] A block 2: The oil reservoir is buried 486 meters deep, 5.7 meters thick, and has a permeability of 714×10 -3 μm 2 , the reservoir temperature is 31.6°C, the viscosity of degassed crude oil at formation temperature is 83500mPa·s, and the oil saturation S O = 56%. It belongs to the shallow medium-high permeability ultra-heavy oil reservoir, which is difficult to produce.

[0033] First, the oil-soluble viscosity reducer (C9 aromatics) with a mass concentration of 3% was used to conduct a viscosity reduction experiment on the crude oil in this block, and the viscosity of the crude oil after viscosity reduction was 16735 mPa·s. Using digital simulation software, the steam injection volume is optimized according to the viscosity of degassed crude oil at the formation temperature of 16735mPa·s, and the steam injection volume is obtained to be 1100t, and the effe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com