Water plugging turnaround fracture process suitable for water breakthrough oily gas well

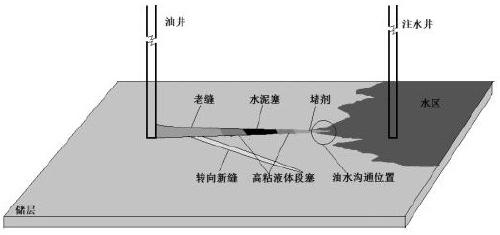

A technology for old oil and gas wells, applied in the field of water plugging and diverting fracturing technology, can solve the problems of oil and gas well water breakthrough, serious fingering phenomenon, limited plugging effect, etc., to expand the scope of injection water, improve production efficiency and Benefits, productivity and recovery effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A water shutoff diversion fracturing process suitable for water breakthrough old oil and gas wells, at least including the following steps:

[0031] Step 1) Use a cement truck to inject a sufficient amount of microemulsion ball particle plugging agent into the oil layer with low displacement;

[0032] Step 2) Inject the first high-viscosity liquid slug for displacing and pushing the microemulsion ball particle plugging agent deeply, wherein the viscosity of the first high-viscosity liquid slug is greater than 50mPa.s;

[0033] Step 3) Use a cement truck to inject cement slurry with specific properties, and solidify in the formation cracks to form cement plugs that isolate and block water;

[0034] Step 4) Use a pump truck to inject the second high-viscosity liquid slug to replace and push the cement slurry with specific performance to the predetermined position, wherein the viscosity of the second high-viscosity liquid slug is greater than 50mPa.s;

[0035] Step 5) Sta...

Embodiment 2

[0037] A water shutoff diversion fracturing process suitable for water breakthrough old oil and gas wells, at least including the following steps:

[0038] Step 1) Use a cement truck to inject a sufficient amount of microemulsion ball particle plugging agent into the oil layer with a low displacement; the low displacement is 0.5-1.0m 3 / min, the sufficient amount of microemulsion ball particle plugging agent is the dosage of 300m 3 or 300m 3 The above microemulsion ball particle blocking agent. The microemulsion ball particle blocking agent is a composite cross-linking blocking agent, with an initial particle size of 100 μm to 400 μm, uniformly dispersed in water;

[0039] Step 2) Inject the first high-viscosity liquid slug for displacing and pushing the microemulsion ball particle plugging agent deeply, wherein the viscosity of the first high-viscosity liquid slug is greater than 50mPa.s;

[0040] Step 3) Use a cement truck to inject cement slurry with specific performance...

Embodiment 3

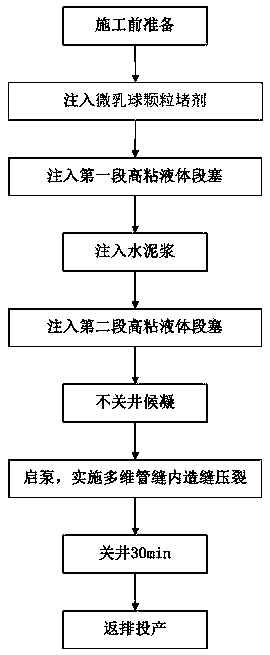

[0046] Such as figure 2 As shown, a water shutoff diversion fracturing process suitable for water breakthrough old oil and gas wells, the specific implementation steps are as follows:

[0047] Step 1: Pre-construction preparations, including preparatory operations such as taking and running pipe strings, flushing wells, etc., and preparing microemulsion ball particle plugging agents, cement slurry, high-viscosity liquids, fracturing fluids, etc. according to construction requirements. agent;

[0048] The second step: use a cement truck to inject a sufficient amount of microemulsion ball particle plugging agent with a low displacement; the low displacement is 0.5-1.0m 3 / min, the sufficient amount of microemulsion ball particle plugging agent is the dosage of 300m 3 or 300m 3For the microemulsion ball particle blocking agent above, the microemulsion ball particle plugging agent is a composite cross-linking plugging agent with an initial particle size of 100 μm to 400 μm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com