Lithium ferric borate block type electrode and preparation method thereof

A block-shaped, lithium-ion battery technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve difficult problems such as improving the volume specific capacity of lithium-ion batteries, shorten the preparation cycle, reduce production process costs, reduce The effect of raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a positive electrode of a lithium ion battery, the method comprising the following steps:

[0030] (1) adding lithium source aqueous solution or suspension, ferric iron source aqueous solution or suspension and boron source aqueous solution or suspension to carbon source aqueous solution in sequence to obtain a mixed solution;

[0031] (2) drying the mixed solution obtained in step (1) to obtain a lithium iron borate precursor;

[0032] (3) Mix the lithium iron borate precursor obtained in step (2) with organic matter to obtain LiFeBO 3 / C precursor;

[0033] (4) LiFeBO obtained in step (3) 3 / C precursor is molded into bulk to obtain LiFeBO 3 / C bulk electrode precursor;

[0034] (5) LiFeBO obtained in step (4) 3 The / C bulk electrode precursor is calcined under the protection of an inert atmosphere to obtain the positive electrode of the lithium-ion battery.

[0035] In the preparation method provided by the present ...

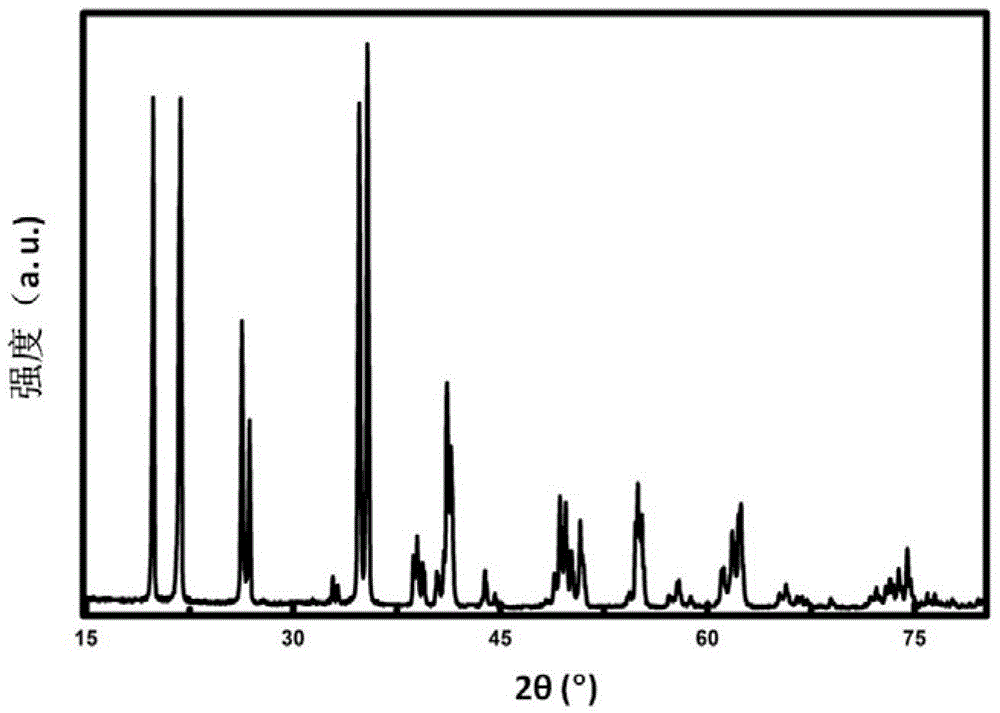

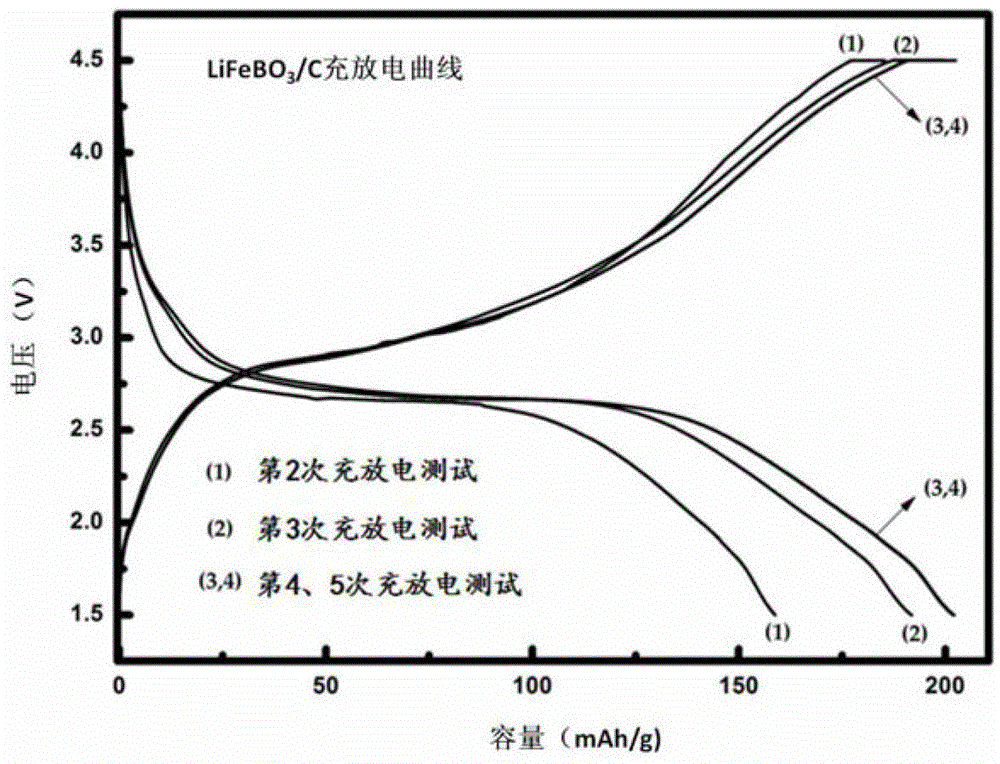

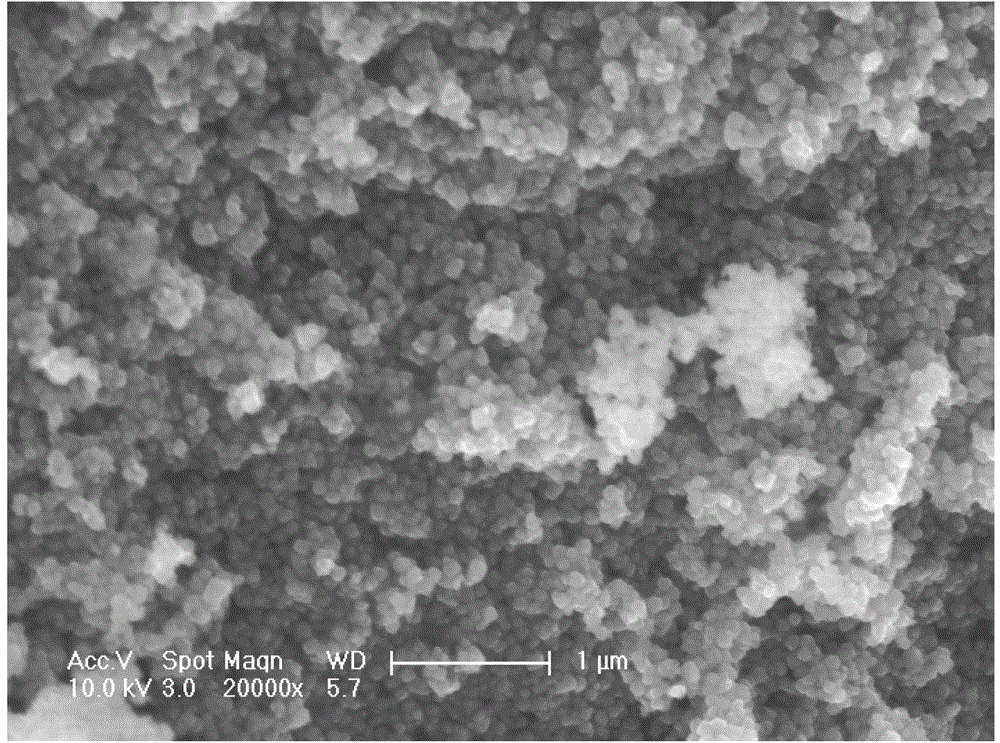

Embodiment 1

[0055] Dissolve 0.0144mol of lithium carbonate, 0.0288mol of boric acid, and 0.0288mol of ferric nitrate in 20mL of water, dissolve 0.014mol of citric acid and 0.009mol of glucose in 20mL of water, stir at a speed of 1200r / min, and successively dissolve the lithium carbonate suspension , ferric nitrate solution and boric acid solution were added to citric acid and glucose solution, and the mixed solution was continuously stirred for 6 hours to obtain a clear and transparent mixed solution. The mixed solution was dried at 80° C. for 16 hours, then heated and decomposed at 220° C. for 4 hours, and ground to obtain a lithium iron borate precursor. The lithium iron borate precursor was ball-milled with 0.0072mol glucose to obtain LiFeBO 3 / C precursor. LiFeBO 3 The / C precursor is cold-pressed in a Φ10mm mold with a cold-pressing pressure of 80 MPa and a cold-pressing time of 120 seconds to obtain LiFeBO 3 / C bulk electrode precursor. This LiFeBO 3 / C The block electrode prec...

Embodiment 2

[0057] Add 0.0288mol of lithium hydroxide, 0.0325mol of boric acid, and 0.0144mol of ferric oxide into 40mL of water, dissolve 0.014mol of citric acid and 0.015mol of sucrose in 20mL of water, stir at a speed of 1000r / min, and successively dissolve hydrogen Lithium oxide solution, ferric oxide suspension and boric acid solution were added to citric acid and sucrose solution, and the mixed solution was continuously stirred for 8 hours to obtain a clear and transparent mixed solution. The mixed solution was dried at 60° C. for 20 hours, then heated and decomposed at 220° C. for 6 hours, and ground to obtain a lithium iron borate precursor. The lithium iron borate precursor was ball milled with 0.0072mol ascorbic acid to obtain LiFeBO 3 / C precursor. LiFeBO 3 The / C precursor is cold-pressed in a Φ10mm mold with a cold-pressing pressure of 60 MPa and a cold-pressing time of 240 seconds to obtain LiFeBO 3 / C bulk electrode precursor. This LiFeBO 3 / C The block electrode precu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com