Surface emitting laser and preparation method thereof

A surface emitting laser, confinement layer technology, applied in the field of lasers, can solve the problems of device failure, poor temperature resistance, large volume change, etc., to achieve the effect of improving stability, high thermal conductivity and electrical conductivity, and reducing process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better illustrate the technical means adopted by the present invention and its effects, a detailed description will be given below in conjunction with the embodiments of the present invention and the accompanying drawings. It will, however, be evident that various changes and modifications can be made to the present invention without departing from the broader spirit and scope of the invention as defined in the appended claims. Therefore, the following examples have an illustrative rather than a limiting meaning.

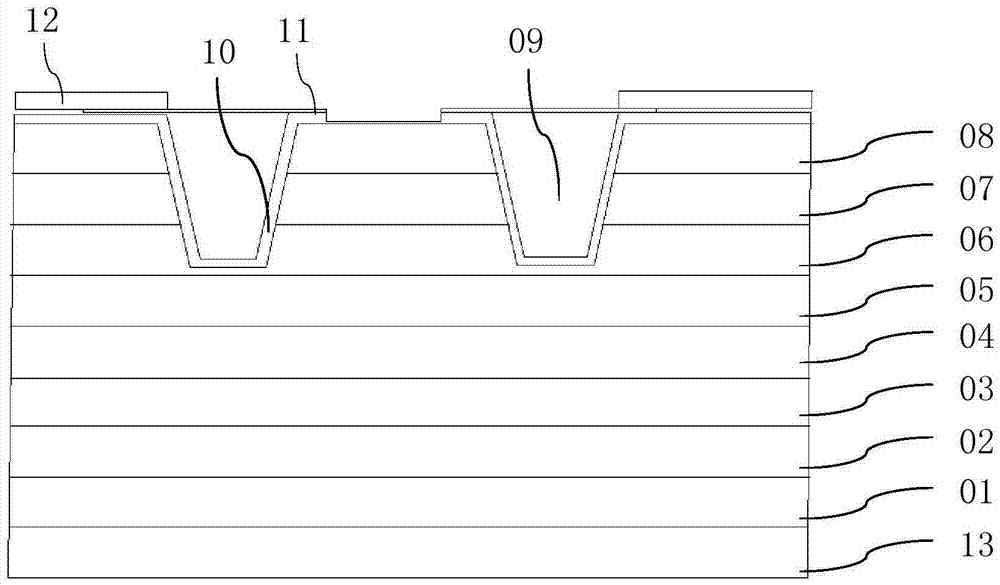

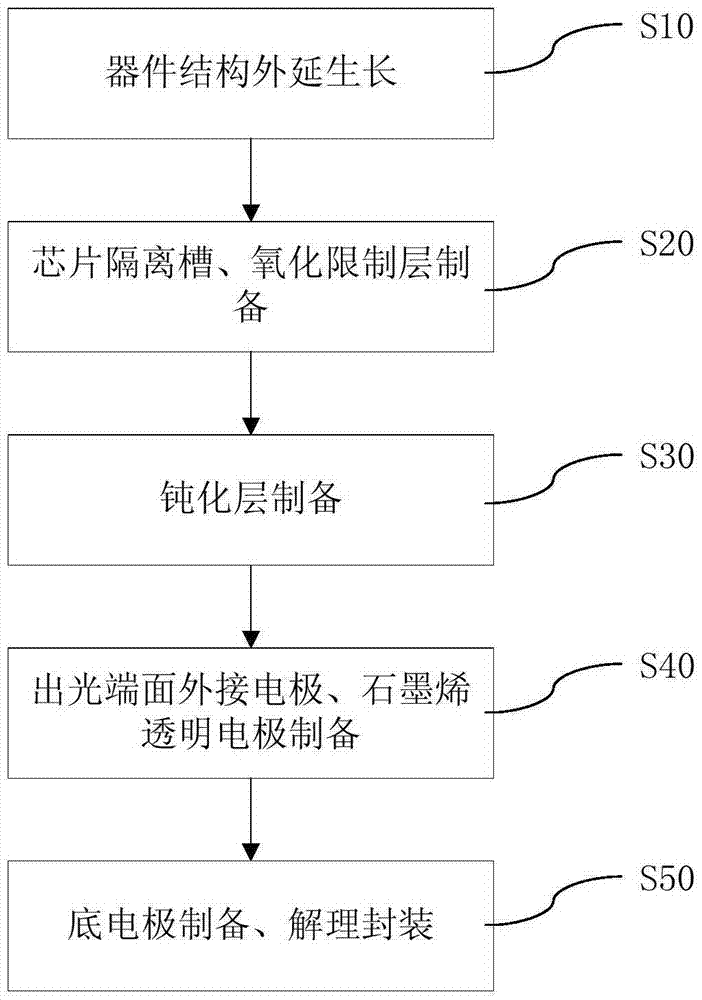

[0024] figure 1 is a schematic cross-sectional structure diagram of a surface-emitting laser according to an embodiment of the present invention.

[0025] refer to figure 1 As shown, the surface emitting laser according to the embodiment of the present invention is bottom electrode 13, substrate 01, lower DBR 02, lower confinement layer 03, active region 04, upper confinement layer 05, oxidation confinement layer 06, The upper DBR 07, the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com