Method for preparing aluminum alloy component through powder metallurgy method

A powder metallurgy, aluminum alloy technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problem of inability to prepare high-performance powder metallurgy aluminum alloy products, poor performance and near-net forming ability, long production process cycle, etc. problem, to achieve the effect of optimizing the alloy composition range, low price and reducing raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of method that adopts powder metallurgy method to prepare aluminum alloy part, concrete steps are as follows:

[0027] a. Proportion the raw material powder used according to the following mass fraction and median diameter, add amide wax C wax with a mass fraction of 1.5% as a lubricant, and then mix on a mixer for 30 minutes to obtain a uniformly mixed powder;

[0028] The mass percent and median diameter of each raw material powder used are as follows:

[0029]

[0030] b. the powder obtained in step a is pressed under a pressing pressure of 300MPa to obtain a circular green body with a diameter of 30mm;

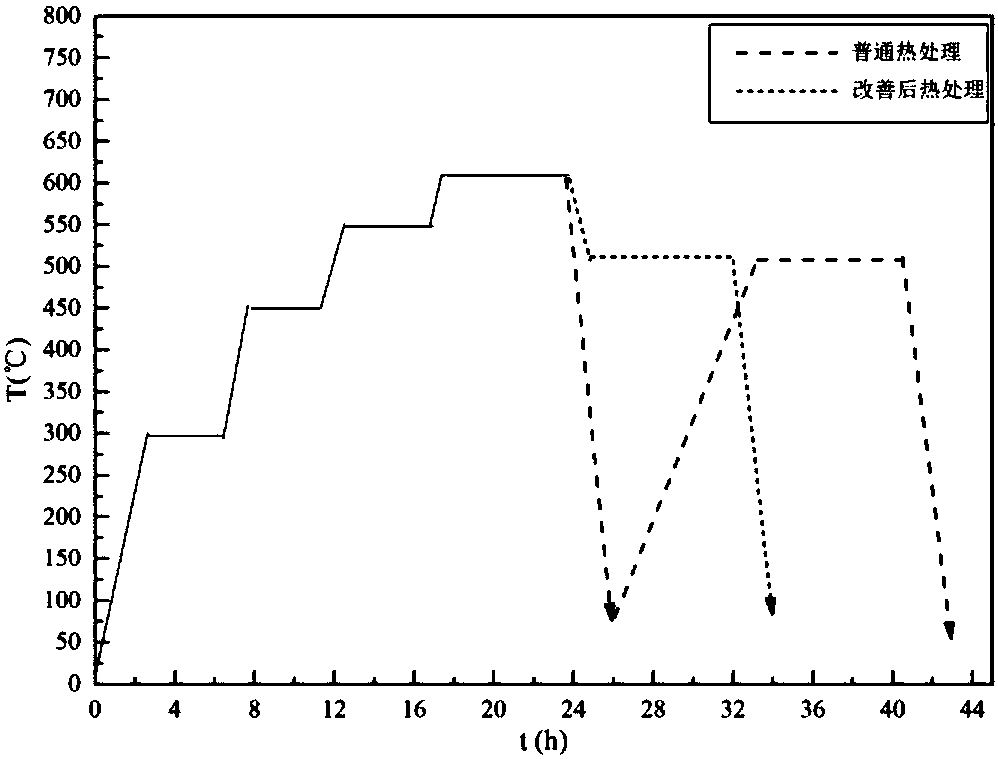

[0031] c. Carry out sintering-solution treatment of the formed body obtained in step b under a nitrogen atmosphere. The specific process parameters are: 300°C (degreasing temperature) for 20min, 460°C for 20min, 560°C for 20min, 600°C for 50min, and heat up The speed is 2°C / min, then the temperature is lowered to 520°C, held for 120 minutes ...

Embodiment 2

[0035] Embodiment 2: A kind of method that adopts powder metallurgy method to prepare aluminum alloy part, concrete steps are as follows:

[0036] a. Proportion the raw material powder used according to the following mass fraction and median diameter, add amide wax C wax with a mass fraction of 1.5%wt as a lubricant, and then mix on a mixer for 60 minutes to obtain a uniformly mixed powder ;

[0037] The mass percentage, median diameter, and sintering density of Al at different median diameters of each raw material powder used are as follows:

[0038]

[0039] b. the powder obtained in step a is pressed under a pressing pressure of 300MPa to obtain a circular green body with a diameter of 30mm;

[0040] c. Carry out sintering-solution treatment of the formed body obtained in step b under a nitrogen atmosphere. The specific process parameters are: 300°C (degreasing temperature) for 40min, 460°C for 40min, 560°C for 50min, 600°C for 240min, heat up The speed is 8°C / min, and...

Embodiment 3

[0044] Embodiment 3: a kind of method that adopts powder metallurgy method to prepare aluminum alloy part, concrete steps are as follows:

[0045] a. Proportion the raw material powder used according to the following mass fraction and median diameter, add amide wax C wax with a mass fraction of 1.5%wt as a lubricant, and then mix on a mixer for 45 minutes to obtain a uniformly mixed powder ;

[0046] The mass percent and median diameter of each raw material powder used are as follows:

[0047]

Mg

Si

Cu

sn

Al

Quality score (%)

1.50

0.8

4.0

0.5

93.2

Median diameter (μm)

75

32

45

27

75

[0048] b. pressing the powder obtained in step a under a pressing pressure of 300 MPa to obtain a circular green body with a diameter of 30 mm;

[0049] c. Carry out sintering-solution treatment of the shaped green body obtained in step b under a nitrogen atmosphere, wherein the heating rate of the whole process is 5°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com