Bearing outer ring raceway grinding monitoring device

A technology of bearing outer ring and monitoring device, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of unstable product processing quality, difficult control of processing procedures and parameters, and achieve the elimination of processing procedures and process parameters, The effect of improving product processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

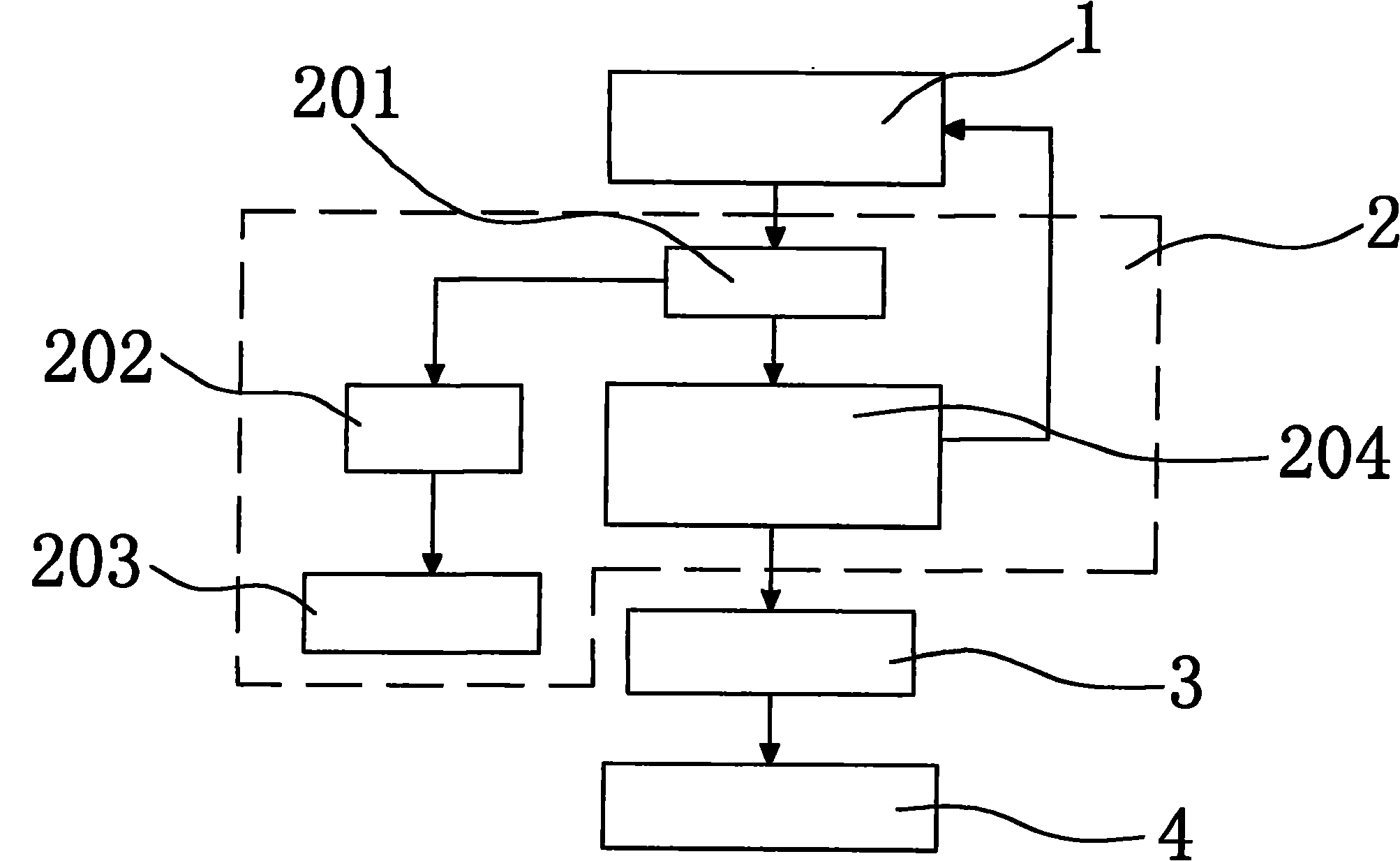

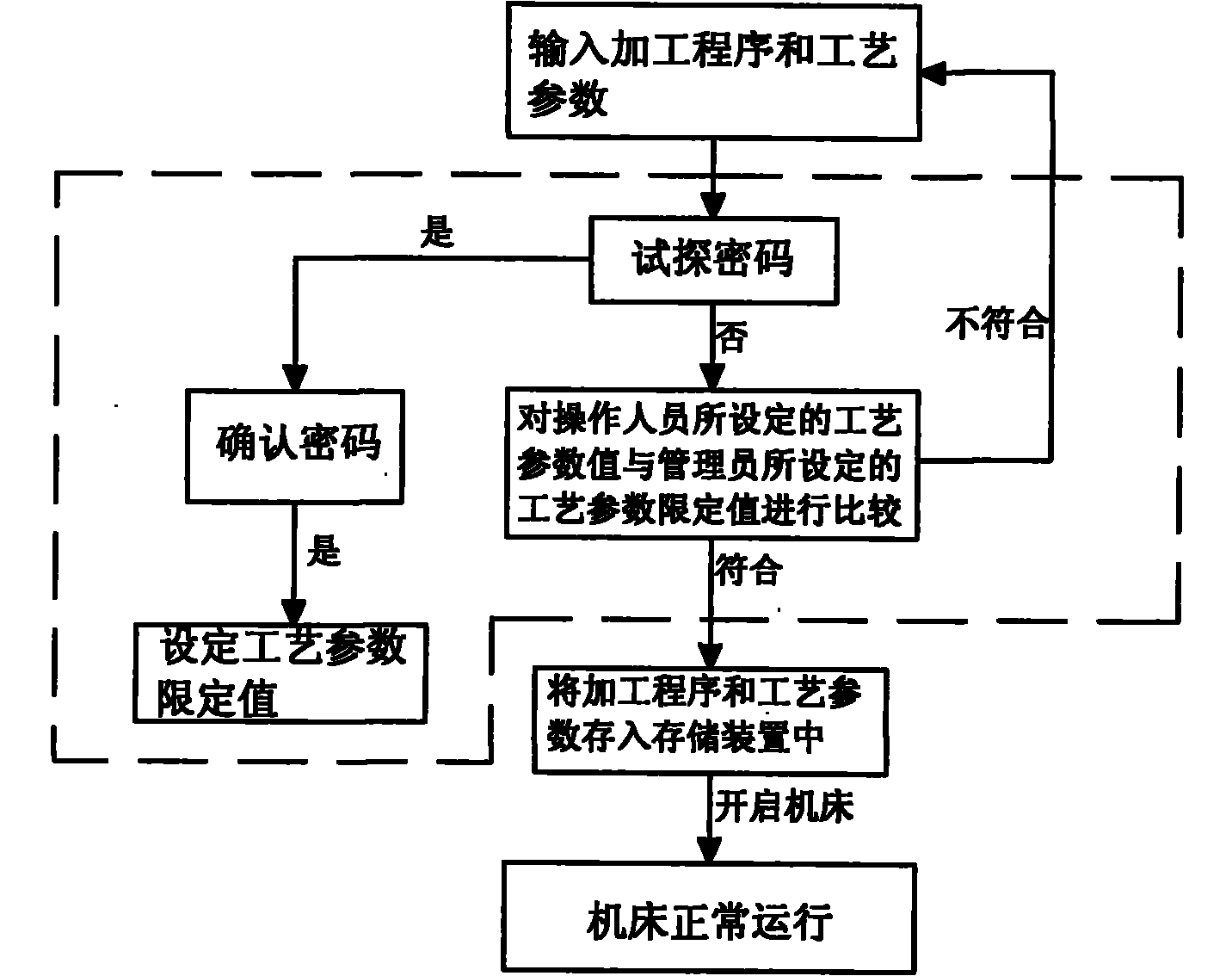

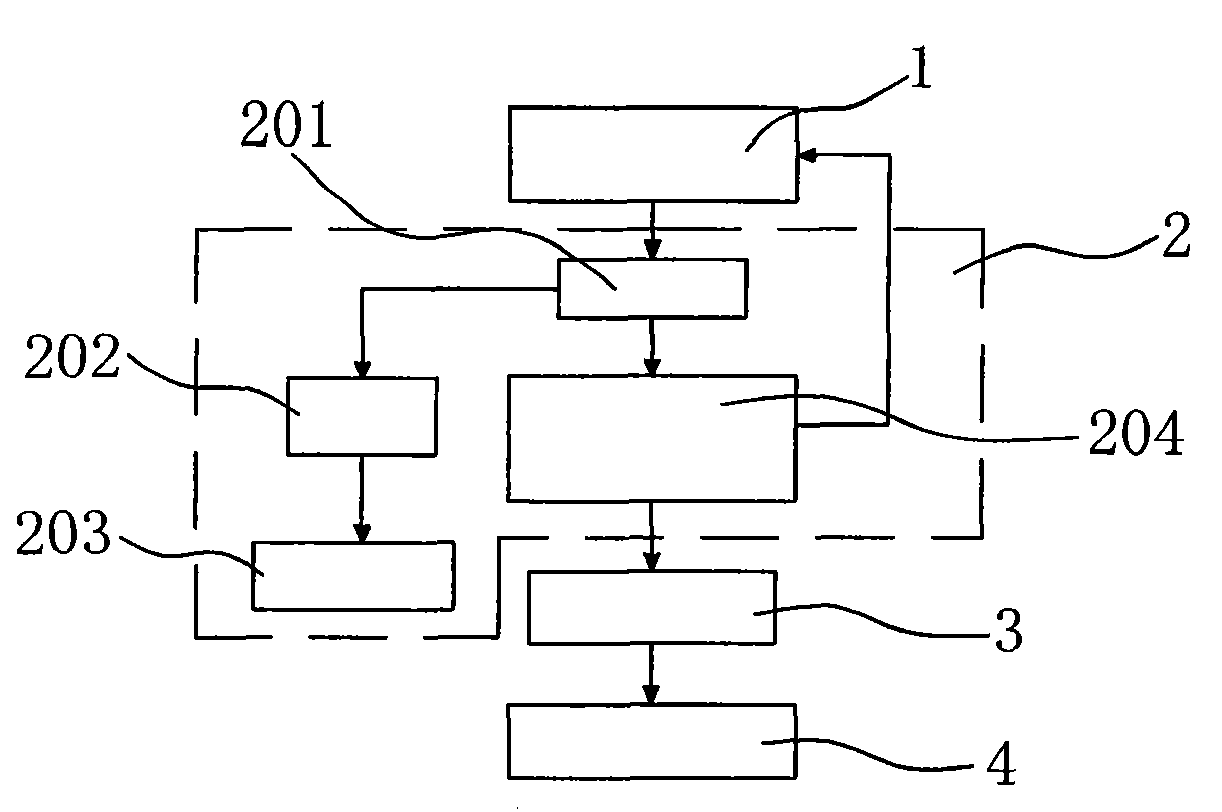

[0012] Now in conjunction with accompanying drawing, the present invention will be further described. Figure 1~2 The names of the serial numbers are: processing program and process parameter setting device 1, programmable logic controller 2, password test program 201, password setting program 202, process parameter limit value setting program 203, process parameter value and process parameter limit Value comparison program 204 , processing program and process parameter storage device 3 , machine tool processing device 4 .

[0013] Such as figure 1 As shown, the main body of the bearing outer ring groove grinding monitoring device is a programmable controller 2, and the program setting of the programmable controller includes a password test program 201, a password setting program 202, and a process parameter limit value setting Program 203 , program 204 comparing process parameter values with process parameter limit values. The input end of the programmable controller is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com