A single-valve expander system and method for isothermal expansion

An isothermal expansion and expander technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as affecting the normal operation of the machine, increasing costs, and frosting on the exhaust holes, and achieves an increase in the output power per unit of working fluid. The effect of improving work efficiency and reducing the number of expansion stages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

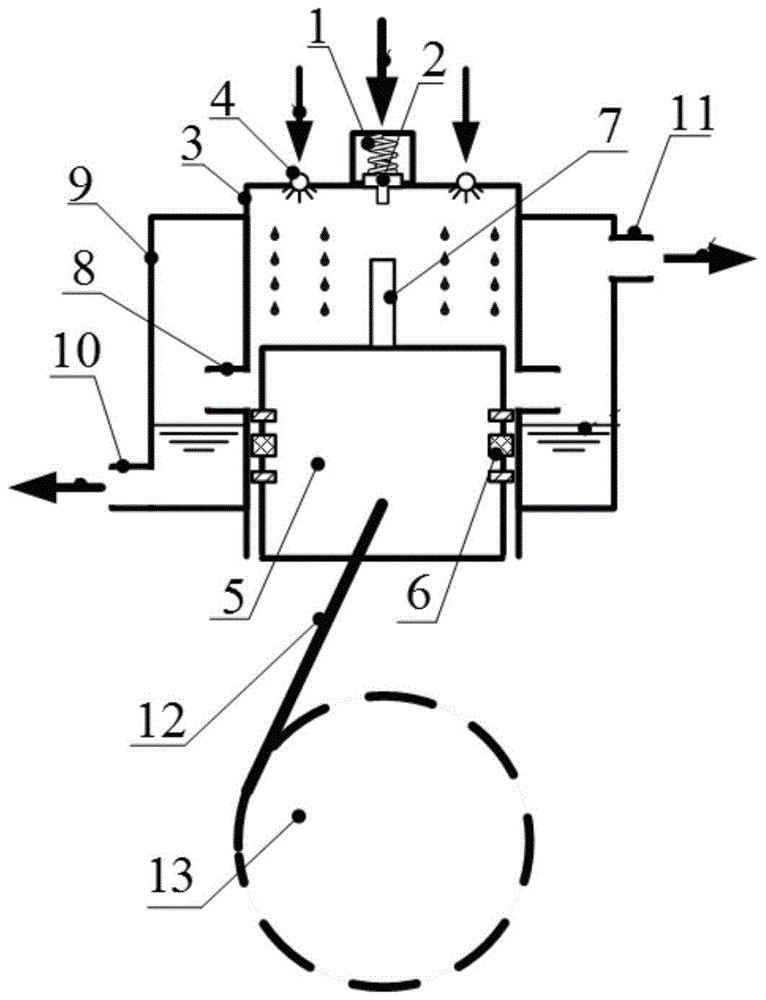

[0029] figure 1 It is a schematic structural diagram of Embodiment 1 of the isothermal expansion single-valve expander system and method of the present invention. The single-valve isothermal expander includes a piston 5, a cylinder 3 and a crank connecting rod mechanism. The piston 5 is slidably mounted in the cylinder 3. The crank connecting rod mechanism includes a connecting rod 12 and a crank 13. One end of the connecting rod 12 is connected to the piston 5 and the other end is connected to the The crank 13 is connected, and an intake valve 2 and an annular injector 4 are installed on the top of the cylinder 3. The intake valve 2 is in communication with an external high-pressure gas working medium source, and the annular injector 4 is in communication with an external heating medium source system for heating medium Atomize or form foam and inject the cylinder 3 with a certain mass flow. An exhaust hole 8 is provided on the cylinder side wall near the bottom dead center of ...

Embodiment 2

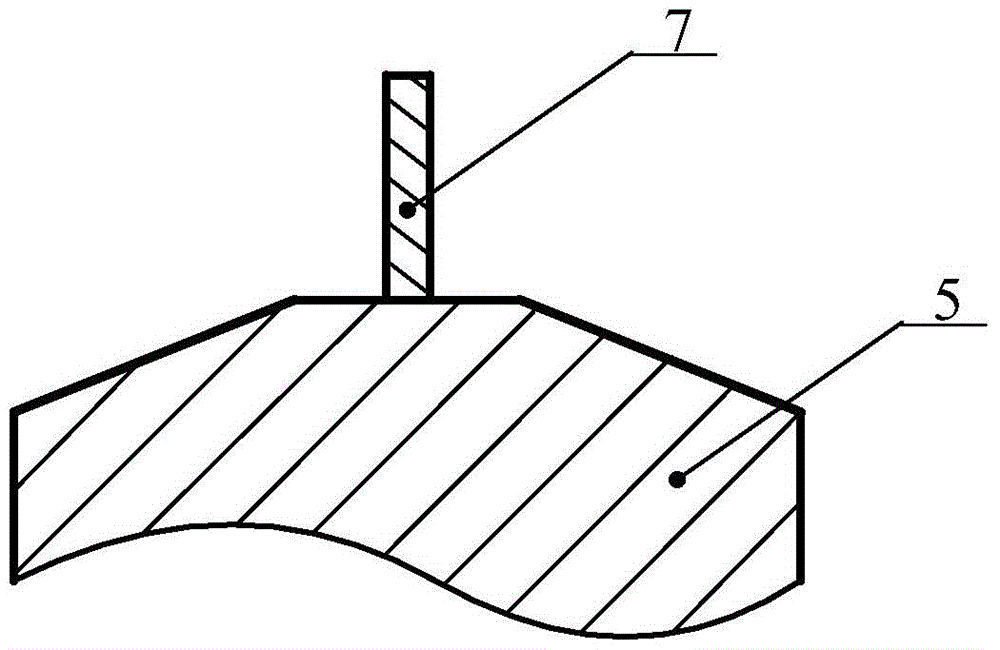

[0031] figure 2 This is a schematic diagram of the structure of Embodiment 2 of the present invention. In the figure, 5 is a part of the piston body and is mainly the top part of the piston, and 7 is the top rod. This embodiment lists the shape of the top of the piston 5, which is given in Embodiment 1. The top of the piston is flat. Such as figure 2 As shown, the top of the piston can also be an inclined plane, and the angle between it and the plane is greater than 0 degrees. When the piston runs to the bottom dead center attachment, this structure facilitates timely discharge of the liquid accumulated on the piston surface to the exhaust buffer 内内。 In the cavity 9.

Embodiment 3

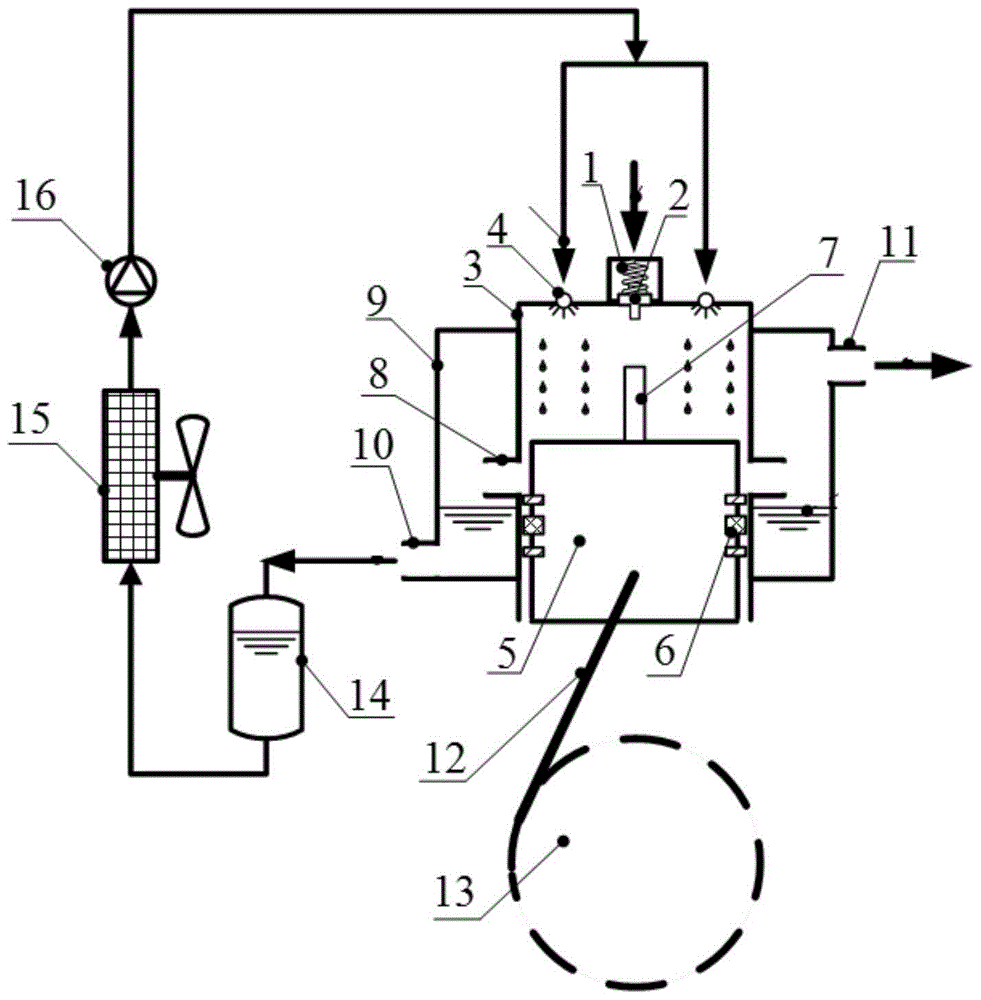

[0033] image 3 This is a schematic diagram of the structure of Embodiment 3 of the present invention, and its main structure is the same as that of Embodiment 1, except that the flow loop of the heating medium is given in this embodiment. The heating medium enters the expander cylinder 3 at ambient temperature, passes through the expansion process of the expander, and is discharged. The temperature drops, and the discharged heating medium enters the liquid tank 14, and then passes through an air cooler 15, where the ambient temperature is used to heat the fluid medium , And then pressurized by a liquid pump 16 and injected into the cylinder again. It should be noted that embodiment 2 can also be used in this embodiment; if the heating medium is sprayed into the cylinder in the form of foam, a special additive such as propylene glycol, low boiling point alkane or fluorocarbon is added to the heating medium Compound etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com