Patents

Literature

64results about "Special engines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

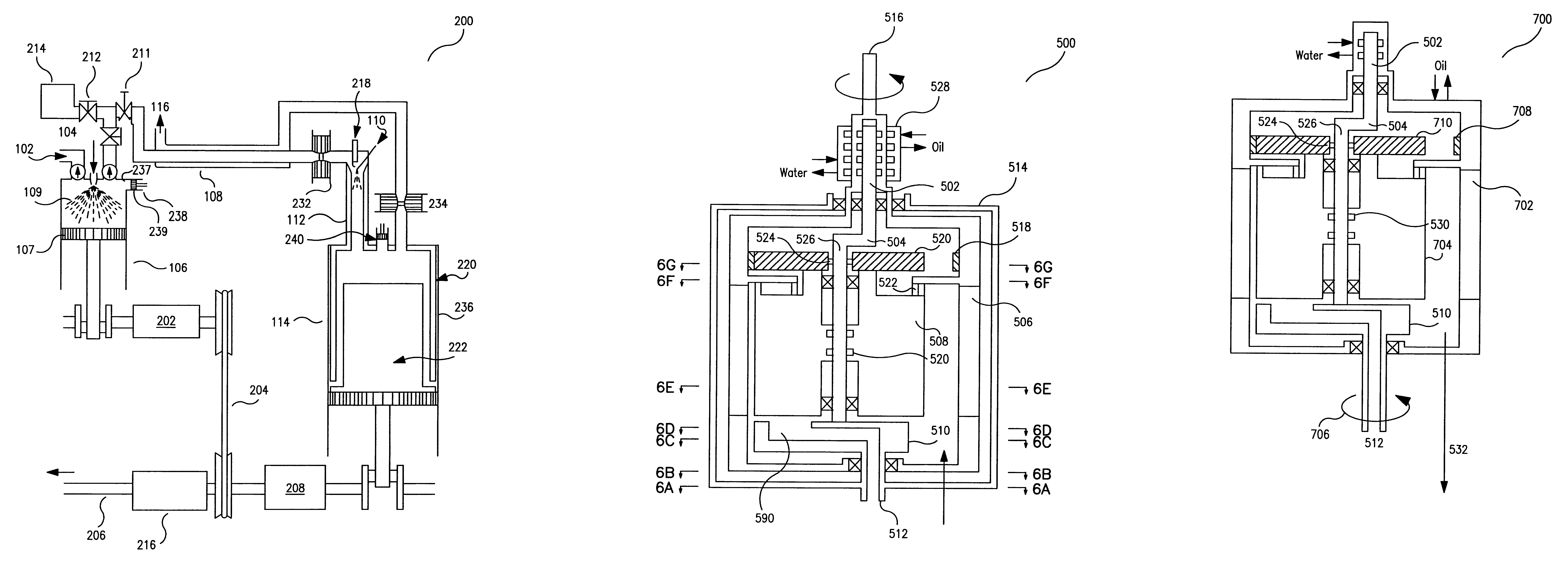

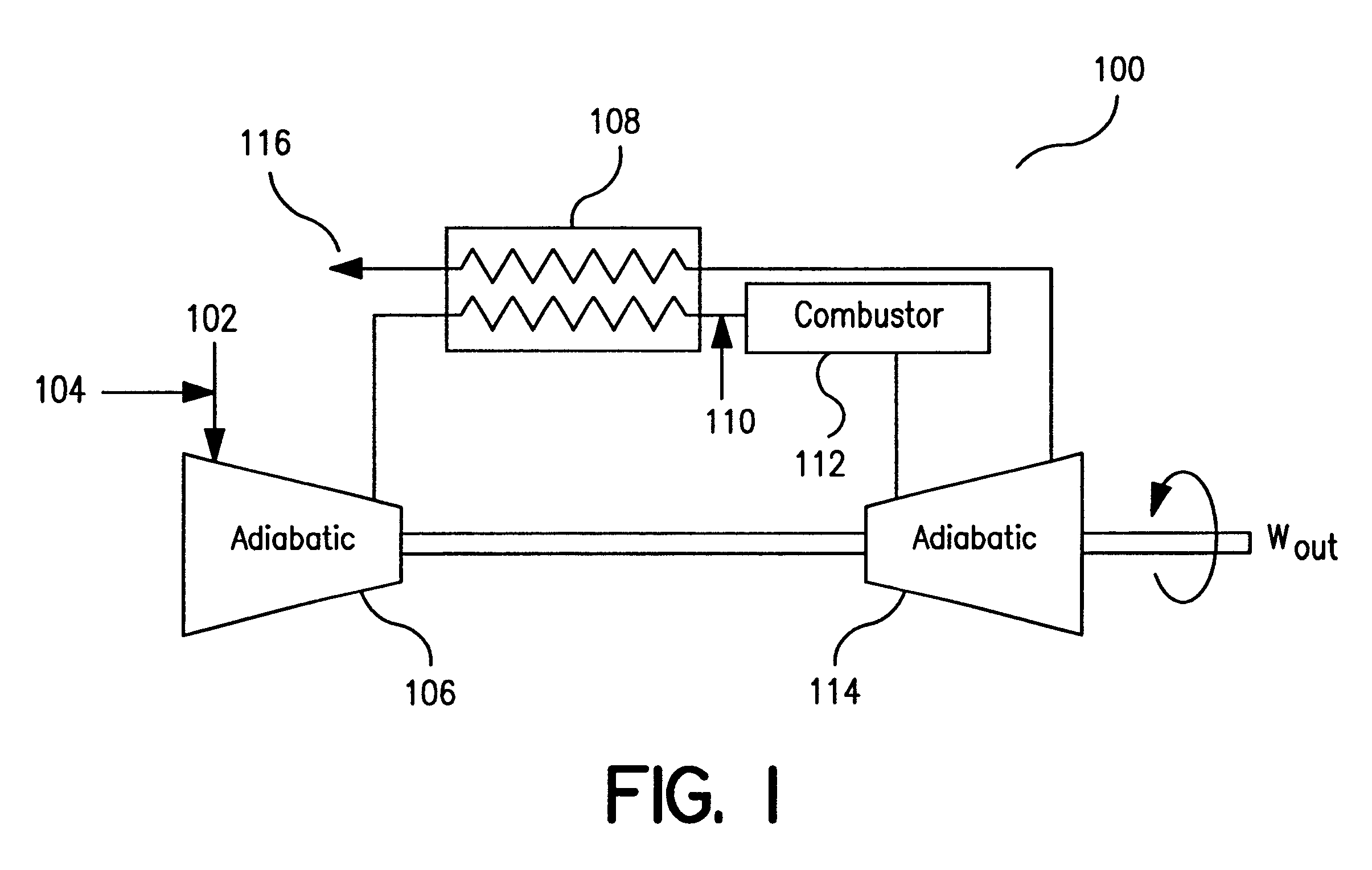

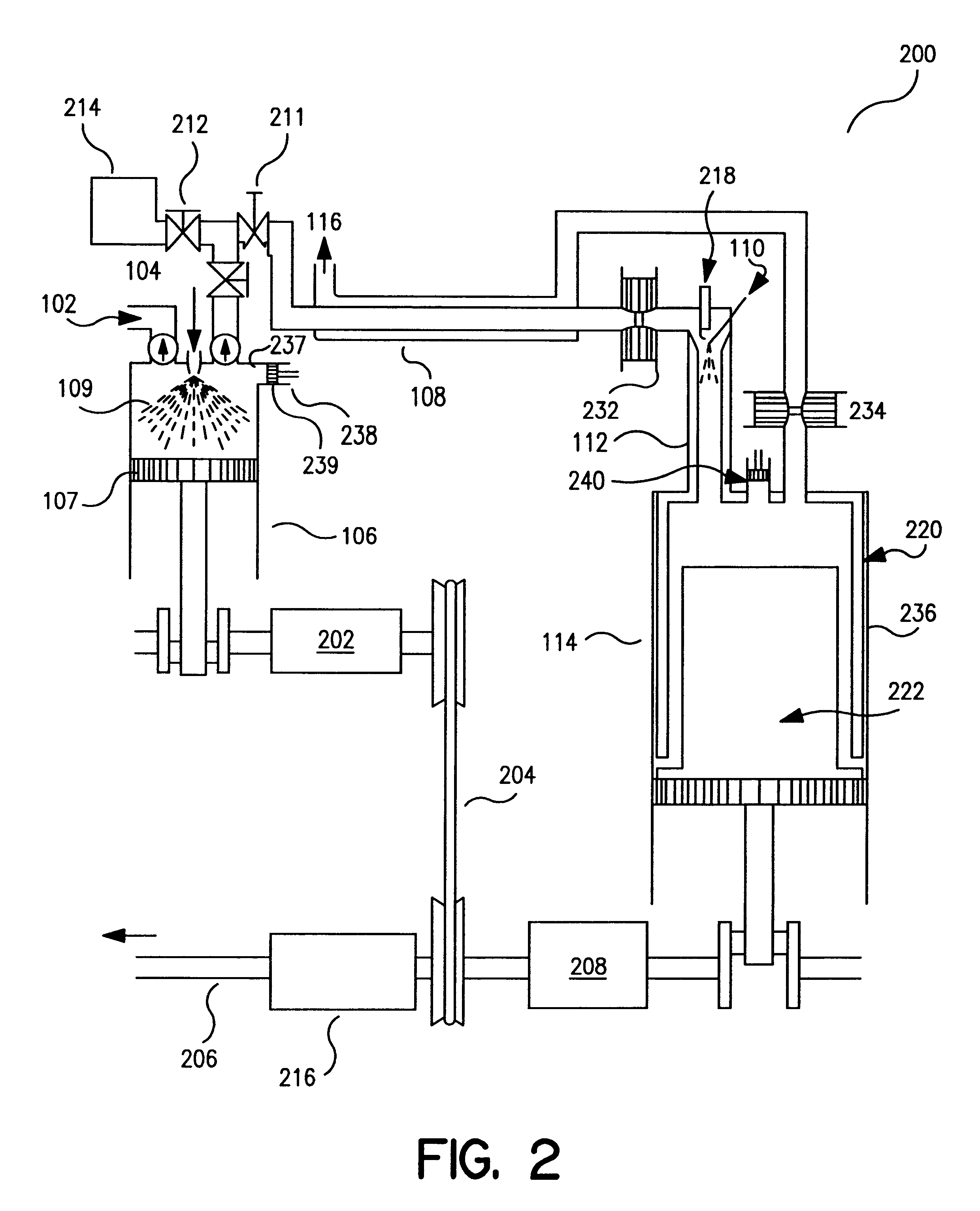

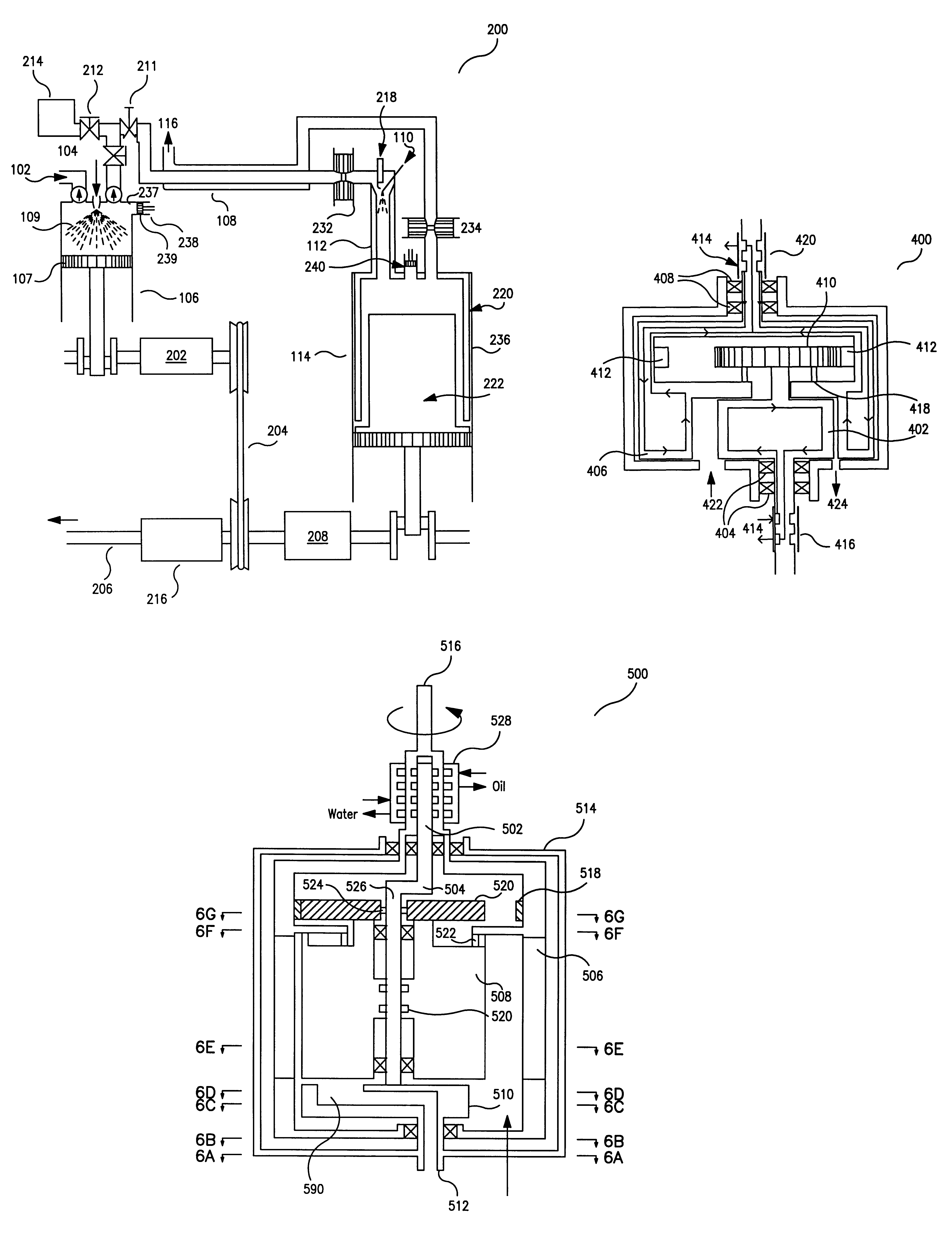

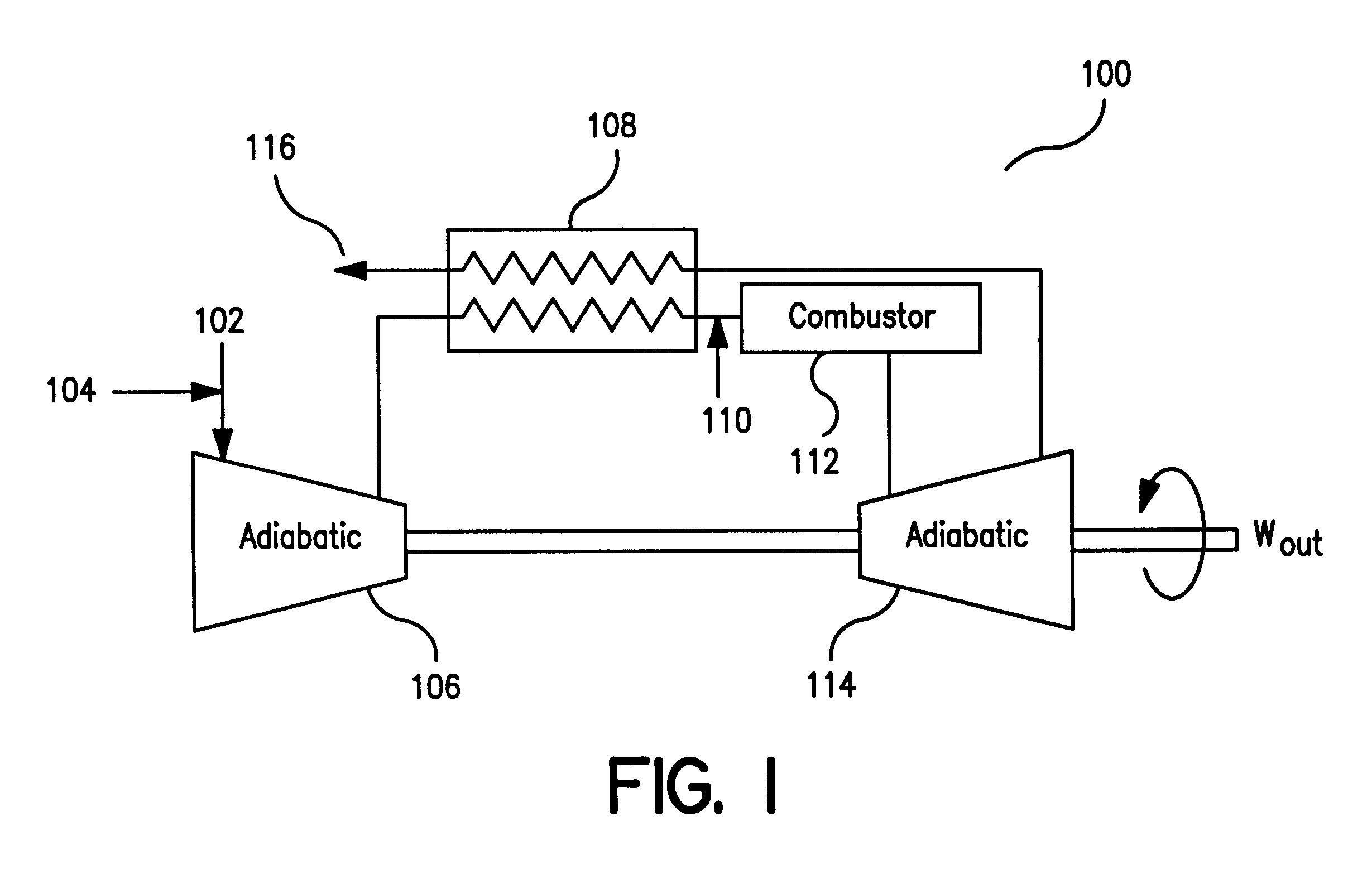

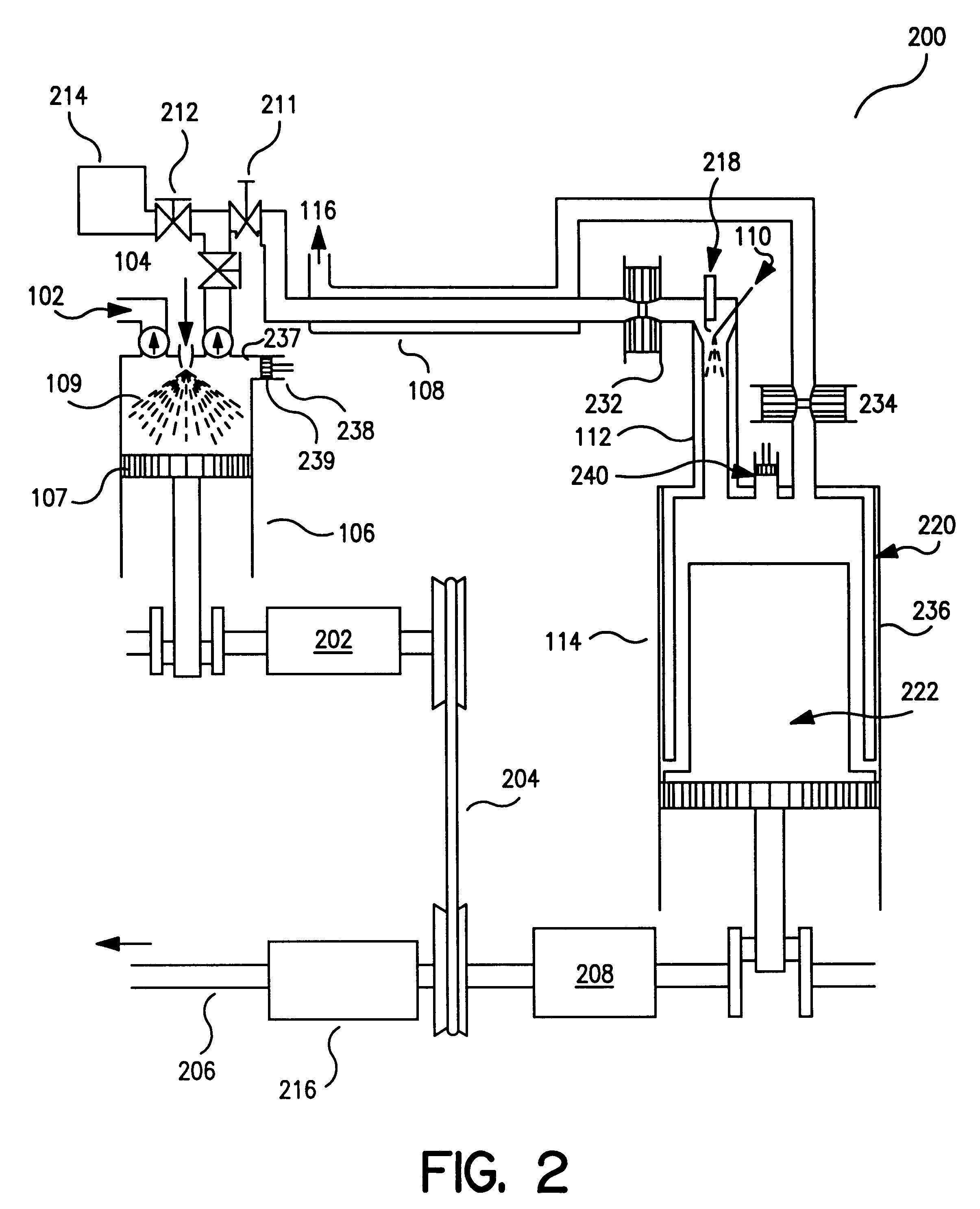

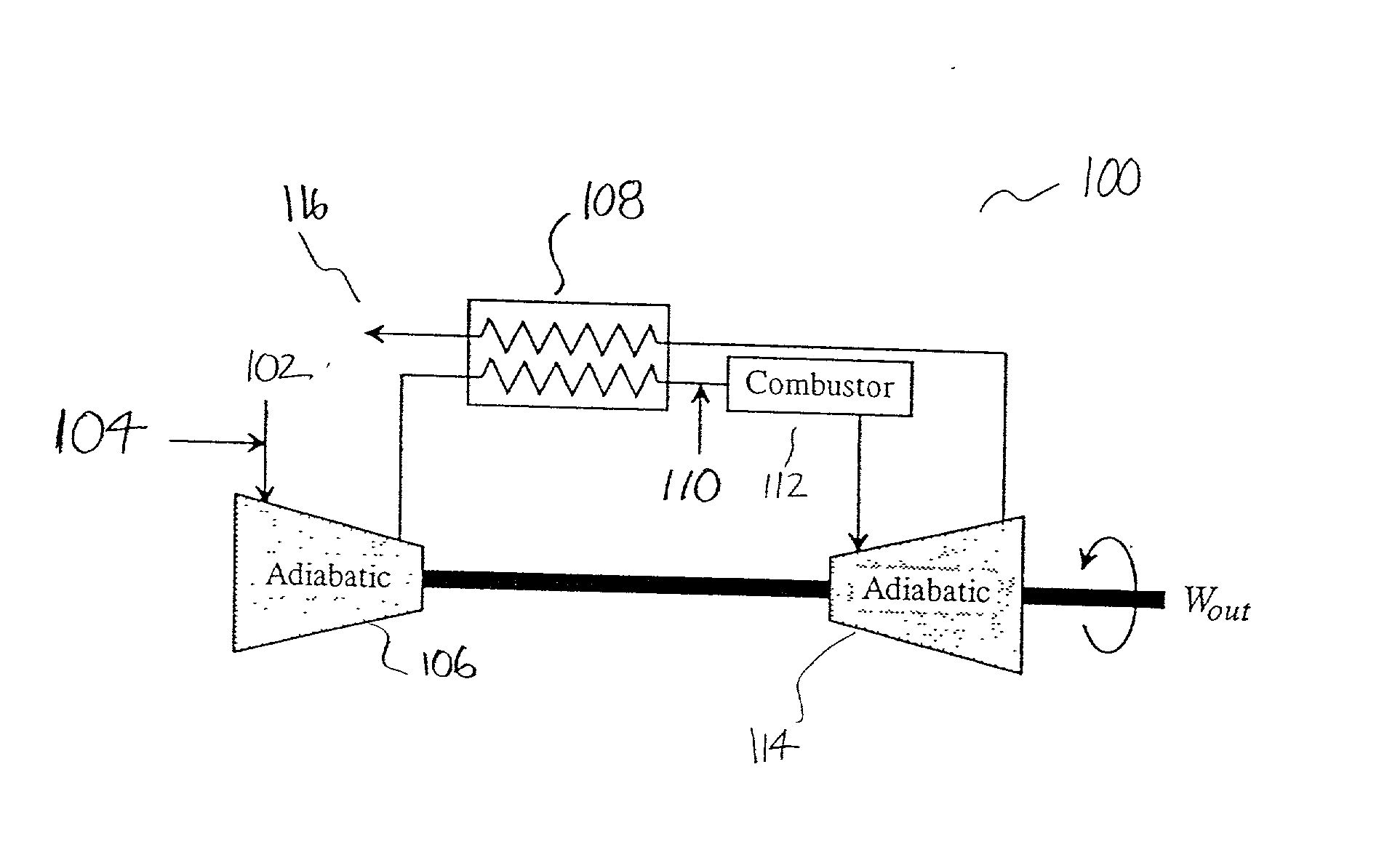

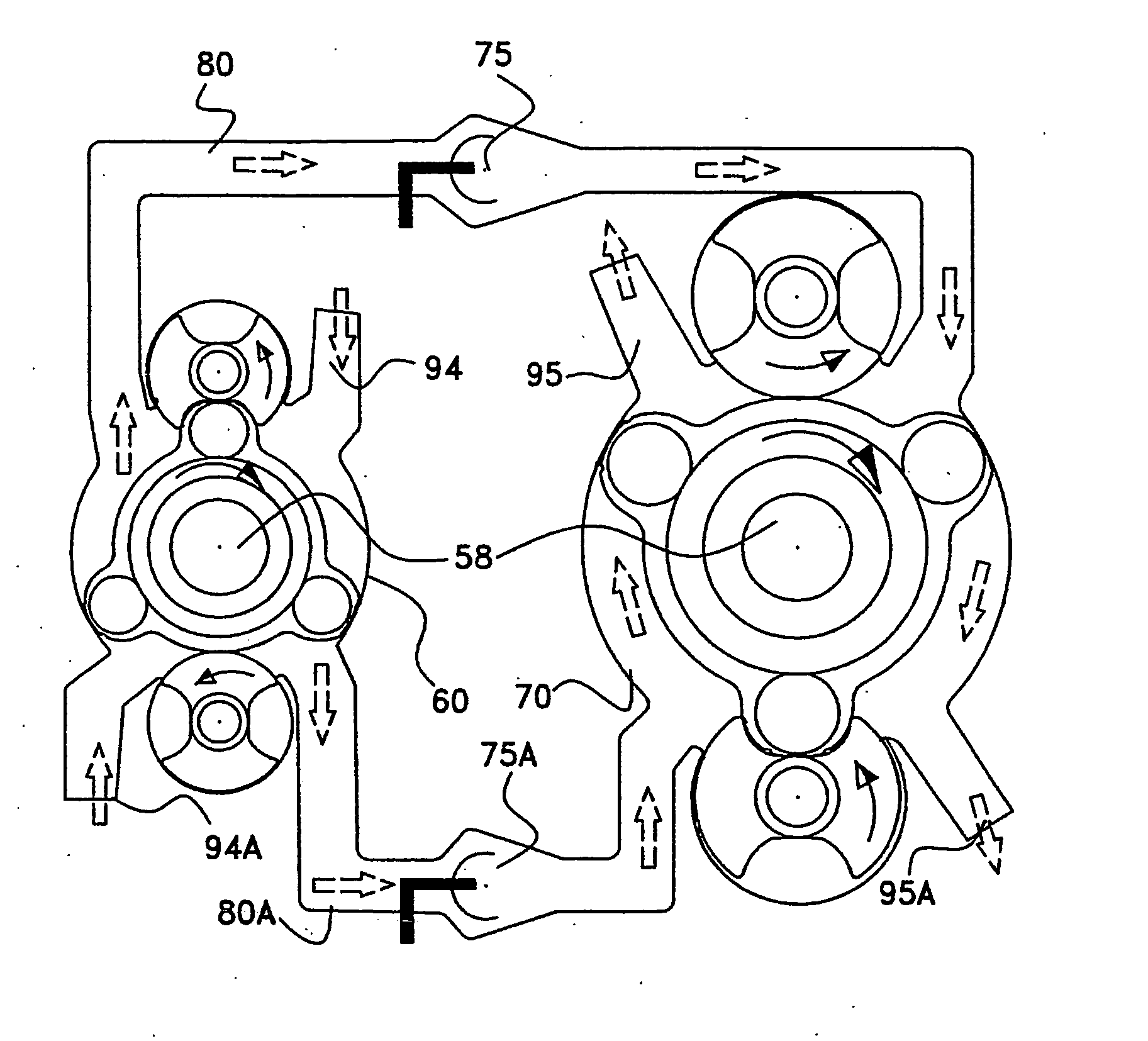

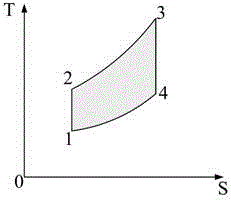

Quasi-isothermal Brayton Cycle engine

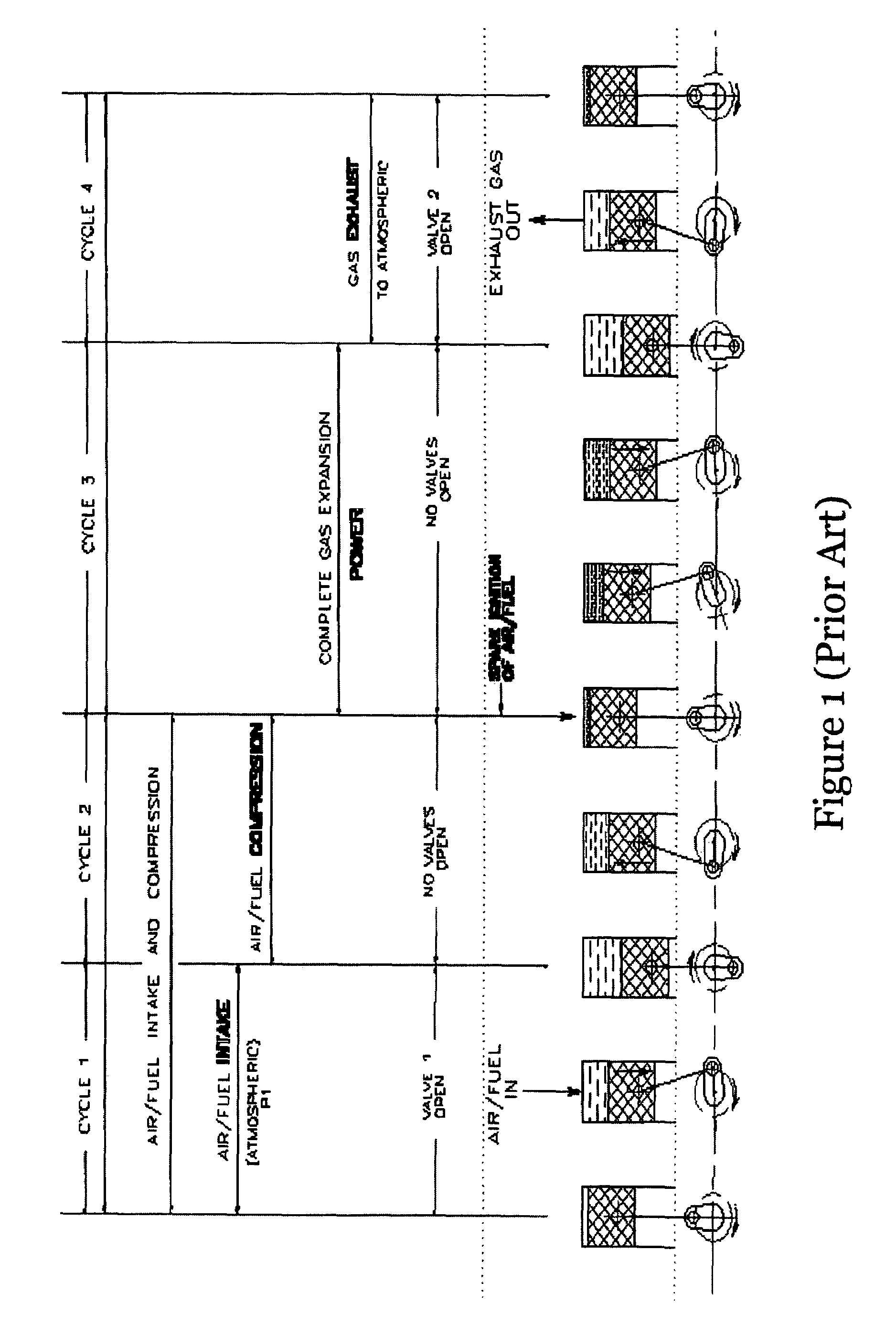

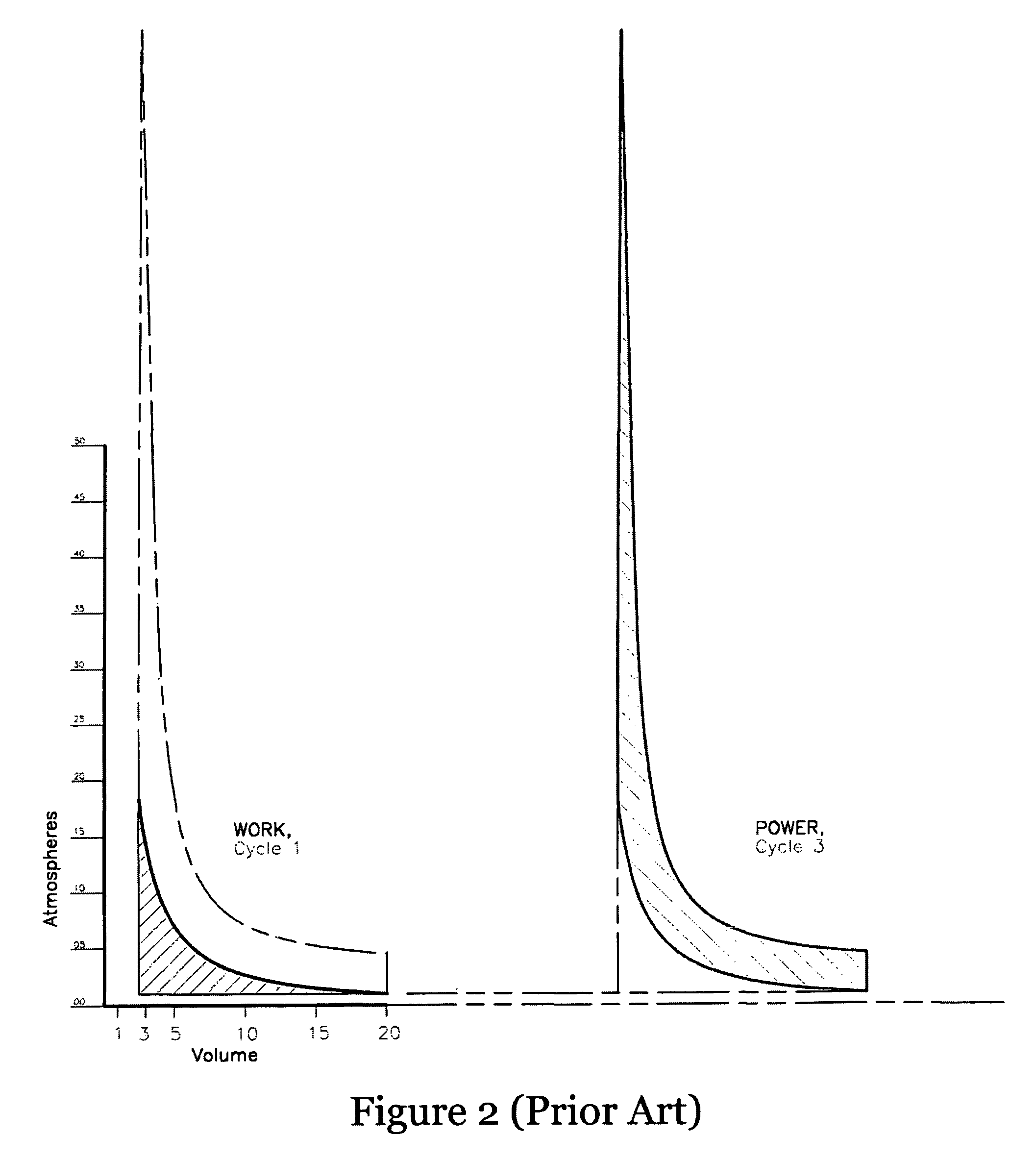

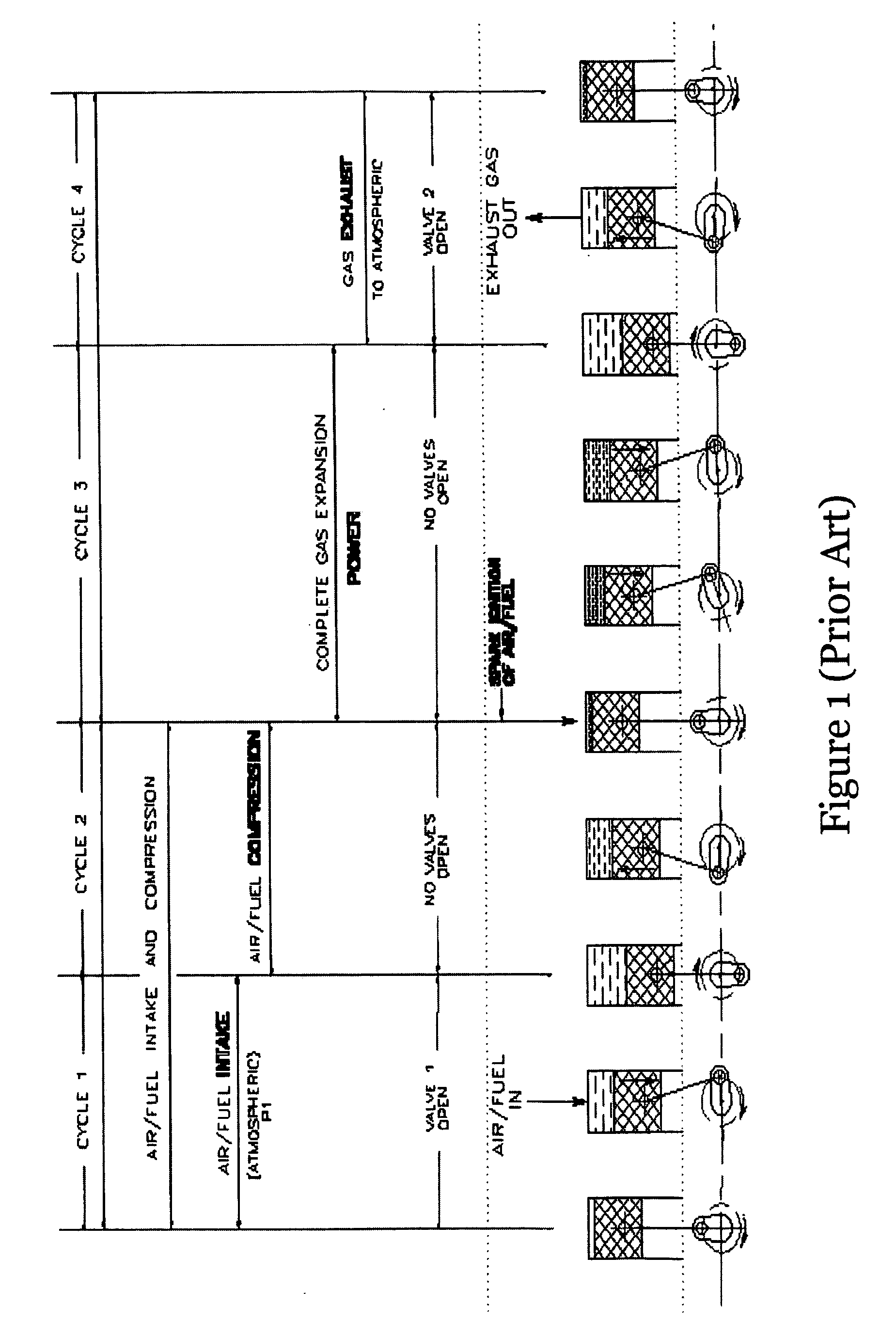

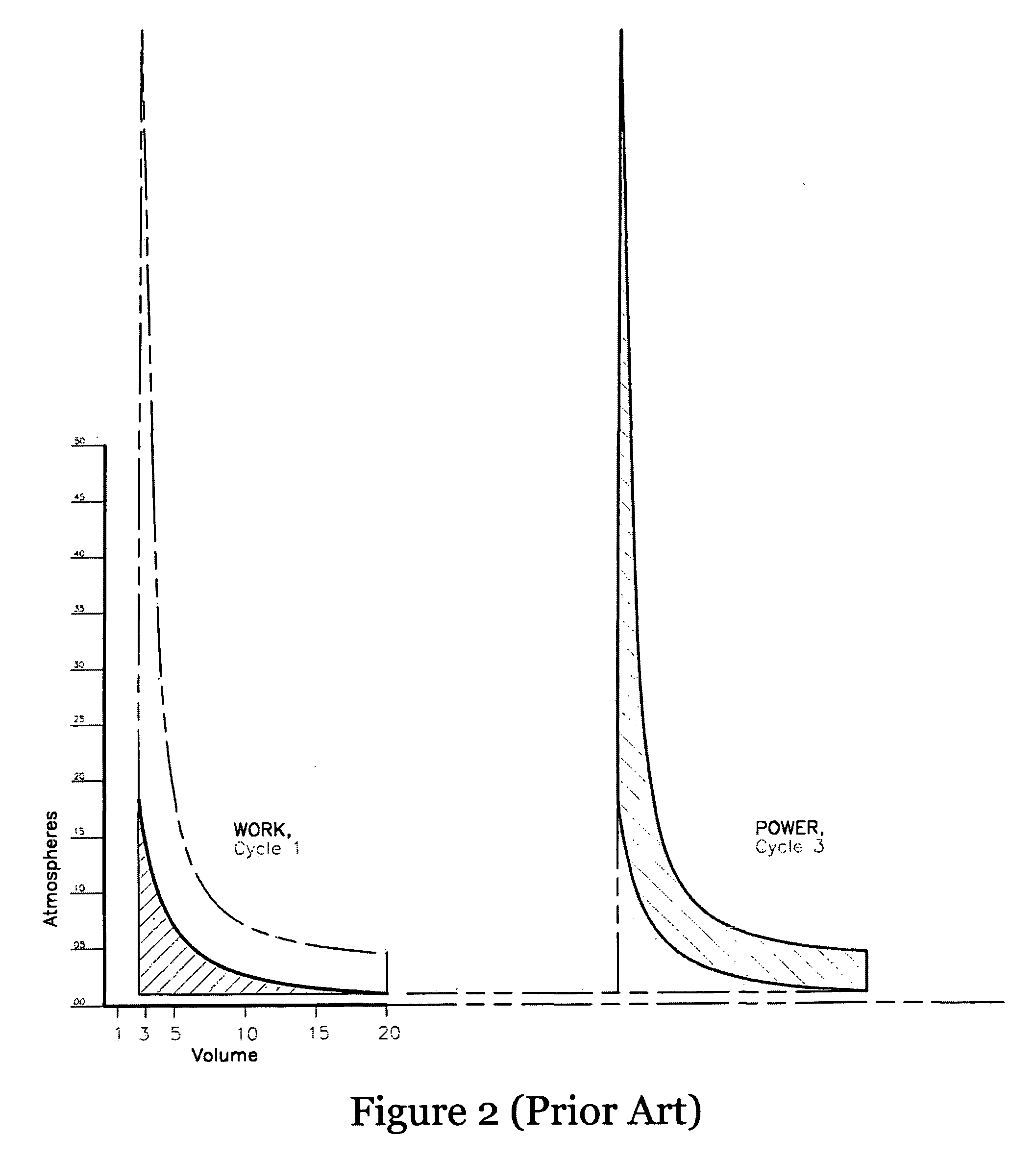

InactiveUS6530211B2Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesEngine of arcuate-engagement typeBrayton cycleCombustor

Owner:HOLTZAPPLE MARK T +1

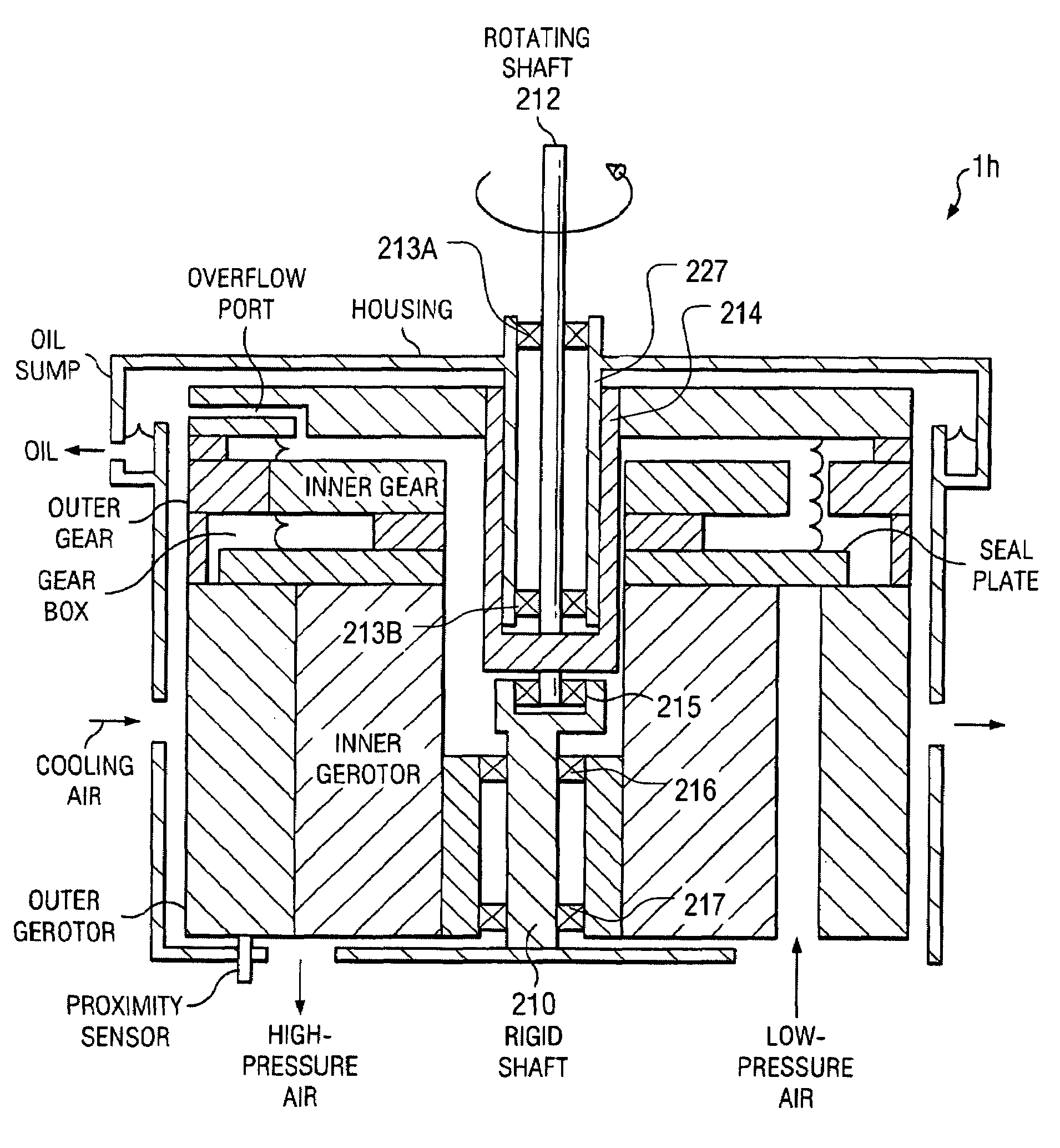

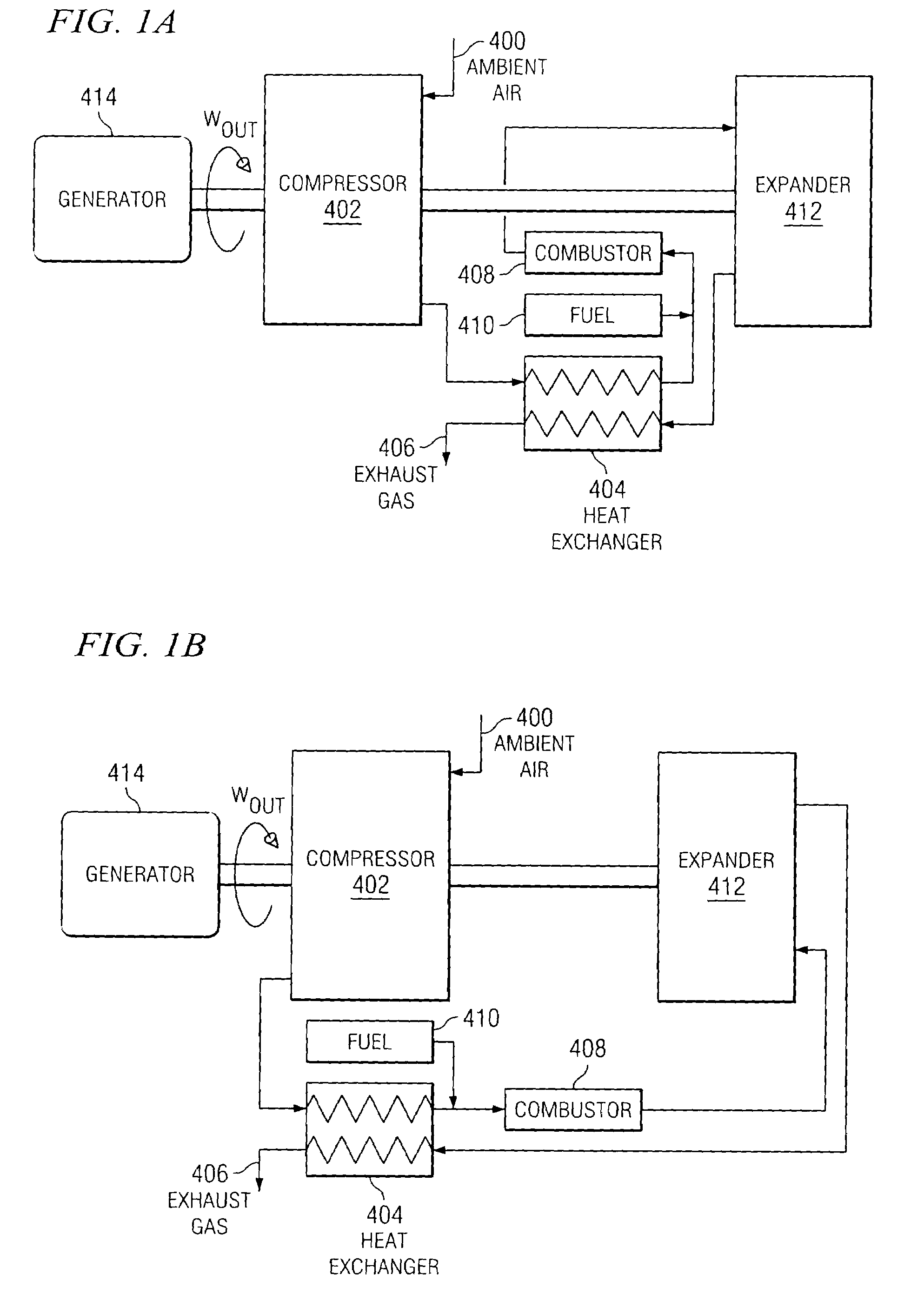

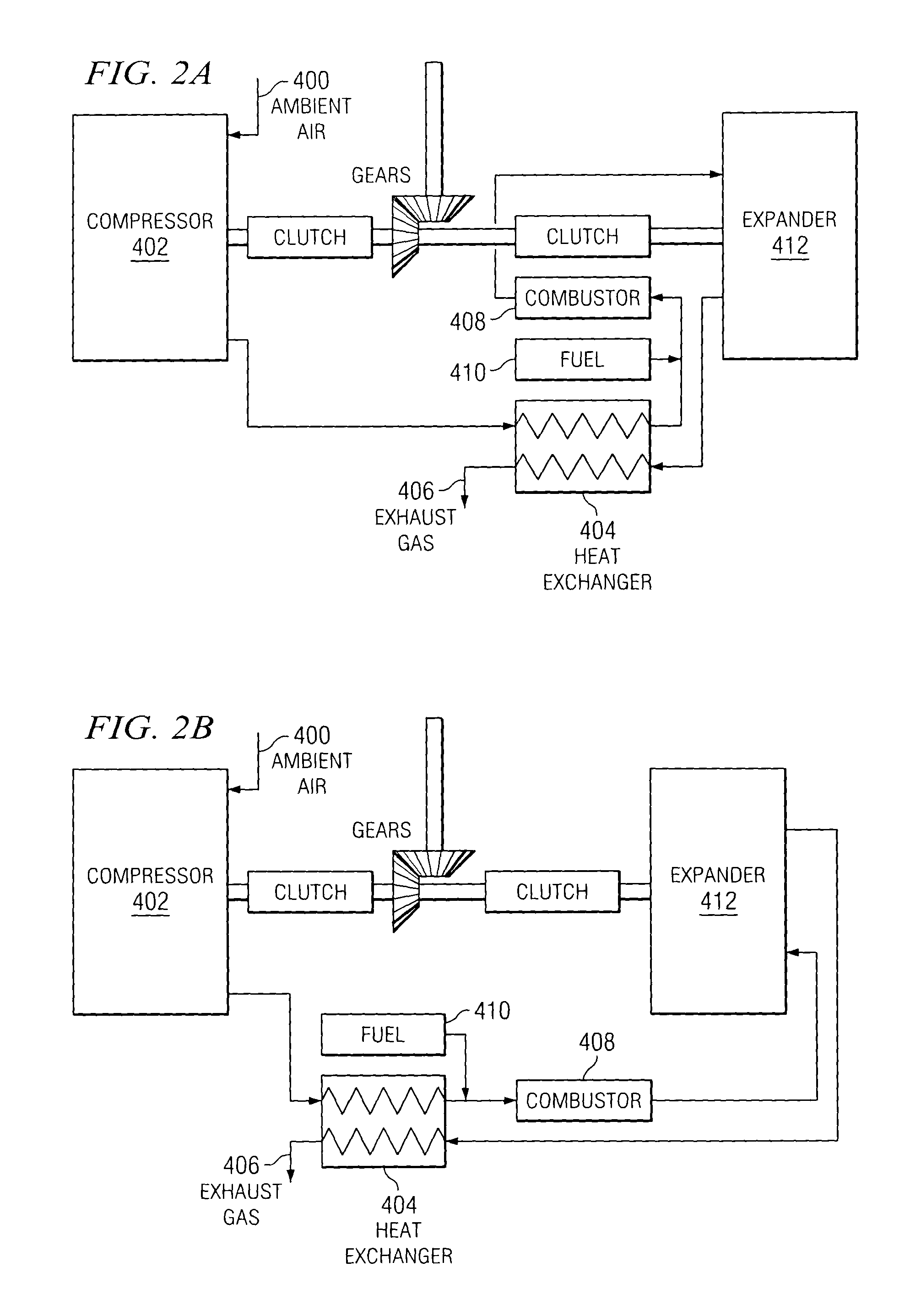

Quasi-isothermal Brayton cycle engine

InactiveUS6336317B1Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesCombination enginesBrayton cycleCombustor

An engine is disclosed. According to one embodiment of the present invention, the engine comprises a compressor, and combustor, and an expander. The compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The expander receives the exhaust gases from the combustor, and expands the exhaust gasses. The compressor may be a gerotor compressor or a piston compressor having variable-dead-volume control. The expander may be a gerotor expander or a piston expander having variable-dead-volume control. In another embodiment, an engine comprises a piston compressor, a combustor, a piston expander, and a pressure tank. The piston compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The piston expander receives the exhaust gasses from the combustor, and expands the exhaust gasses. The pressure tank receives and stores the compressed air from the compressor. In another embodiment, a gerotor compressor or a gerotor expander comprises an inner gerotor, and an outer gerotor. The inner gerotor and the outer gerotor are driven so that they do not touch. The gerotors may be cantilevered or non-cantilevered.

Owner:TEXAS A&M UNIVERSITY

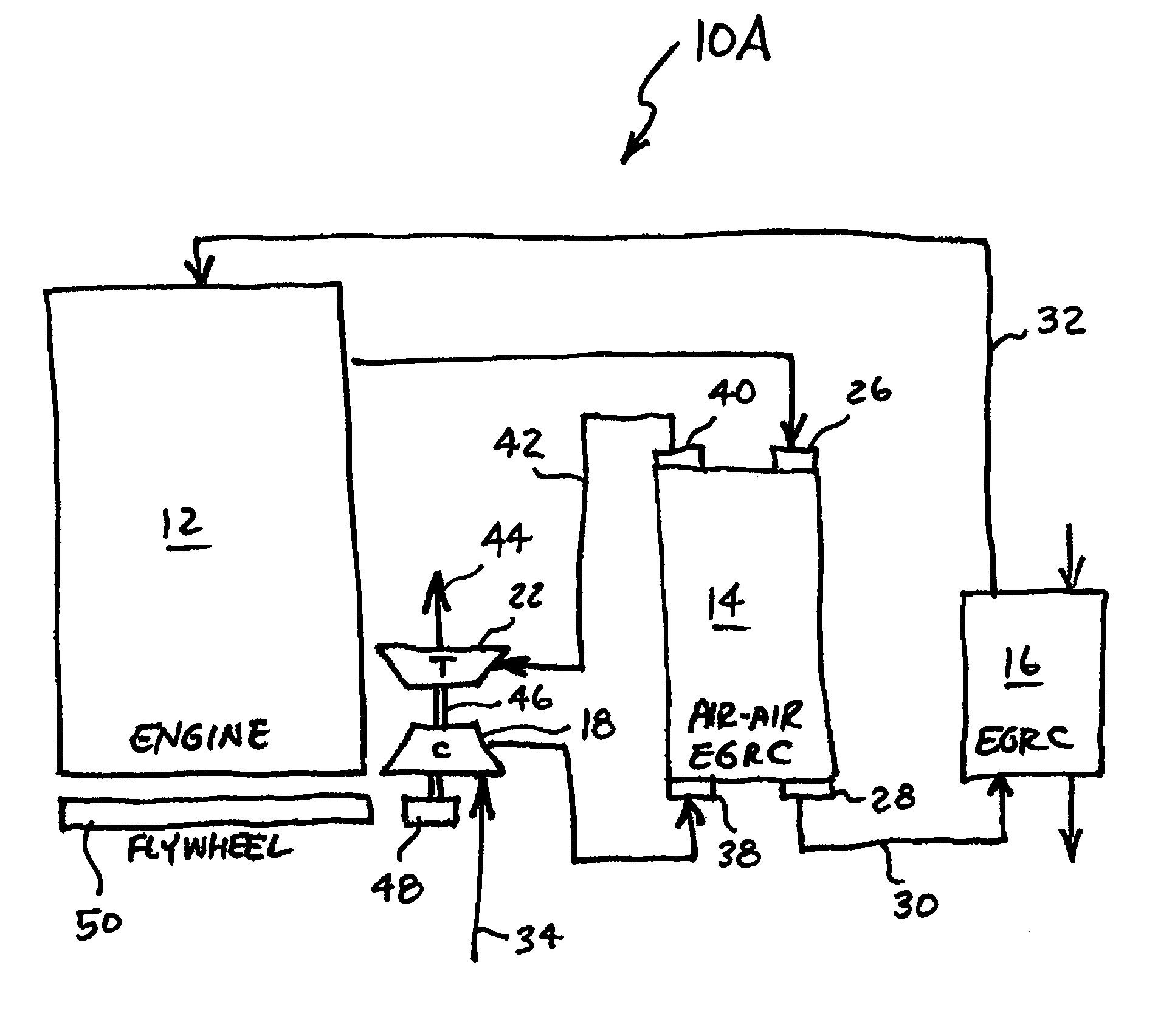

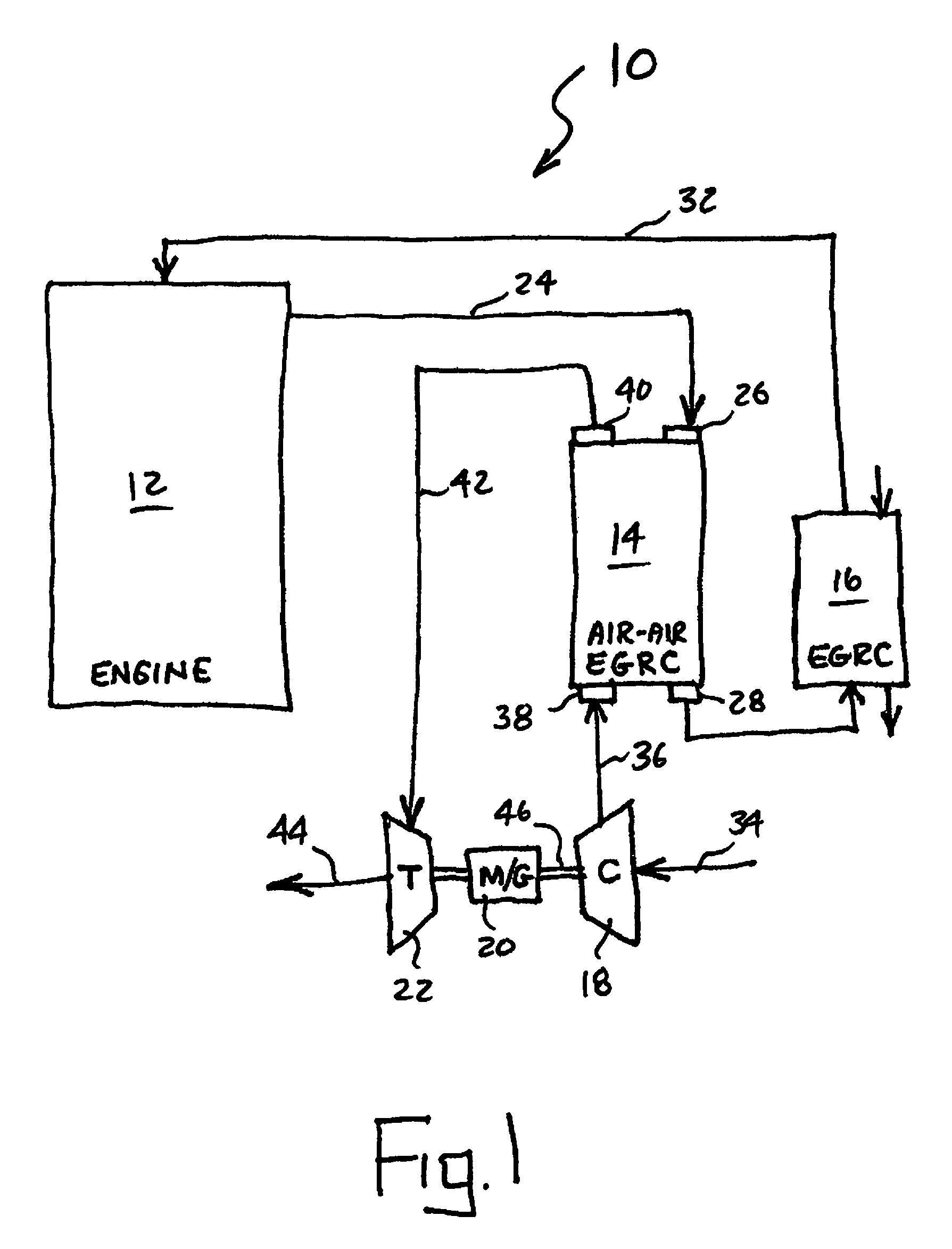

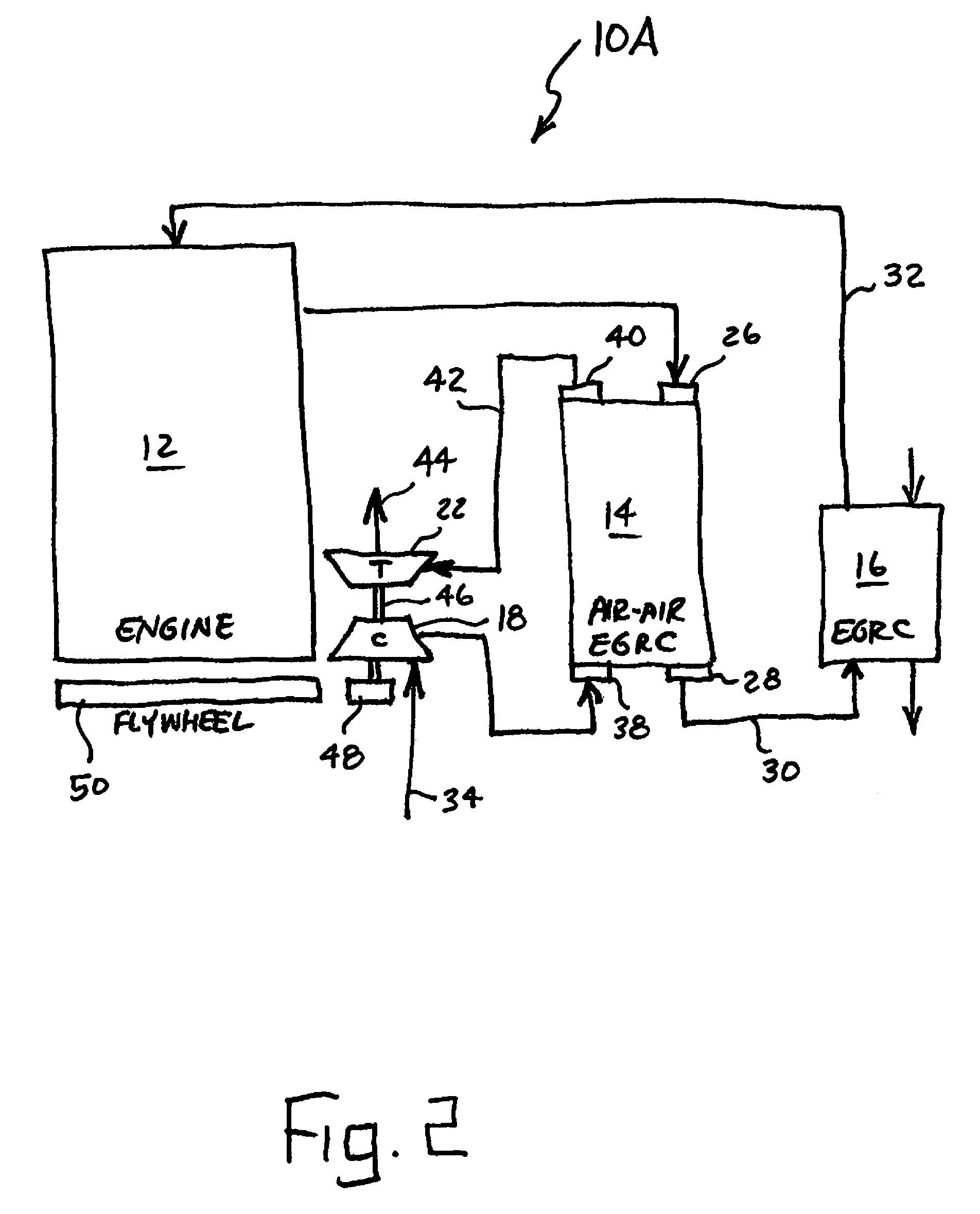

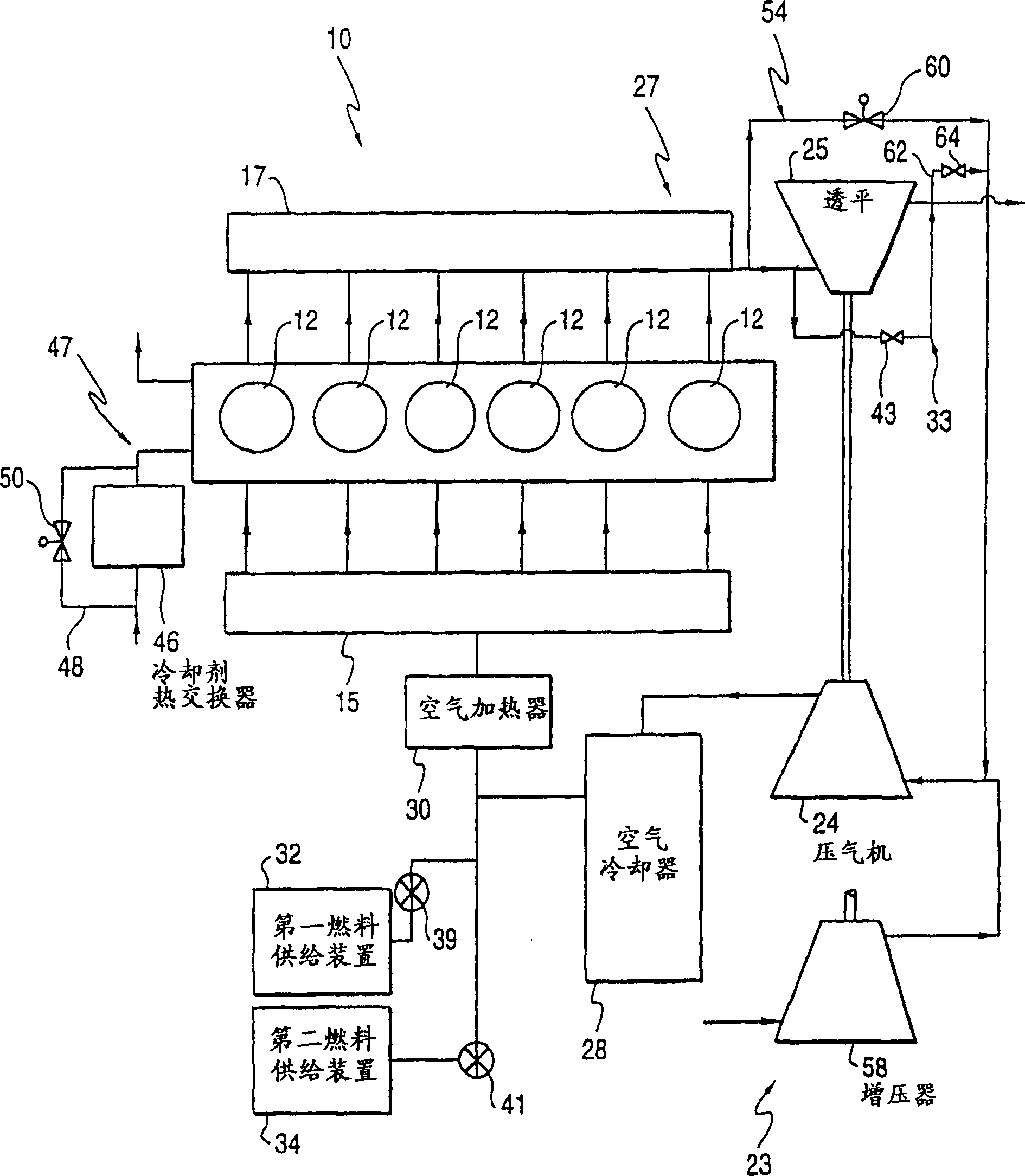

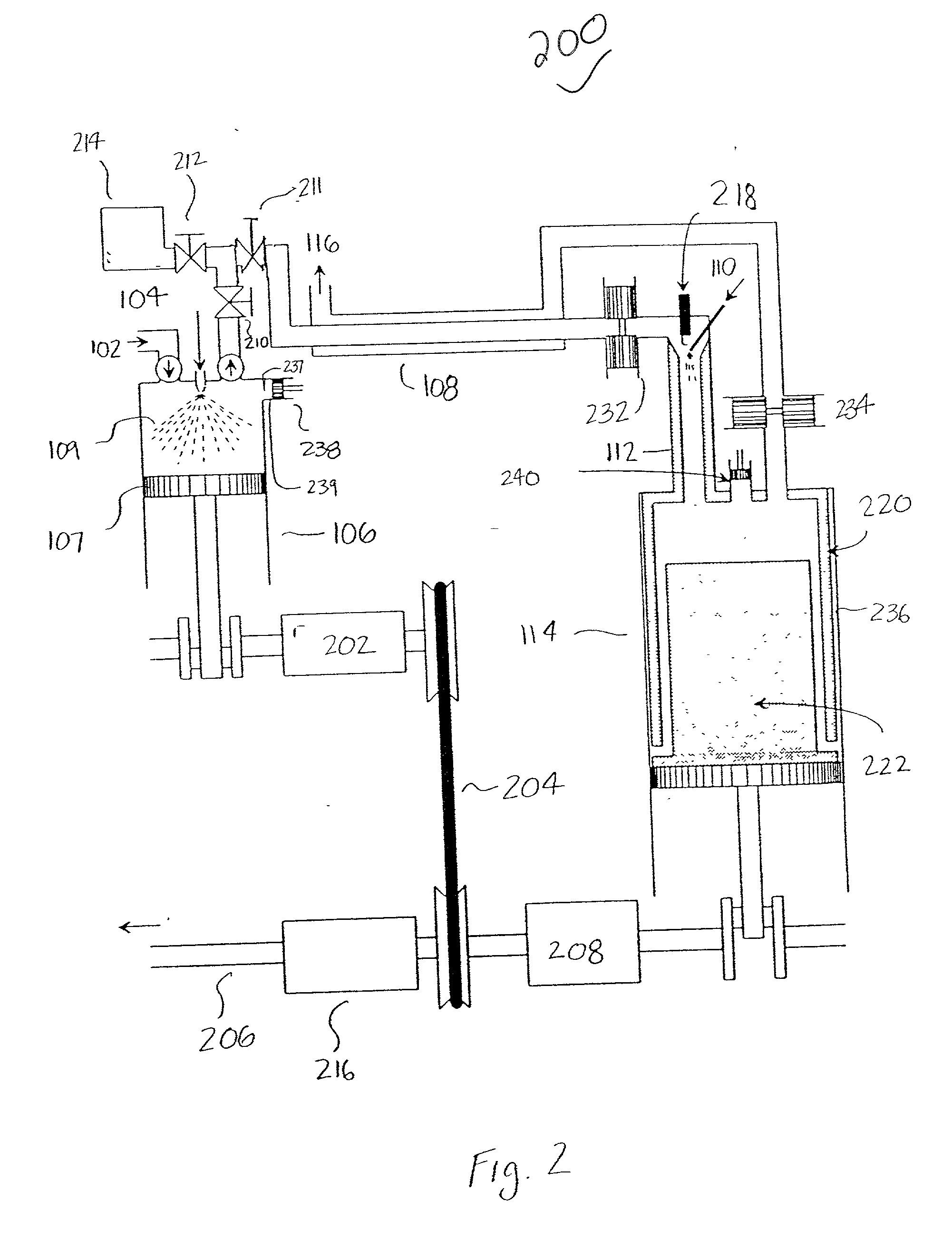

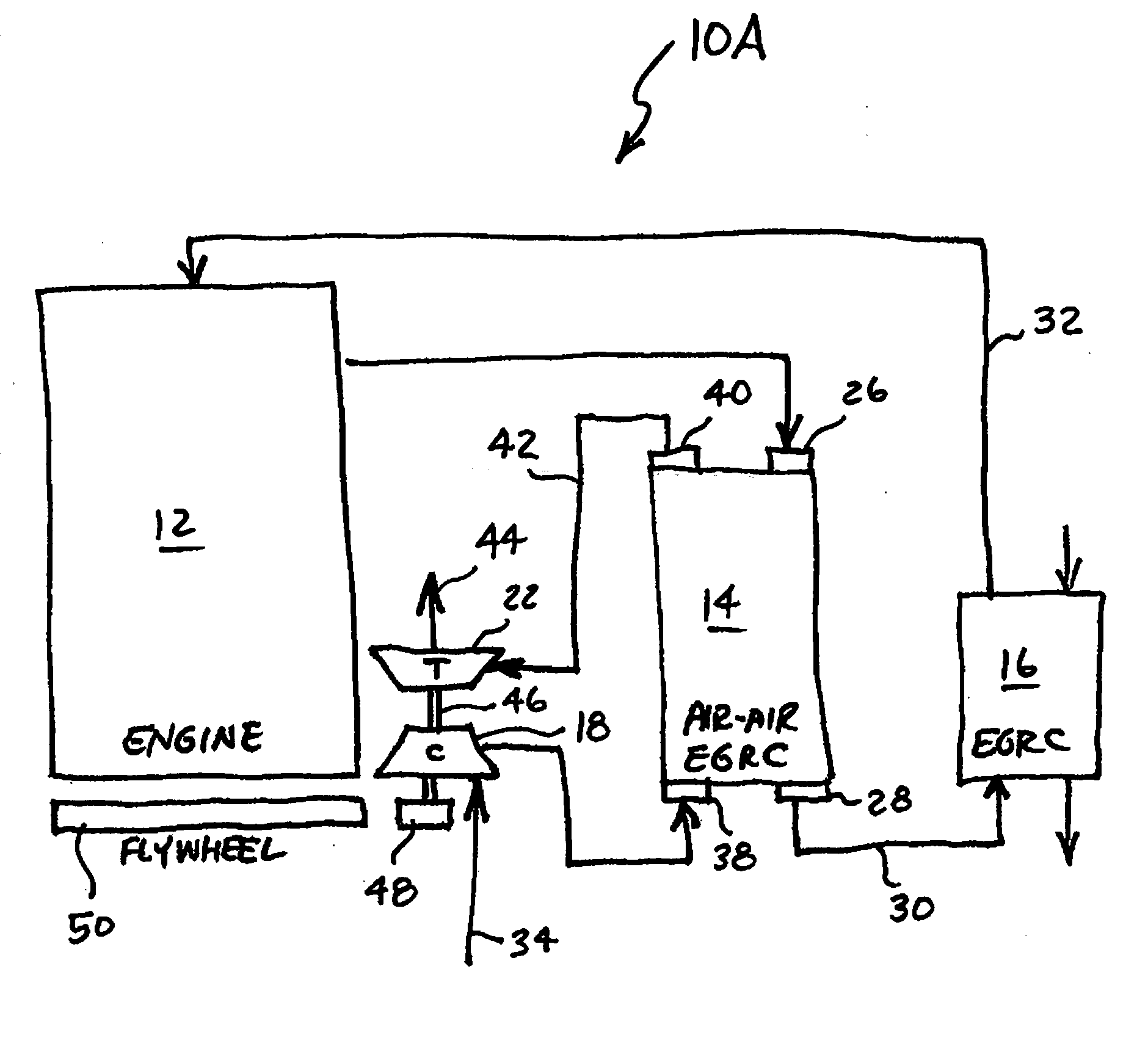

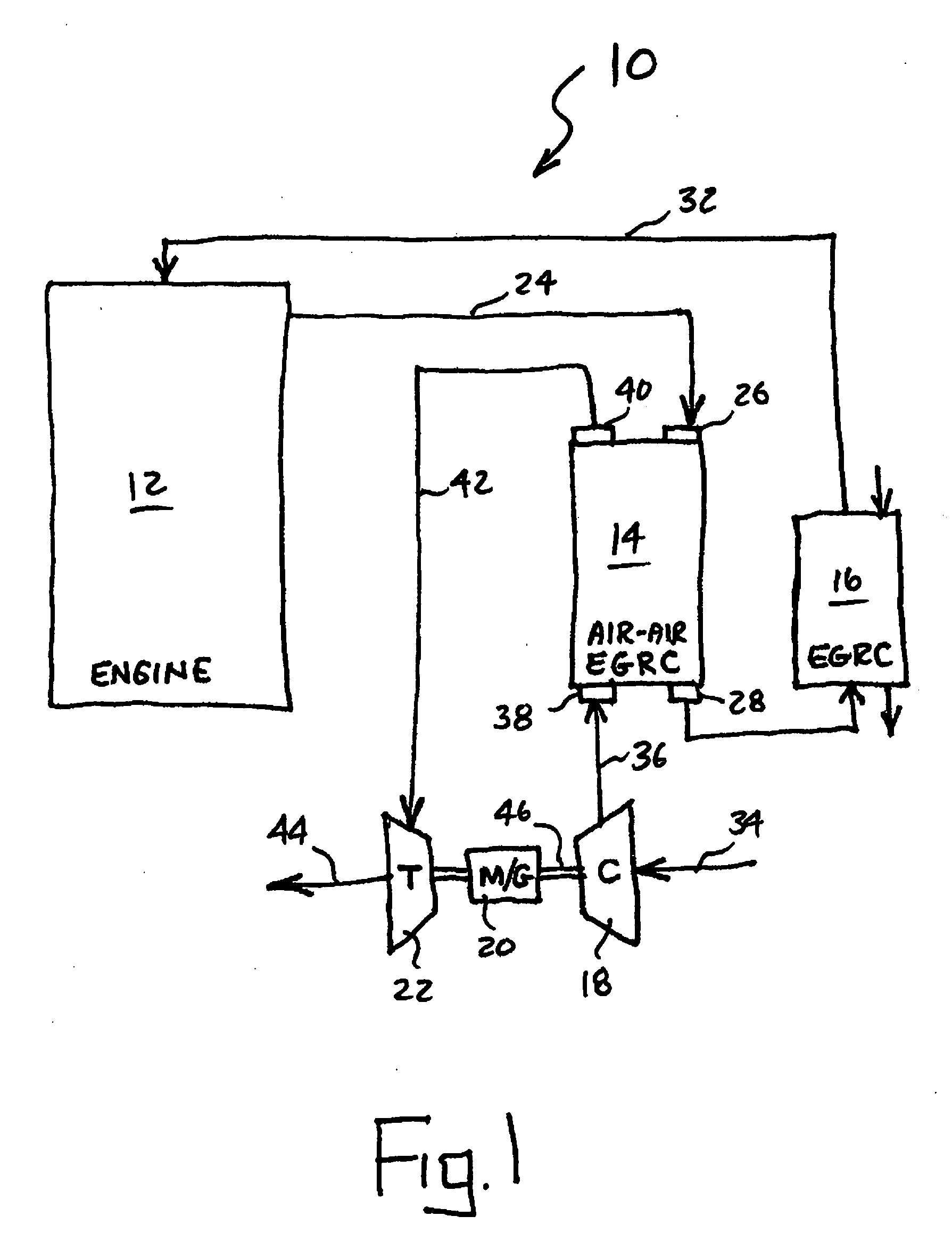

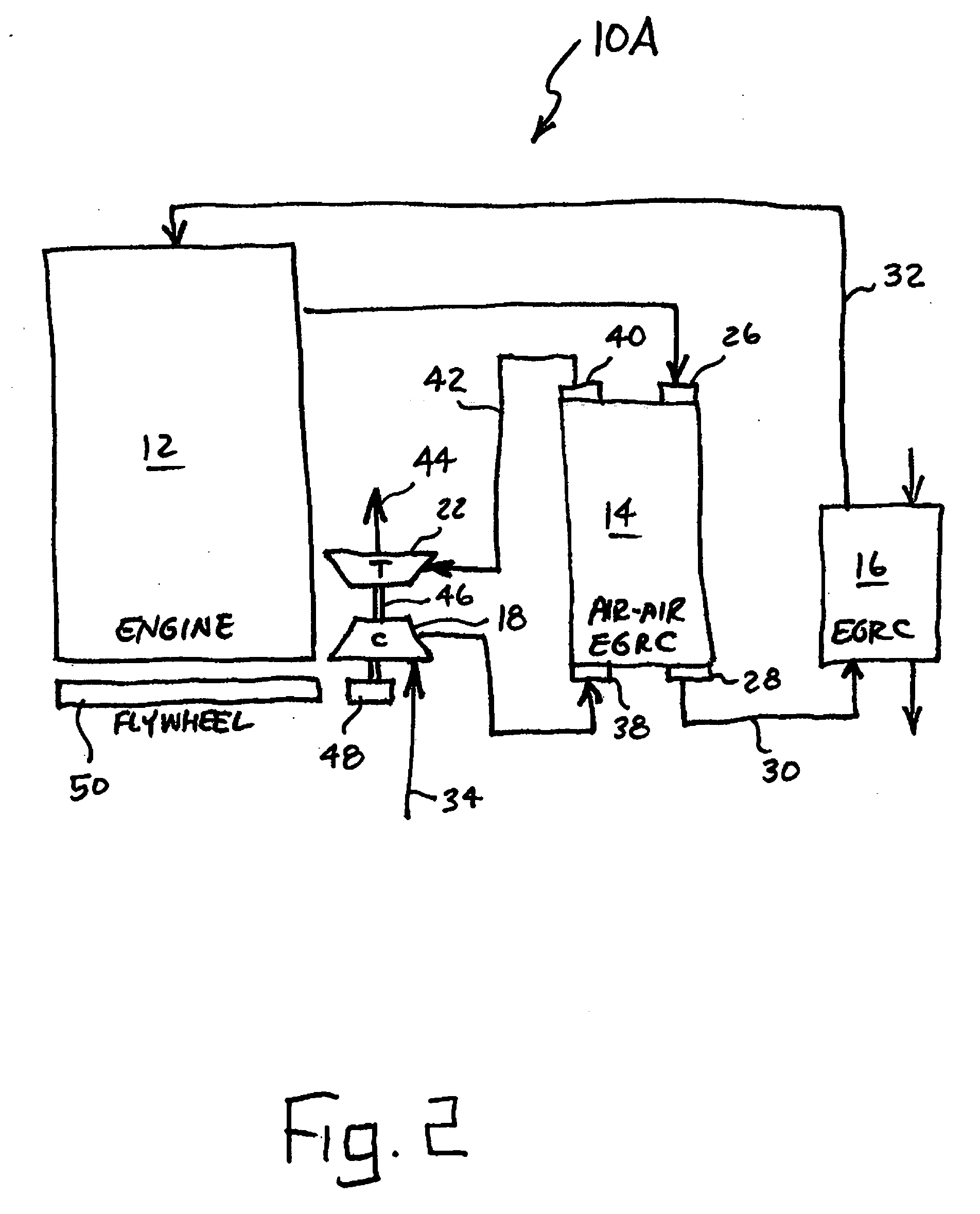

Open loop Brayton cycle for EGR cooling

ActiveUS7958873B2Lower exhaust gas temperatureReduce heat dissipationInternal combustion piston enginesNon-fuel substance addition to fuelBrayton cycleTurbine

A system for reducing the temperature of waste heat from a waste heat source of a vehicle engine, including an open loop Brayton cycle having a cooler, a compressor, a turbine, and a shaft coupling the compressor to the turbine. Waste heat and compressed air from the compressor flow through the cooler, thereby transferring heat from the waste heat to the compressed air and lowering the temperature of the waste heat. The heated and compressed air is expanded across the turbine, to cause rotation of the shaft, thereby powering rotation of the compressor. Excess power beyond that necessary to drive the compressor may be drawn off through a generator which has its rotor mounted on the same shaft as the compressor and turbine.

Owner:CUMMINS INC

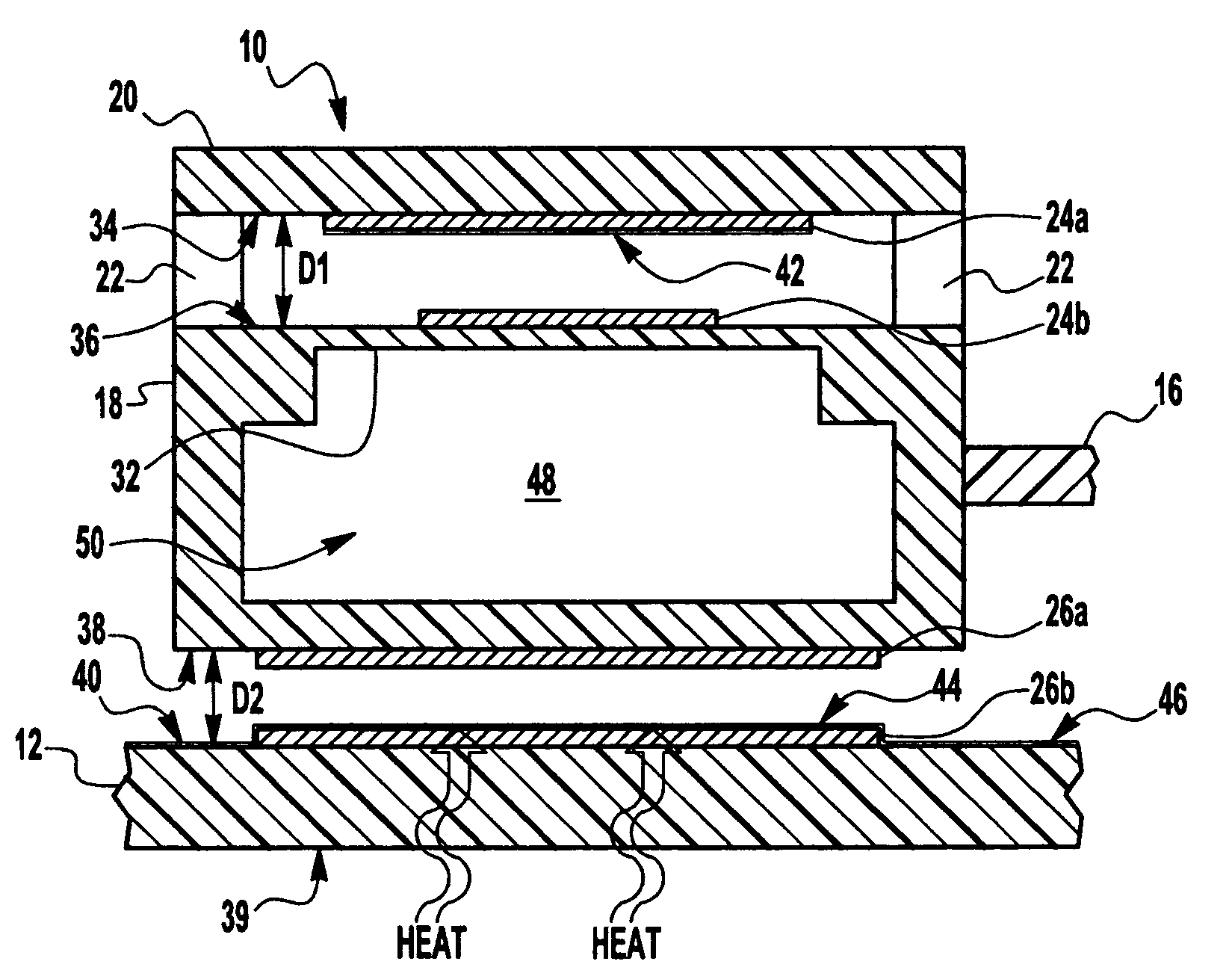

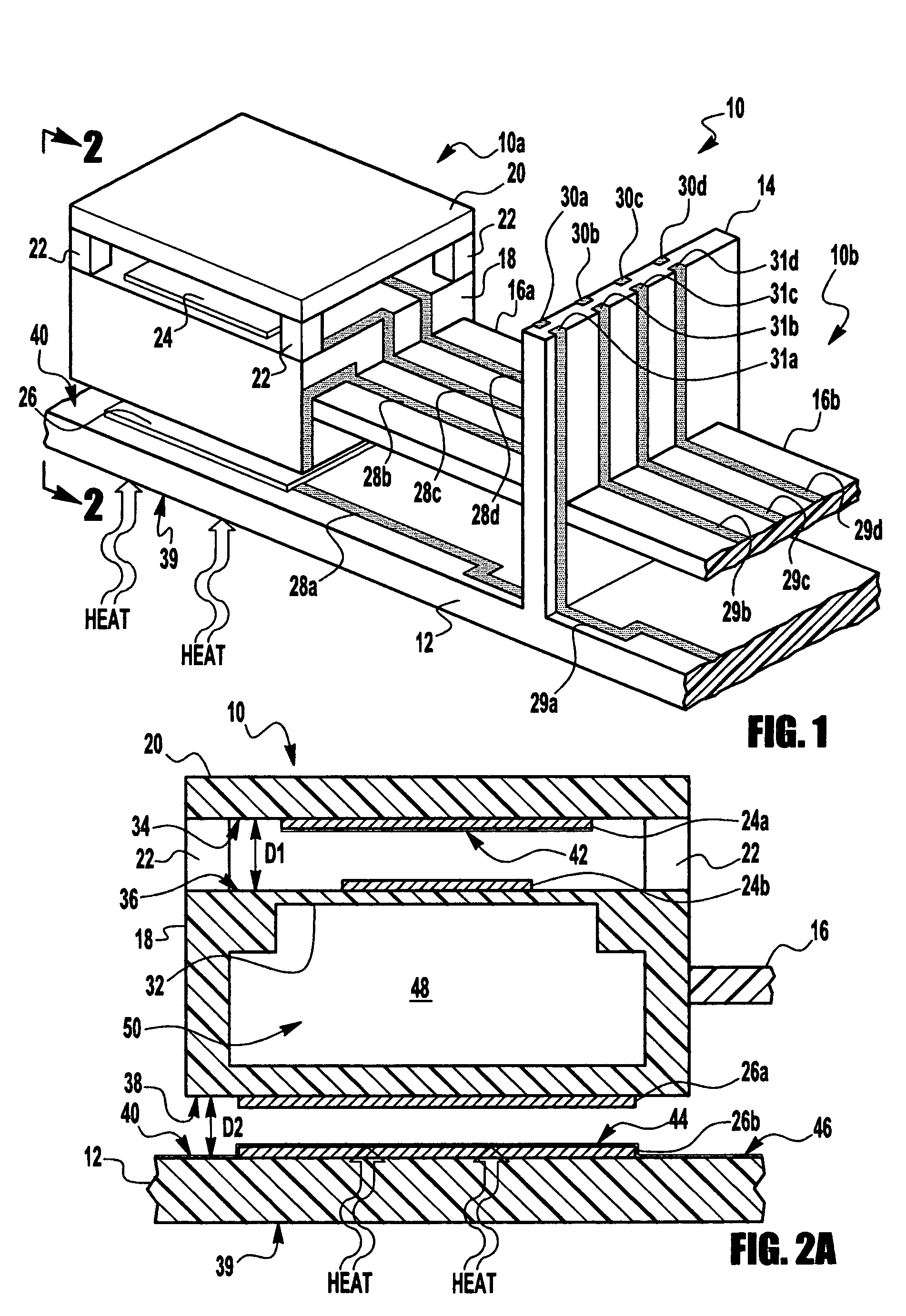

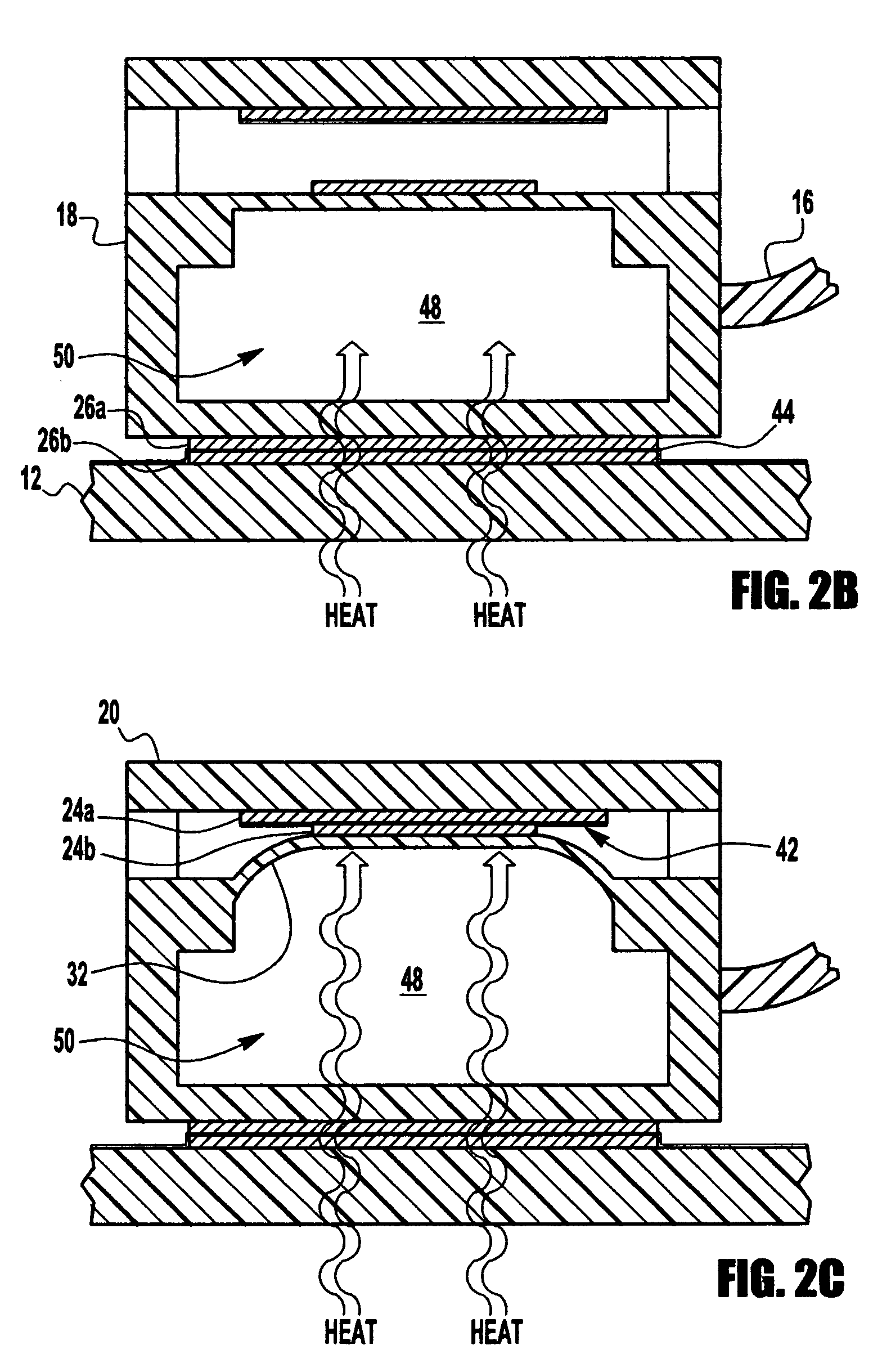

MEMS closed chamber heat engine and electric generator

A heat engine, preferably combined with an electric generator, and advantageously implemented using micro-electromechanical system (MEMS) technologies as an array of one or more individual heat engine / generators. The heat engine is based on a closed chamber containing a motive medium, preferably a gas; means for alternately enabling and disabling transfer of thermal energy from a heat source to the motive medium; and at least one movable side of the chamber that moves in response to thermally-induced expansion and contraction of the motive medium, thereby converting thermal energy to oscillating movement. The electrical generator is combined with the heat engine to utilize movement of the movable side to convert mechanical work to electrical energy, preferably using electrostatic interaction in a generator capacitor. Preferably at least one heat transfer side of the chamber is placed alternately into and out of contact with the heat source by a motion capacitor, thereby alternately enabling and disabling conductive transfer of heat to the motive medium.

Owner:NASA UNITED STATES OF AMERICA THE AS REPRESENTED BY THE ADMINISTATOR

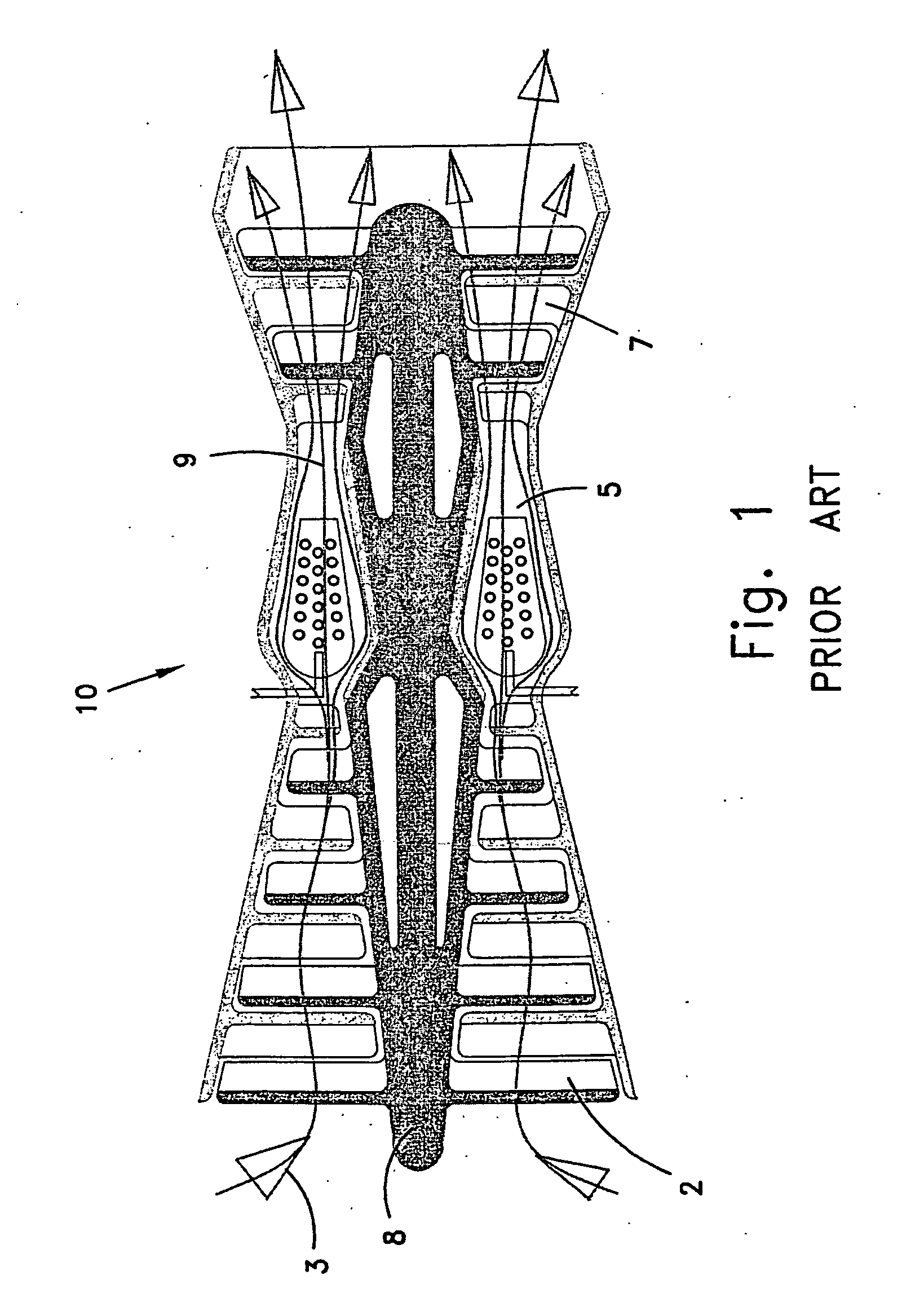

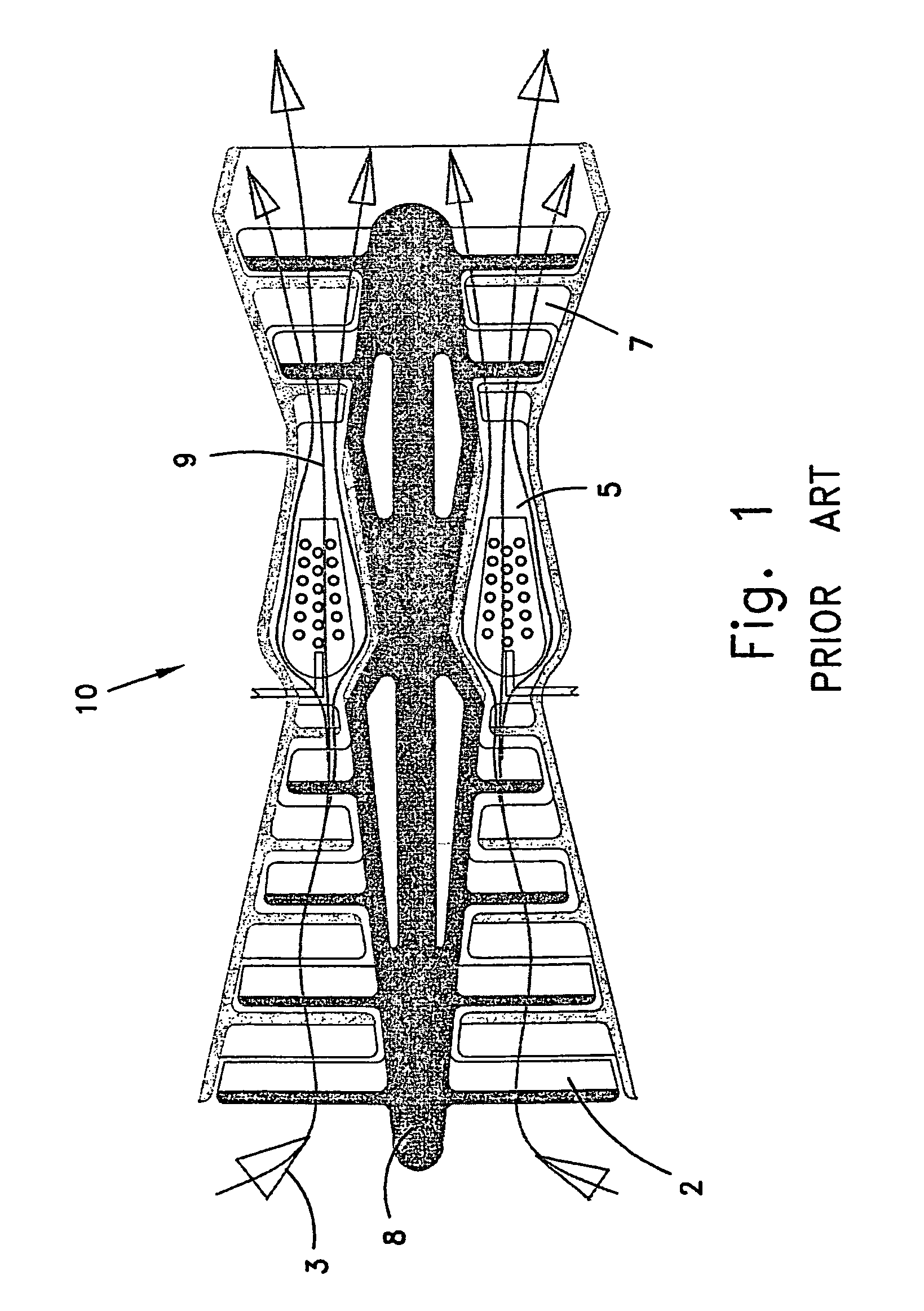

Micro-scalable thermal control device

InactiveUS6385973B1Wide rangeIncrease surface areaCompression machinesRefrigeration componentsThermal energySteady state temperature

A microscalable thermal control module consists of a Stirling cycle cooler that can be manipulated to operate at a selected temperature within the heating and cooling range of the module. The microscalable thermal control module is particularly suited for controlling the temperature of devices that must be maintained at precise temperatures. It is particularly suited for controlling the temperature of devices that need to be alternately heated or cooled. The module contains upper and lower opposing diaphragms, with a regenerator region containing a plurality of regenerators interposed between the diaphragms. Gaps exist on each side of each diaphragm to permit it to oscillate freely. The gap on the interior side one diaphragm is in fluid connection with the gap on the interior side of the other diaphragm through regenerators. As the diaphragms oscillate working gas is forced through the regenerators. The surface area of each regenerator is sufficiently large to effectively transfer thermal energy to and from the working gas as it is passed through them. The phase and amplitude of the oscillations can be manipulated electronically to control the steady state temperature of the active thermal control surface, and to switch the operation of the module from cooling to heating, or vice versa. The ability of the microscalable thermal control module to heat and cool may be enhanced by operating a plurality of modules in series, in parallel, or in connection through a shared bottom layer.

Owner:NAT AERONAUTICS & SPACE ADMININSTRATION UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC

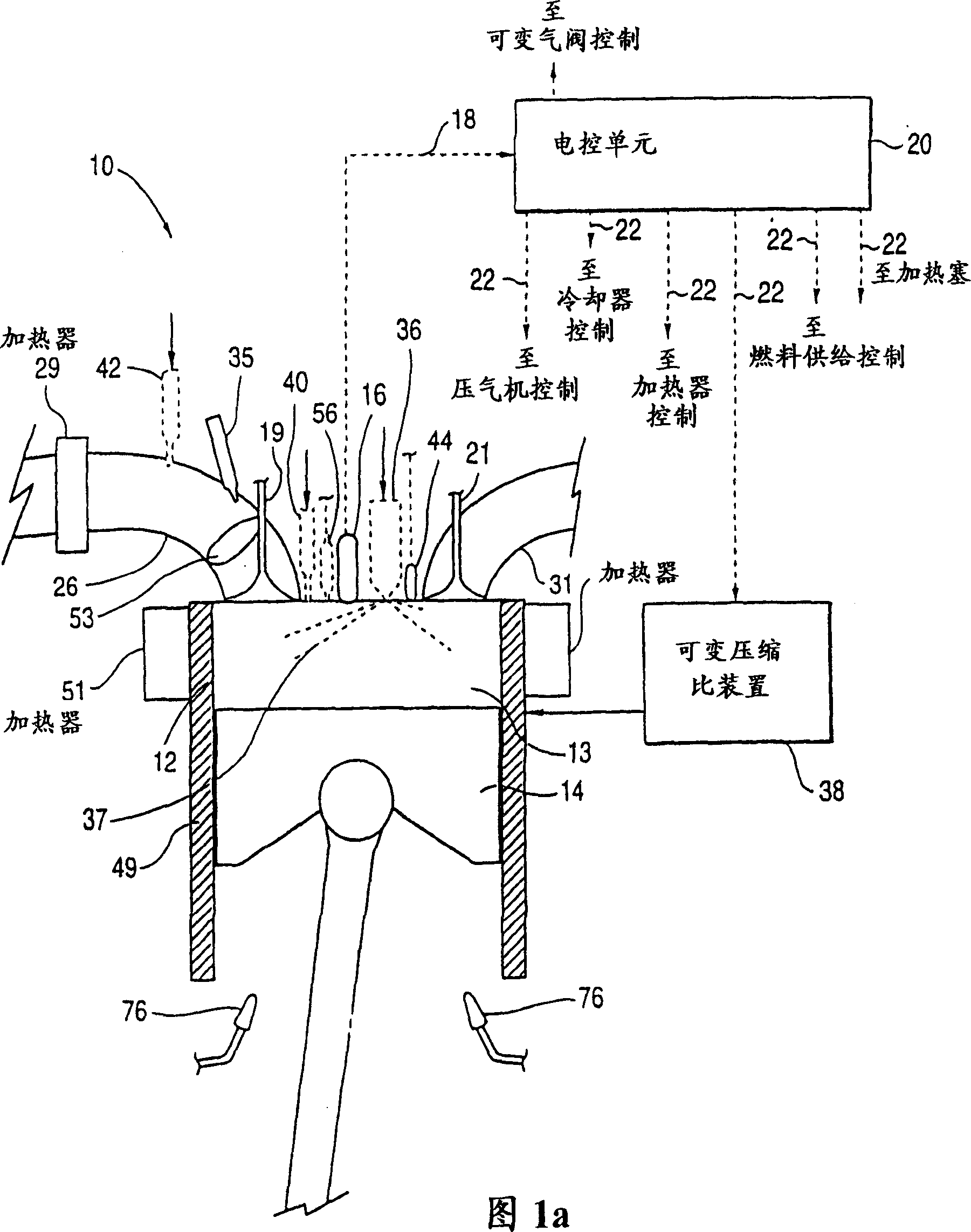

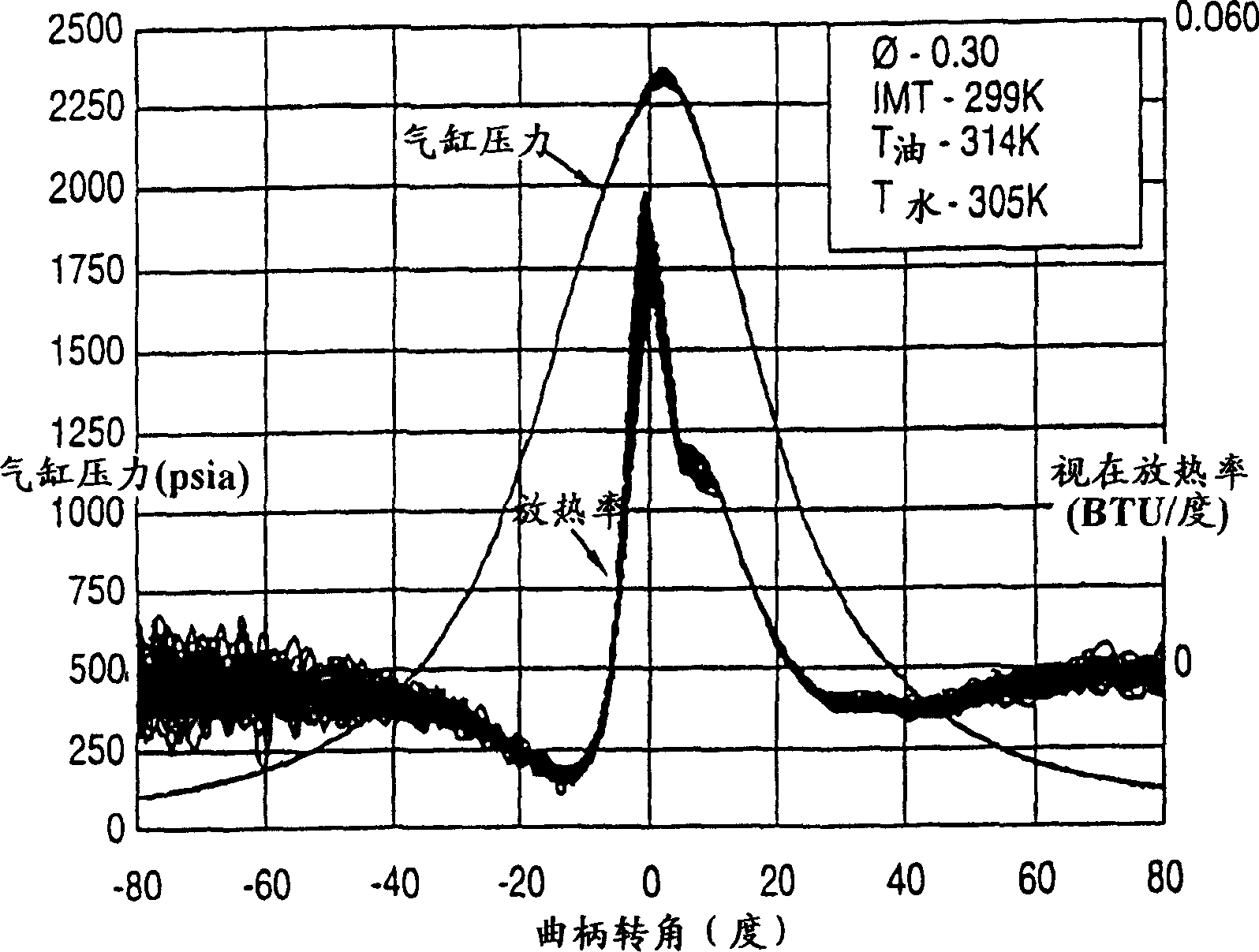

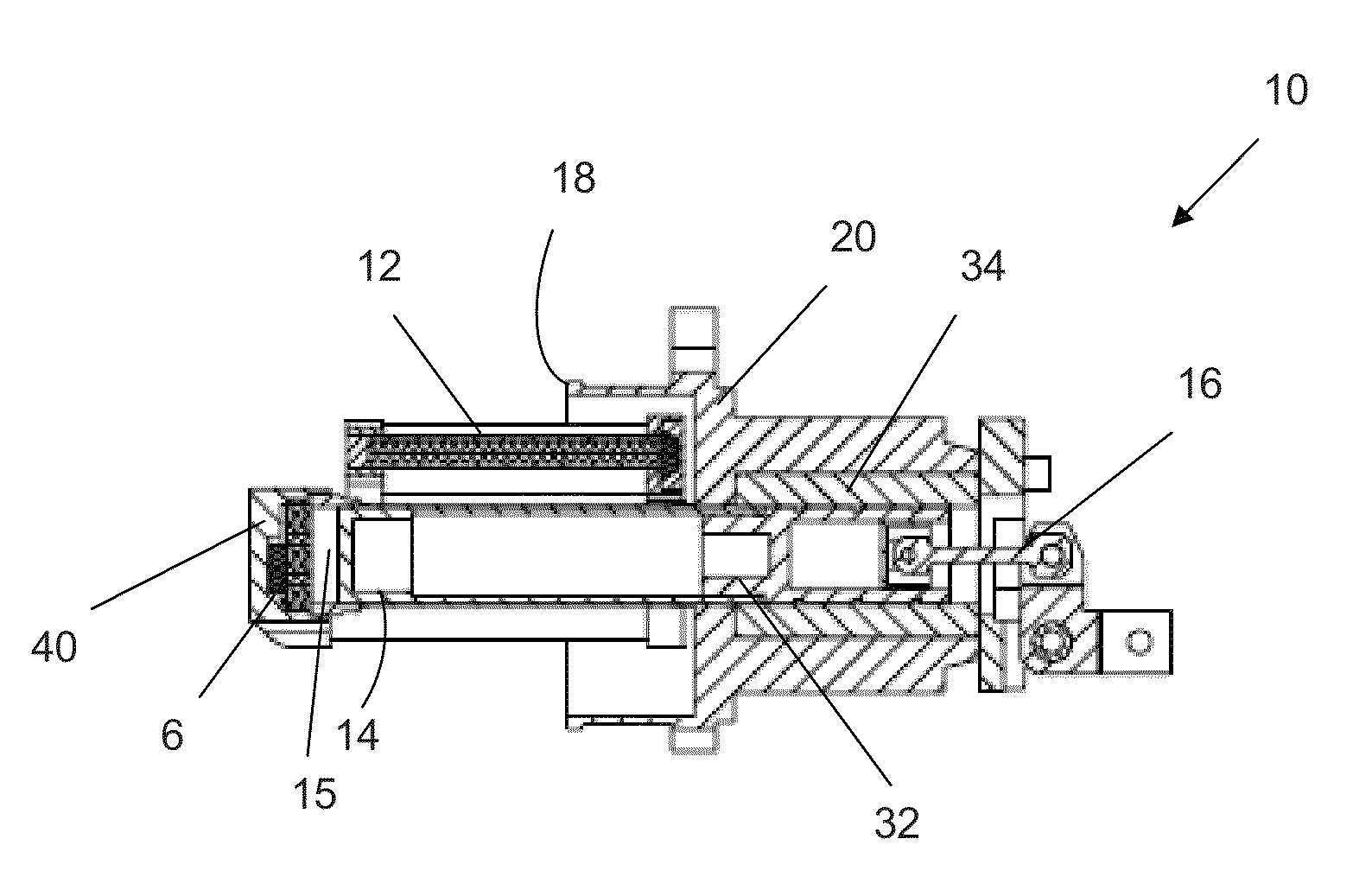

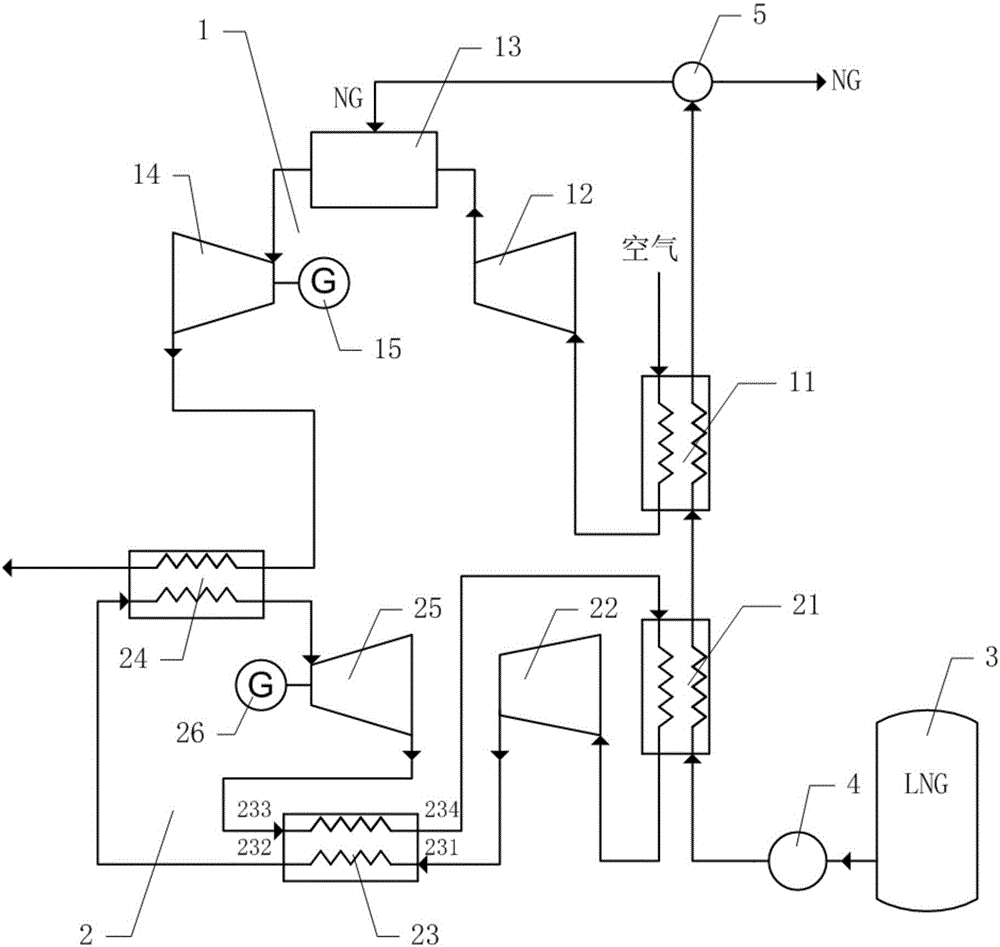

Premixed charge compression ignition engine with optimal combustion control

InactiveCN1624305AControl control systemEffective controlElectrical controlInternal combustion piston enginesTemperature controlActive feedback

The present invention provides a premixed charge compression ignition engine and control system (10), which can effectively trigger combustion and maintain stable combustion by means of compression ignition, while achieving extremely low nitrogen oxide emissions, good overall efficiency and Acceptable combustion noise and cylinder pressure. The engine and control system (10) of the present invention can effectively control the combustion process by controlling certain control variables of temperature control, pressure control, mixture self-ignitability control and equivalence ratio control, that is, the time of combustion initiation, the combustion rate , duration of combustion and / or completeness of combustion. The combustion control system (10) provides active feedback control of combustion and includes a sensor for detecting engine operating conditions representative of a combustion process, such as ignition of combustion, and generating a corresponding engine operating condition signal (18) , such as the pressure sensor (16).

Owner:CUMMINS INC

Quasi-Isothermal brayton cycle engine

InactiveUS20020014069A1Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesCombination enginesBrayton cycleCombustor

An engine is disclosed. According to one embodiment of the present invention, the engine comprises a compressor, and combustor, and an expander. The compressor compresses ambient air. The combustor bums the compressed air, and produces exhaust gasses. The expander receives the exhaust gases from the combustor, and expands the exhaust gasses. The compressor may be a gerotor compressor or a piston compressor having variable-dead-volume control. The expander may be a gerotor expander or a piston expander having variable-dead-volume control. In another embodiment, an engine comprises a piston compressor, a combustor, a piston expander, and a pressure tank. The piston compressor compresses ambient air. The combustor bums the compressed air, and produces exhaust gasses. The piston expander receives the exhaust gasses from the combustor, and expands the exhaust gasses. The pressure tank receives and stores the compressed air from the compressor. In another embodiment, a gerotor compressor or a gerotor expander comprises an inner gerotor, and an outer gerotor. The inner gerotor and the outer gerotor are driven so that they do not touch. The gerotors may be cantilevered or non-cantilevered.

Owner:HOLTZAPPLE MARK T +1

Open loop Brayton cycle for EGR cooling

ActiveUS20090277430A1Lower exhaust gas temperatureReduce system capacityNon-fuel substance addition to fuelInternal combustion piston enginesBrayton cycleTurbine

A system for reducing the temperature of waste heat from a waste heat source of a vehicle engine, including an open loop Brayton cycle having a cooler, a compressor, a turbine, and a shaft coupling the compressor to the turbine. Waste heat and compressed air from the compressor flow through the cooler, thereby transferring heat from the waste heat to the compressed air and lowering the temperature of the waste heat. The heated and compressed air is expanded across the turbine, to cause rotation of the shaft, thereby powering rotation of the compressor. Excess power beyond that necessary to drive the compressor may be drawn off through a generator which has its rotor mounted on the same shaft as the compressor and turbine.

Owner:CUMMINS INC

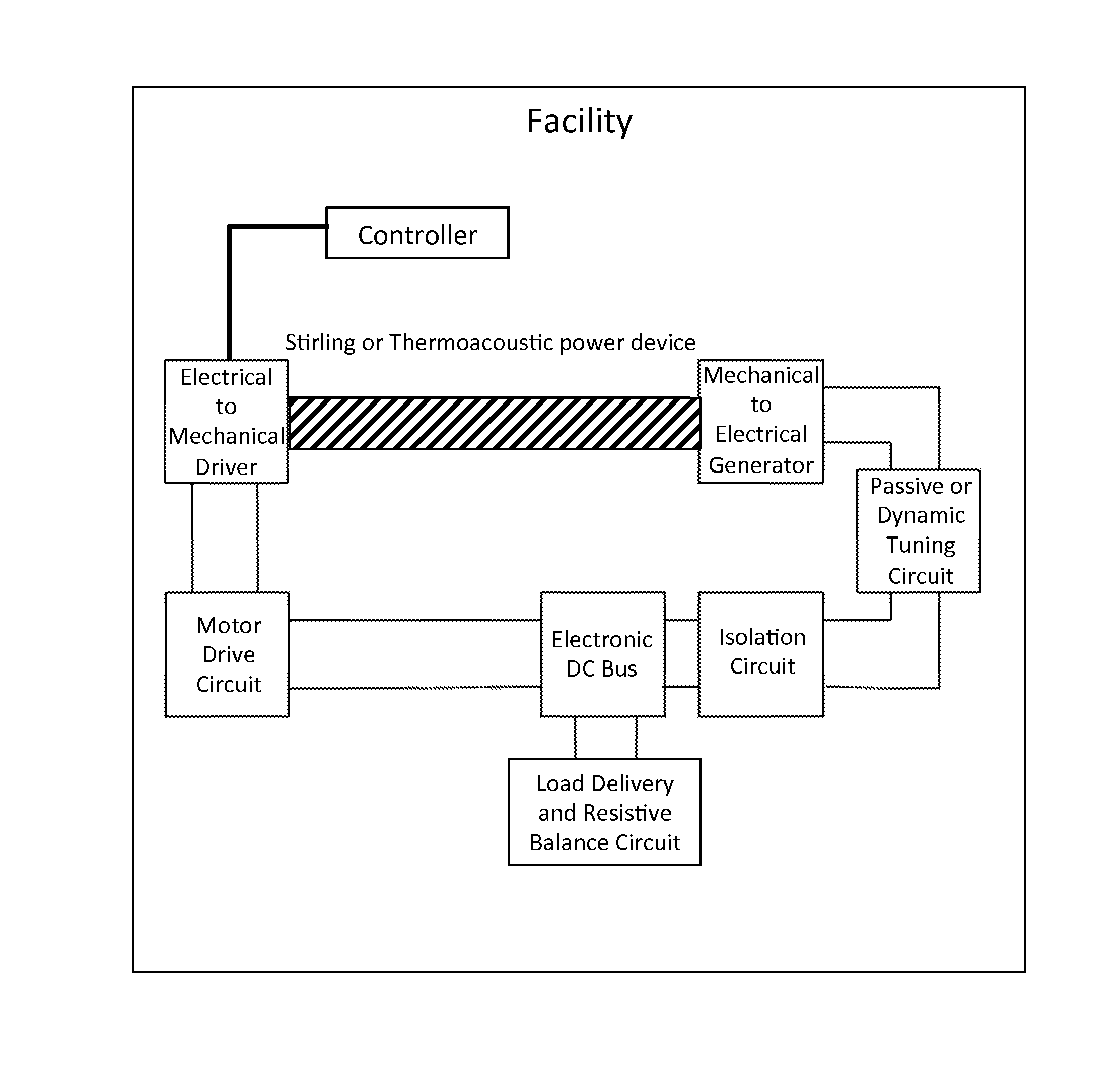

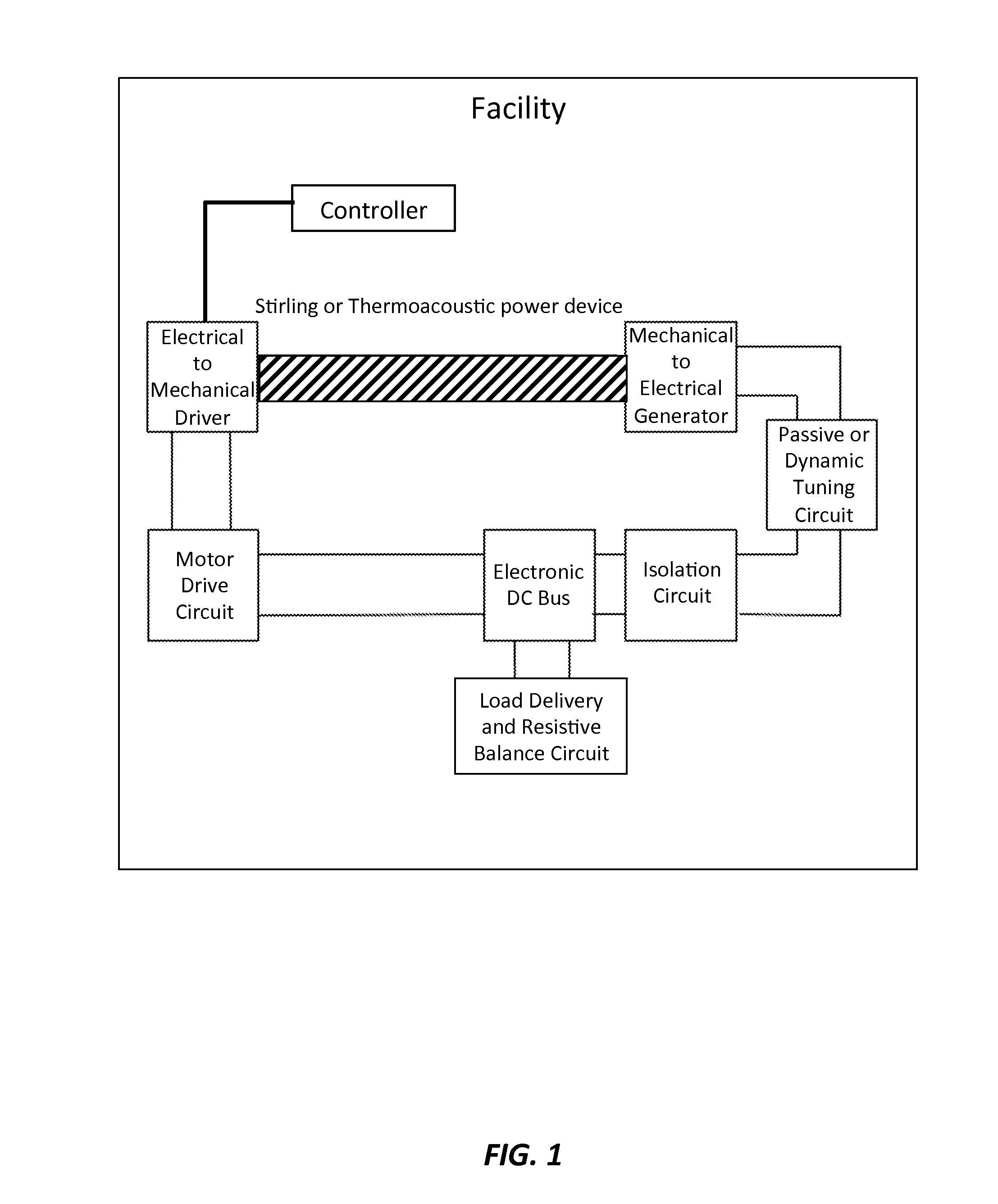

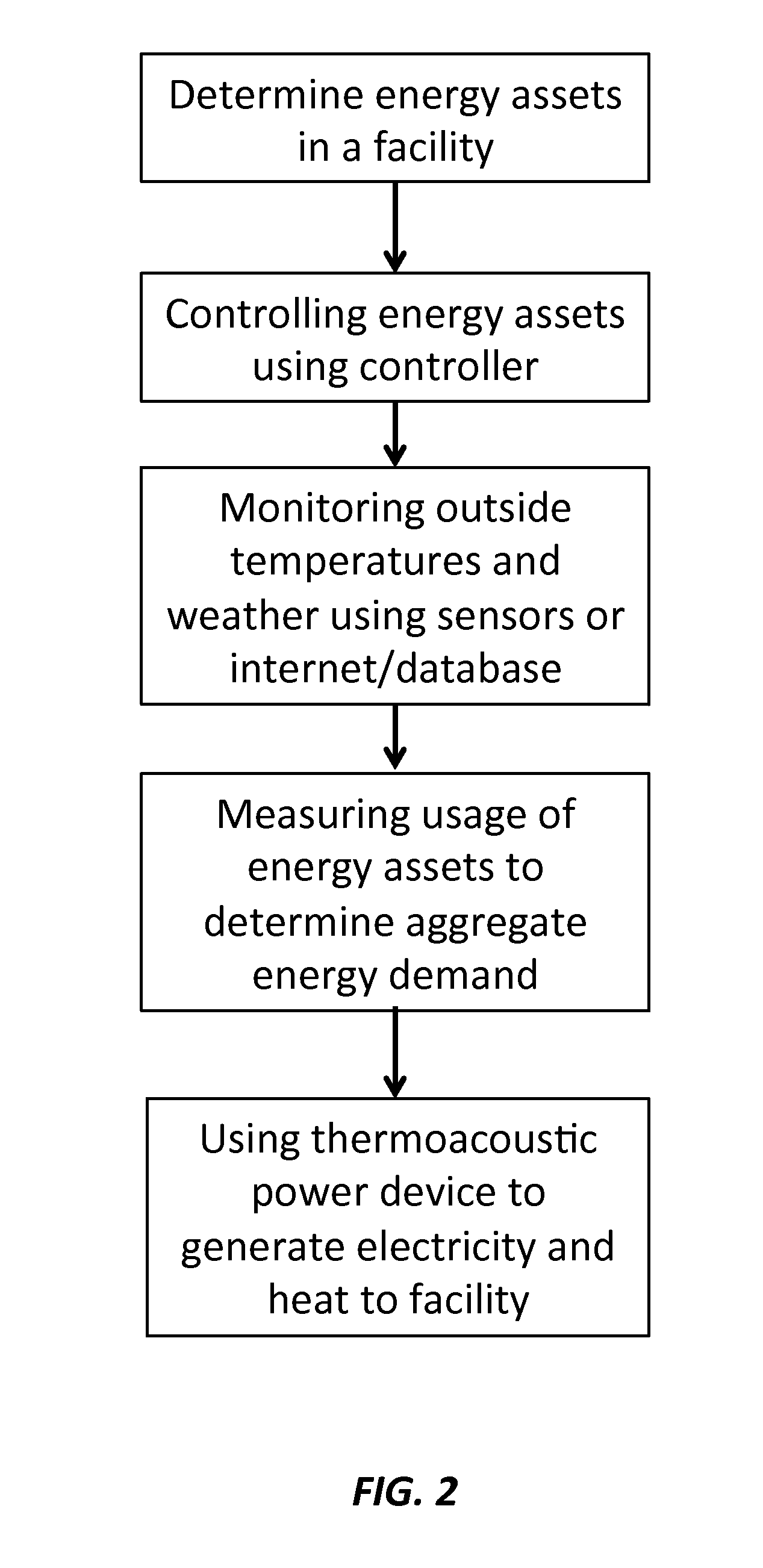

Secure Control System for Multistage Thermo Acoustic Micro-CHP Generator

ActiveUS20160146153A1Improve efficiencyStirling type enginesEngine fuctionsElectricityProcess engineering

A method of controlling facility power requirements using a thermoacoustic power device is provided that includes determining energy assets in a facility, controlling the energy assets using an appropriately programmed controller across a network having a security system protocol, monitoring outside temperatures and weather, measuring usage of the energy assets using a temperature sensor or an electrical usage sensor to a load-response signal of an on / off operation and usage of the energy assets to identify a specific energy asset by the controller to determine aggregate energy needs of the energy assets, and using a thermoacoustic power device controlled by the controller to generate electricity and heat according to the monitored temperature, weather and energy assets.

Owner:NIRVANA ENERGY SYST

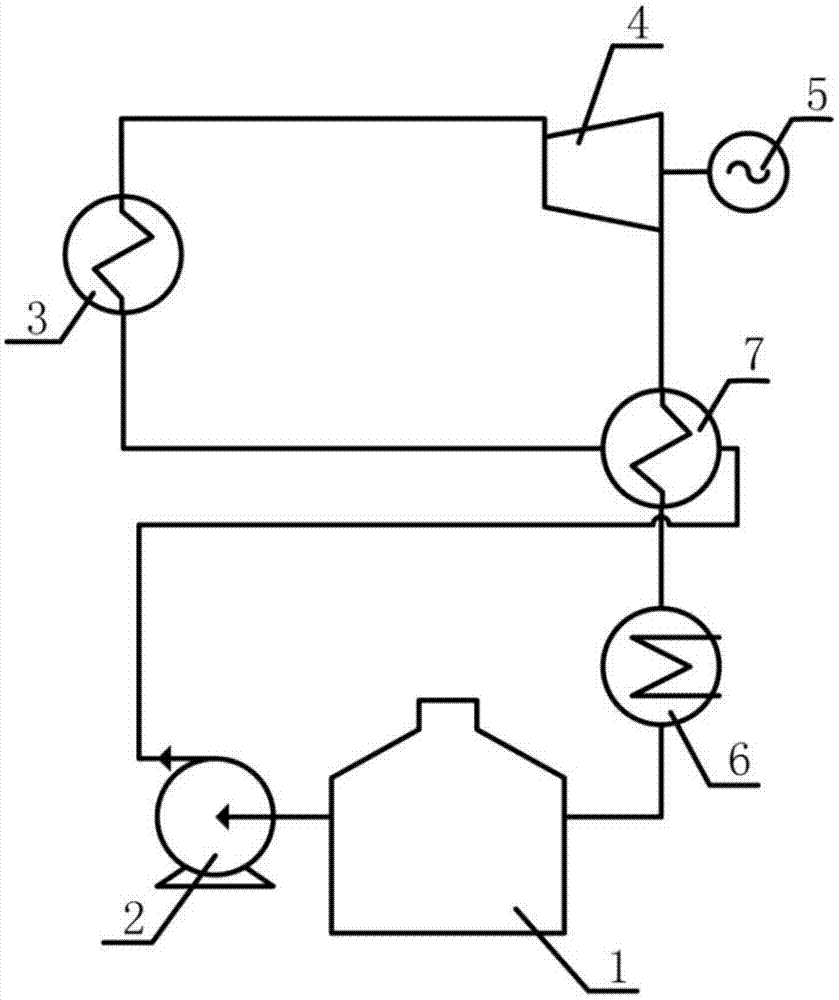

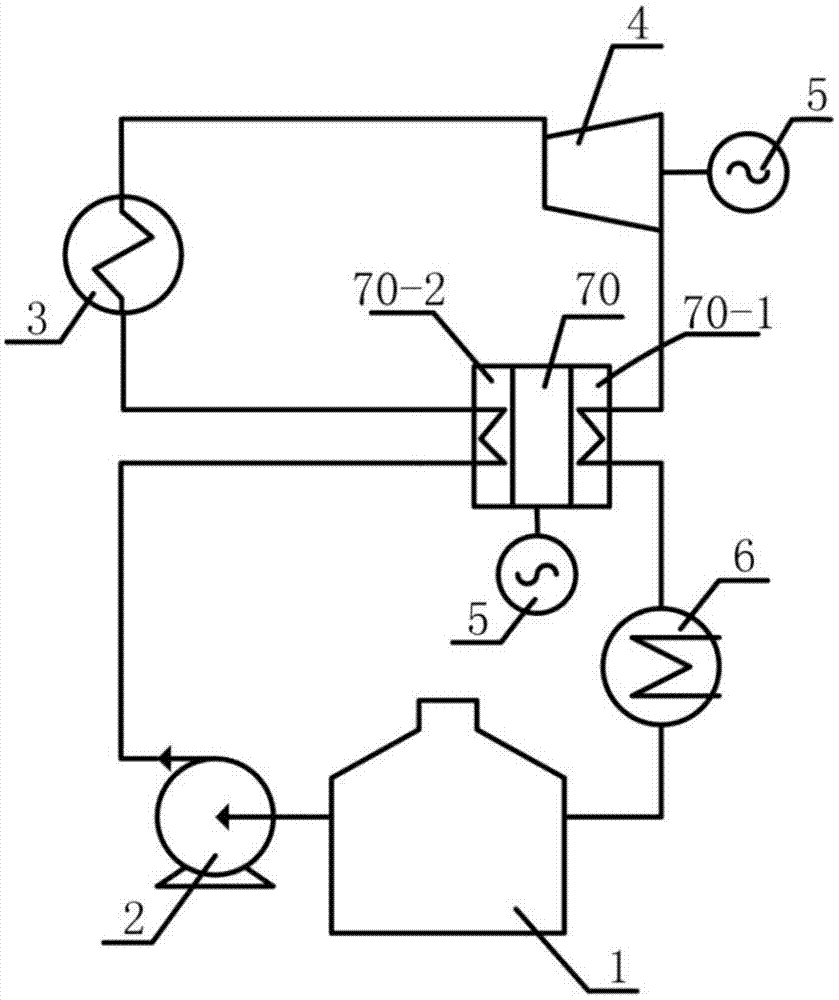

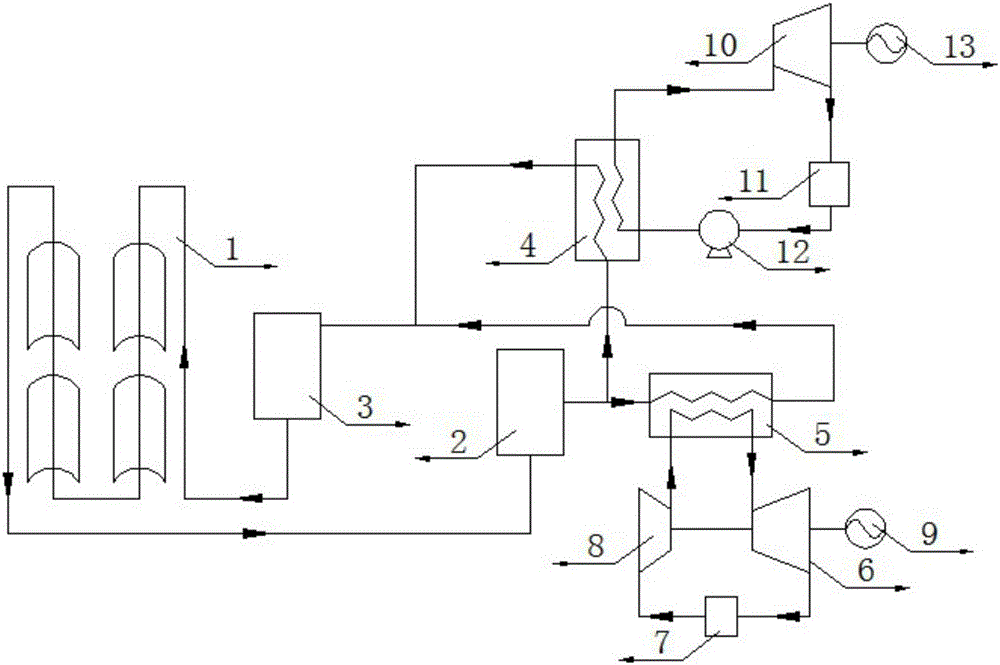

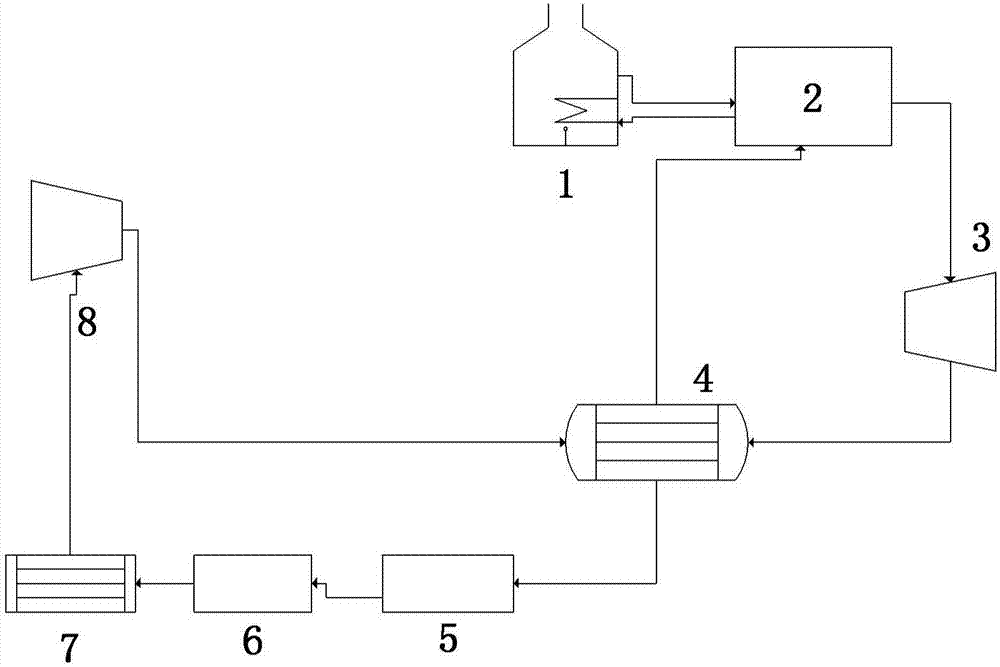

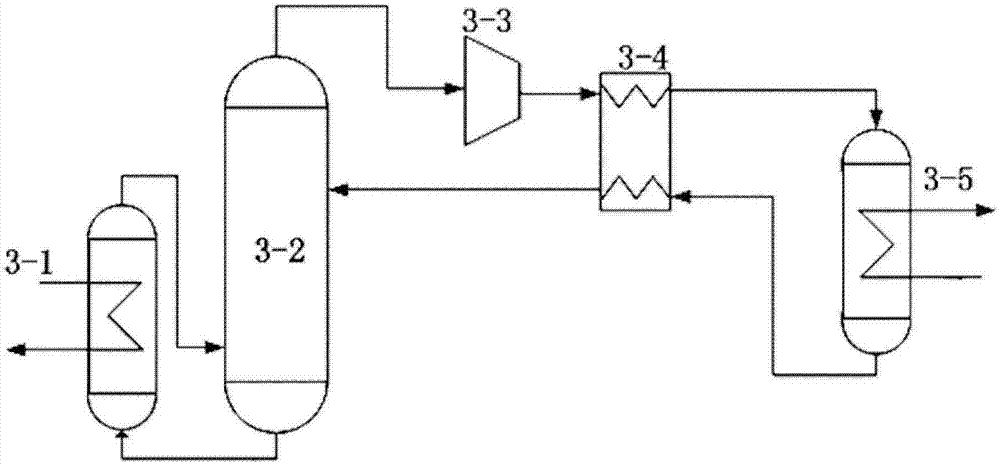

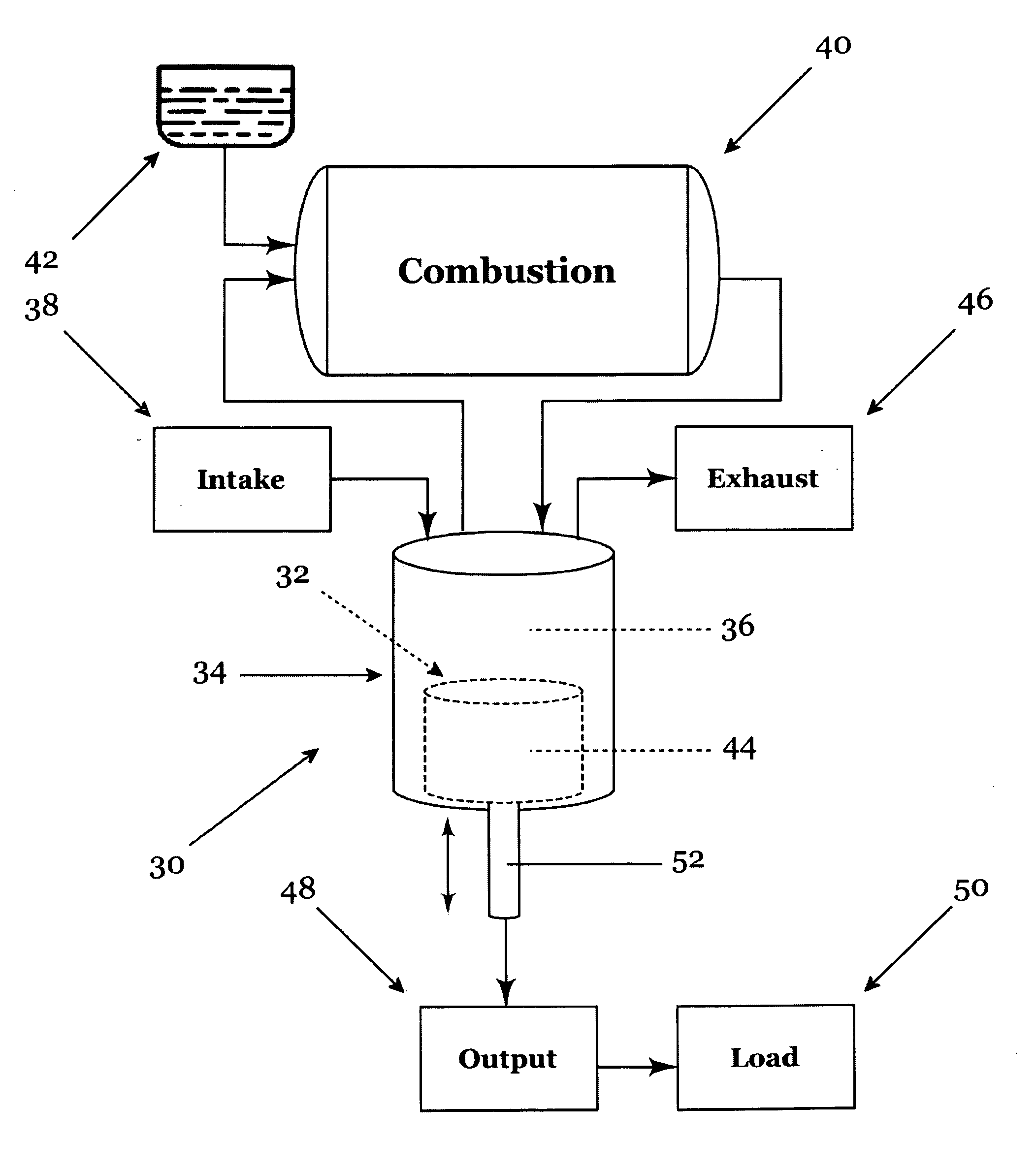

Stirling heat regenerator-organic Rankine cycle system and use method thereof

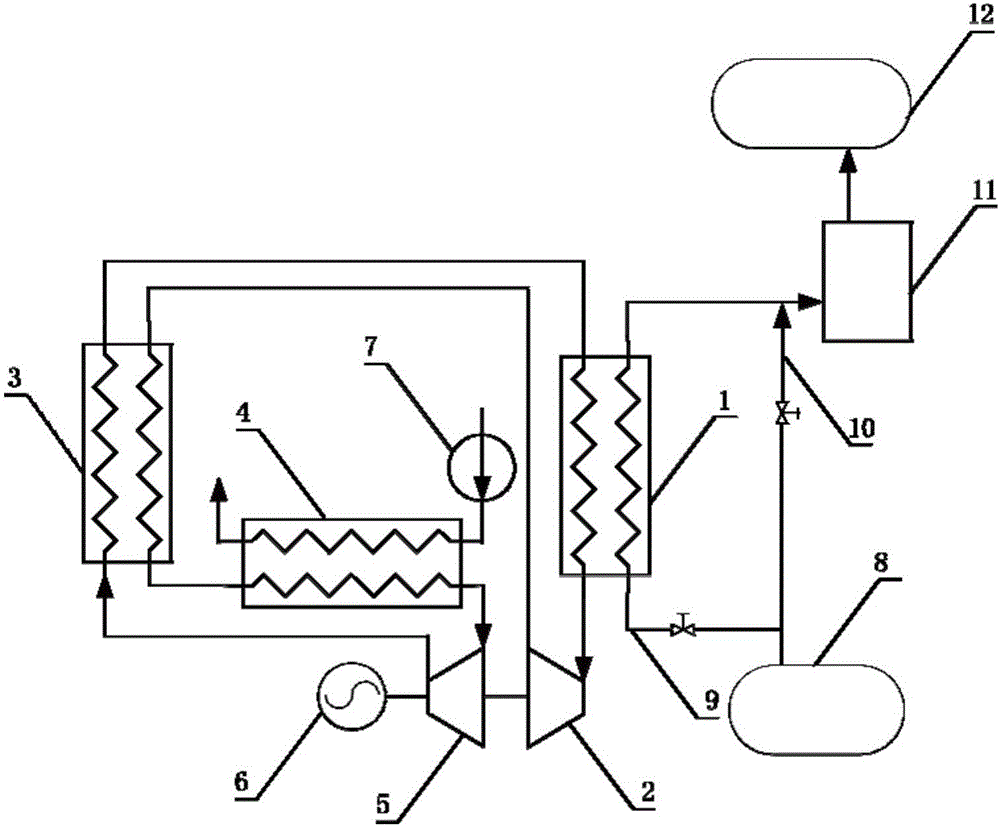

InactiveCN104763553AHigh thermal efficiencyTo achieve the purpose of saving energy and reducing consumptionSpecial enginesHot gas positive displacement engine plantsOrganic Rankine cycleLiquid storage tank

The invention belongs to the technical field of energy and power, in particular to a Stirling heat regenerator-organic Rankine cycle system and a use method thereof. According to the Stirling heat regenerator-organic Rankine cycle system, a working medium liquid storage tank, a working medium pump, a Stirling cold-cavity heat exchanger, a working medium evaporator, a thermal power conversion device, a Stirling thermal-cavity heat exchanger, a working medium condenser and a working medium liquid storage tank are connected in sequence to form a circulation loop; the Stirling cold-cavity heat exchanger and Stirling thermal-cavity heat exchanger are respectively connected with a Stirling engine; each of the thermal power conversion device and Stirling engine is connected with a corresponding generator. The Stirling heat regenerator-organic Rankine cycle system fully combines the existing organic Rankine cycle technology with the Stirling engine, steam exhaust from the outlet of the thermal power conversion device is converted into high-quality electric energy through the Stirling engine, the heat is transmitted to low-temperature working medium at the outlet of the working medium pump in the process to serve as the heat regenerator of the system, the thermal efficiency of the system is improved, and energy saving and consumption reducing are realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

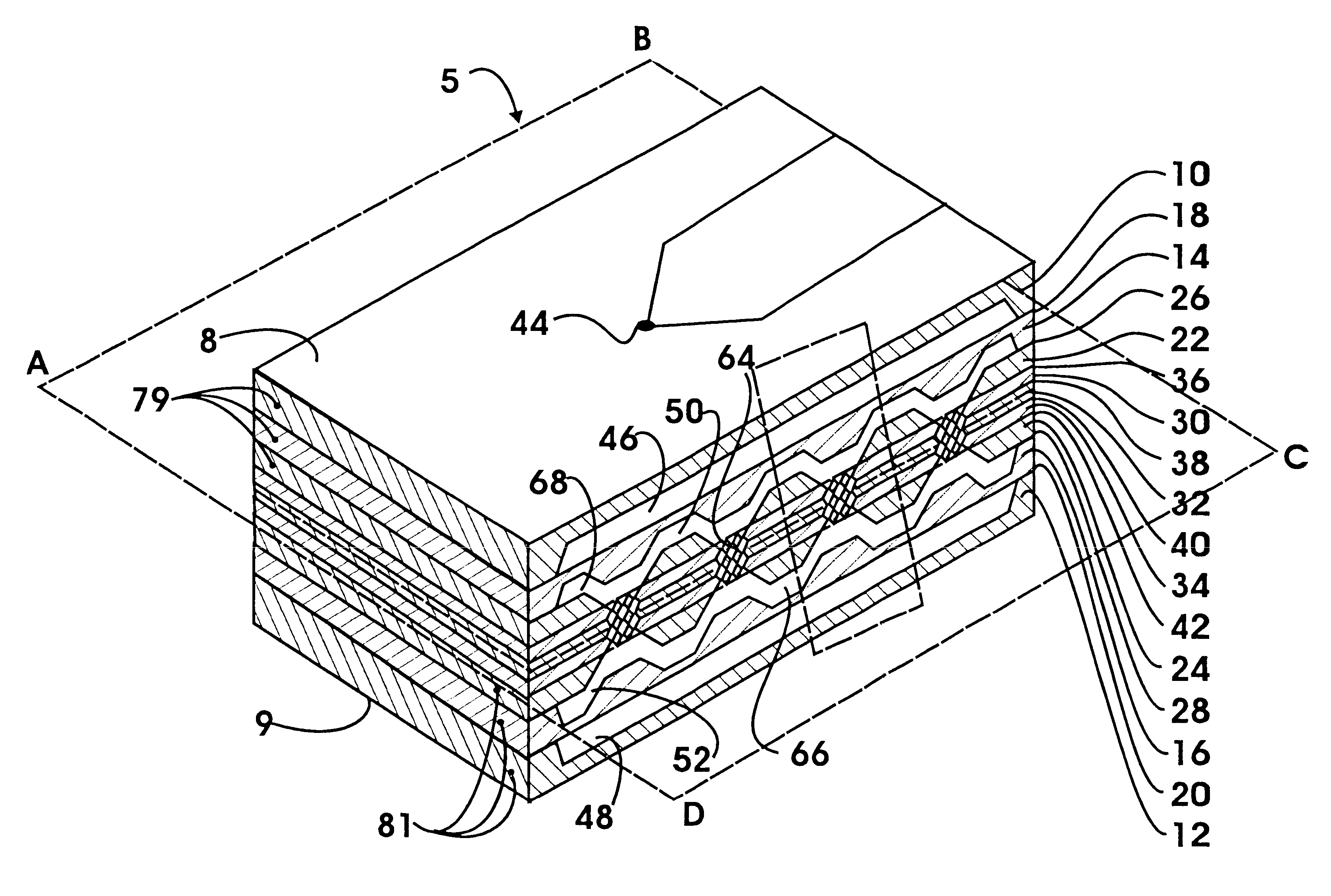

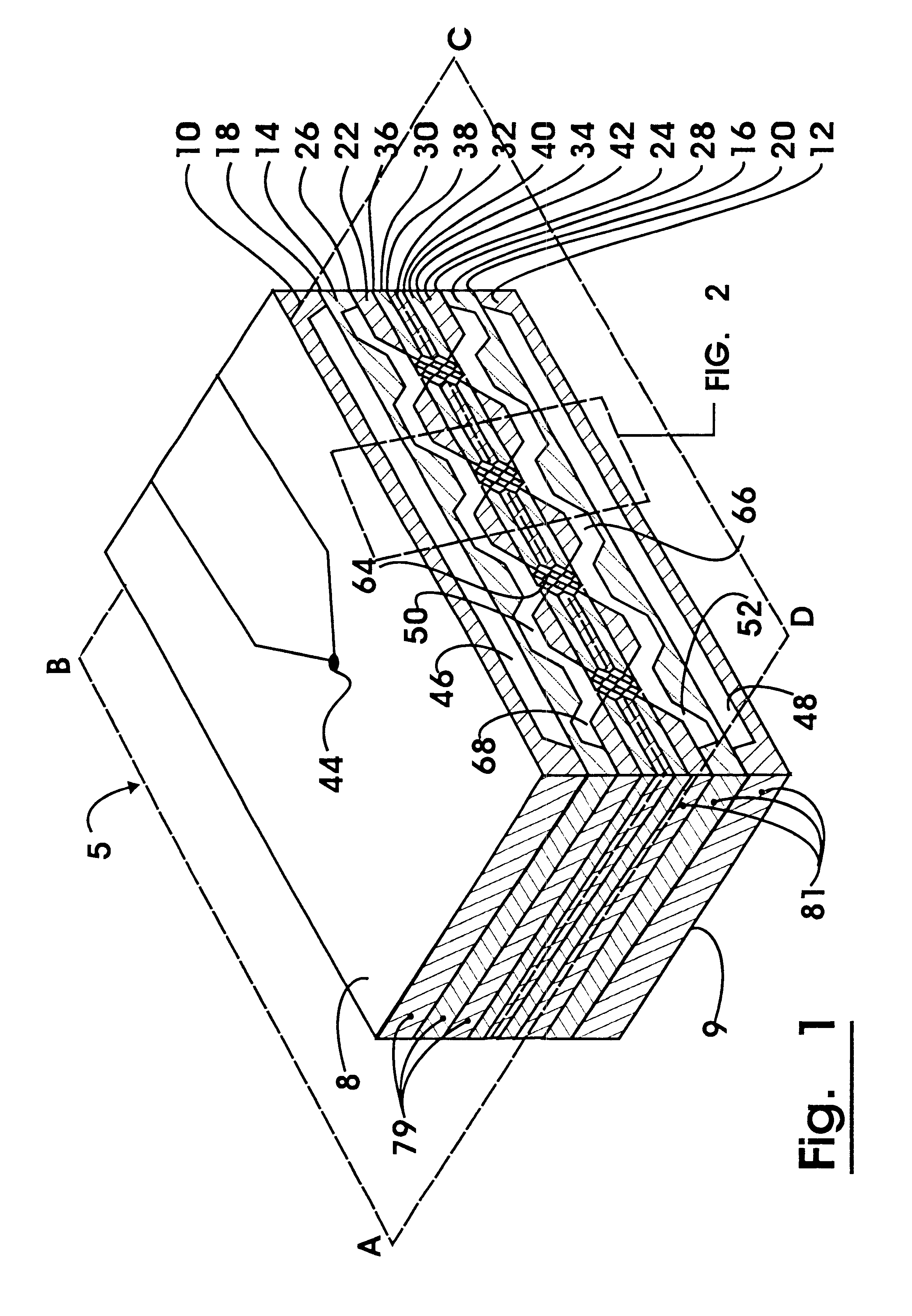

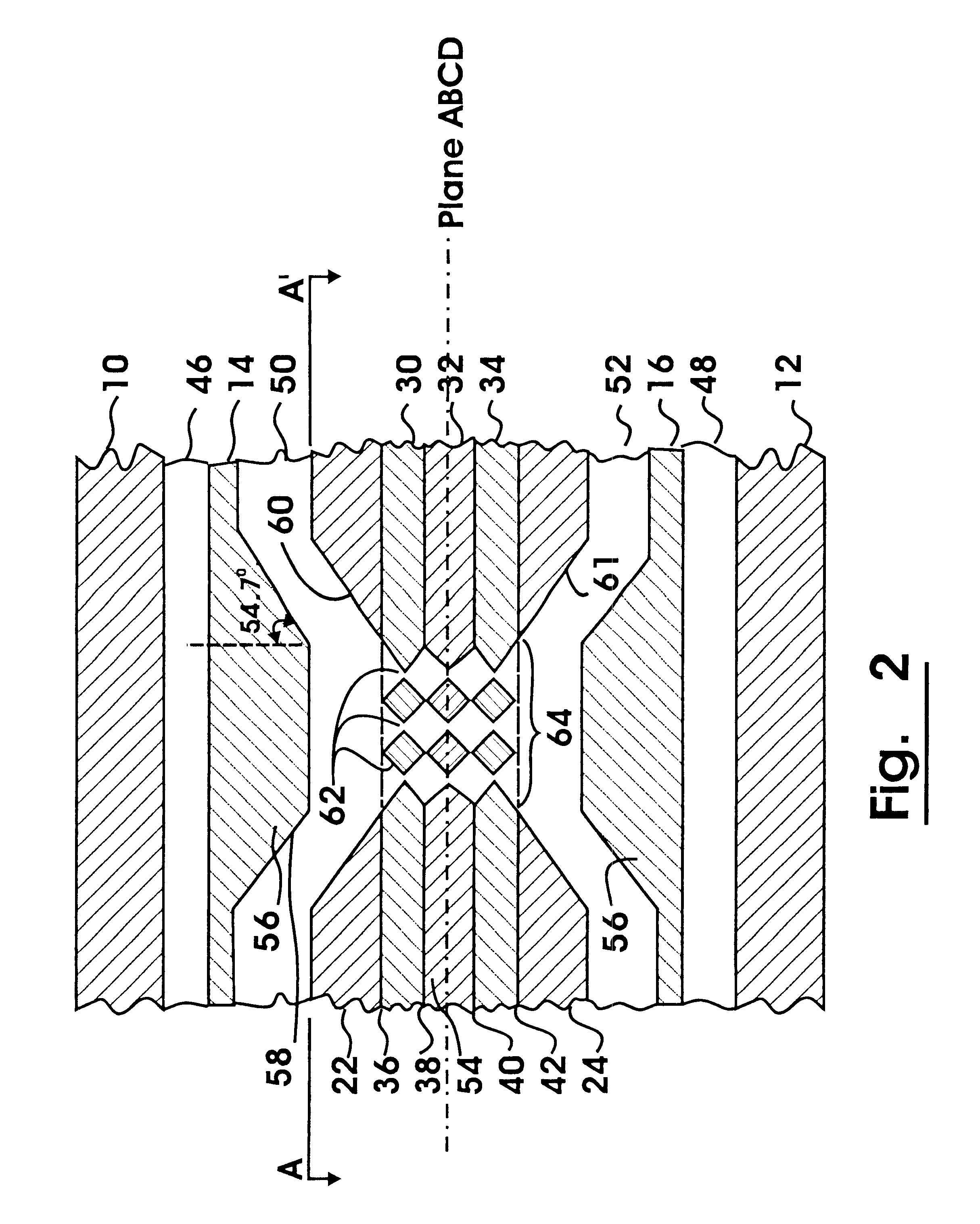

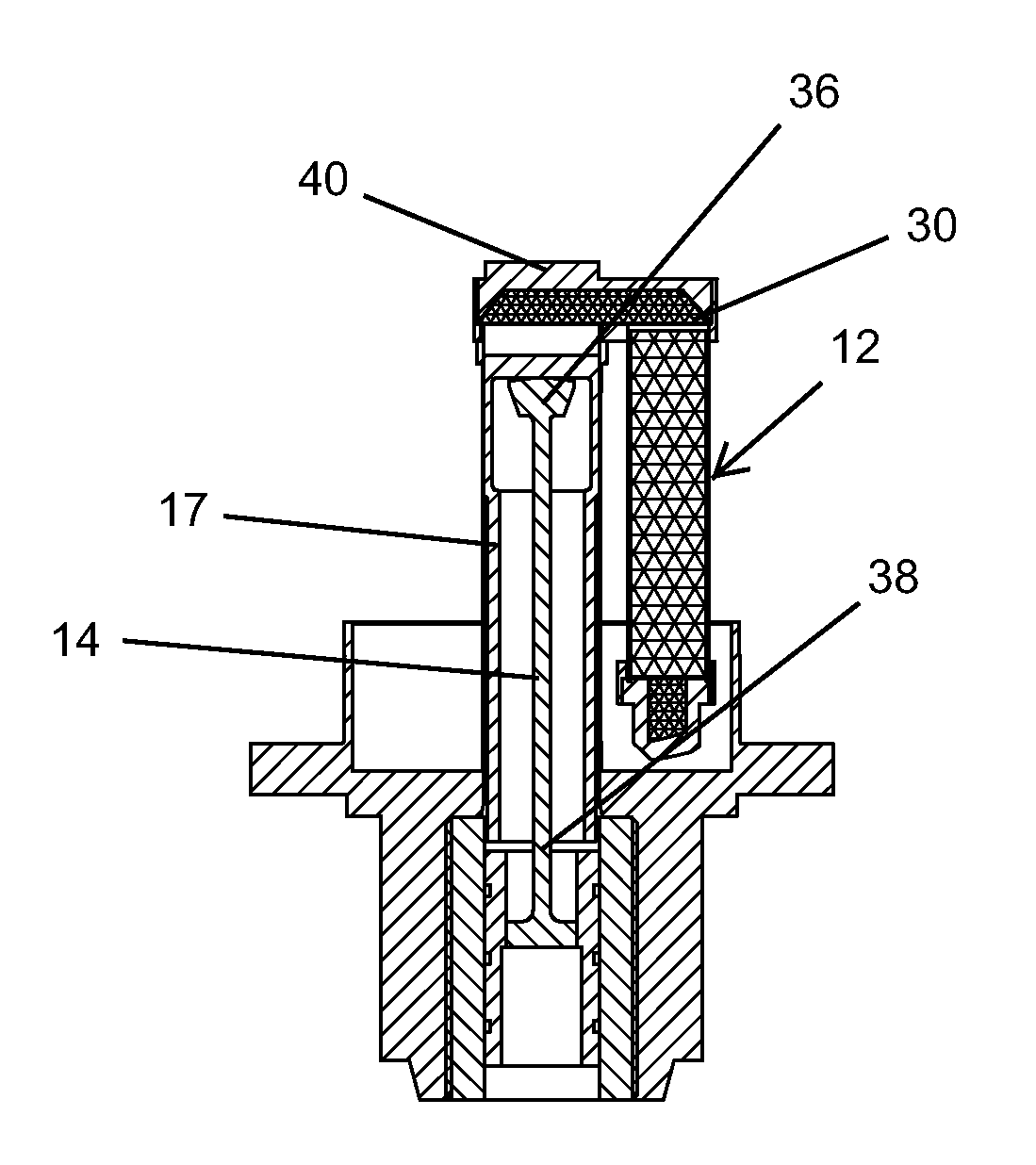

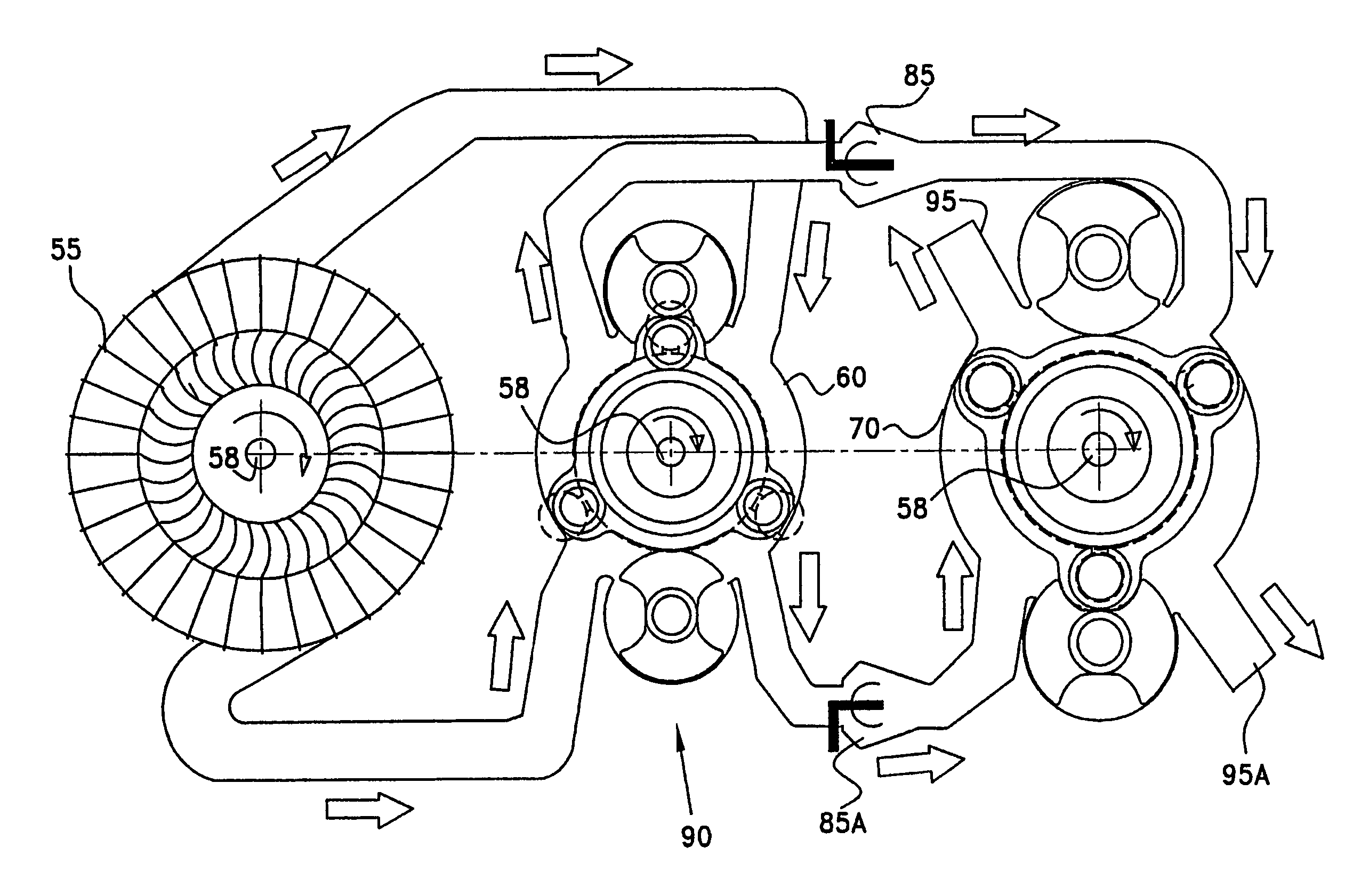

Gerotor apparatus for a quasi-isothermal Brayton cycle Engine

InactiveUS7186101B2Simpler gas flow pathLess loadInternal combustion piston enginesCombination enginesBrayton cycleCycloid

According to one embodiment of the invention, a gerotor apparatus includes an outer gerotor having an outer gerotor chamber, an inner gerotor, at least a portion of which is disposed within the outer gerotor chamber, and a synchronizing apparatus operable to control the rotation of the inner gerotor relative to the outer gerotor. The inner gerotor includes one or more entrance passages operable to communicate a lubricant into the outer gerotor chamber.

Owner:TEXAS A&M UNIVERSITY

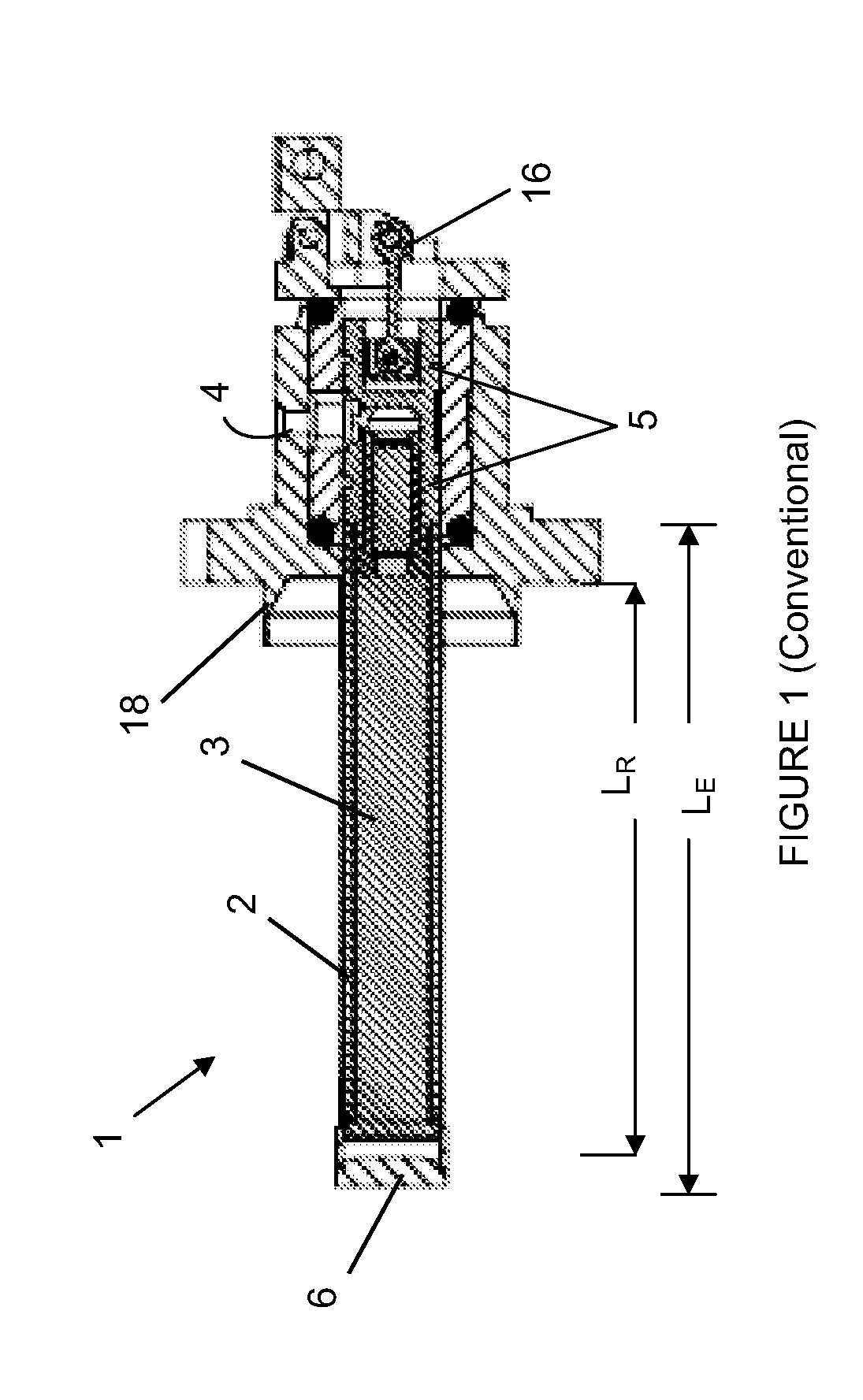

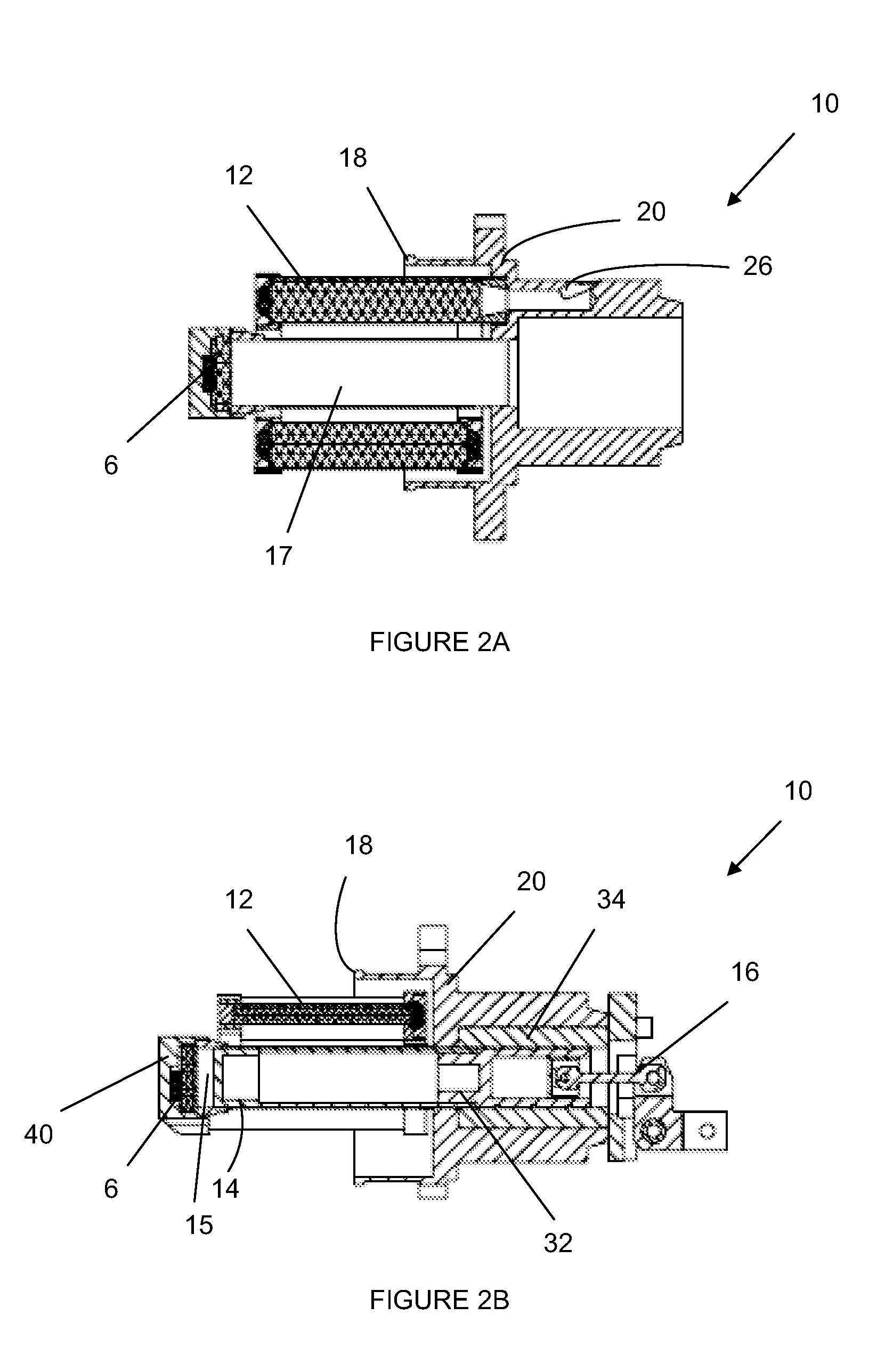

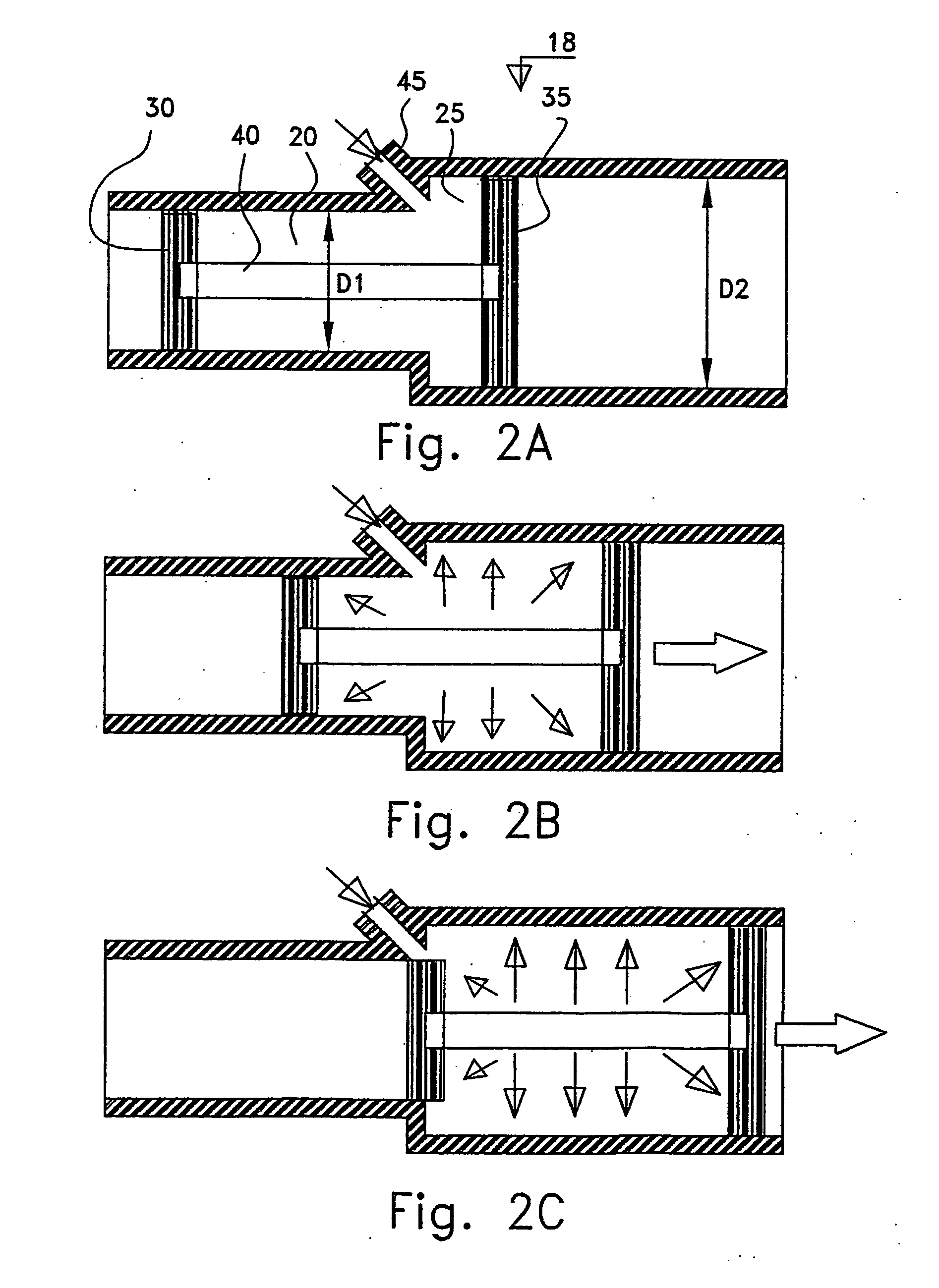

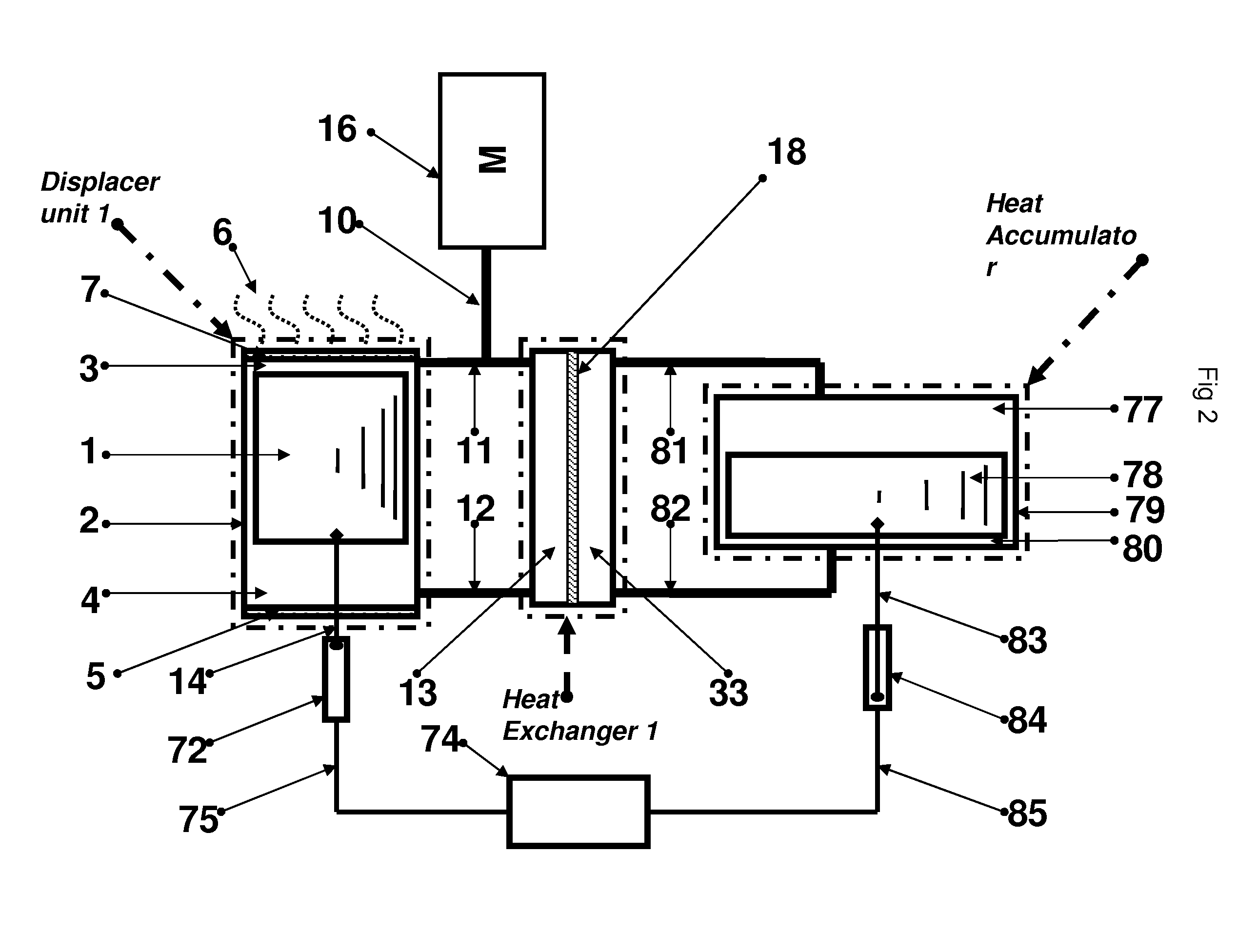

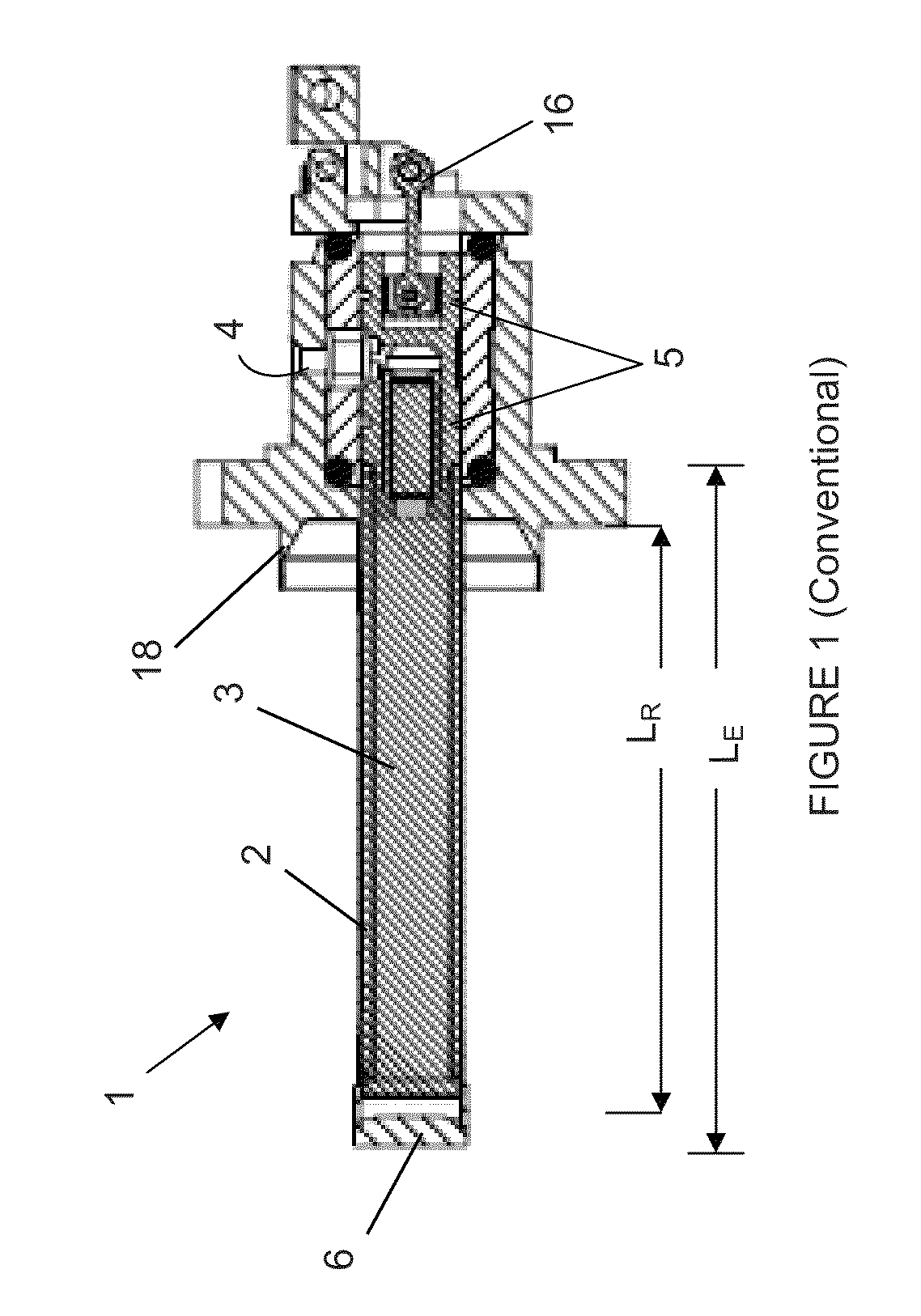

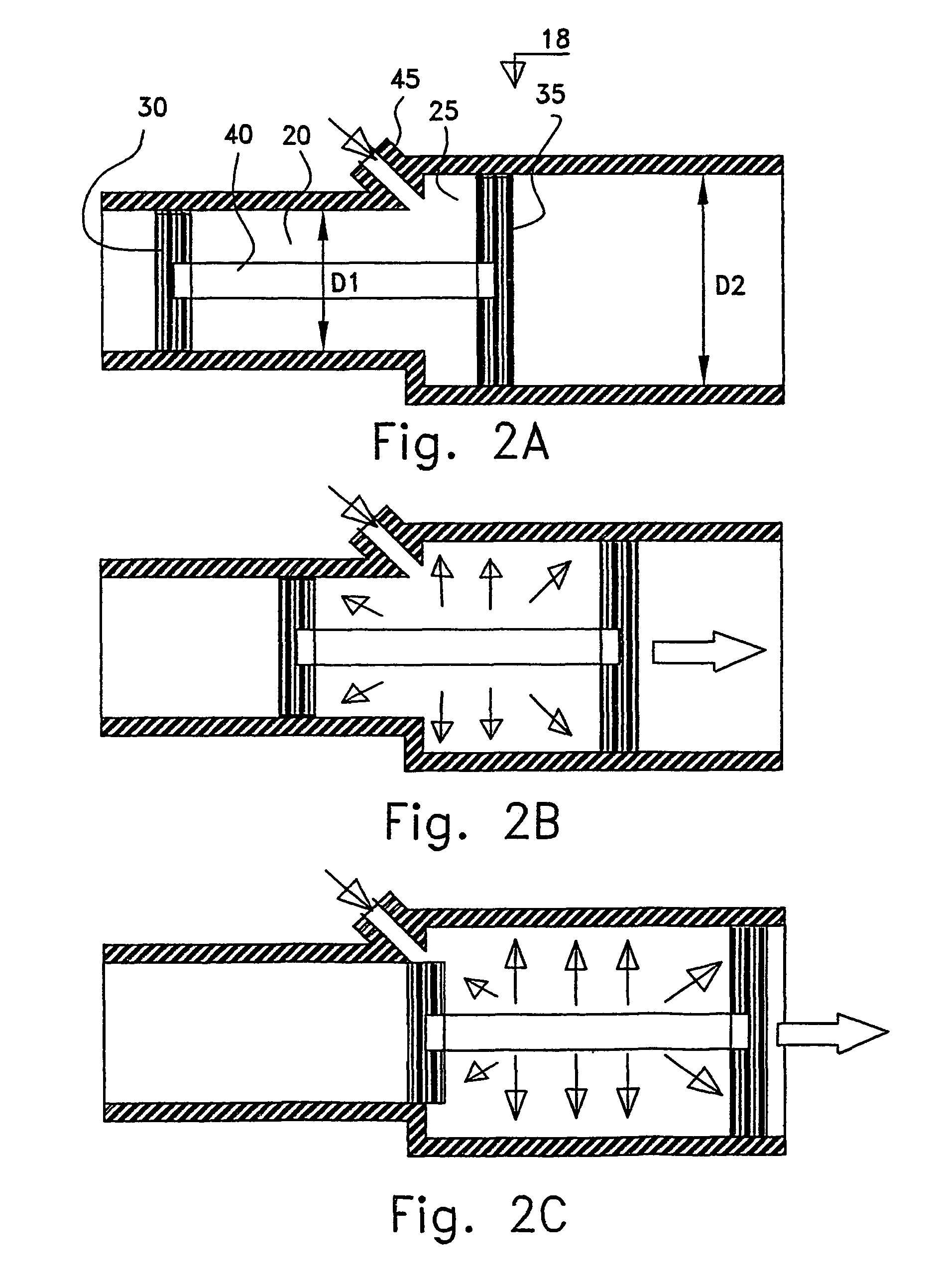

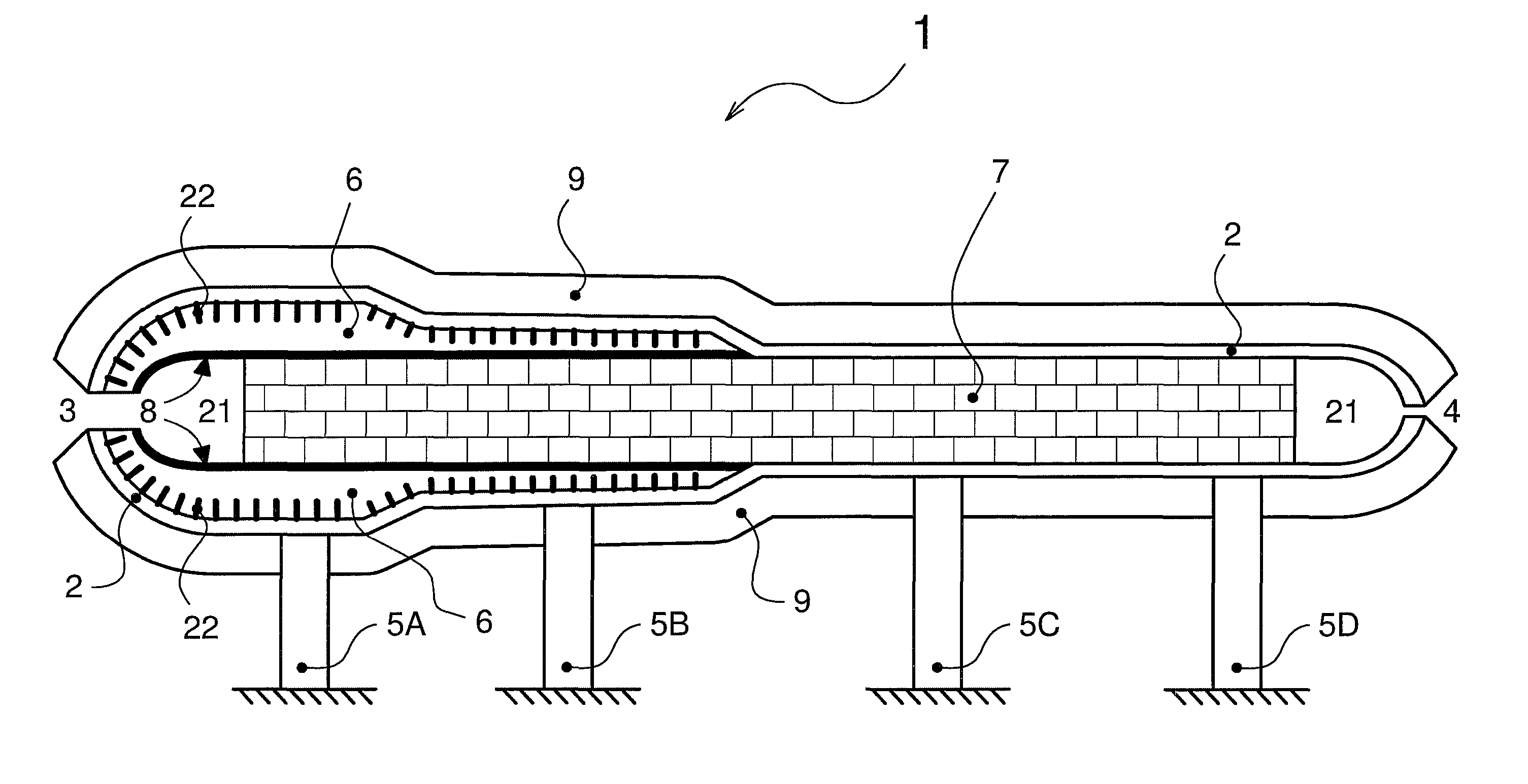

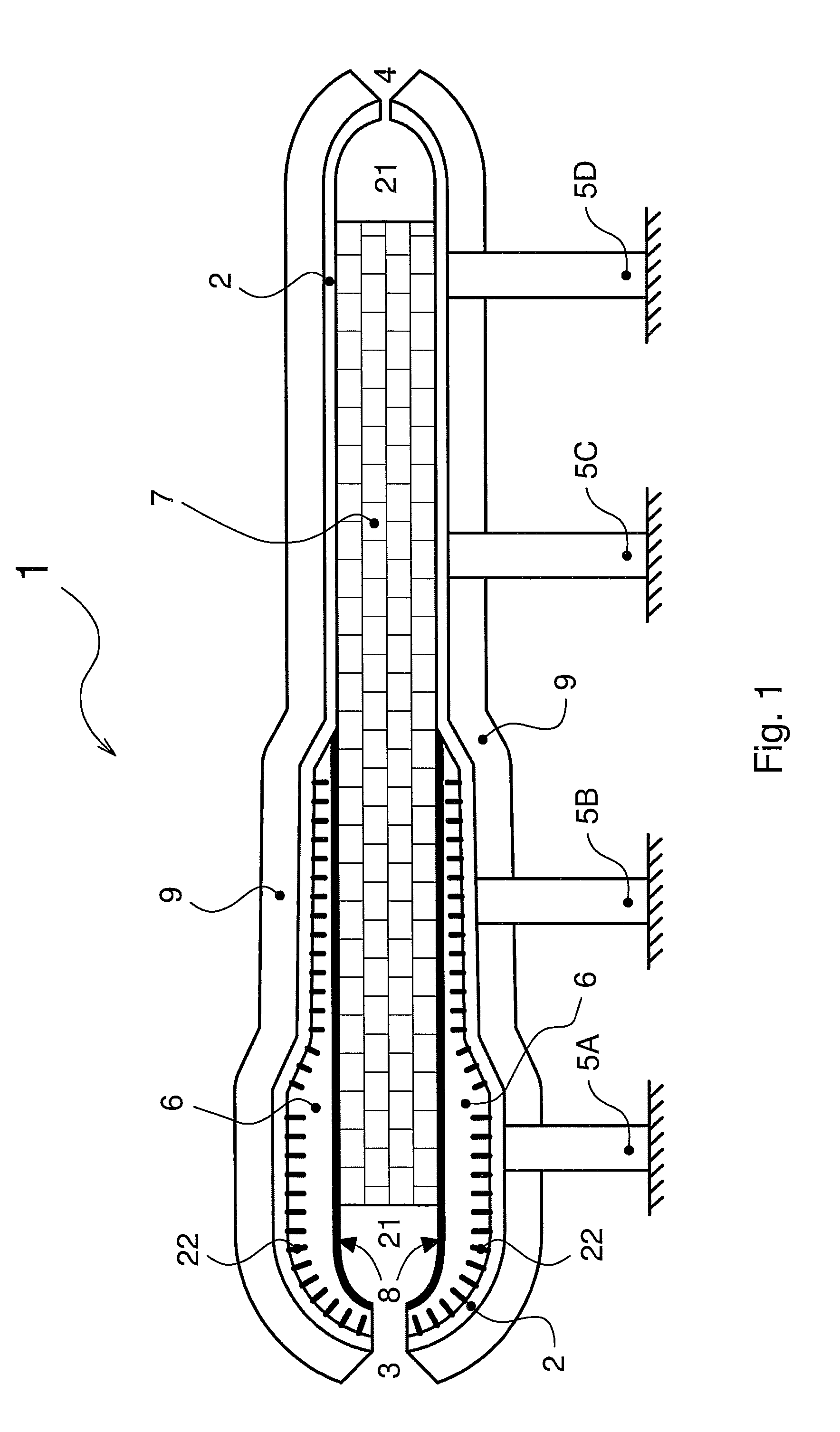

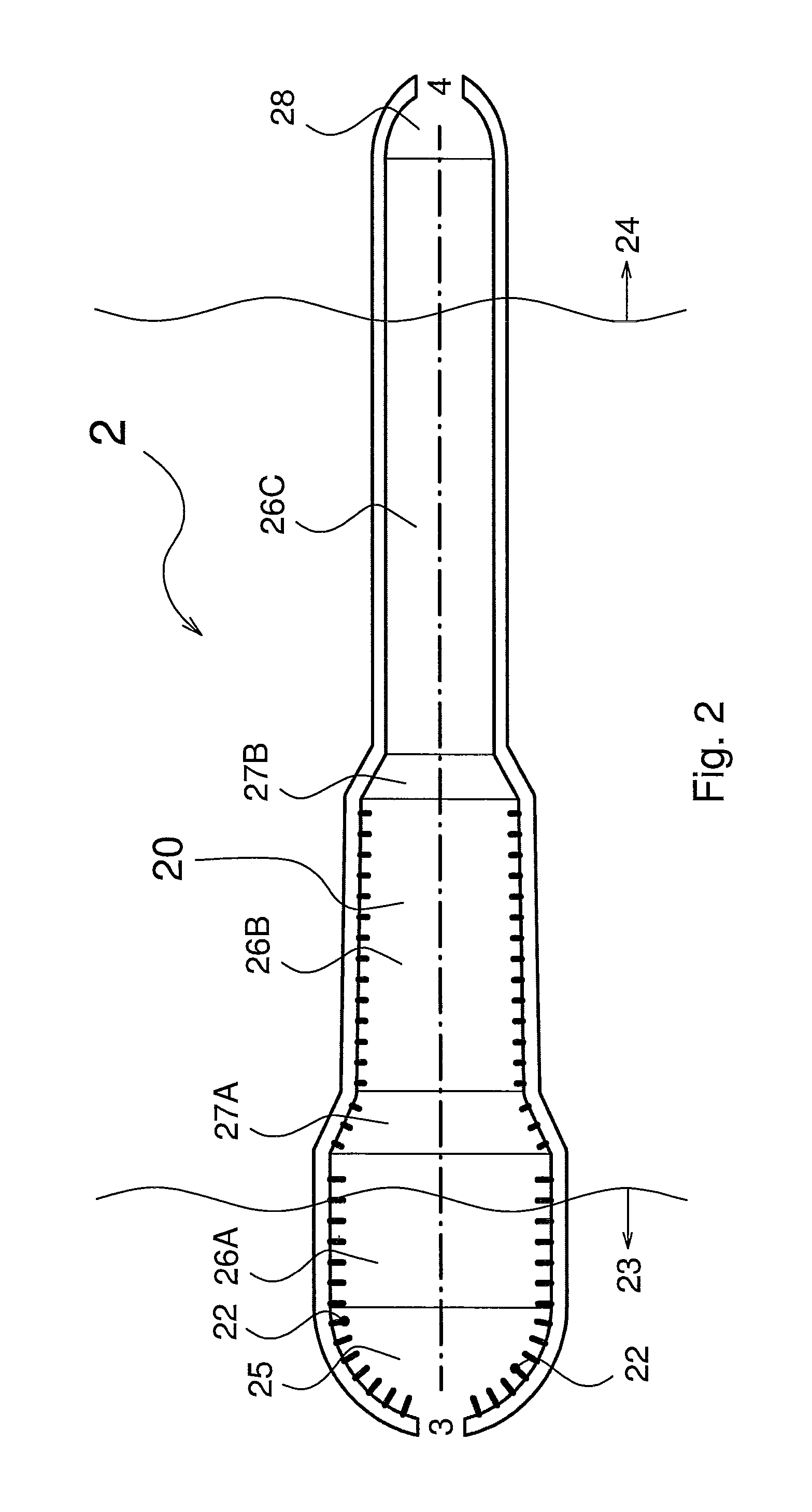

Expander for Stirling Engines and Cryogenic Coolers

InactiveUS20120017607A1Minimize heat conduction lossLow thermal conductivityCompression machinesGas cycle refrigeration machinesEngineeringPiston

The invention is directed to an improved cryogenic cooler with an expander where the regenerator matrix is decoupled from the displacer or piston, thereby allowing the design of each to be optimized substantially independently. The regenerator matrix is preferably positioned spaced apart from the displacer and can be designed to enhance thermal exchanges and flow rates of the working gas. In one embodiment, the regenerator matrix has a serpentine shape or U-shape disposed around the displacer and the cold finger. Preferably, the regenerator matrix is static. The thermal lengths of the cold finger and / or the displacer can be extended by minimizing their geometrical lengths. Additionally, the structural integrity or stiffness of the cold finger and / or displacer can be strengthened.

Owner:TELEDYNE FLIR LLC

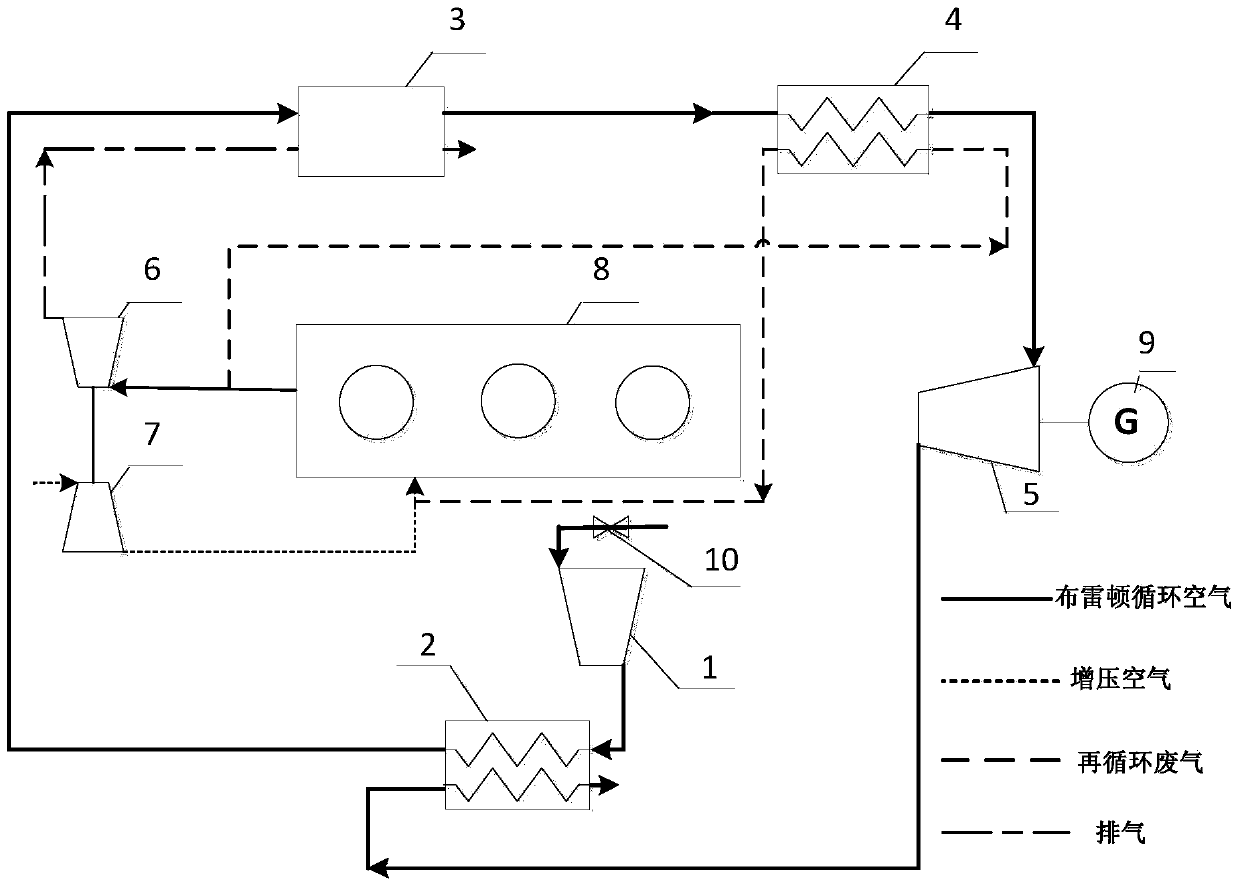

High-temperature waste heat recovery system for diesel engine

InactiveCN104265500APerformance impactCause harmNon-fuel substance addition to fuelInternal combustion piston enginesAtmospheric airAir compressor

The invention discloses a high-temperature waste heat recovery system for a diesel engine. The technical scheme is that an air compressor, a regenerator, a thermo-electric generator, an EGR heat exchanger and an expander are sequentially connected to form a Brayton air regenerative cycle system, and an airflow regulating valve is connected with the air inlet of the air compressor; high-temperature exhaust gas discharged by an engine is output in two ways: one part sequentially passes through a turbine and the thermo-electric generator and then is discharged to the atmosphere, the other part is mixed with supercharged air from a supercharger through the EGR heat exchanger, and the mixture enters the air inlet of the engine; and Brayton circulating air serves as the cold end of the thermo-electric generator, exhaust passing through the turbine serves as the hot end, and the thermo-electric generator pre-heats the Brayton circulating air while outputting power. The high-temperature waste heat recovery system can efficiently utilizes high-temperature waste heat of an internal combustion engine, thereby improving the fuel economy of the internal combustion engine and lowering the heat load of the system. Meanwhile, the system has a relatively simple composition, ensures safe and environment-friendly running, is convenient and flexible in layout, and can be easily implemented in the internal combustion engine.

Owner:TIANJIN UNIV

Gas turbine engine system

InactiveUS20060101800A1Efficient combustionCost-effectiveReciprocating combination enginesInternal combustion piston enginesContinuous flowGas turbines

An engine system comprises at least a first volumetric device, and a second volumetric device in which said second volumetric device is larger in volume than said first volumetric device, in which, during continuous flow of a compressible fluid from said first to said second volumetric device work is performed.

Owner:NEWTON PROPULSION TECH

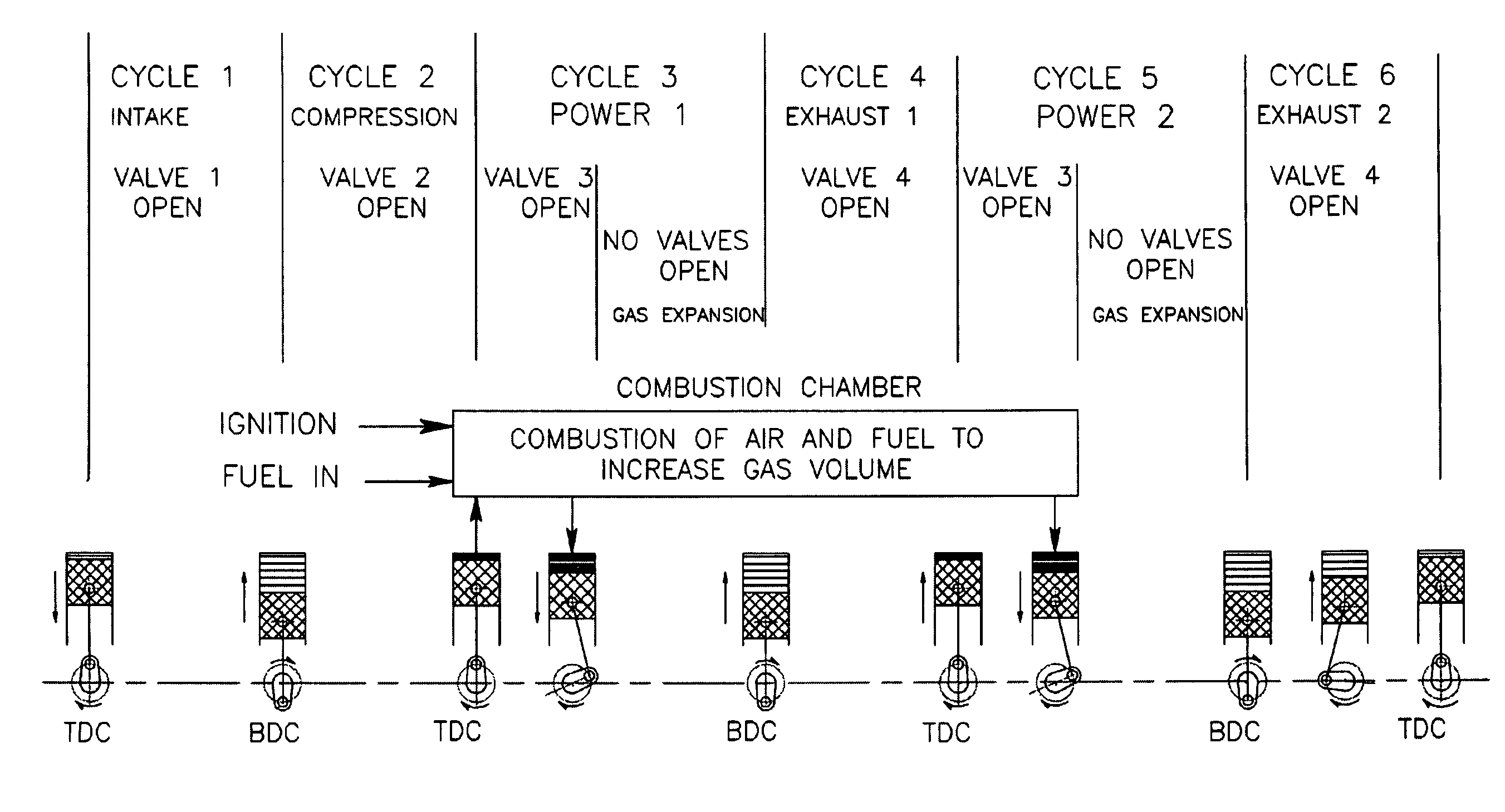

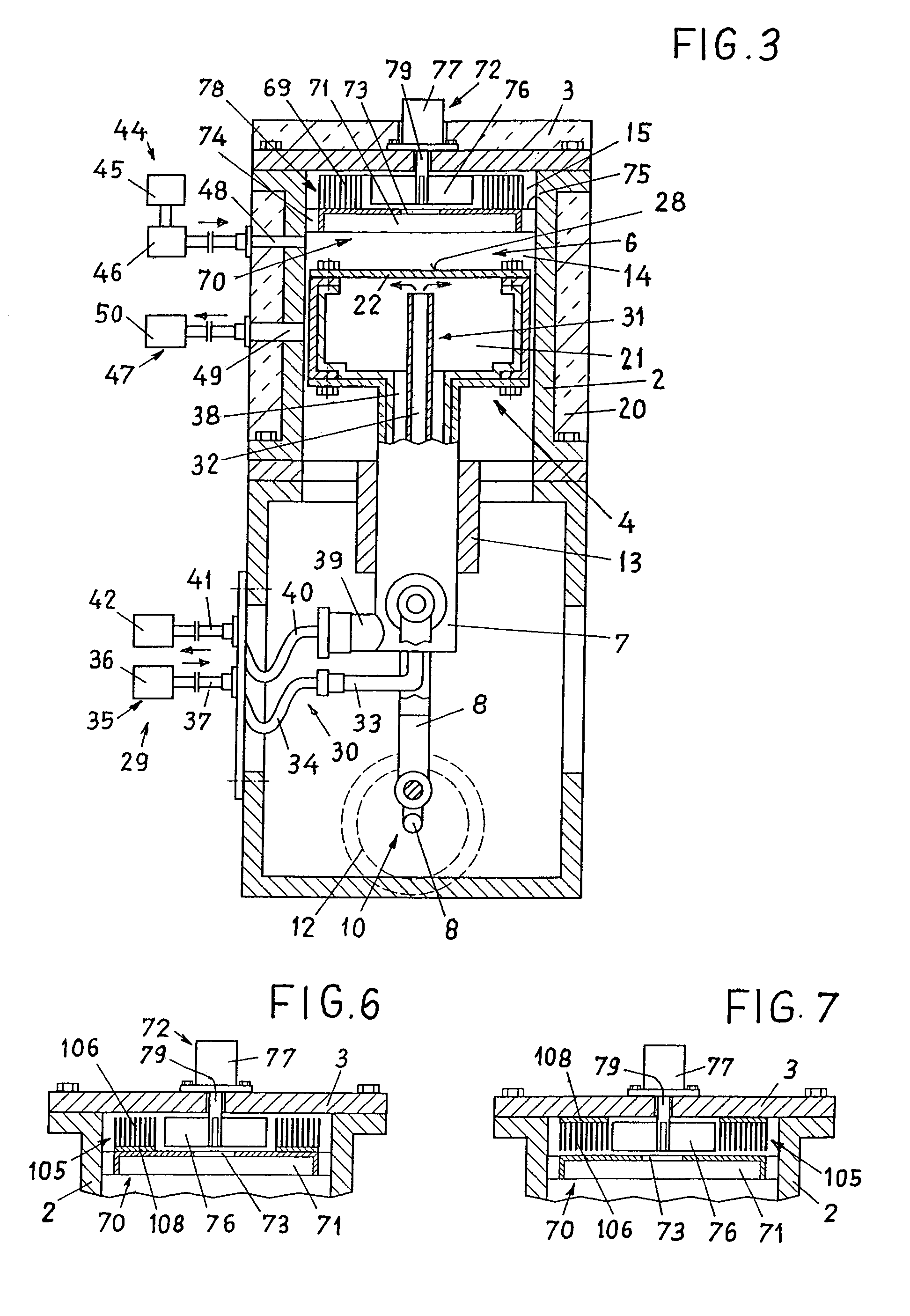

Combustion engine

InactiveUS7765785B2Requires minimizationChanging compression ratio during engine operationTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionBrayton cycleCombustion chamber

A combustion engine that has at least a plurality of power strokes during a complete cycle of engine operation that is of compact packaging and Brayton cycle operable. In a preferred embodiment, a piston-cylinder arrangement used to compress air and deliver it to a combustion chamber where it is combusted along with fuel. The combustion gases are returned back to the piston-cylinder arrangement where they act on the piston to output power in a power stroke. A second power stroke can be implemented where additional combustion gases are available to extract additional power from. In a preferred embodiment, the same piston-cylinder arrangement receives the additional combustion gases from the combustion chamber in the second power stroke.

Owner:KASHMERICK GERALD E

Trough type solar combined cycle power generation system

ActiveCN106014891ACompact structureExtended generating hoursSolar heating energyFrom solar energyThermal energyBrayton cycle

Owner:SOUTHEAST UNIV

Energy conversion device and operation method thereof

InactiveUS20070234719A1Improve efficiencyImprove isolationStirling type enginesEricsson type enginesHot zoneNew energy

Owner:SCHUSTER ALEXANDER +1

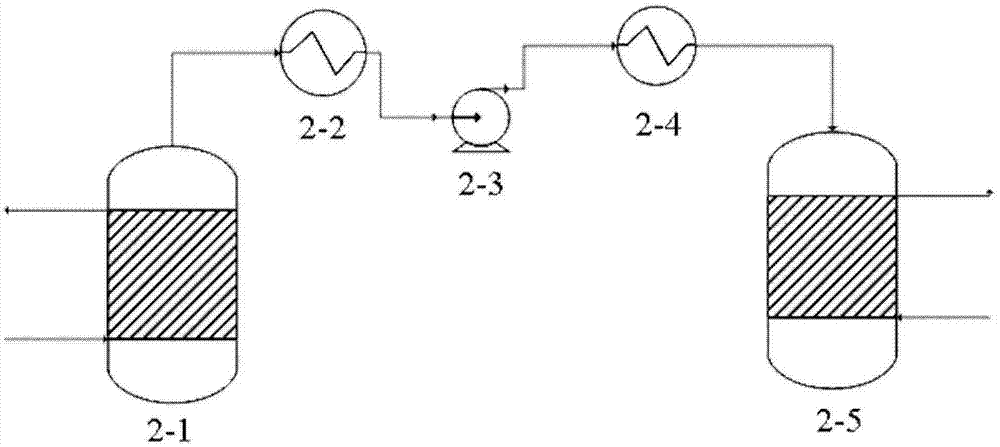

Heat pump and supercritical carbon dioxide brayton cycle coupled combined cooling and heating power supply system

InactiveCN107514837ARaise the gradeImprove utilization efficiencyHeat pumpsEnergy industryBrayton cycleElectricity

The invention discloses a heat pump and supercritical carbon dioxide brayton cycle coupled combined cooling and heating power supply system. The system comprises a heating energy storage unit, a turbine, a heat regenerator, a waste heat unit, a cooler and a compressor. The heating energy storage unit is used for storing energy and heating supercritical carbon dioxide. The turbine does work to generate electricity through heat of the heated supercritical carbon dioxide. The heated supercritical carbon dioxide is cooled through the heat regenerator and then goes into a heat pump unit to generate high-temperature steam. The supercritical carbon dioxide is cooled through the heat pump unit, goes into a refrigerating unit to form cold water, then is cooled through the cooler, compressed through the compressor and heated through the heat regenerator and returns to the heating energy storage unit again to complete one circulation.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

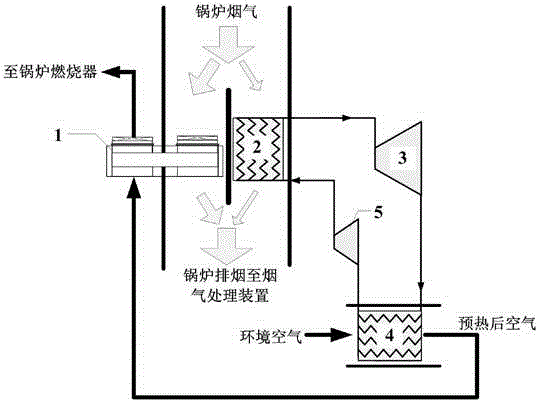

Thermal power plant medium-low temperature flue gas heat energy gradient utilization system and method

ActiveCN105823077AReduce irreversible lossReduce consumption rateCombustion processIndirect carbon-dioxide mitigationAir preheaterBrayton cycle

The invention provides a thermal power plant medium-low temperature flue gas heat energy gradient utilization system and method. According to the thermal power plant medium-low temperature flue gas heat energy gradient utilization system, a Brayton cycle is arranged at thermal power plant boiler tail flues in a coupled mode, the thermal power plant boiler tail flues are separated flues, that is, two flues are adopted, one of the flues communicates with a flue gas inlet of an air pre-heater, and the other flue communicates with a flue gas inlet of a Brayton cycle heater; a working medium outlet of the Brayton cycle heater communicates with an inlet of a turbine; an outlet of the turbine communicates with a working medium inlet of a Brayton cycle cooler; a working medium outlet of the Brayton cycle cooler communicates with a working medium inlet of the Brayton cycle heater through an air compressor; a hot air outlet of the Brayton cycle cooler communicates with an air inlet of the air pre-heater; and an air outlet of the air pre-heater is connected with a boiler burner. The invention further discloses the flue gas heat energy gradient utilization method, the heat exchanging process of thermal power plant medium-low temperature flue gas can be optimized, the irreversible loss of the air pre-heater is reduced, accordingly, the efficiency of a whole thermal power plant is improved, the temperature of air entering the air pre-heater is increased at the same time, and safe operation of the air pre-heater is facilitated.

Owner:XI AN JIAOTONG UNIV

Expander for stirling engines and cryogenic coolers

InactiveUS8910486B2Minimize frictional contactLow thermal conductivitySolidificationLiquefactionEngineeringPiston

The invention is directed to an improved cryogenic cooler with an expander where the regenerator matrix is decoupled from the displacer or piston, thereby allowing the design of each to be optimized substantially independently. The regenerator matrix is preferably positioned spaced apart from the displacer and can be designed to enhance thermal exchanges and flow rates of the working gas. In one embodiment, the regenerator matrix has a serpentine shape or U-shape disposed around the displacer and the cold finger. Preferably, the regenerator matrix is static. The thermal lengths of the cold finger and / or the displacer can be extended by minimizing their geometrical lengths. Additionally, the structural integrity or stiffness of the cold finger and / or displacer can be strengthened.

Owner:TELEDYNE FLIR LLC

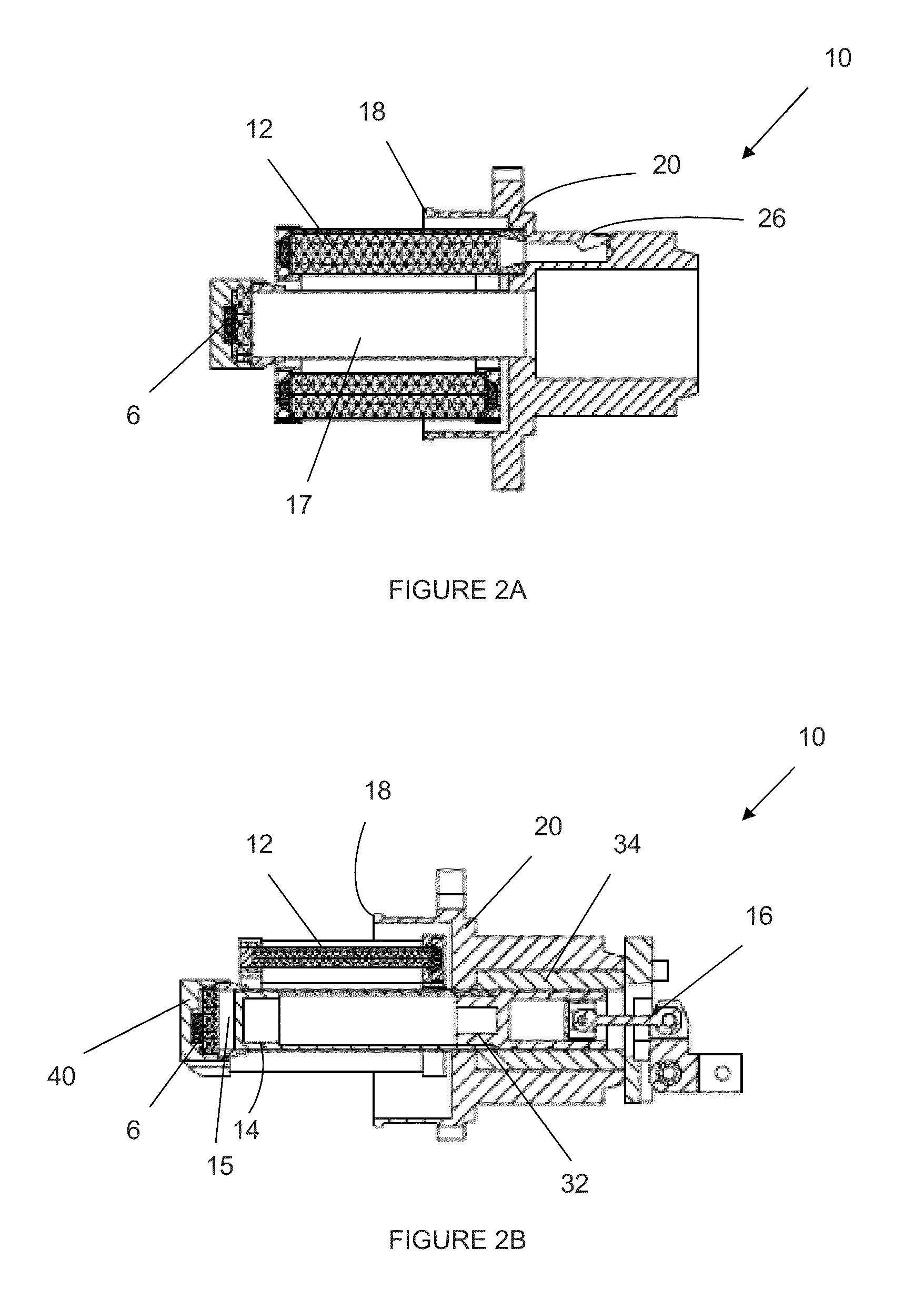

Gas turbine-nitrogen Brayton cycle combined power generation system using cold energy of LNG (liquefied natural gas)

ActiveCN106837441ASolve technical problems that reduce outputIncrease cycle temperature ratioEngine componentsSteam engine plantsNitrogen gasAir compressor

The invention provides a gas turbine-nitrogen Brayton cycle combined power generation system using cold energy of LNG (liquefied natural gas). The power generation system comprises a gas turbine cycle, a nitrogen Brayton cycle, an LNG storage tank and a pressure regulation station, wherein the gas turbine cycle comprises an air-LNG heat exchanger, an air compressor, a combustor, a gas turbine and a first power generator; the nitrogen Brayton cycle comprises a nitrogen-LNG heat exchanger, a nitrogen compressor, a heat regenerator, a flue gas-nitrogen heat exchanger, a nitrogen turbine and a second power generator, wherein a flue gas outlet of the gas turbine in the gas turbine cycle is connected with a flue gas inlet of the flue gas-nitrogen heat exchanger in the nitrogen Brayton cycle. According to the power generation system, working media at inlets of the gas turbine and the nitrogen compressor are cooled through LNG, the cycle temperature ratio is increased, and the efficiency of the gas turbine-nitrogen Brayton cycle combined power generation system is improved effectively.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Combustion engine

InactiveUS20070044478A1Minimizing engine packaging requirementRequires minimizationTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionBrayton cycleCombustion chamber

A combustion engine that has at least a plurality of power strokes during a complete cycle of engine operation that is of compact packaging and Brayton cycle operable. In a preferred embodiment, a piston-cylinder arrangement used to compress air and deliver it to a combustion chamber where it is combusted along with fuel. The combustion gases are returned back to the piston-cylinder arrangement where they act on the piston to output power in a power stroke. A second power stroke can be implemented where additional combustion gases are available to extract additional power from. In a preferred embodiment, the same piston-cylinder arrangement receives the additional combustion gases from the combustion chamber in the second power stroke.

Owner:KASHMERICK GERALD E

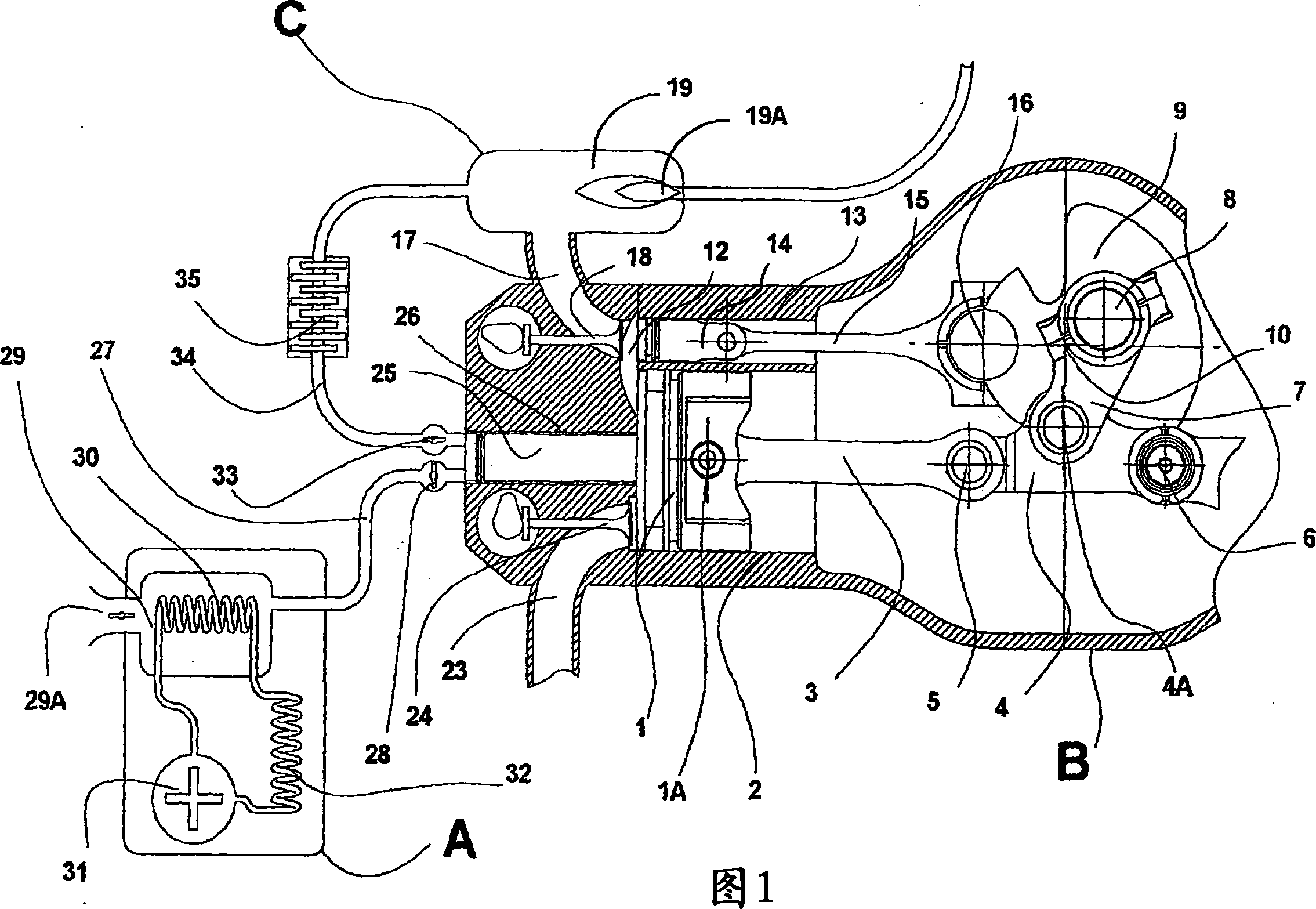

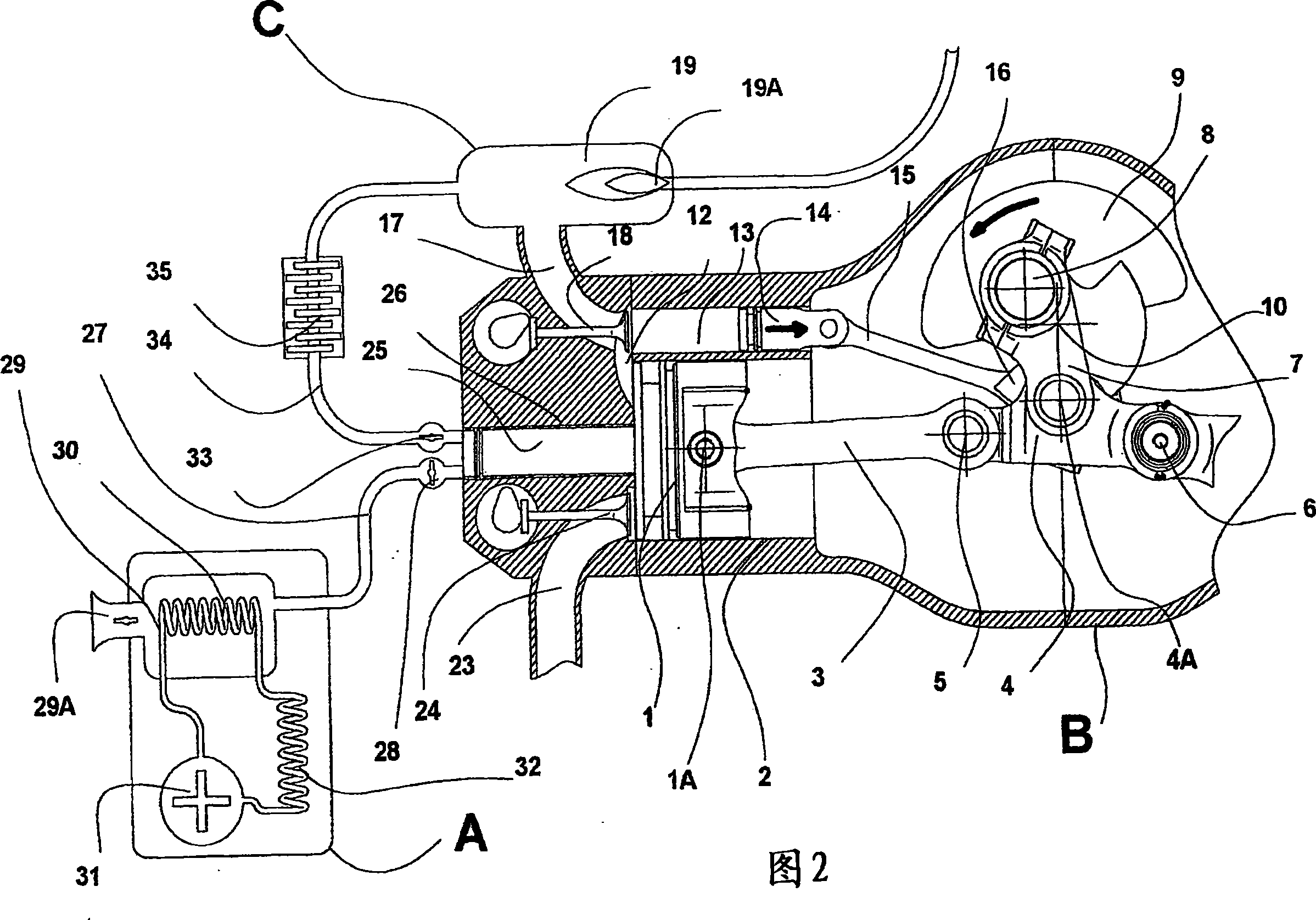

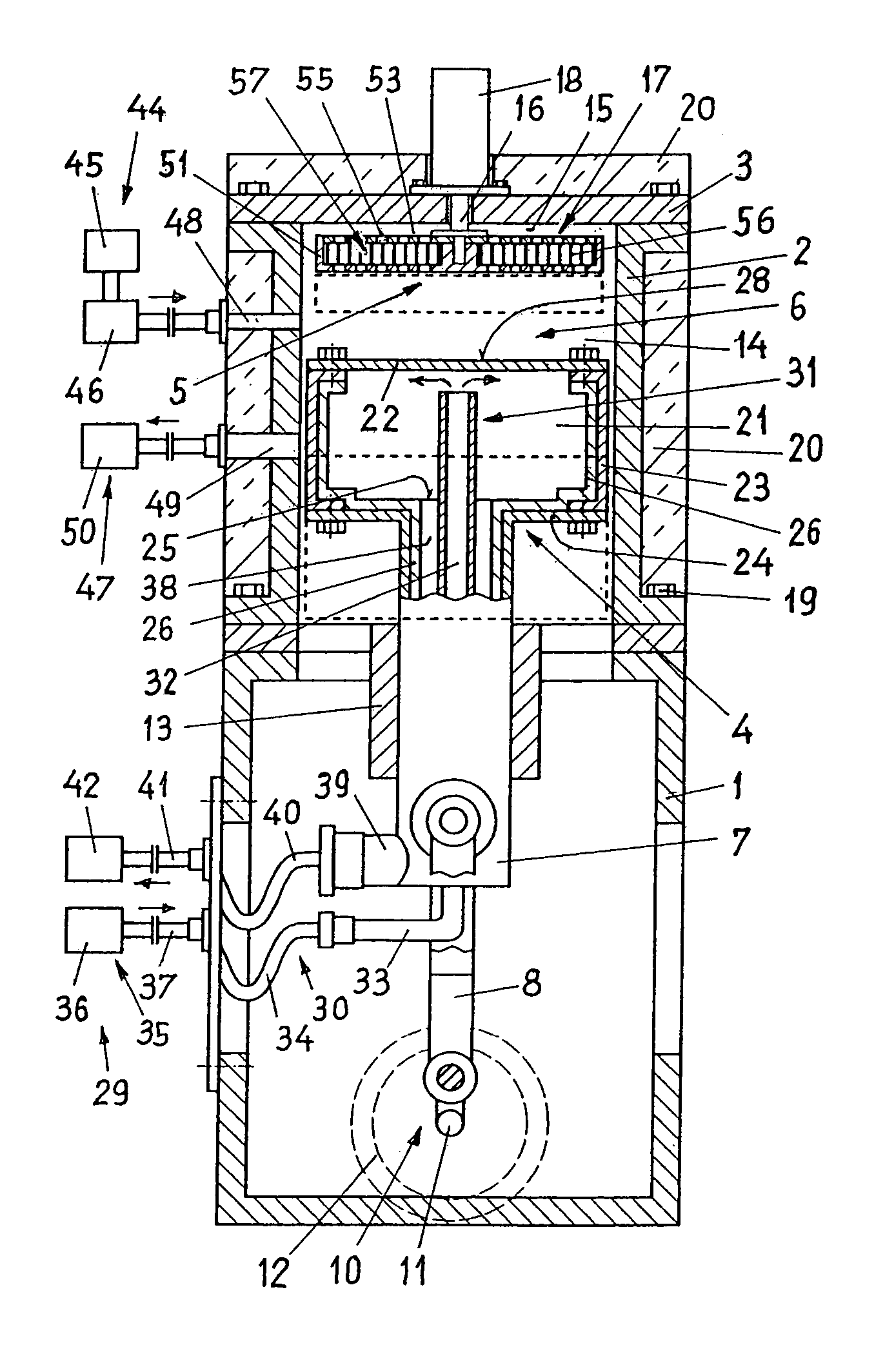

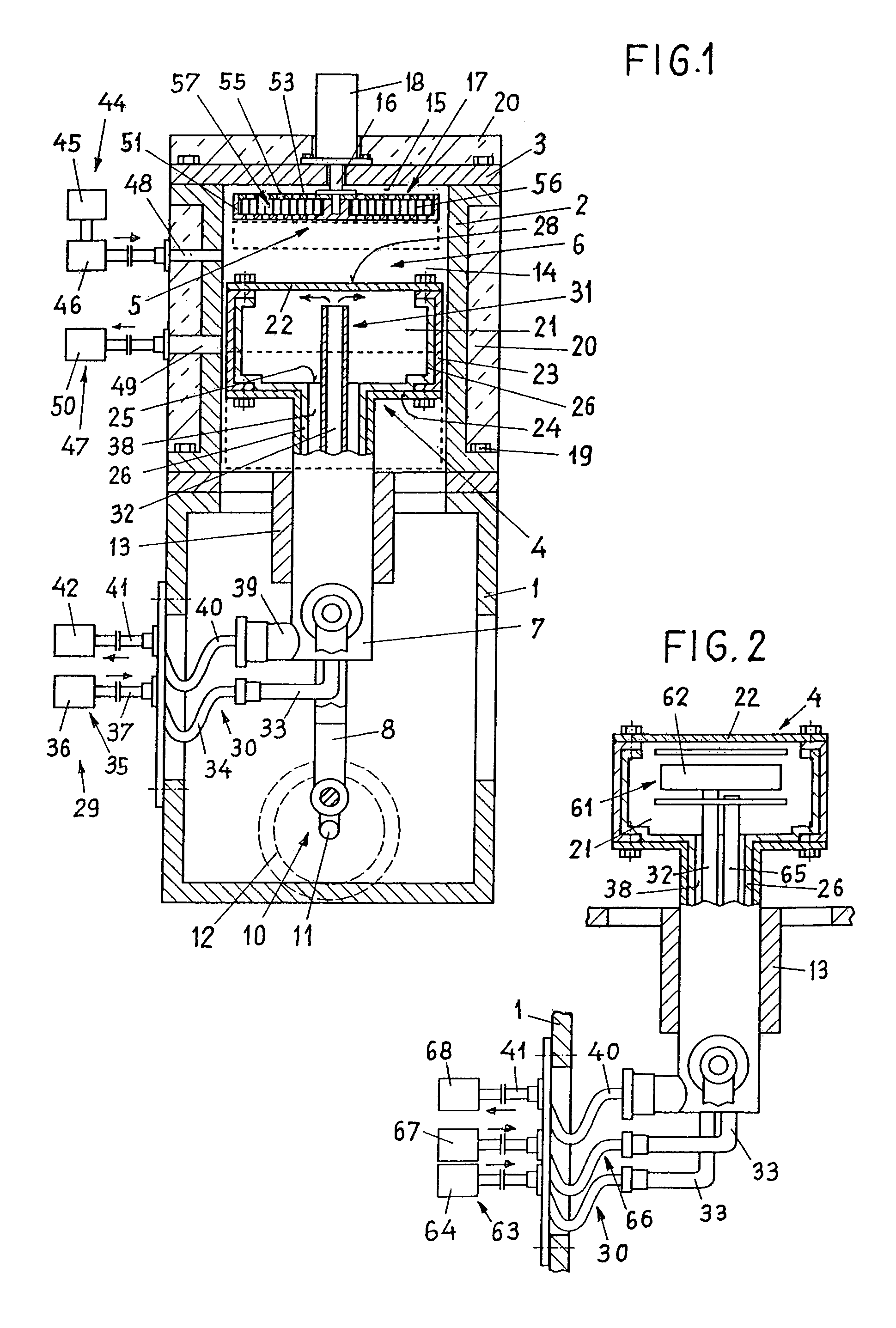

Low-temperature motor compressor unit with continuous 'cold' combustion at constant pressure and with active chamber

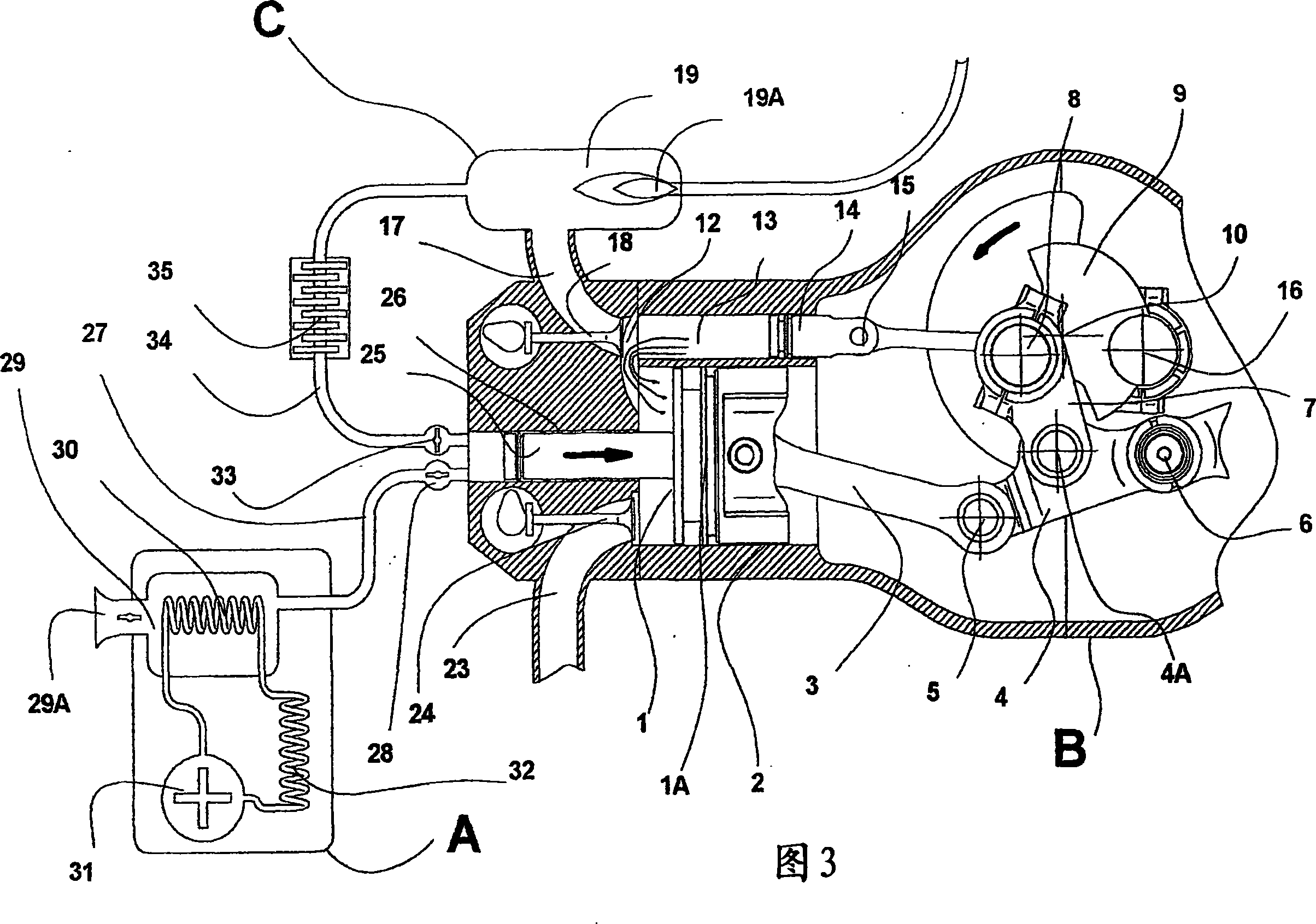

InactiveCN101233296AInternal combustion piston enginesCombined combustion mitigationAir compressionCombustion chamber

The invention relates to an active chamber type constant pressure continuous "cold" combustion type cryogenic engine-compressor unit, which works in particular with working compressed air and uses: a piston stroke control device and an active chamber with a cold chamber (29) which The atmosphere at the inlet (28) of the supply air compression device (28, 25, 26, 33) can be lowered to a very low temperature, which then compresses this working compressed air, which is still at low temperature, into the outer combustion chamber (19 ), the outer combustion chamber (19) is equipped with a constant pressure heating device (19A), and the working compressed air increases in volume in the heating device (19A), and then is transported quasi-isothermally to the active chamber ( 13), and then expand in the working cylinder (2) to do work again. The invention is applied to land vehicles, cars, buses, motorcycles, ships, airplanes, emergency power generation devices, household appliances, and stationary heat engines.

Owner:MDI MOTOR DEV INT SA

Gas turbine engine system

InactiveUS8109074B2Efficient combustionCost effectiveReciprocating combination enginesInternal combustion piston enginesMechanicsGas turbines

An engine system comprises at least a first volumetric device, and a second volumetric device in which said second volumetric device is larger in volume than said first volumetric device, in which, during continuous flow of a compressible fluid from said first to said second volumetric device work is performed.

Owner:NEWTON PROPULSION TECH

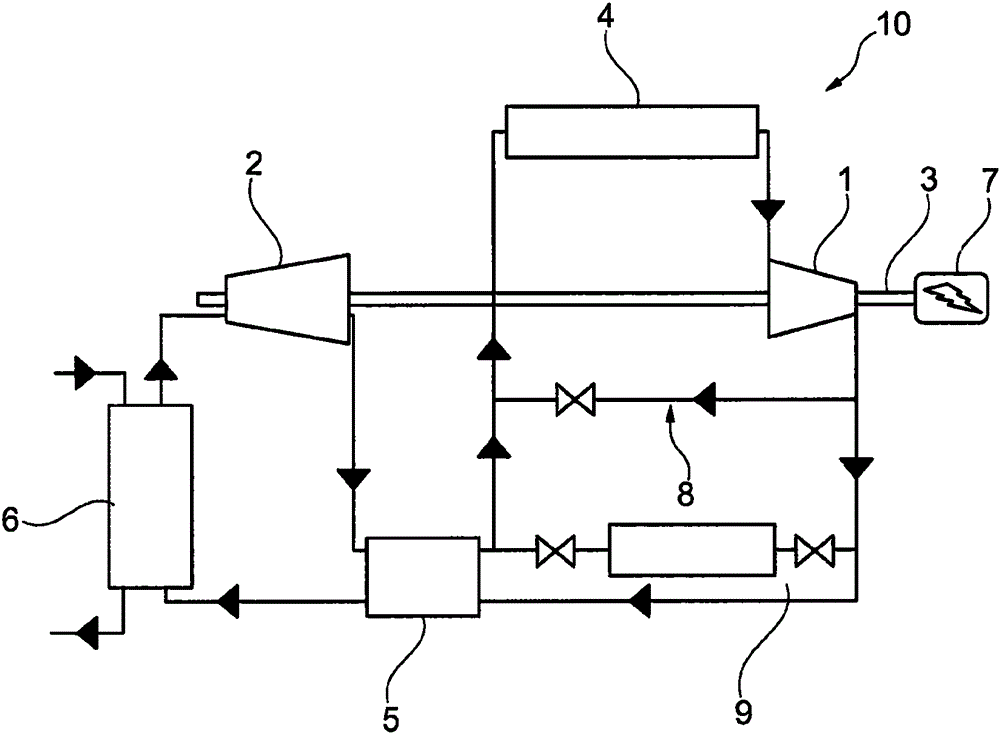

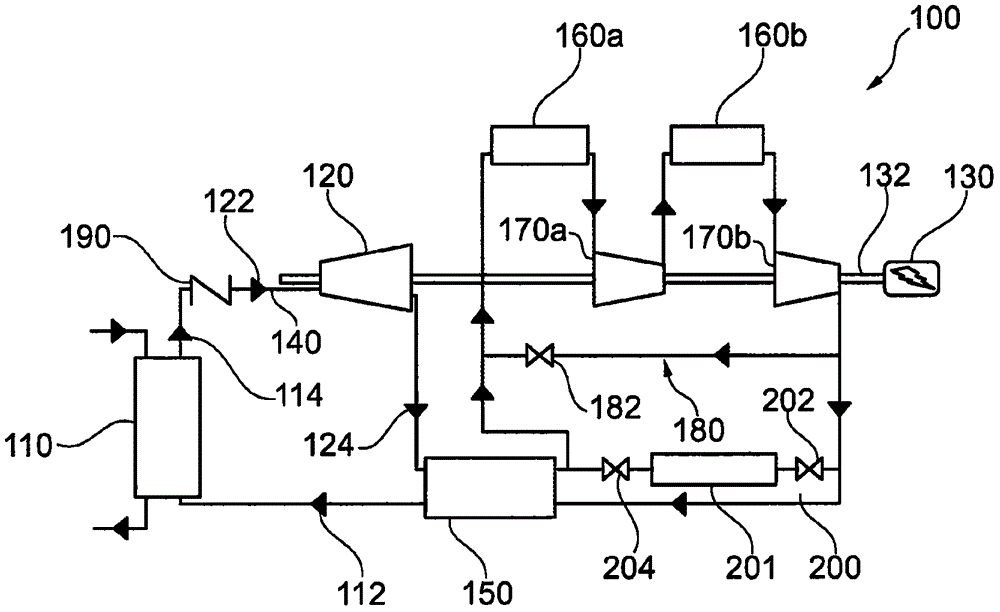

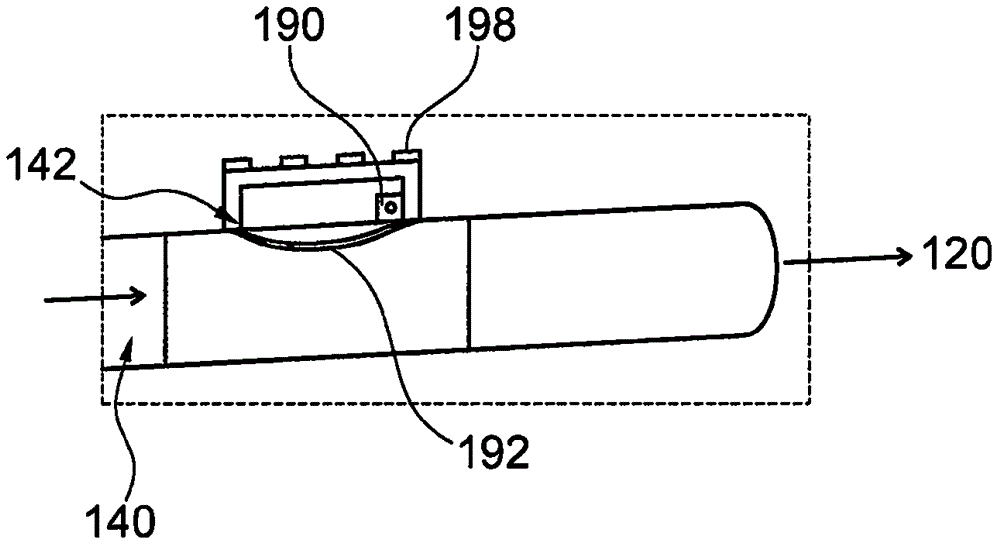

Control concept for closed loop brayton cycle

The invention relates to a control concept for a closed loop brayton cycle. The improved closed loop Brayton cycle 100 for a power plant is provided that includes a heater 110, at least one turbine 120, a recuperator 150, at least one cooler 160, at least one compressor 170, a bypass line 180 and a flap valve arrangement 190 in a closed circuit in which working fluid is circulated to produce electricity via a generator 132. Depending upon the requirement, such as, in case of gird load disconnection, speed of a shaft-line to which the turbine 120, the compressor 170 and the generator 132 are configured is also required to be reduced without any impact on the pressure drop in the cycle. For that the non-tight flap valve arrangement 190 is configured on each conduit 140 between the heater 110 and the at least one turbine 120 in a closest possible proximity to each turbine inlet 122.

Owner:GENERAL ELECTRIC TECH GMBH

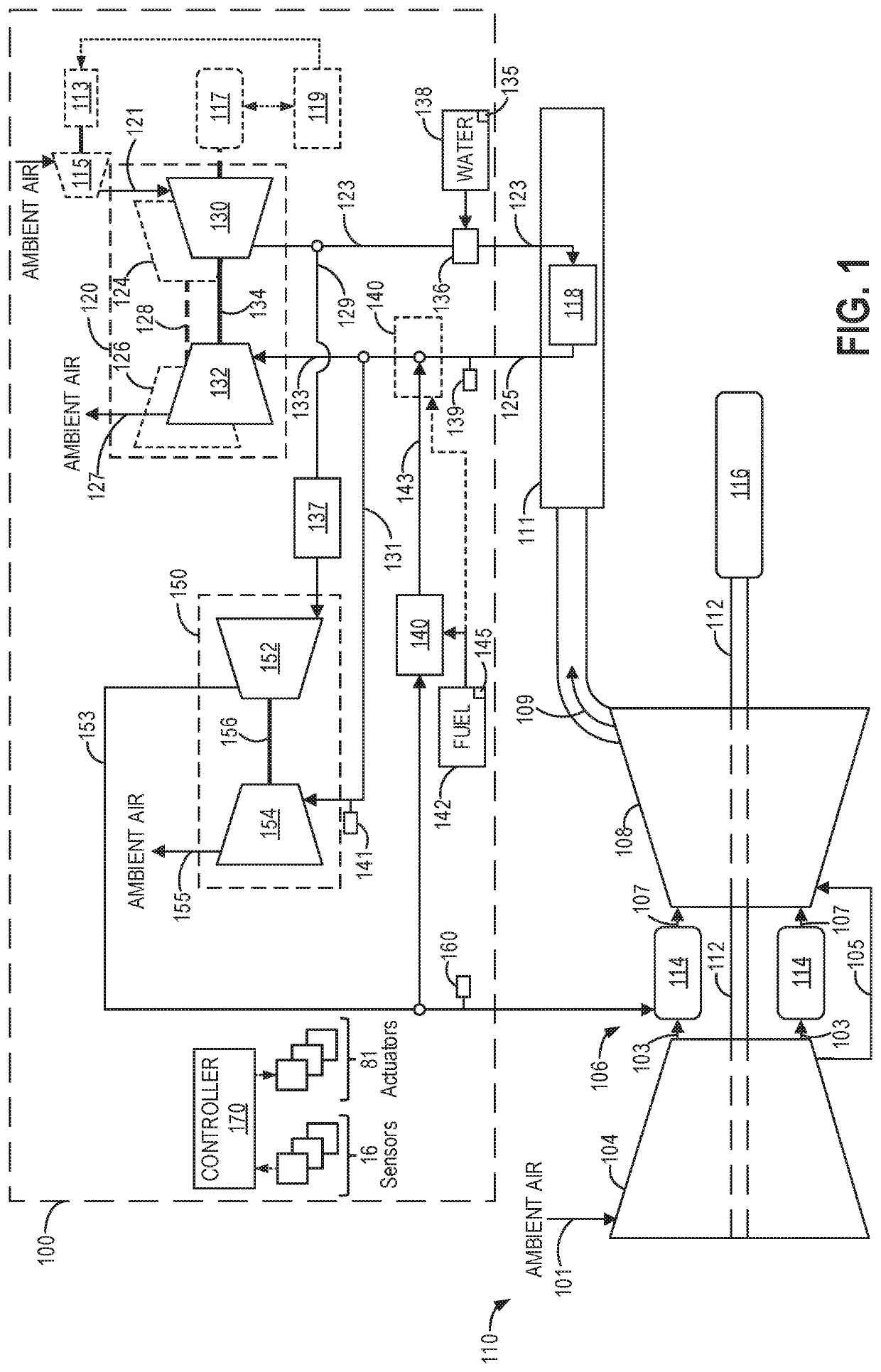

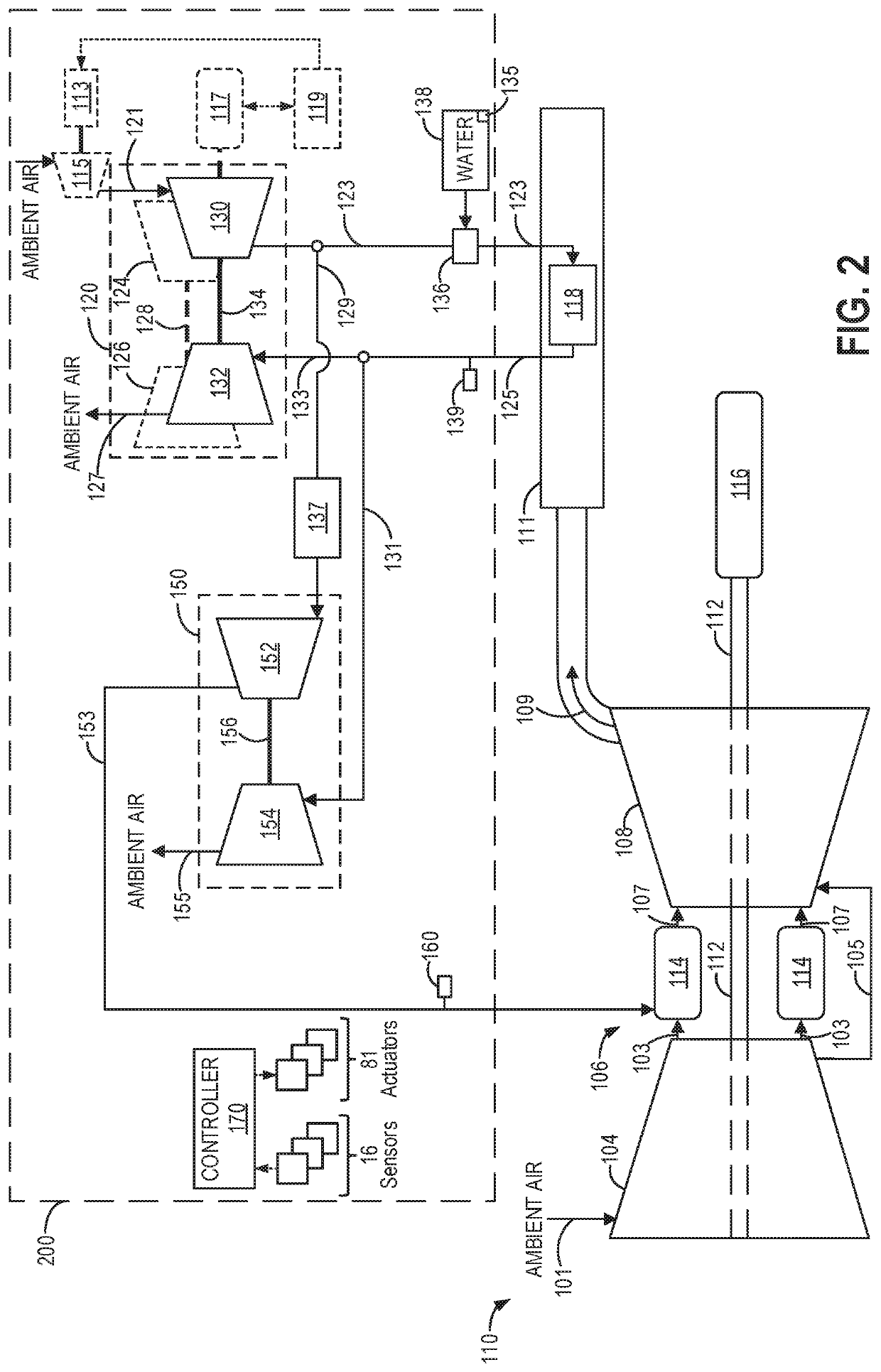

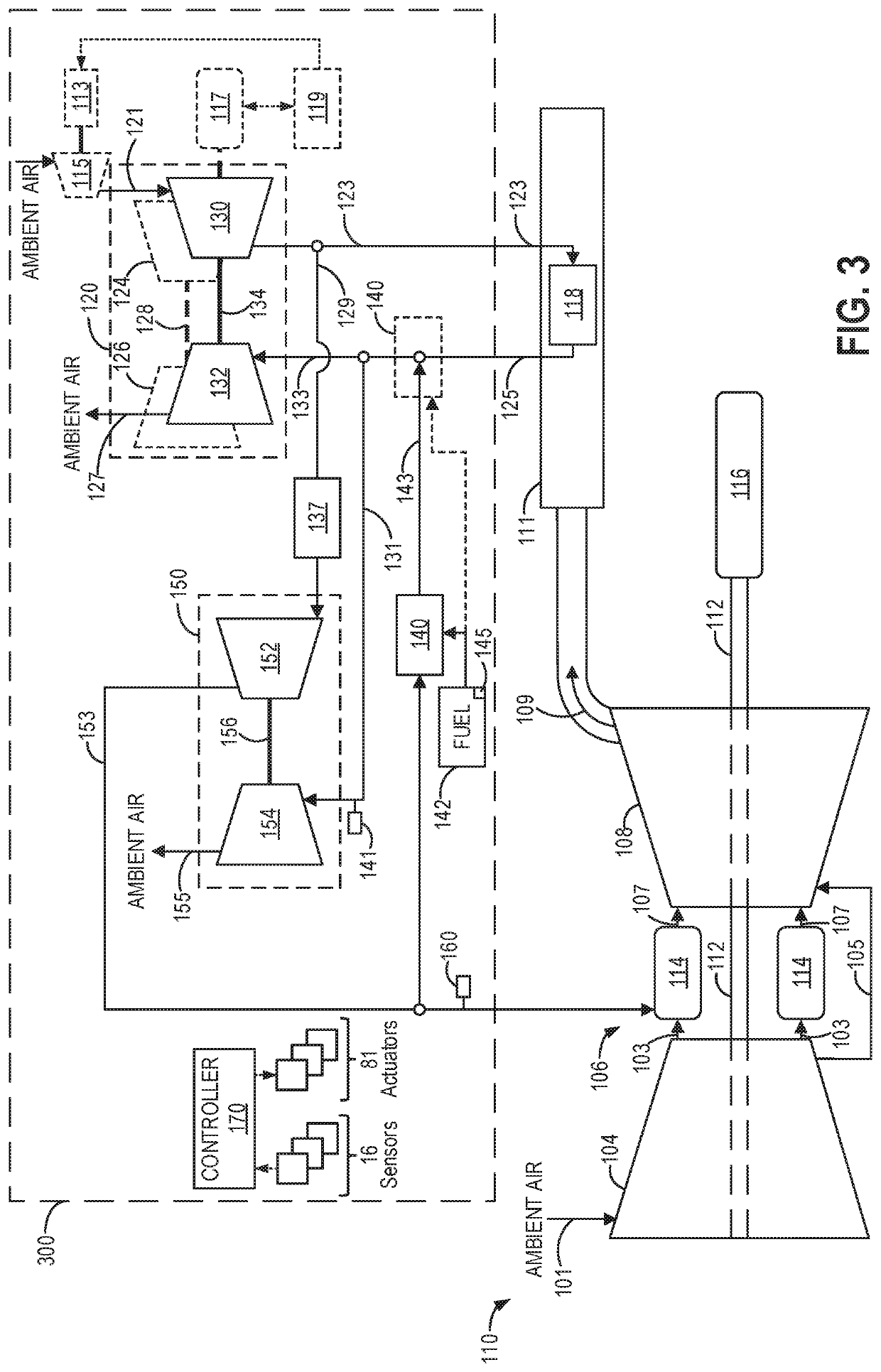

Systems and methods for increasing power output in a waste heat driven air brayton cycle turbocharger system

Various systems and methods are provided for a turbocharger system. In one example, system for use with a power generator having a rotary machine including a combustor comprises: a heat exchanger positioned to receive exhaust gases from the combustor; and a turbocharger system, comprising: a low pressure turbocharger including a low pressure turbine adapted to receive gas flow from the heat exchanger and a low pressure compressor adapted to supply compressed air to the heat exchanger; a high pressure turbocharger including a high pressure turbine adapted to receive gas flow from the heat exchanger and a high pressure compressor adapted to receive gas flow from the low pressure compressor and supply compressed air to the rotary machine; and a second combustor adapted to inject exhaust gases into a flow path arranged between the heat exchanger and an inlet to each of the high pressure turbine and the low pressure turbine.

Owner:GE GLOBAL SOURCING LLC

Hot-gas engine

InactiveUS7028473B2Simplified heat supplySimpler and compact and economical designStirling type enginesEricsson type enginesEngineeringInjection device

The hot-gas engine comprises a cylinder, a working piston which together with a cylinder cover delimits a cylinder space designed to accommodate a working medium, a displacement piston which divides the cylinder space into a first and a second working space, as well as a heating device for heating device for heating up the working medium contained in the first working space, and a cooling device for cooling the heated working medium. The working spaces are connected so as to be communicating by way of a regenerator arranged in the displacement piston. The heating device comprises a heating area on the end wall of the working piston, and a heating arrangement associated with the working piston. The cooling device comprises an injection device for feeding liquefied working medium into the first working space. This design provides improved heat supply to the working medium contained in the cylinder, and further provides direct cooling of said working medium. At the same time, a simpler and compact construction of the hot-gas engine can be achieved.

Owner:SERVIS WILHELM +1

Vessel of a heat storage and release apparatus, heat storage and release assembly, and energy production plant

A vessel of a heat storage and release apparatus, the vessel comprises a shell comprising a metallic material, the shell having an elongated shape with a first end region and a second end region remote from the first end region, and an internal surface defining a cavity configured to contain a heat storage and release device and to guide gas-flow; a first opening through the shell for a flow of gas at high temperature and high pressure, the first opening being located in the first end region; a second opening through the shell for a flow of gas at low temperature and high pressure, the second opening being located in the second end region; and a lining of thermally insulating material adjacent to the internal surface and only partially covering the internal surface, the lining being located at least in the first end region.

Owner:NUOVO PIGNONE TECH SRL

S-CO2 cycle waste-heat utilizing system for EGR cooler of marine low-speed diesel engine

InactiveCN106499550ASolve the emission problemSolve the problem of energy consumptionInternal combustion piston enginesExhaust gas recirculationEngineeringHigh pressure

The invention aims to provide an S-CO2 cycle waste-heat utilizing system for an EGR cooler of a marine low-speed diesel engine. The S-CO2 cycle waste-heat utilizing system is characterized in that a supercritical CO2 Brayton cycle of an S-CO2 loop absorbs the energy of exhaust in the EGR cooler, and reduces the temperature of the exhaust to a temperature above an exhaust acid-dew-point or cools the exhaust to a temperature below the acid dew point through a corrosion-resistant material; high-temperature high-pressure supercritical CO2 gas discharged form a working medium side of the EGR cooler enters an expansion machine to do work, and electricity is generated through a shaft generator; S-CO2 discharged from the expansion machine enters a heat regenerator to preheat S-CO2 on the low-temperature side of the regenerator, and then enters a cooler to be cooled; and S-CO2 discharged from the cooler enters a compressor to be compressed to be pressurized, is preheated through the heat regenerator and then enters the EGR cooler to perform heating to finish a whole cycle. The S-CO2 cycle waste-heat utilizing system provided by the invention effectively recycles the energy of high-temperature flue gas in the EGR cooler of the marine low-speed diesel engine, and relieves the problem that the oil consumption is increased because the marine low-speed diesel engine adopts an EGR technology.

Owner:HARBIN ENG UNIV

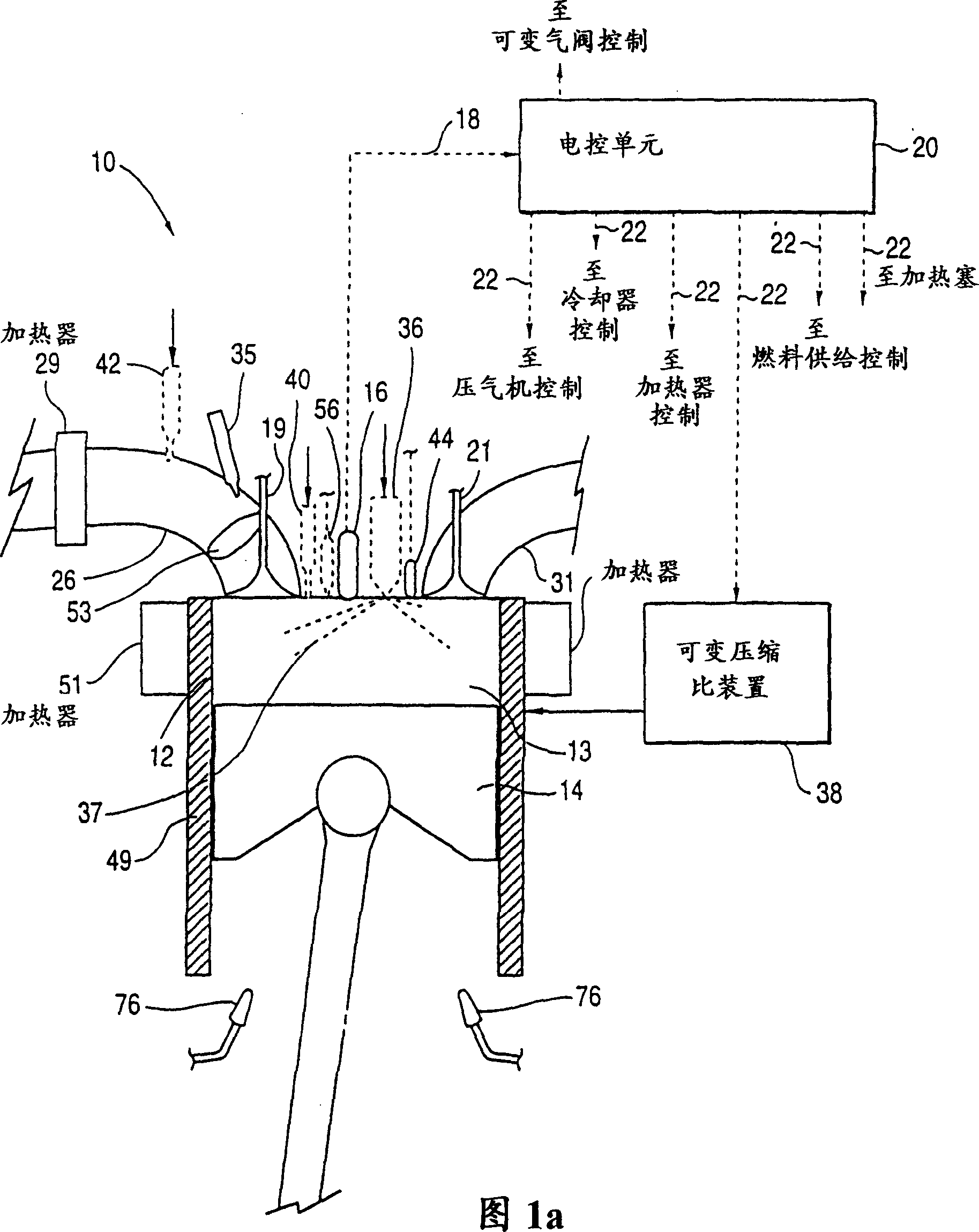

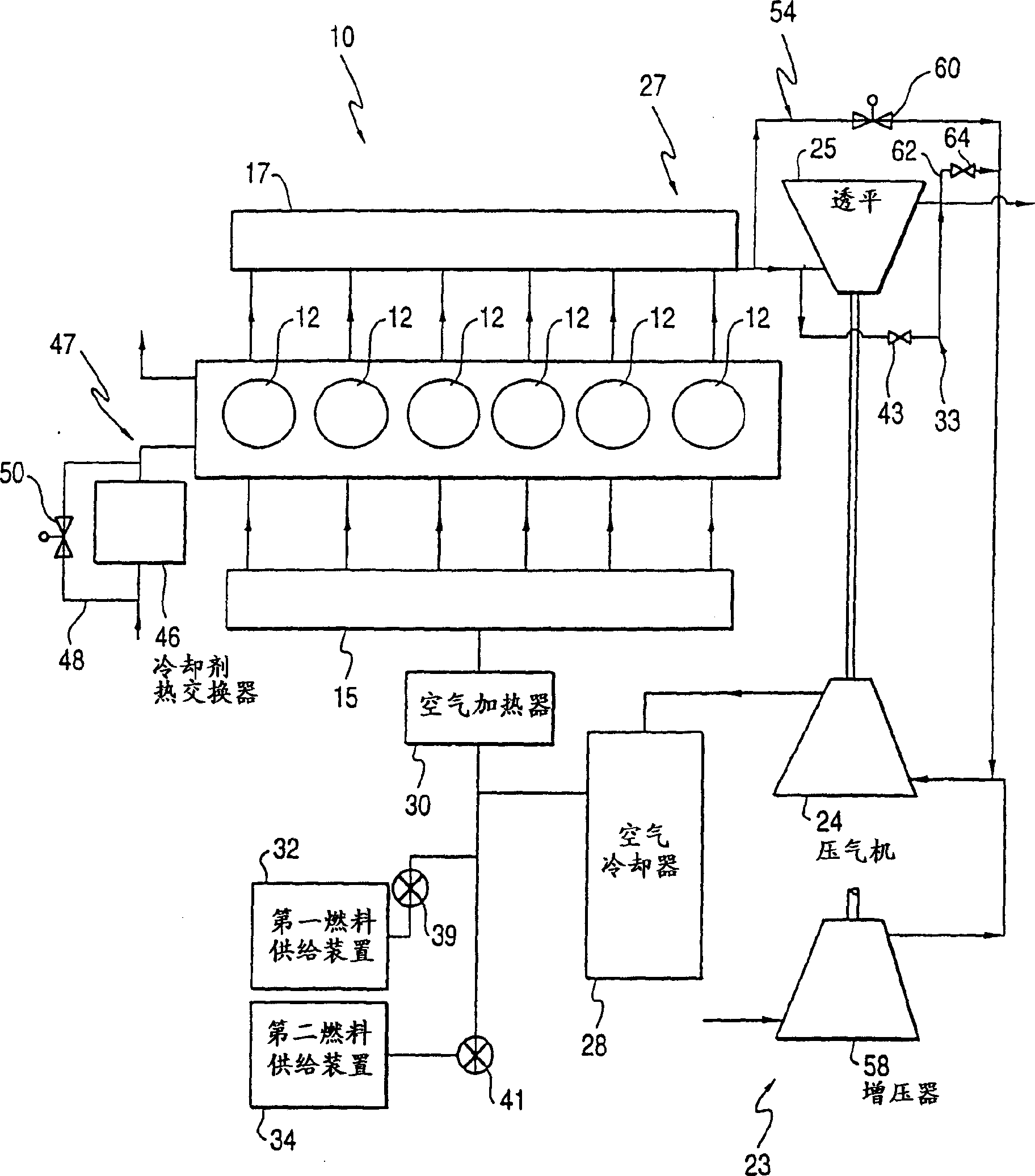

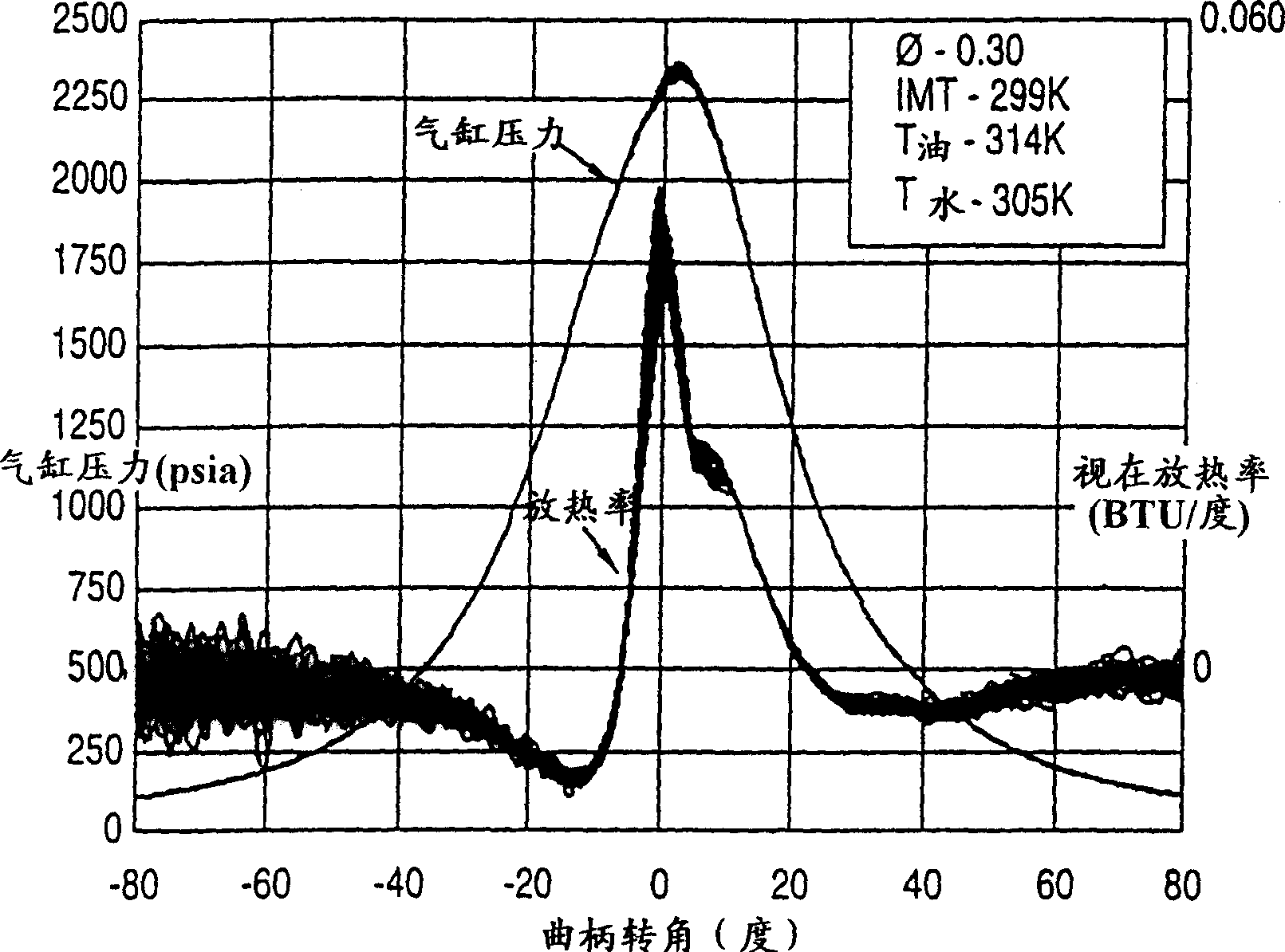

Internal combustion engine operated according to premixed charge compression ignition mode

InactiveCN1188589CControl control systemEffective controlElectrical controlInternal combustion piston enginesCombustion noiseEquivalence ratio

A premixed charge compression ignition engine, and a control system, is provided which effectively initiates combustion by compression ignition and maintains stable combustion while achieving extremely low oxides of nitrogen emissions, good overall efficiency and acceptable combustion noise and cylinder pressures. The present engine and control system effectively controls the combustion history, that is, the time at which combustion occurs, the rate of combustion, the duration of combustion and / or the completeness of combustion, by controlling the operation of certain control variables providing temperature control, pressure control, control of the mixture's autoignition properties and equivalence ratio control. The combustion control system provides active feedback control of the combustion event and includes a sensor, e.g. pressure sensor, for detecting an engine operating condition indicative of the combustion history, e.g. the start of combustion, and generating an associated engine operating condition signal. A processor receives the signal and generates control signals based on the engine operating condition signal for controlling various engine components to control the temperature, pressure, equivalence ratio and / or autoignition properties so as to variably control the combustion history of future combustion events to achieve stable, low emission combustion in each cylinder and combustion balancing between the cylinders.

Owner:CUMMINS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com