Patents

Literature

87results about "Open-cycle gas positive displacement engine plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

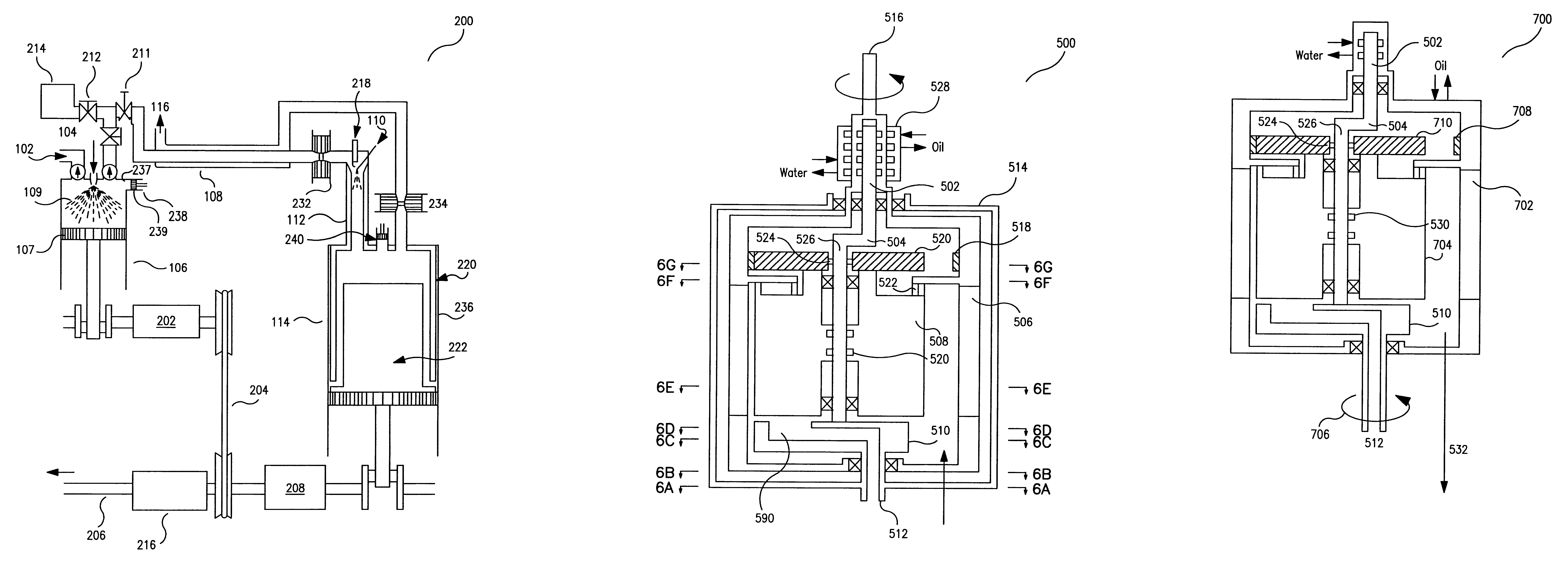

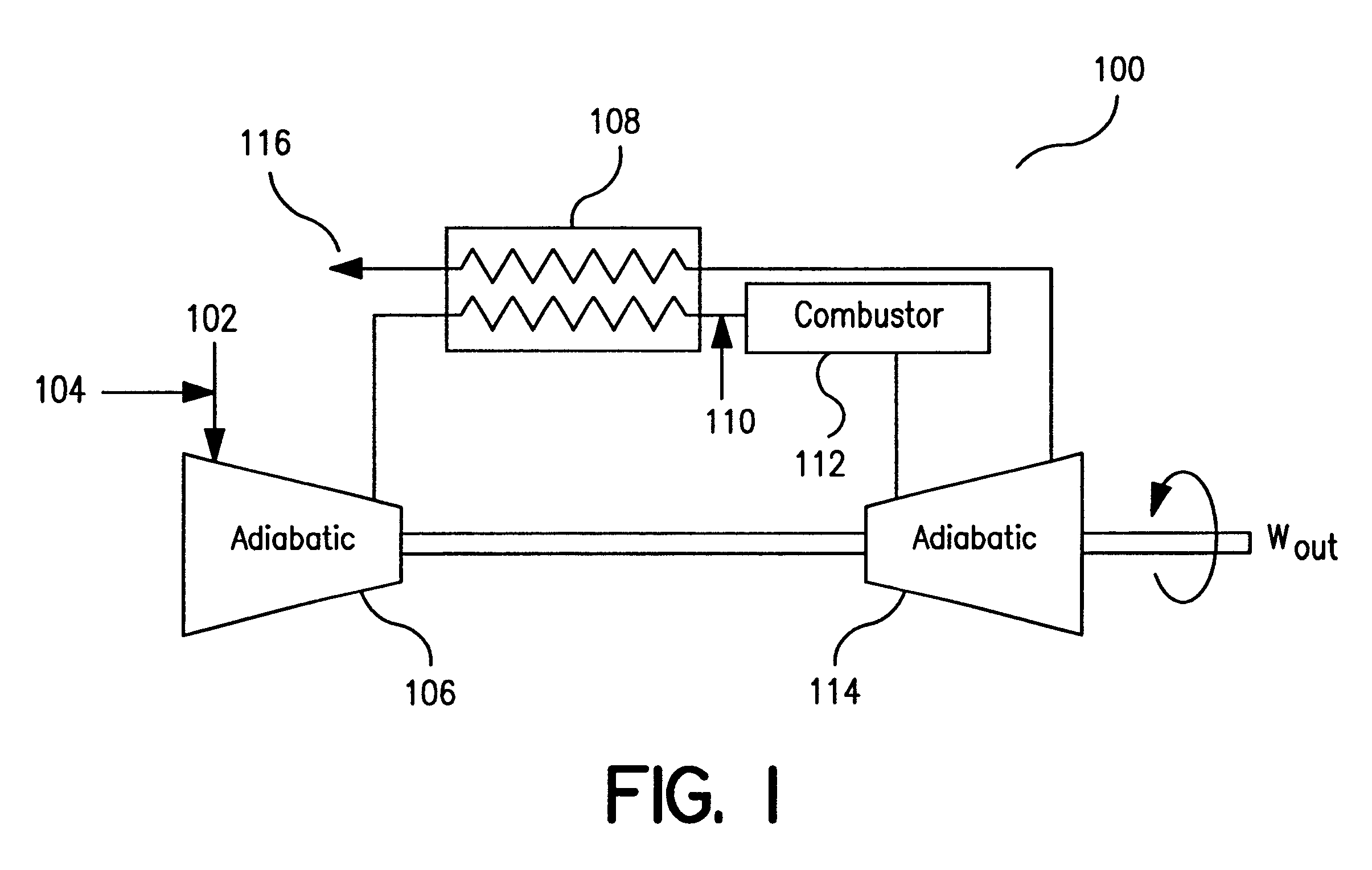

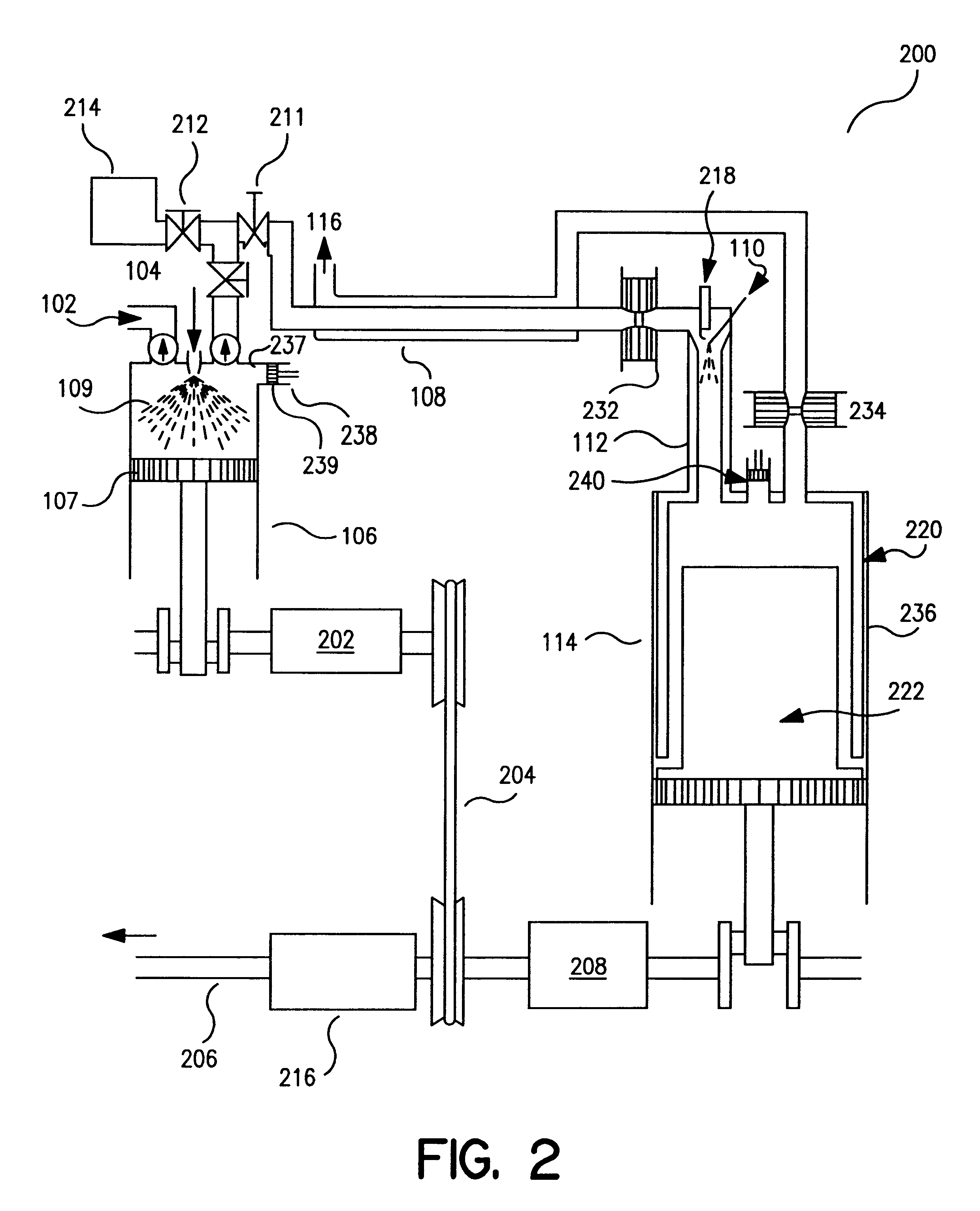

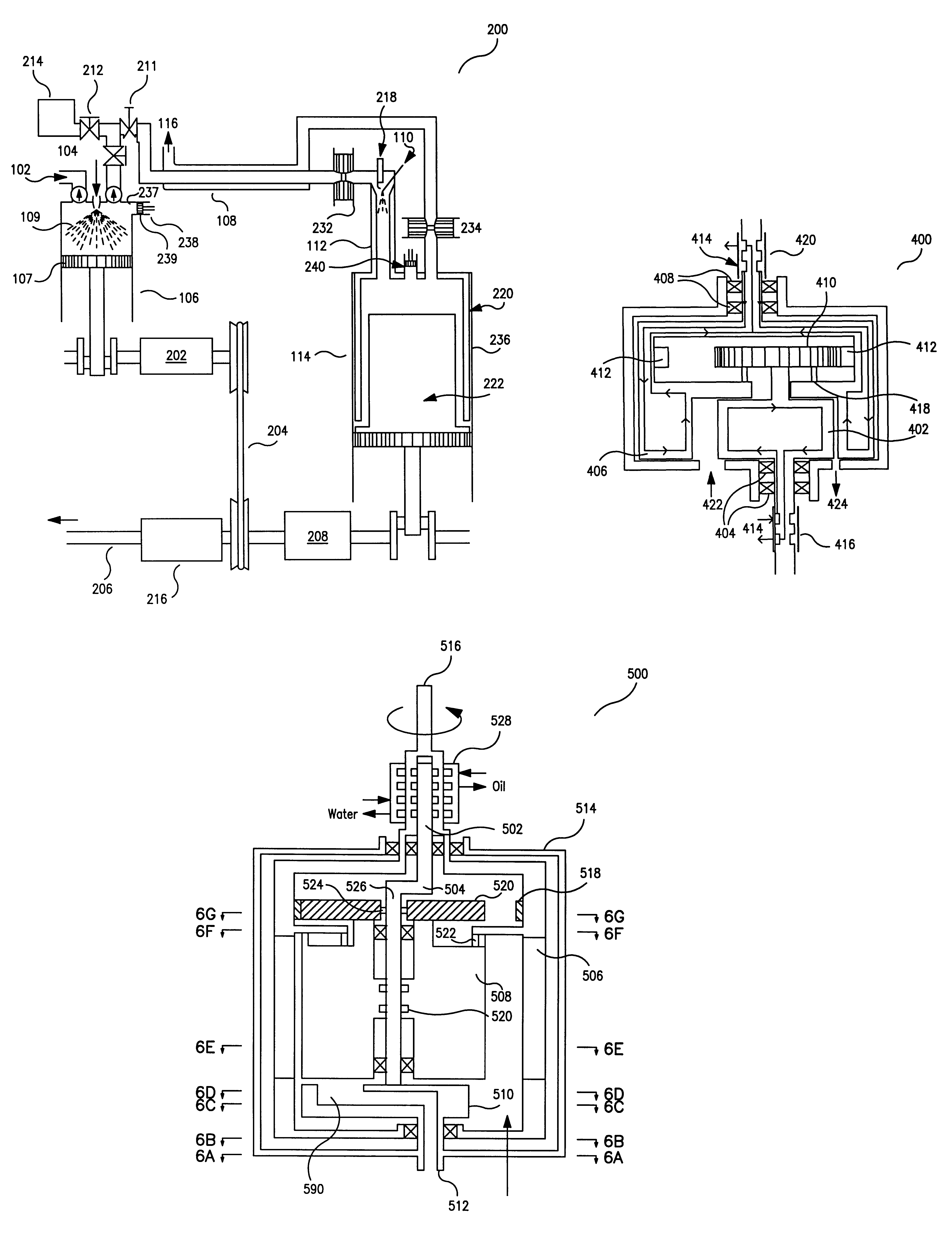

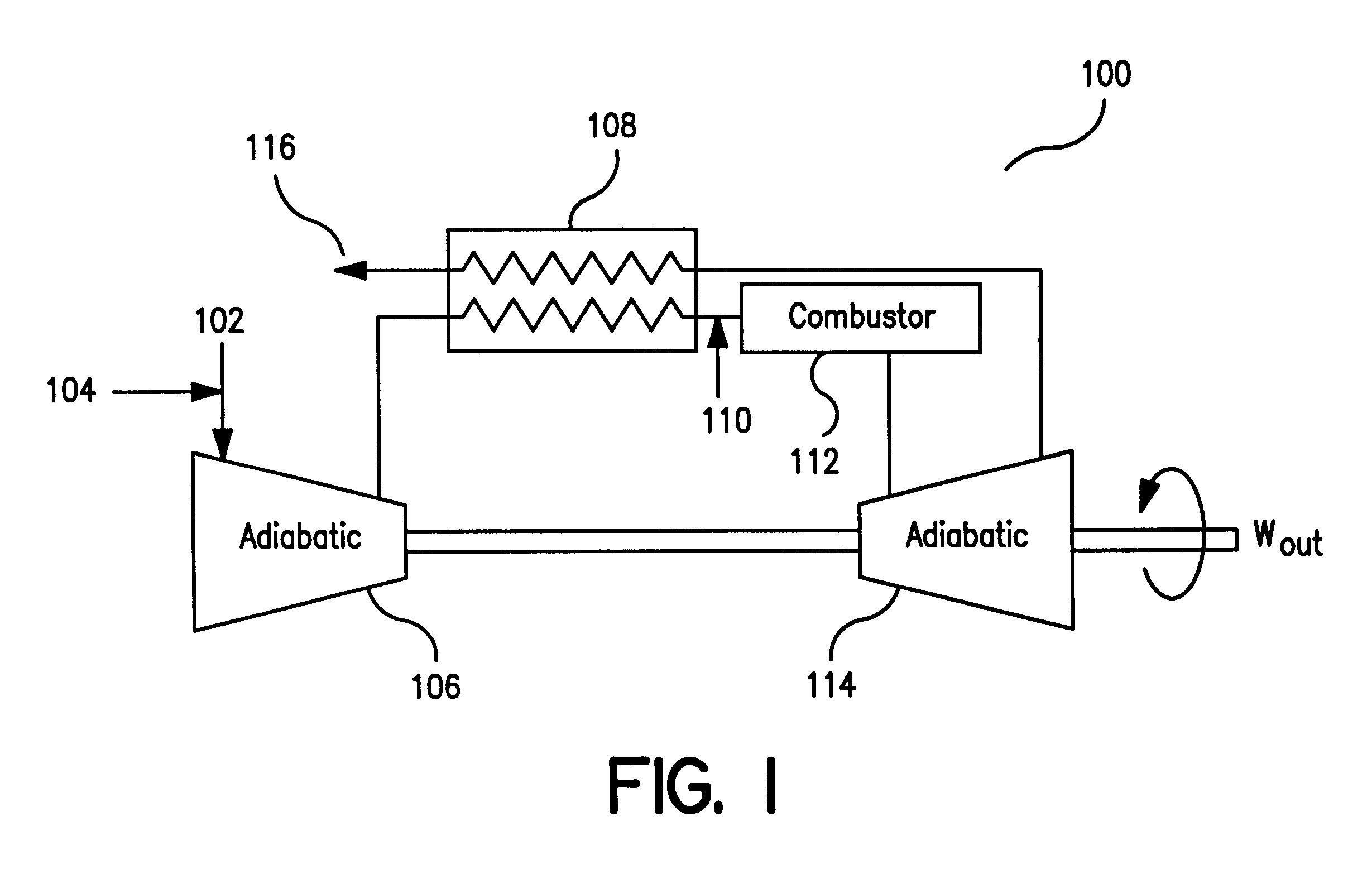

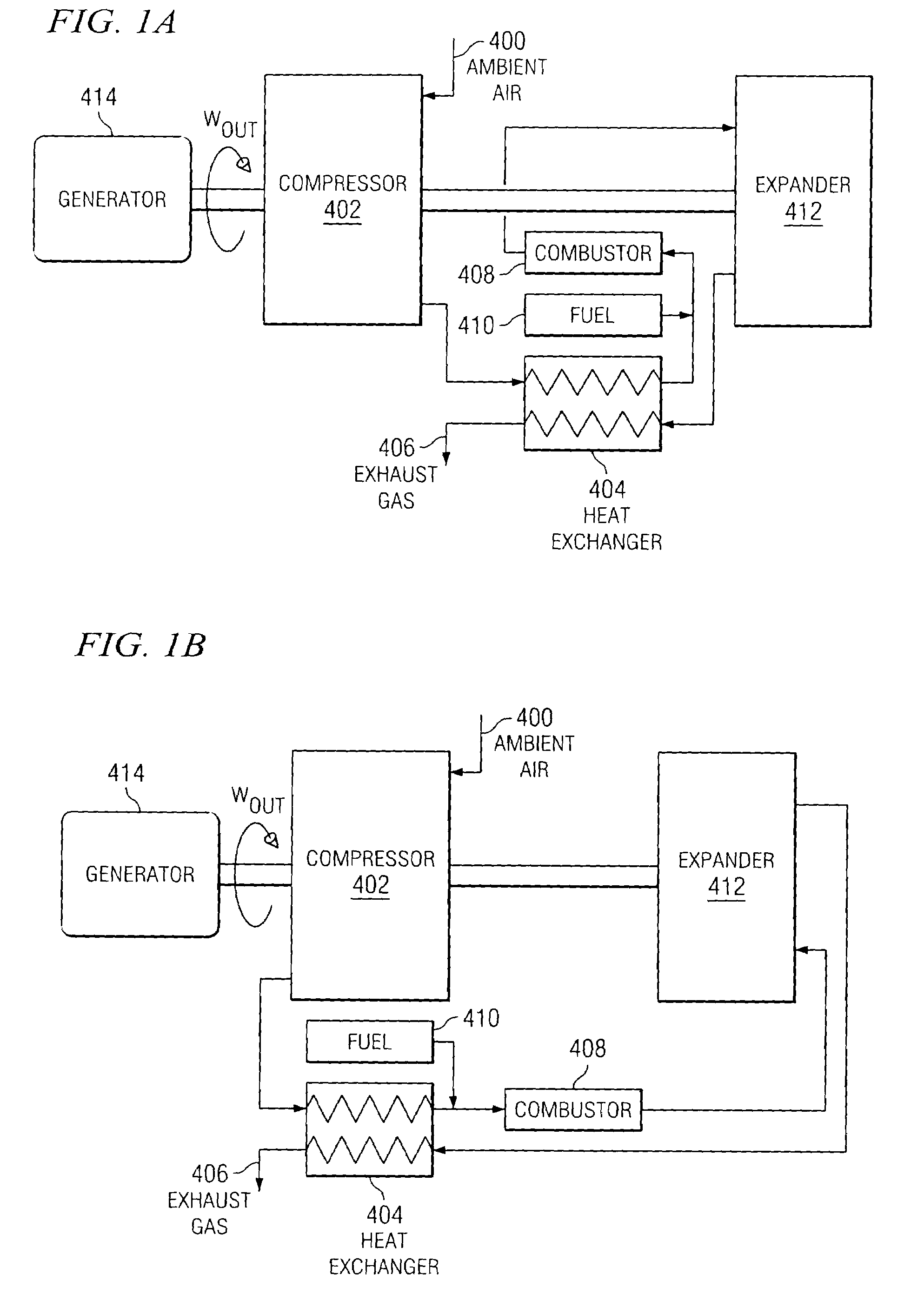

Quasi-isothermal Brayton Cycle engine

InactiveUS6530211B2Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesEngine of arcuate-engagement typeBrayton cycleCombustor

Owner:HOLTZAPPLE MARK T +1

Quasi-isothermal Brayton cycle engine

InactiveUS6336317B1Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesCombination enginesBrayton cycleCombustor

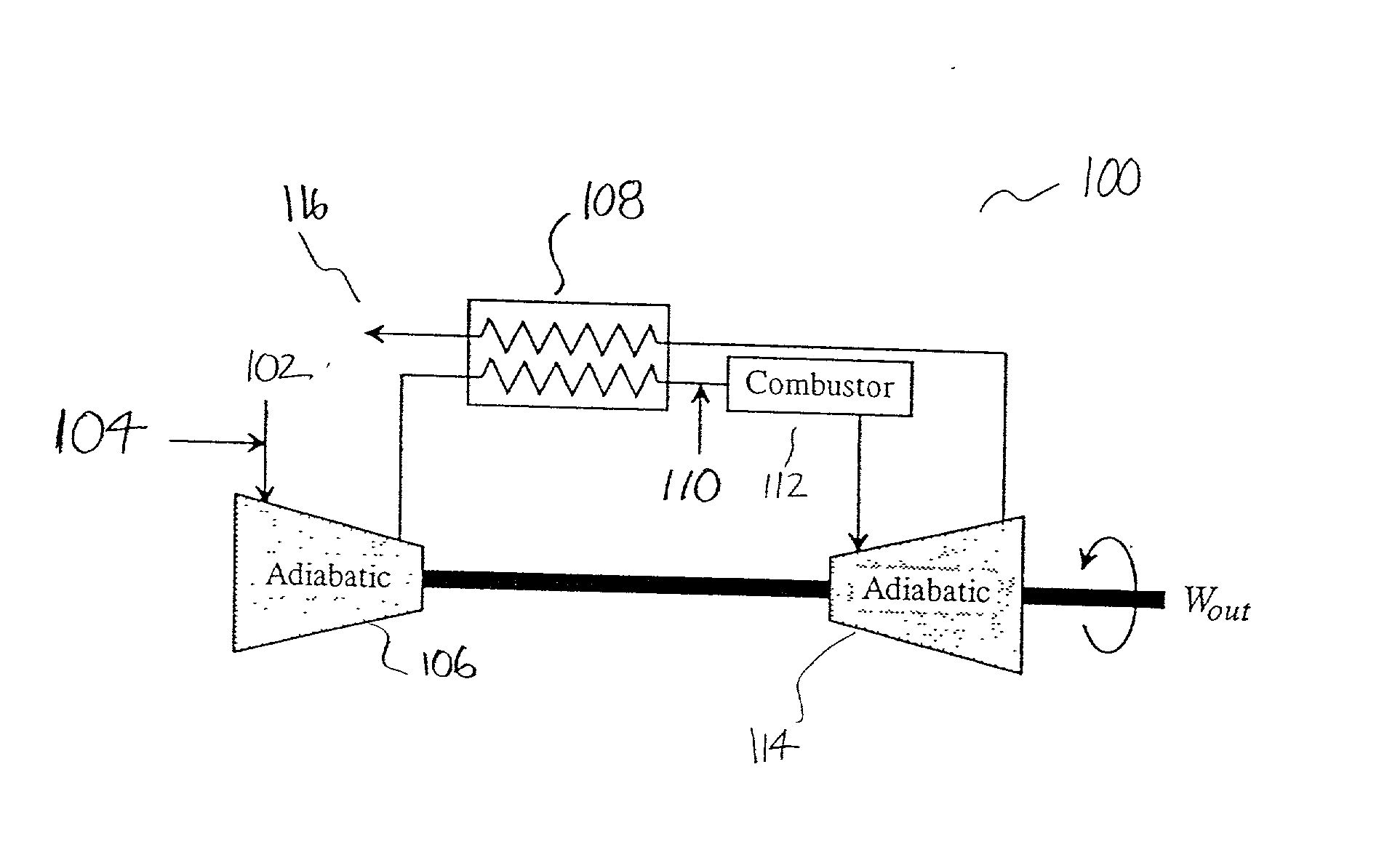

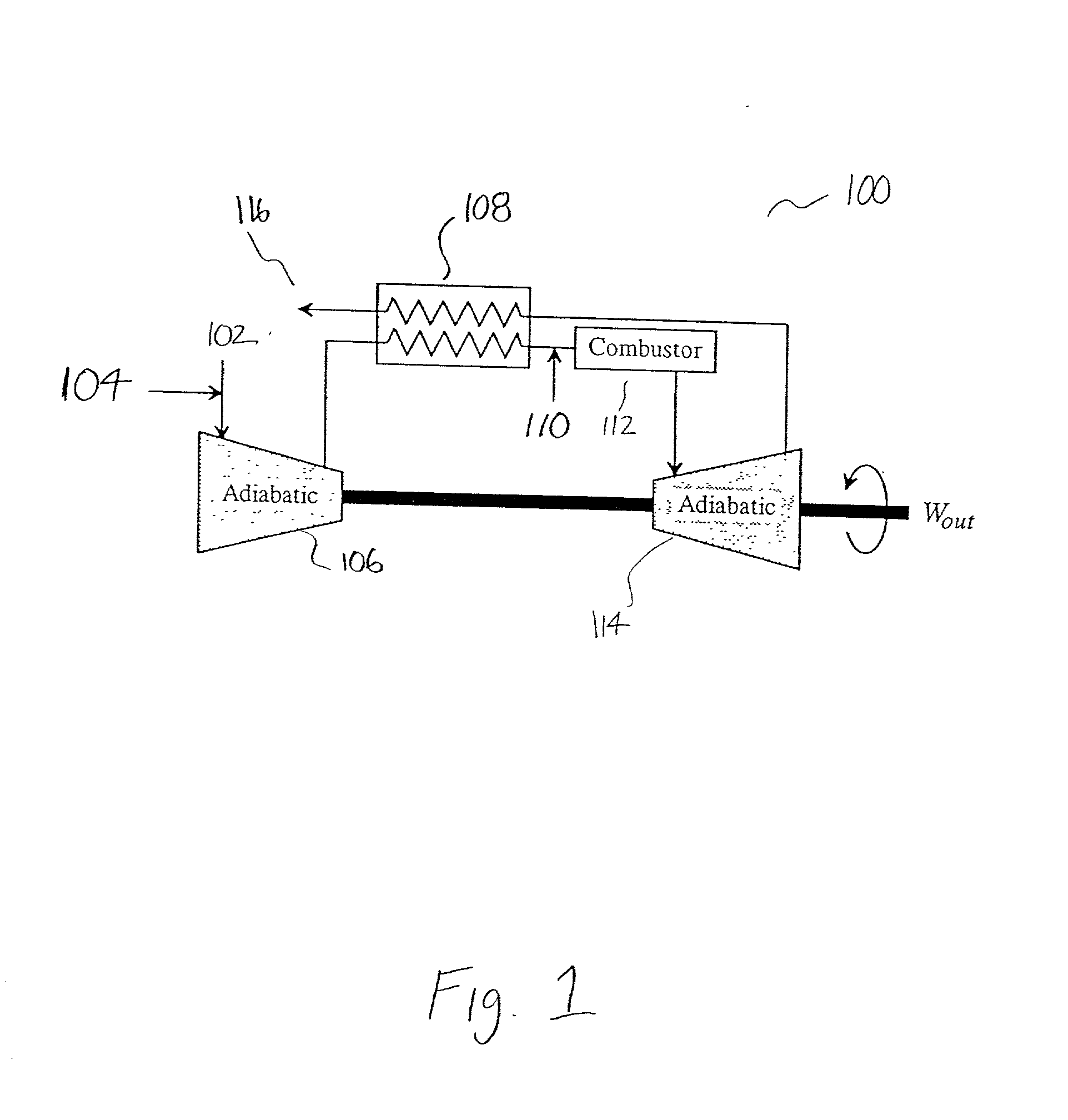

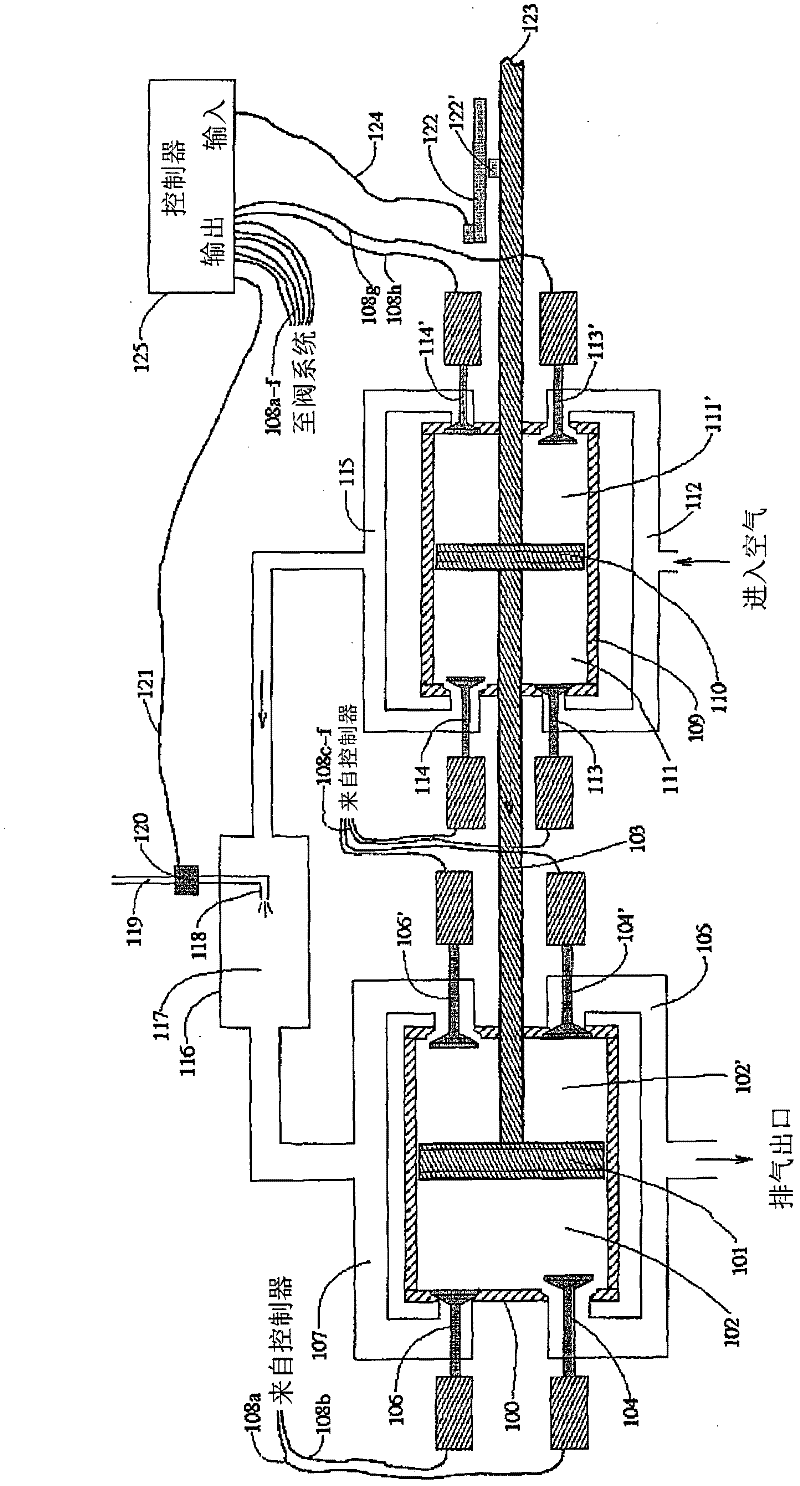

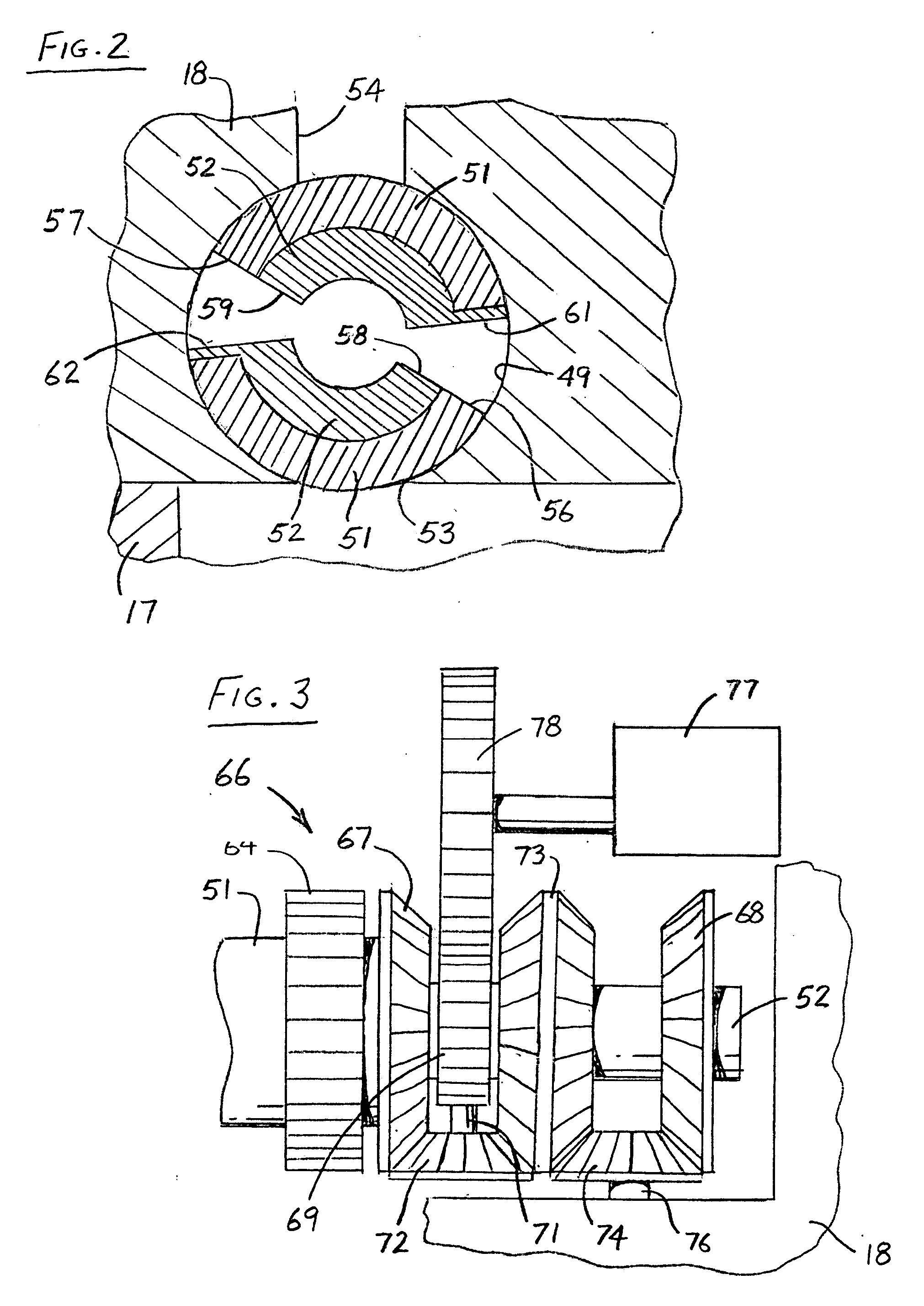

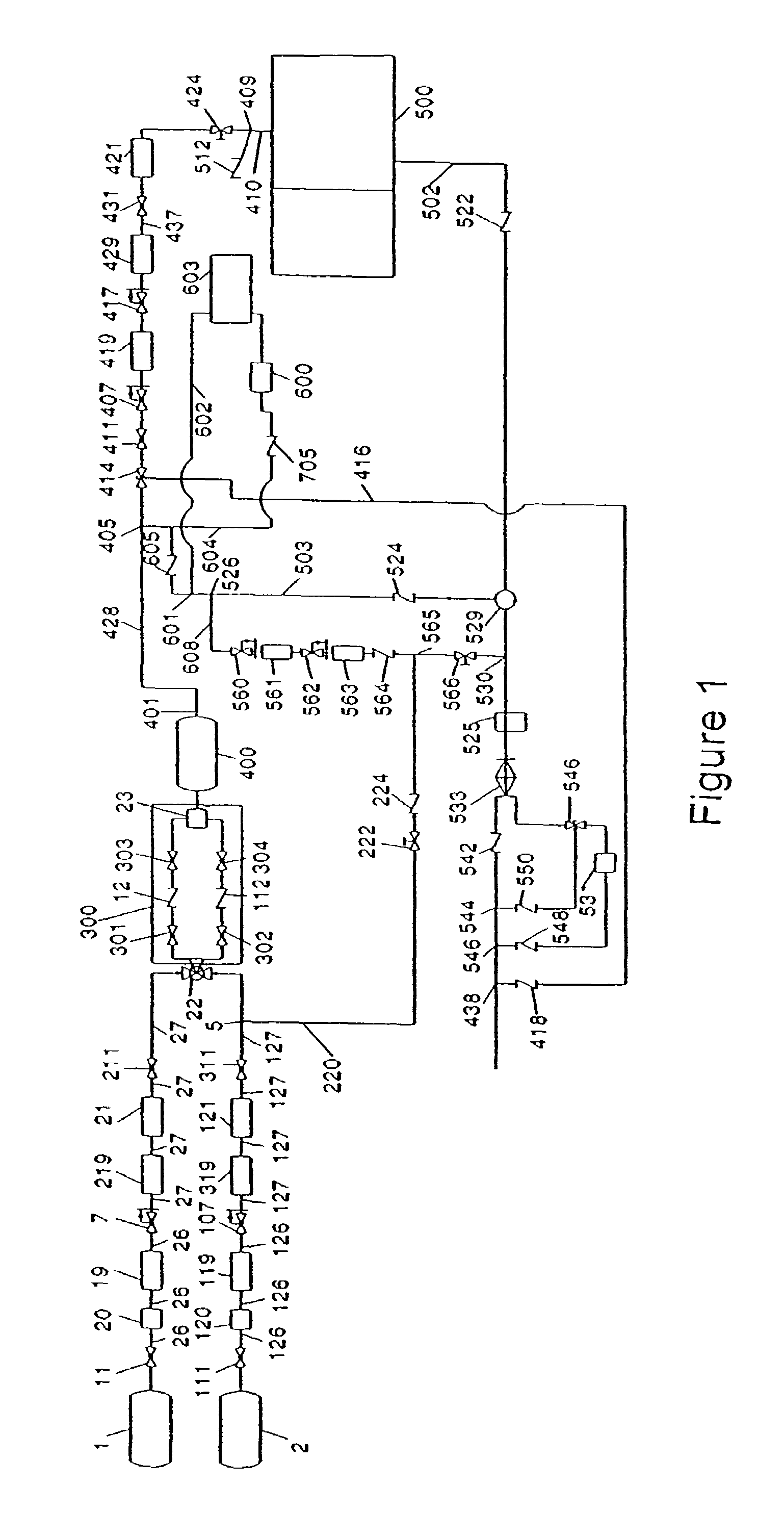

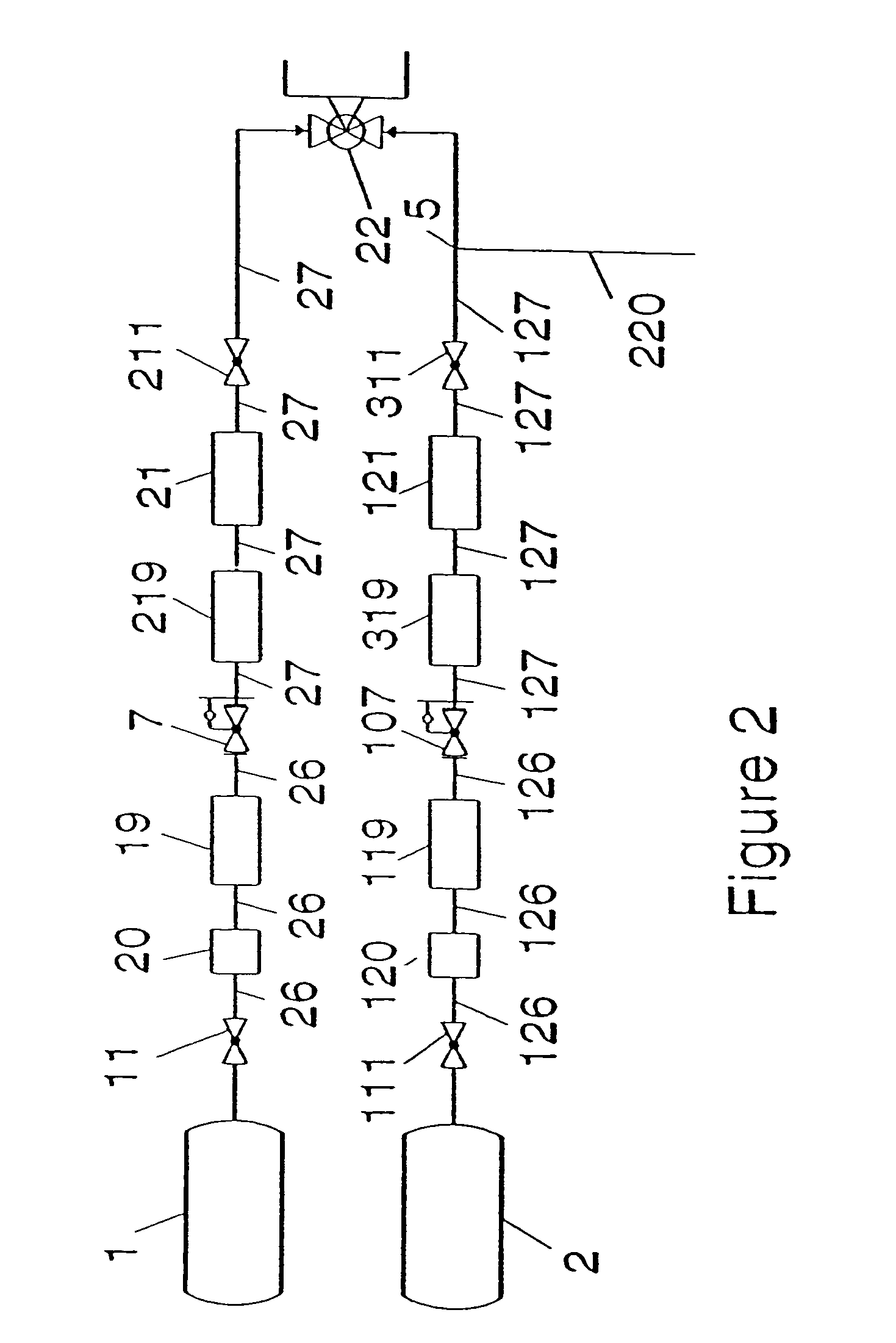

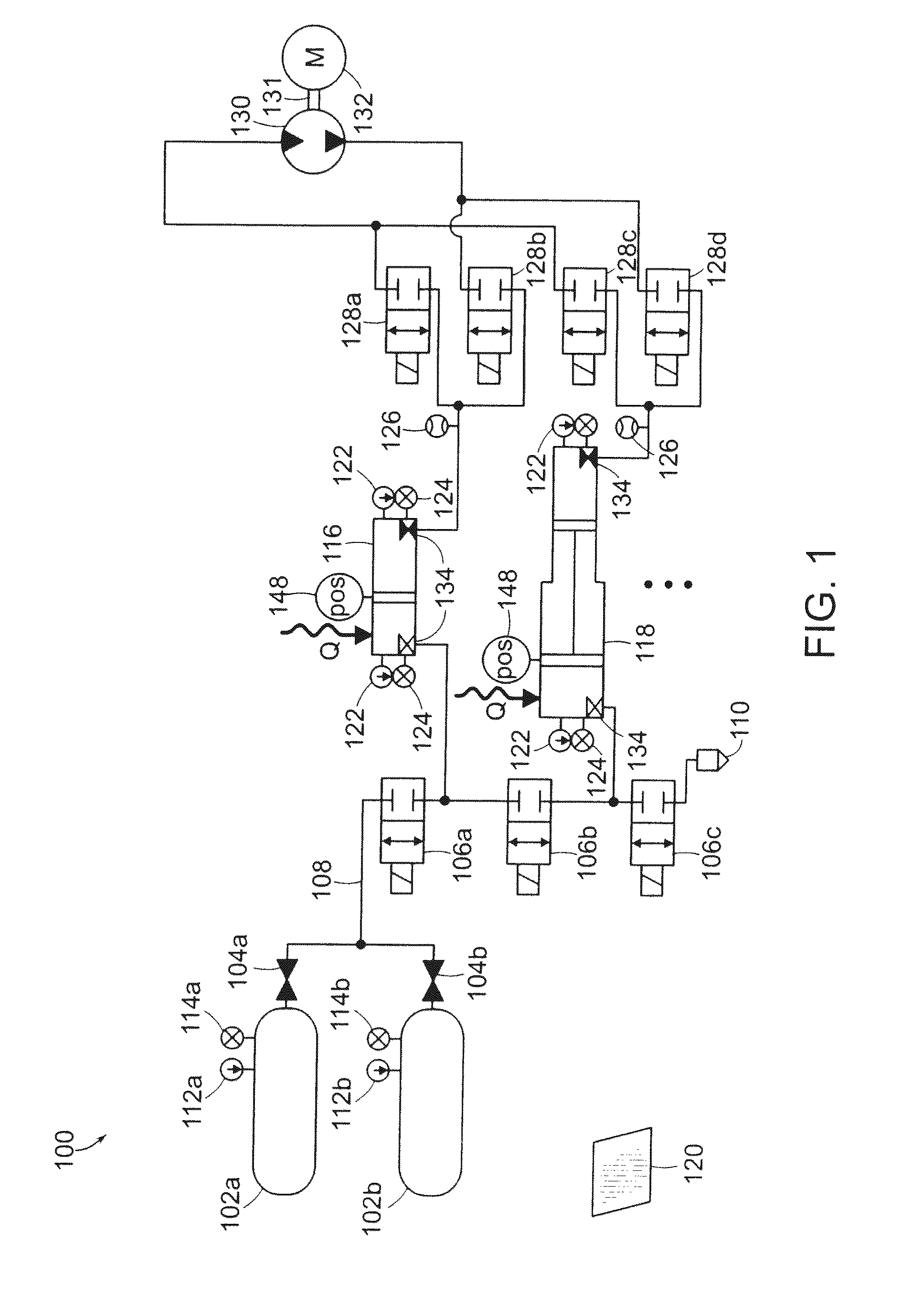

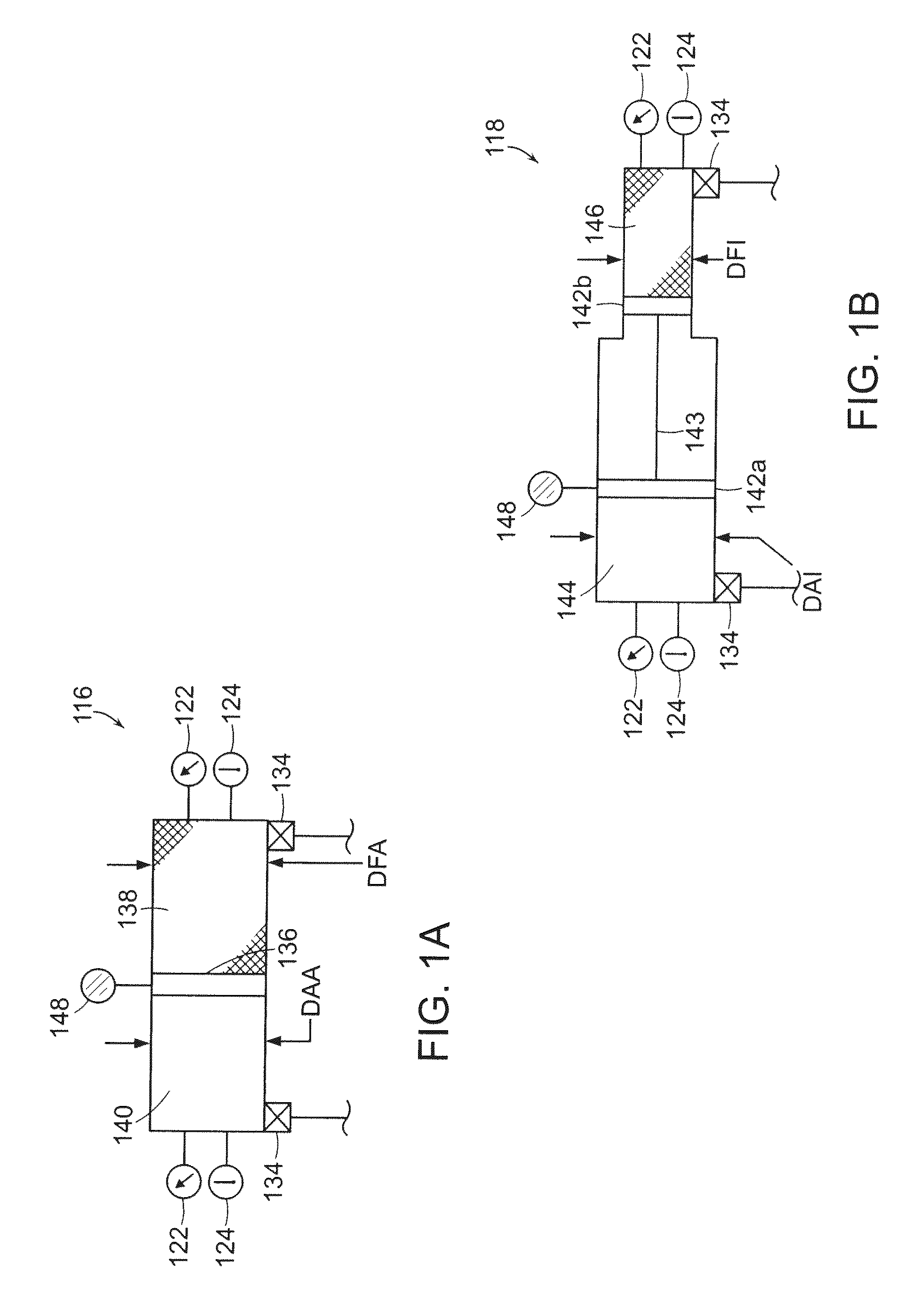

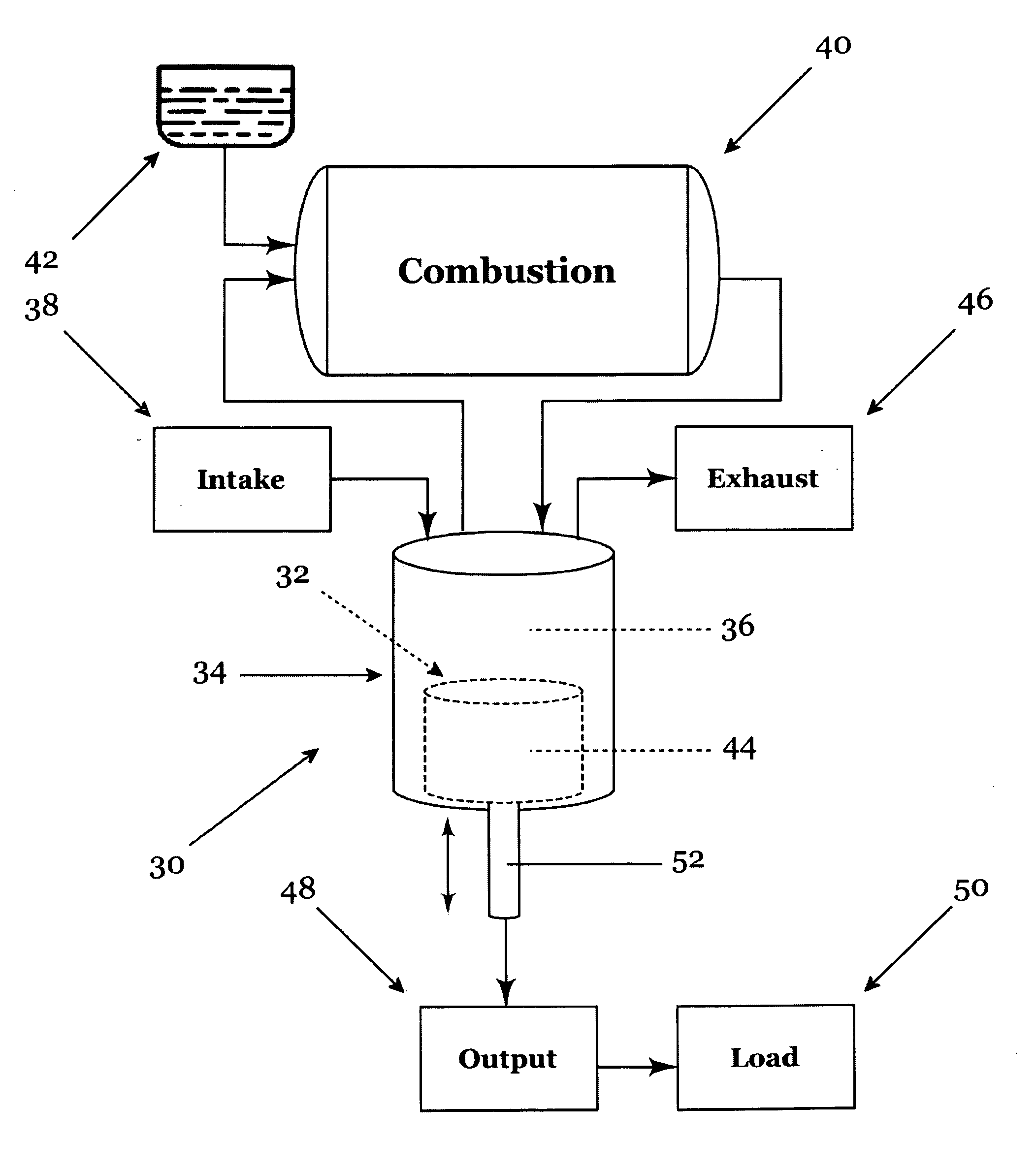

An engine is disclosed. According to one embodiment of the present invention, the engine comprises a compressor, and combustor, and an expander. The compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The expander receives the exhaust gases from the combustor, and expands the exhaust gasses. The compressor may be a gerotor compressor or a piston compressor having variable-dead-volume control. The expander may be a gerotor expander or a piston expander having variable-dead-volume control. In another embodiment, an engine comprises a piston compressor, a combustor, a piston expander, and a pressure tank. The piston compressor compresses ambient air. The combustor burns the compressed air, and produces exhaust gasses. The piston expander receives the exhaust gasses from the combustor, and expands the exhaust gasses. The pressure tank receives and stores the compressed air from the compressor. In another embodiment, a gerotor compressor or a gerotor expander comprises an inner gerotor, and an outer gerotor. The inner gerotor and the outer gerotor are driven so that they do not touch. The gerotors may be cantilevered or non-cantilevered.

Owner:TEXAS A&M UNIVERSITY

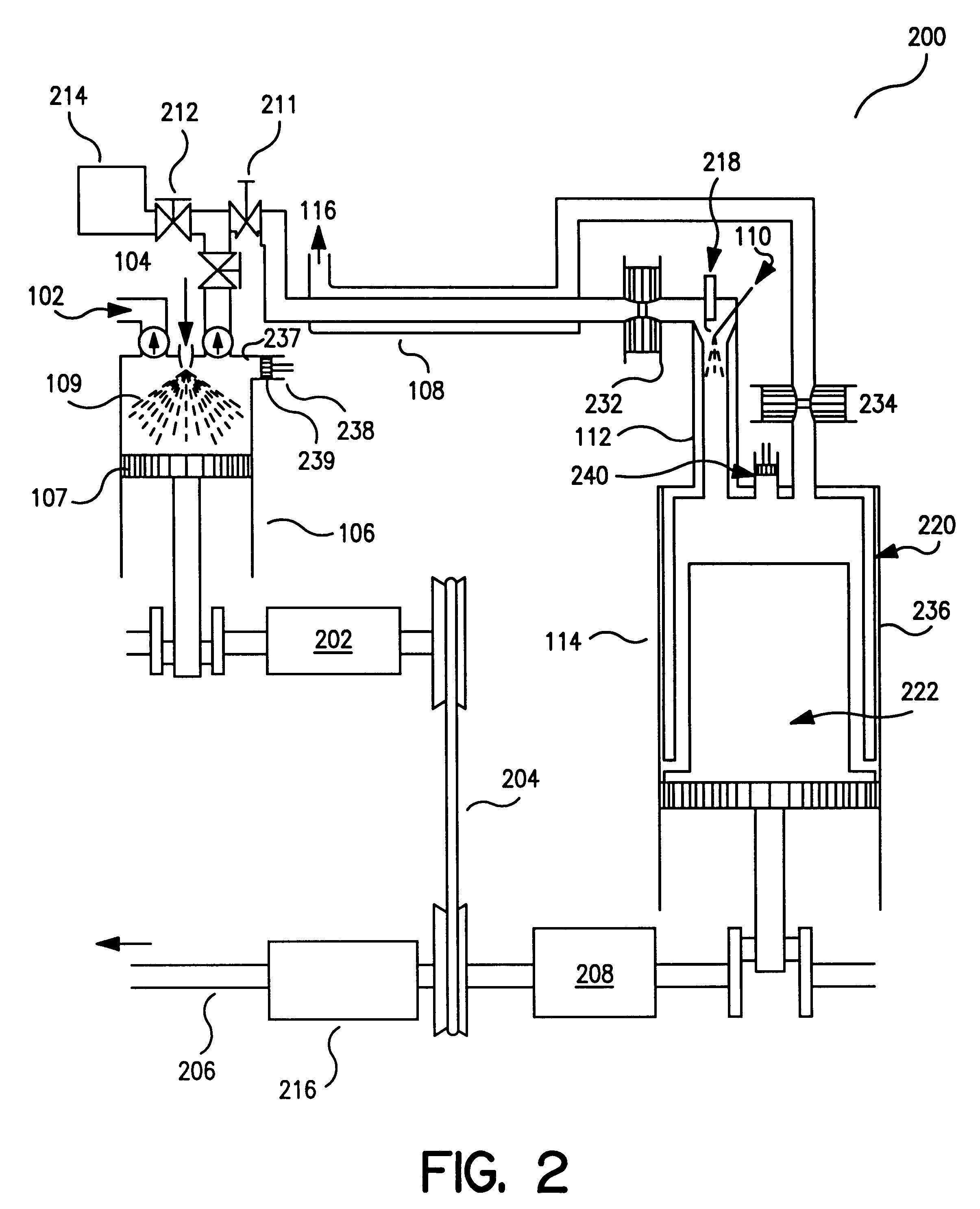

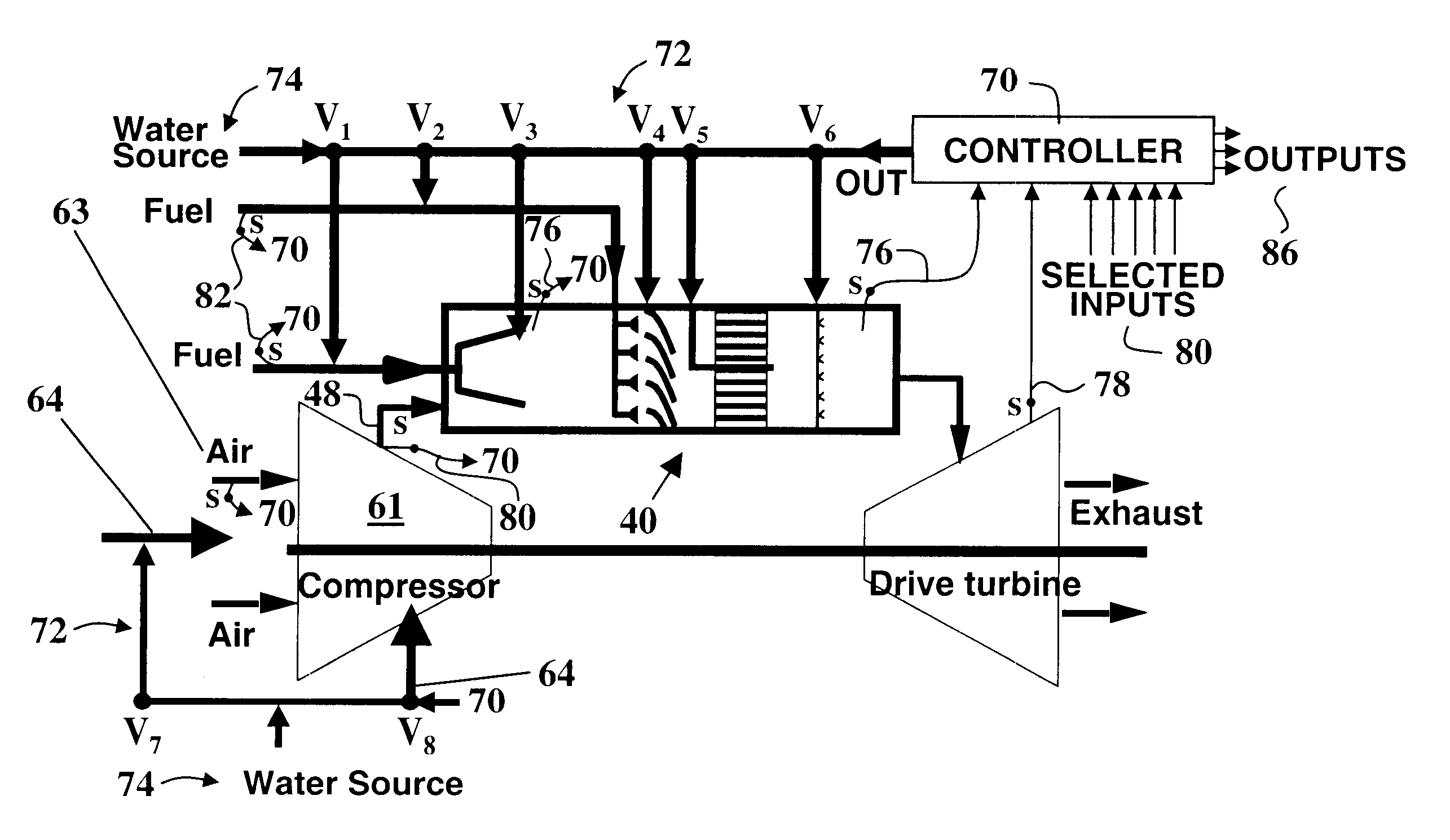

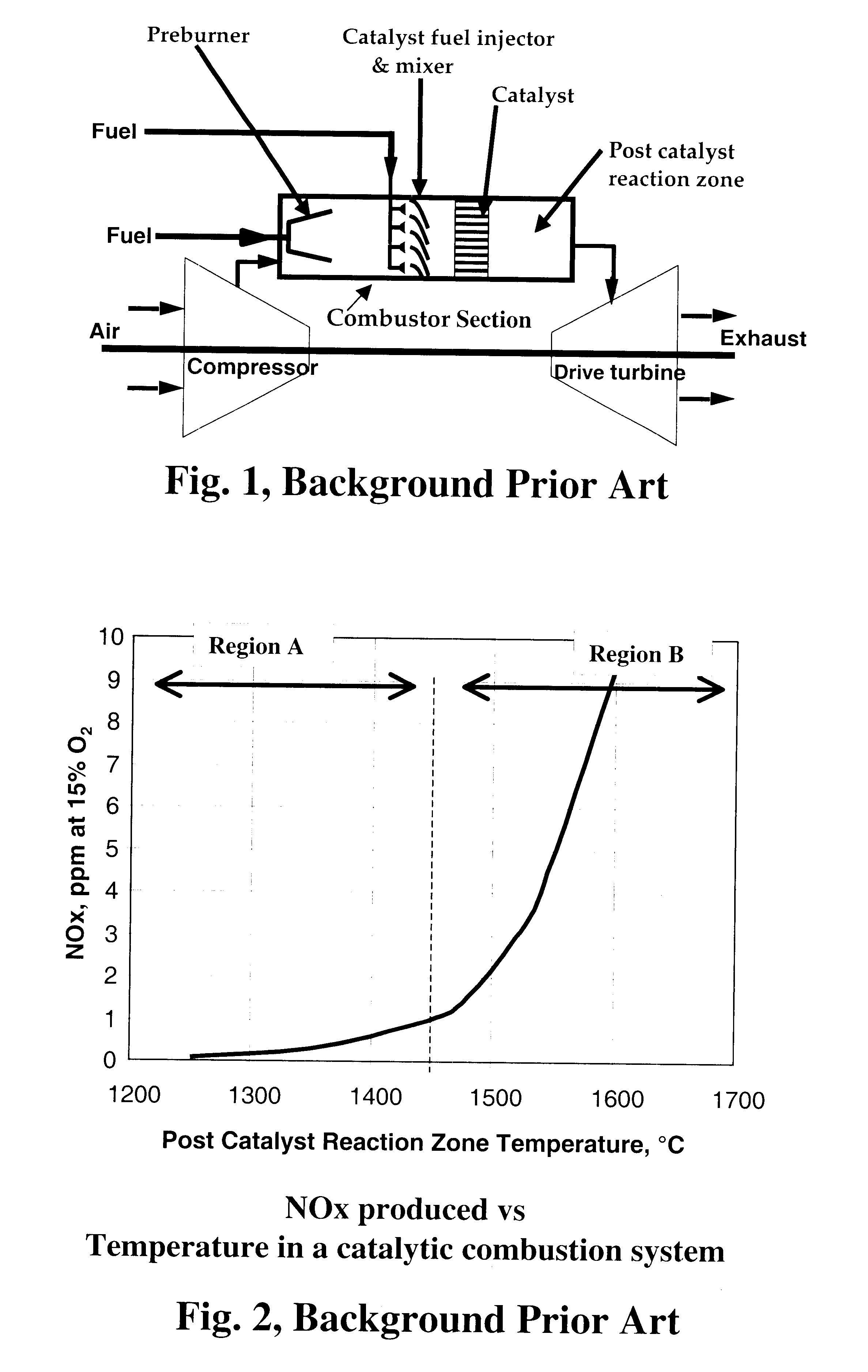

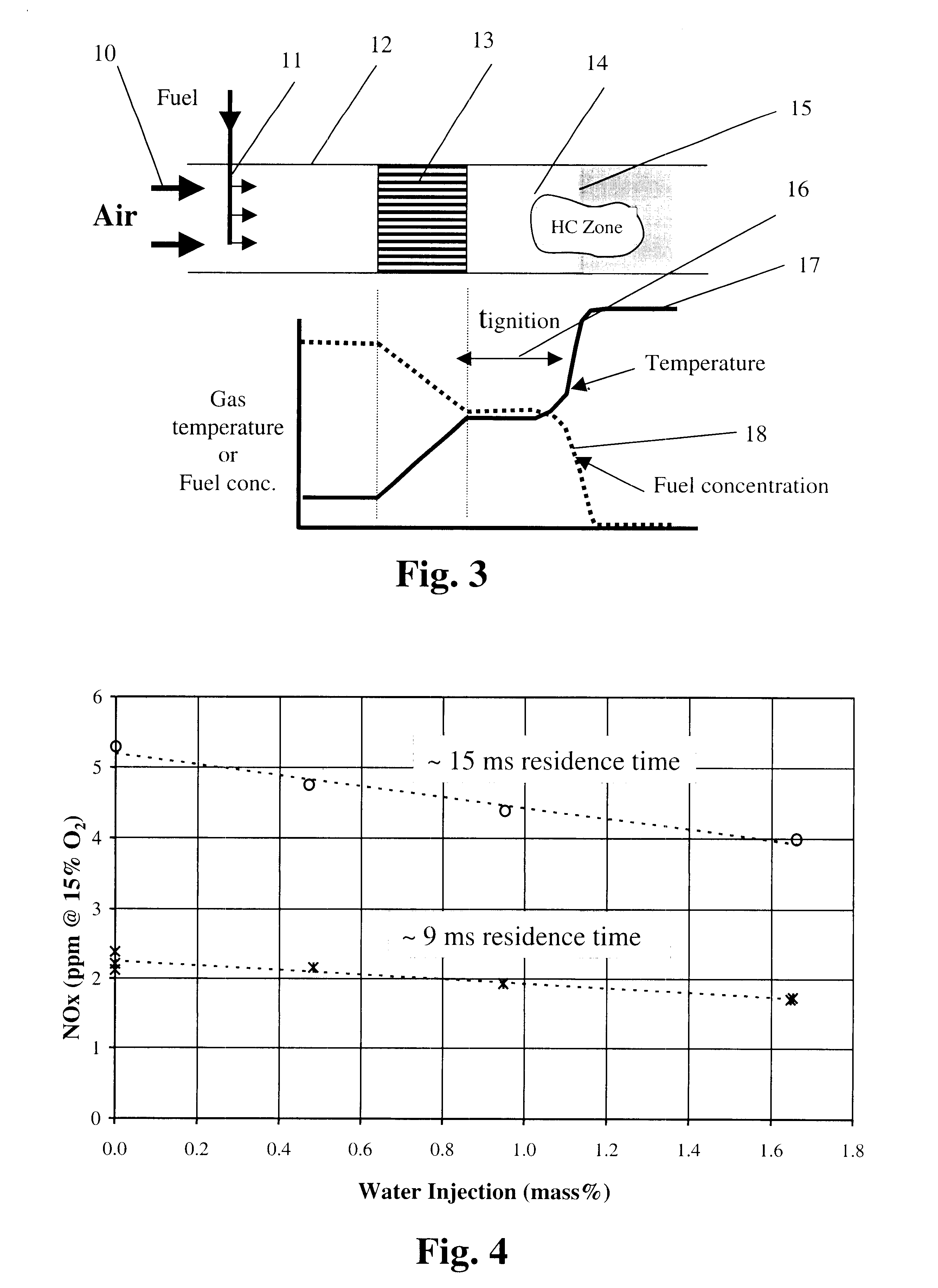

Process and apparatus for control of NOx in catalytic combustion systems

InactiveUS6595003B2Turbine/propulsion fuel supply systemsContinuous combustion chamberCombustion systemLiquid water

Methods and apparatus for control of NOx in catalytic combustion systems, and more particularly to control of thermal or / and prompt NOx produced during combustion of liquid or gaseous fuels in the combustor sections of catalytic combustor-type gas turbines, by controlled injection of water in liquid or vapor form at selected locations, orientations, amounts, rates, temperatures, phases, forms and manners in the compressor and combustor sections of gas turbines. The ratio of thermal NOx ppm reduction to water addition, in weight %, is on the order of 4-20, with % NOx reduction on the order of up to about 50-80% and NOx of below 2 ppm. Liquid water, steam or superheated steam can be used to reduce NOx in combustion systems operating at reaction zone temperatures above 900° C., preferably 1400° C. to 1700° C. The amount of water added is sufficient to provide a concentration of water in the range of from about 0.1% to about 20% by weight of the total air and fuel mixture flowing into the post catalyst reaction zone. Water is introduced simultaneously or sequentially in a plurality of locations, at selected rates, amounts, temperatures, forms, and purity, preferably in accord with a suitable control algorithm.

Owner:KAWASAKI HEAVY IND LTD

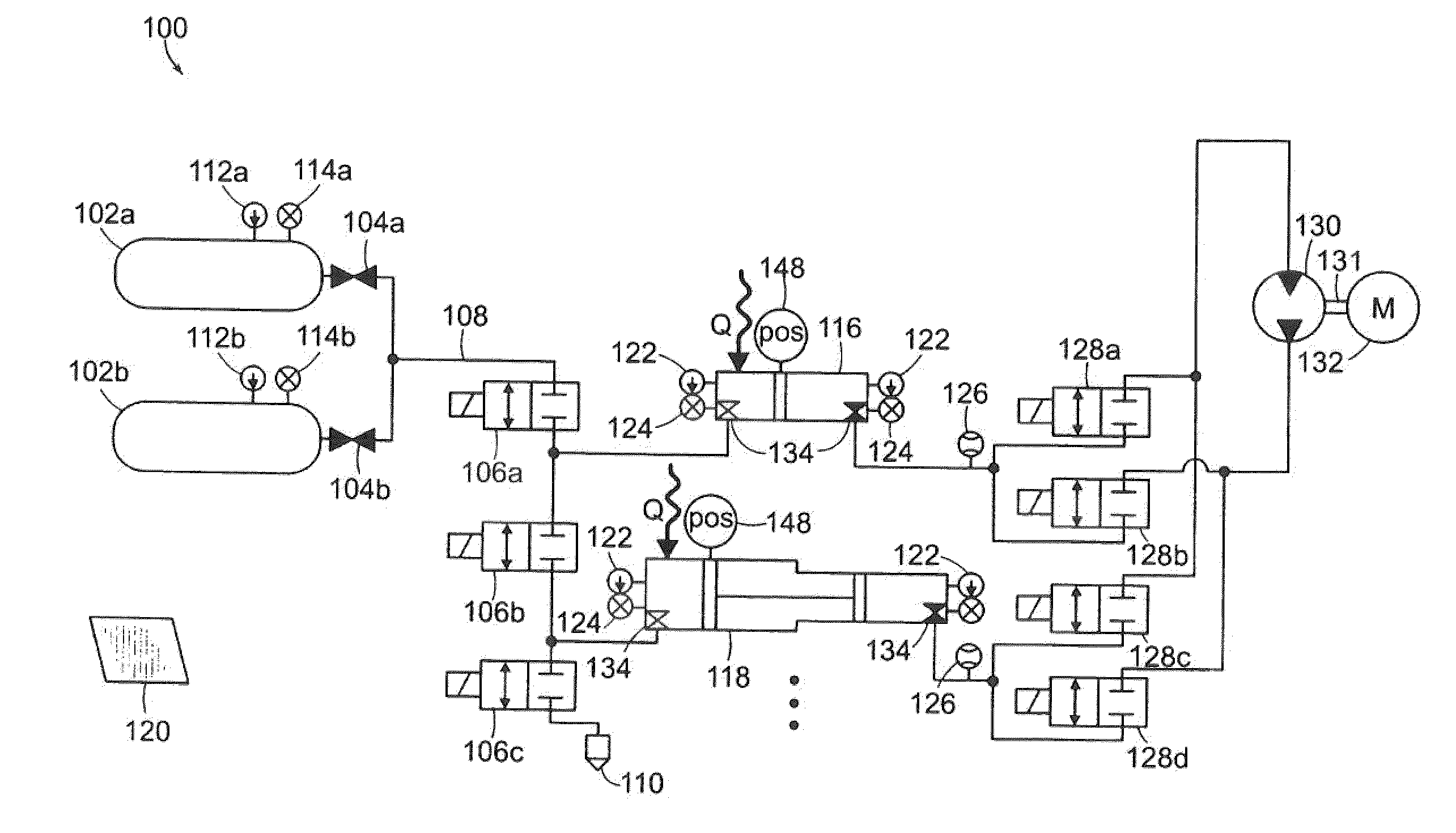

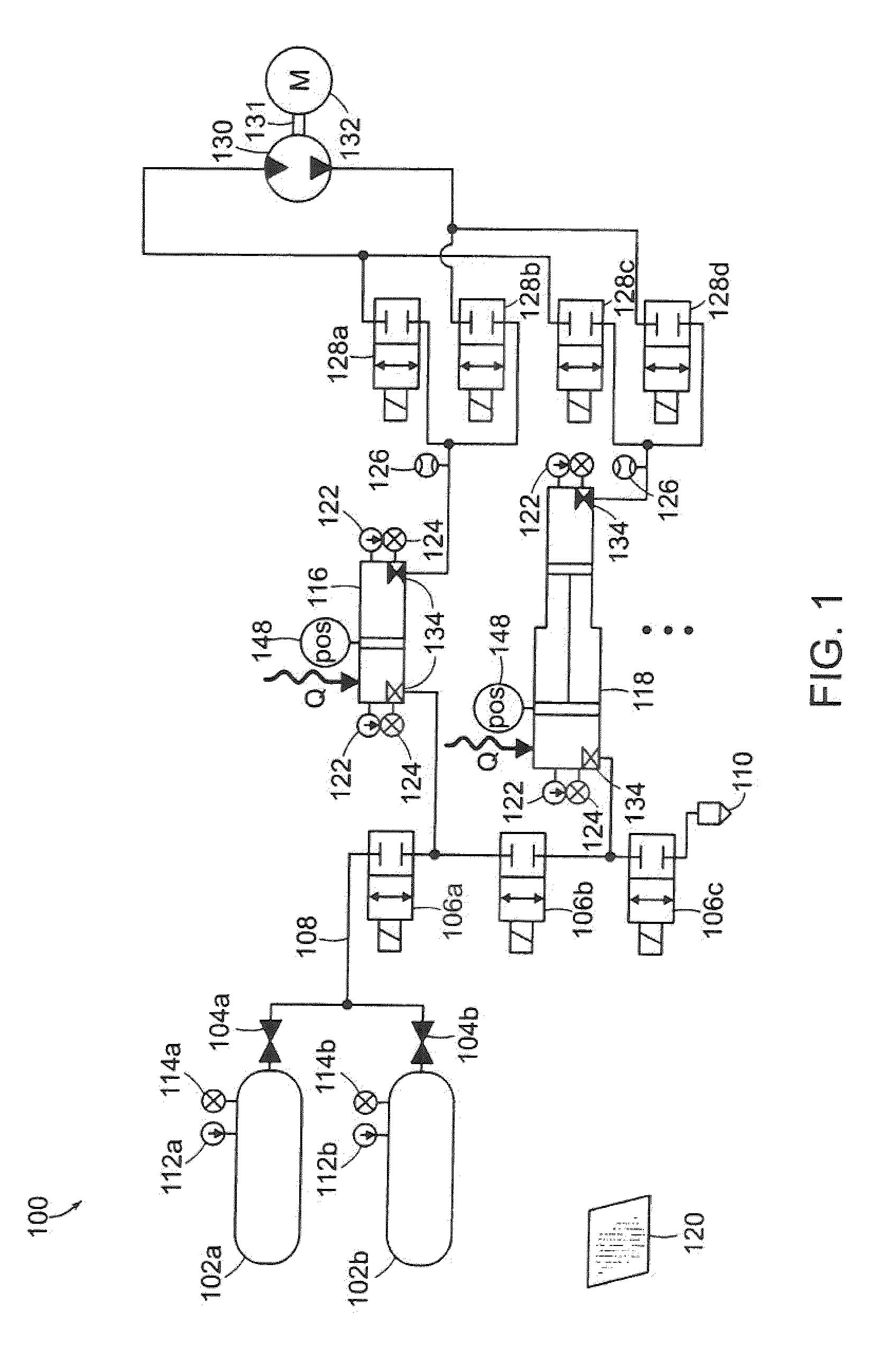

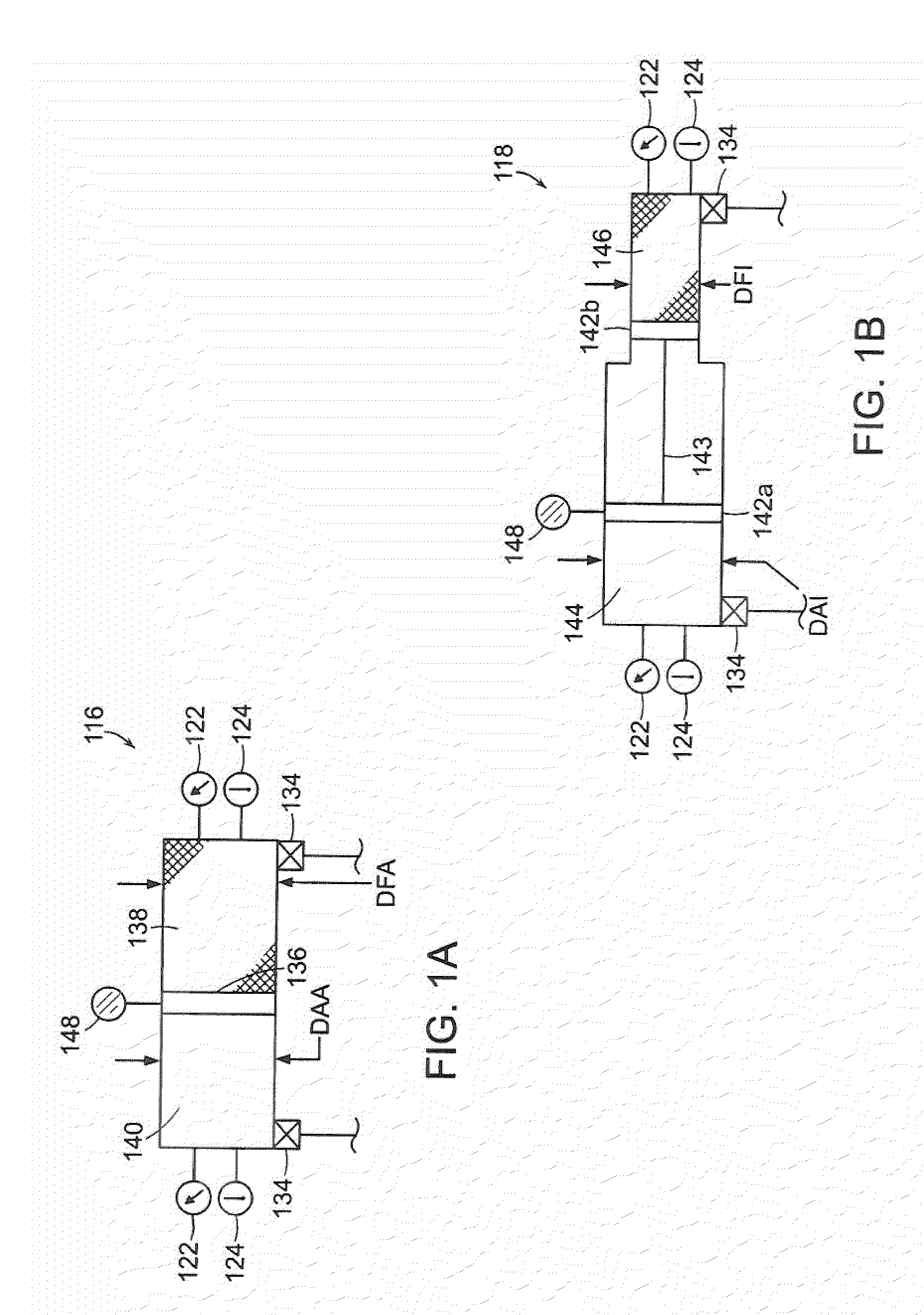

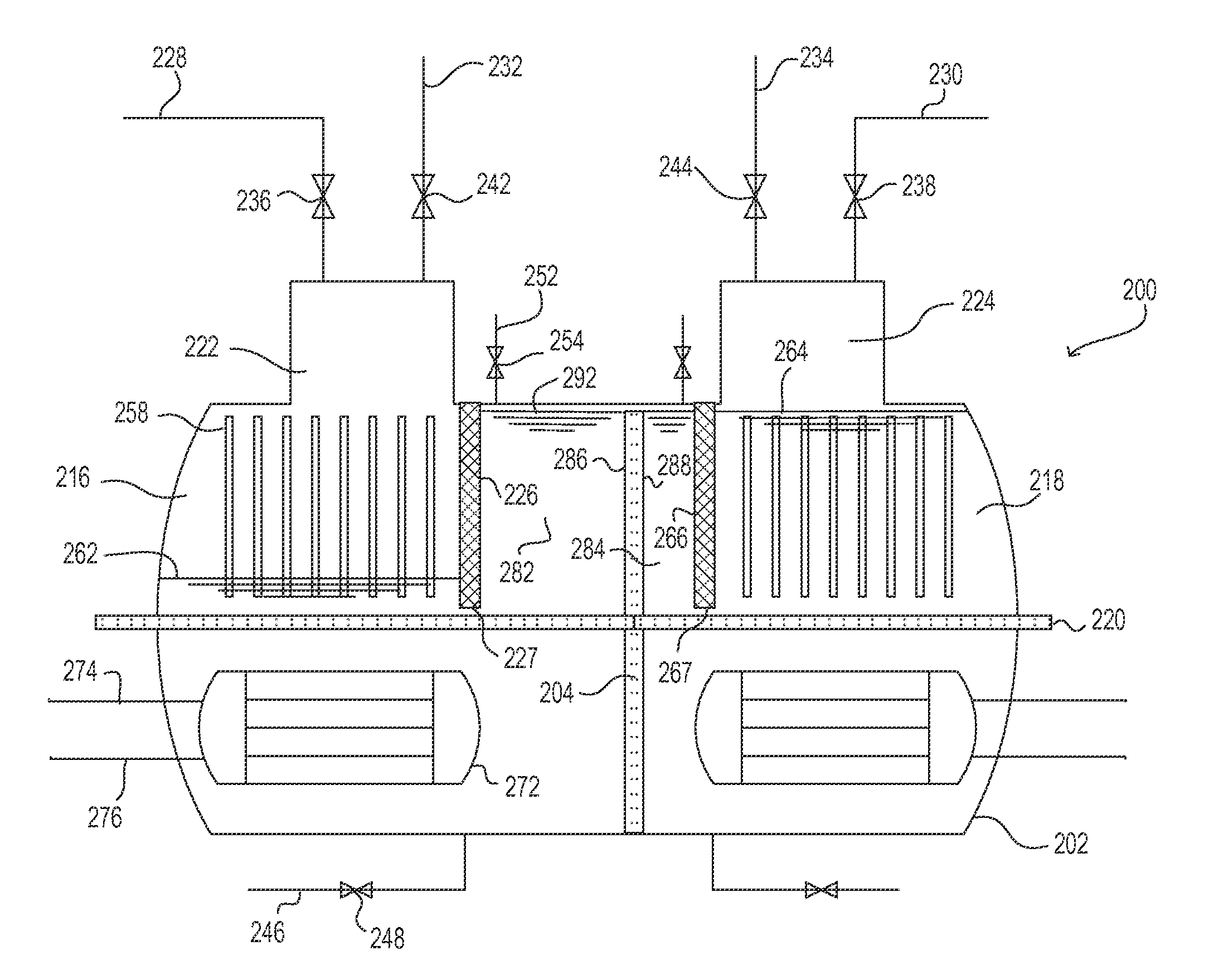

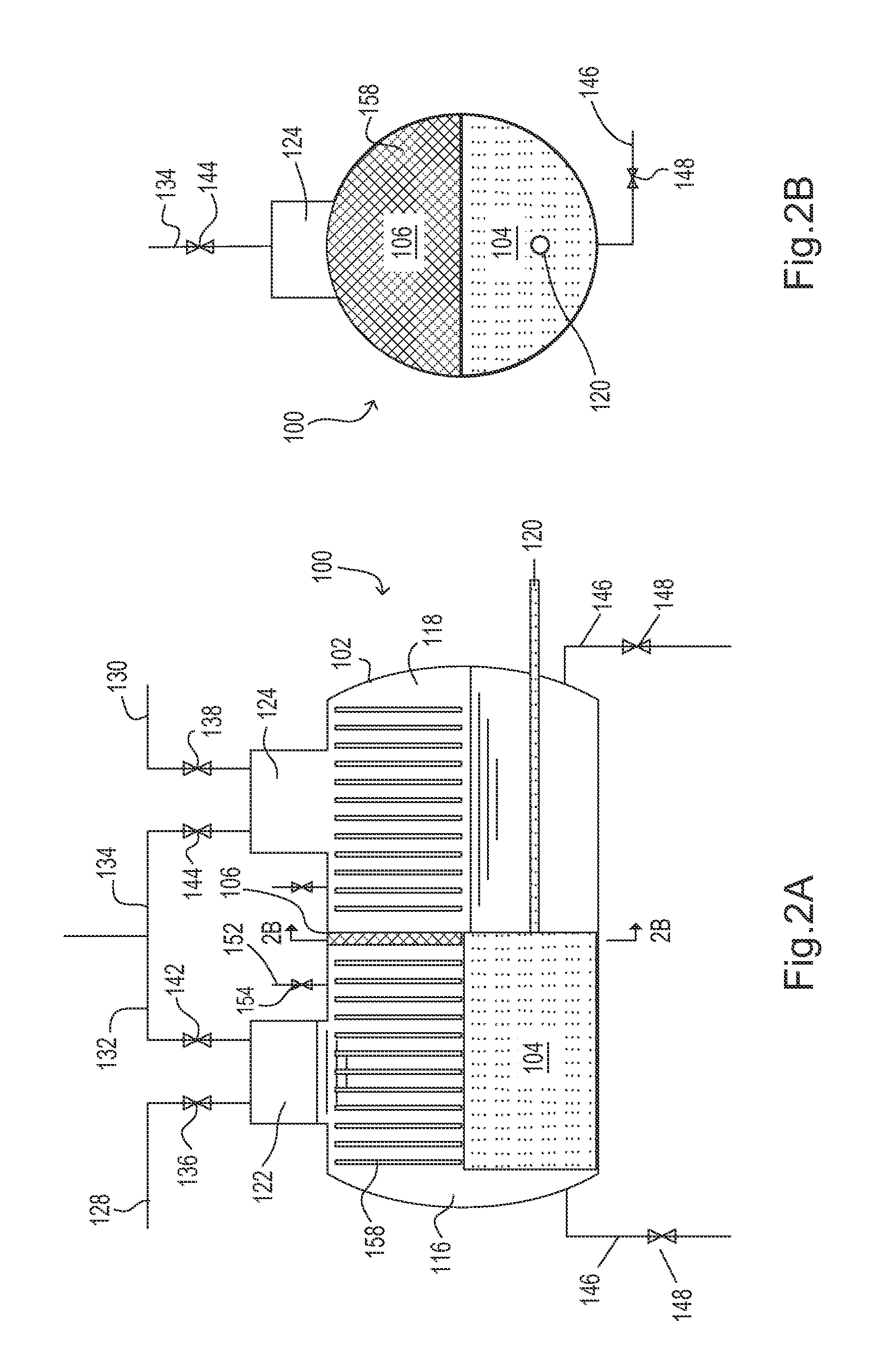

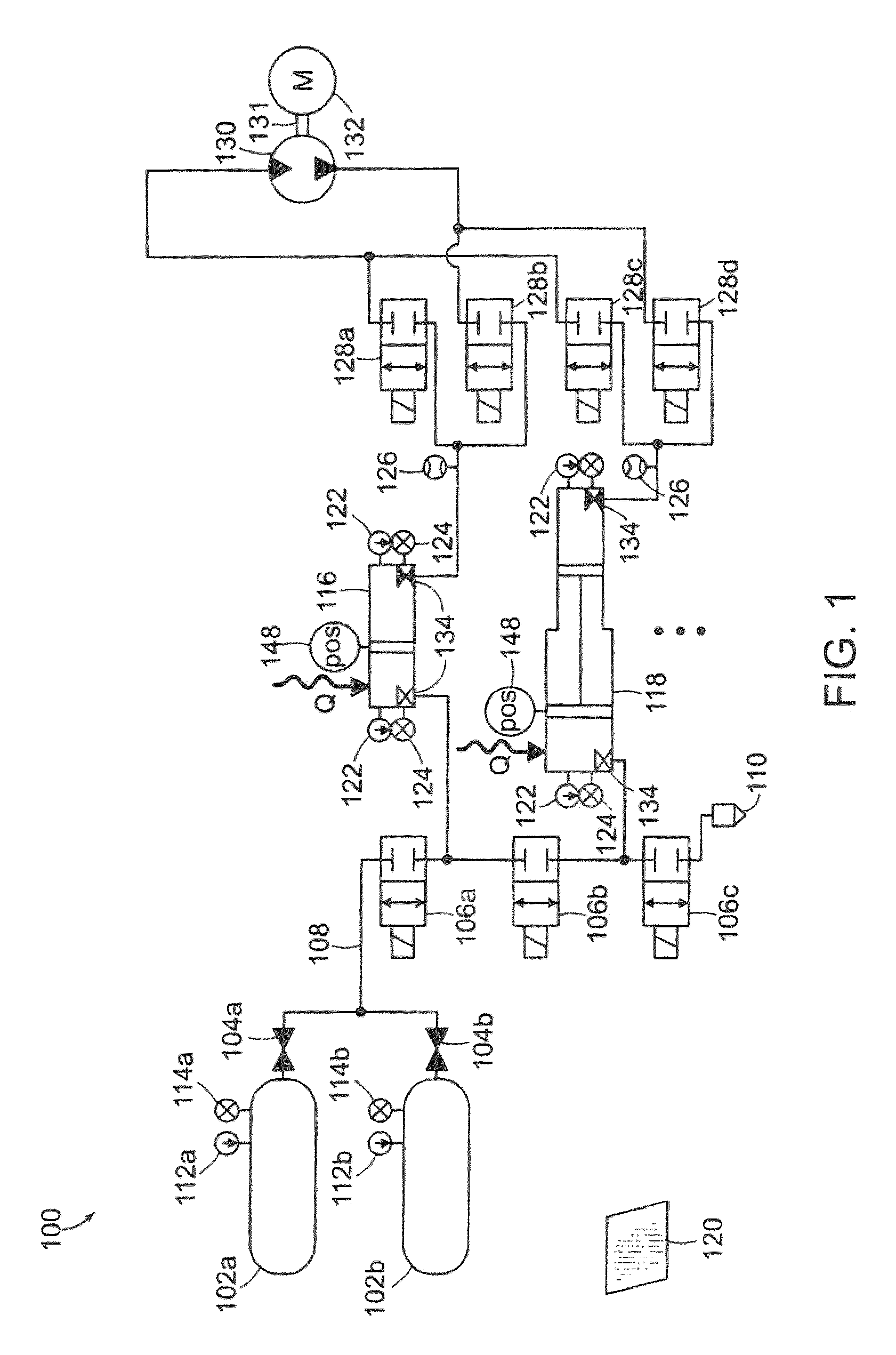

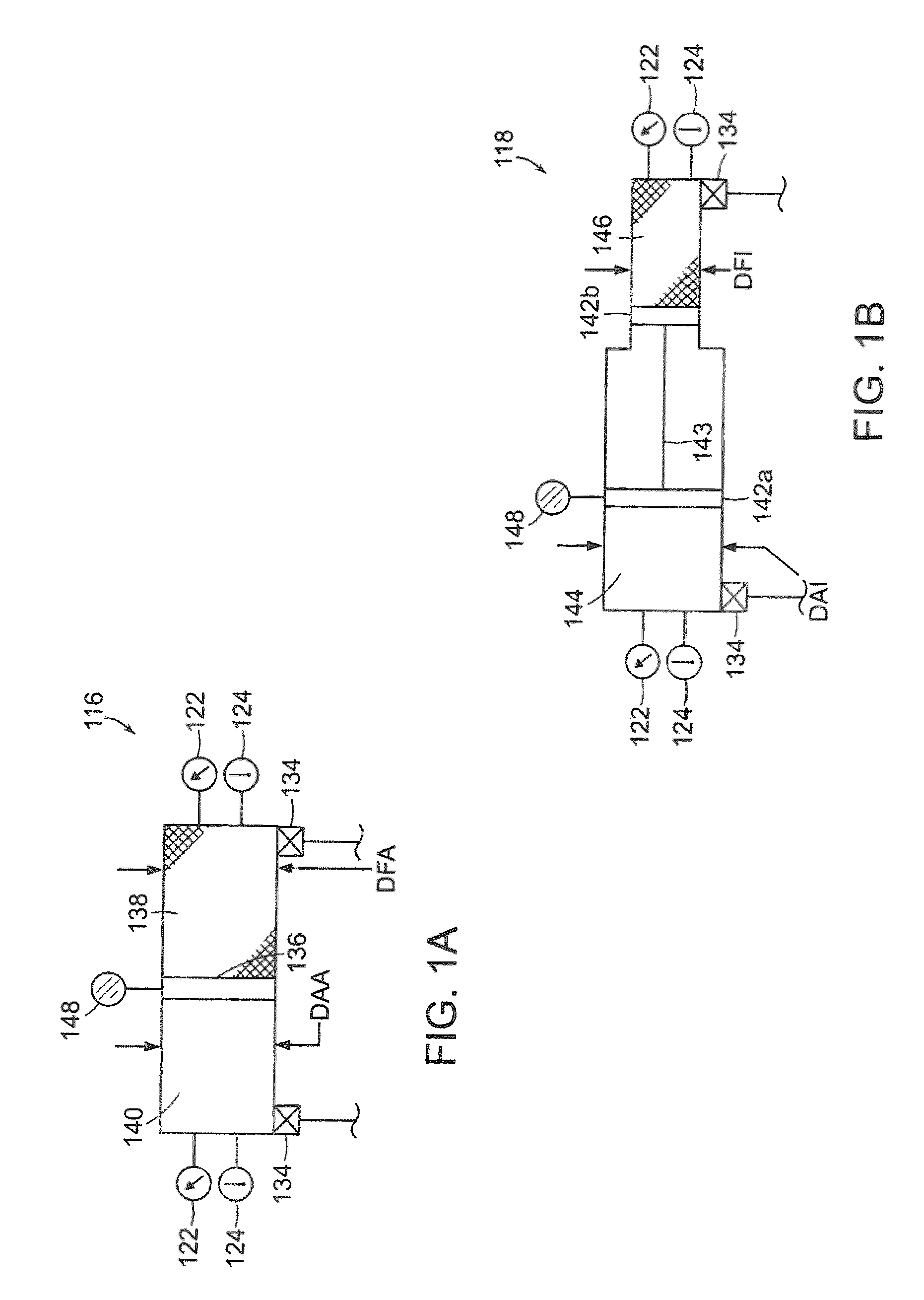

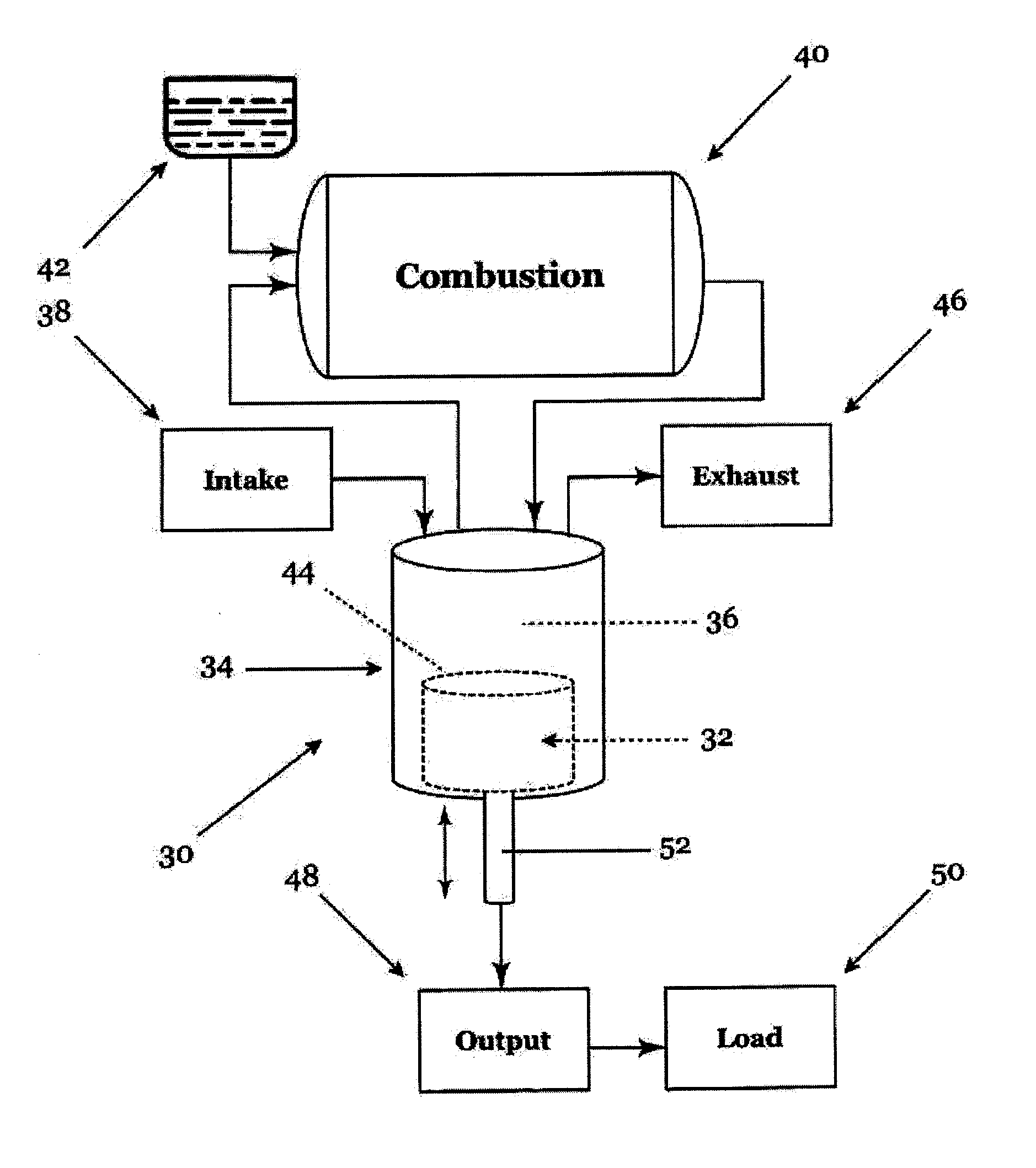

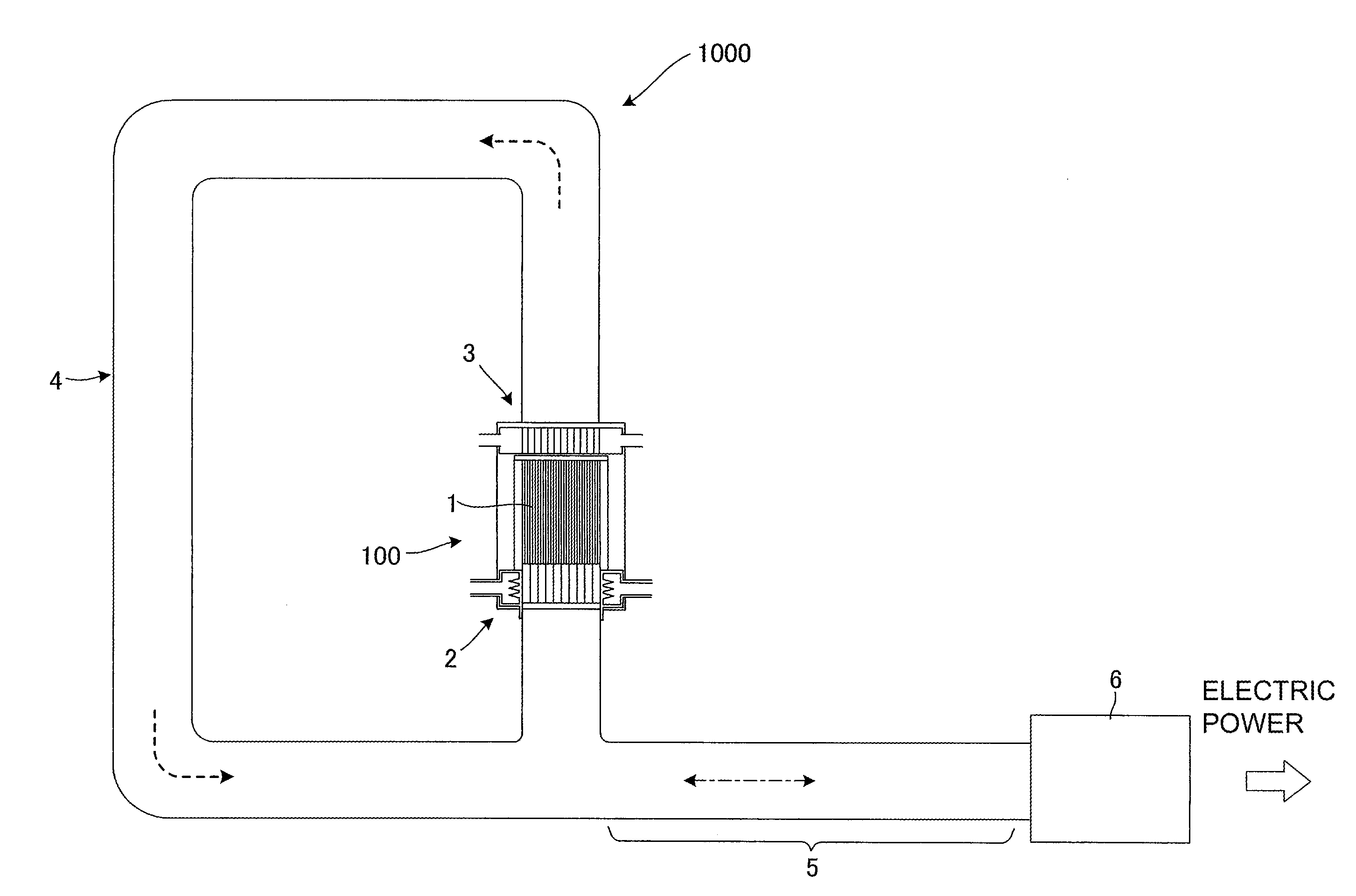

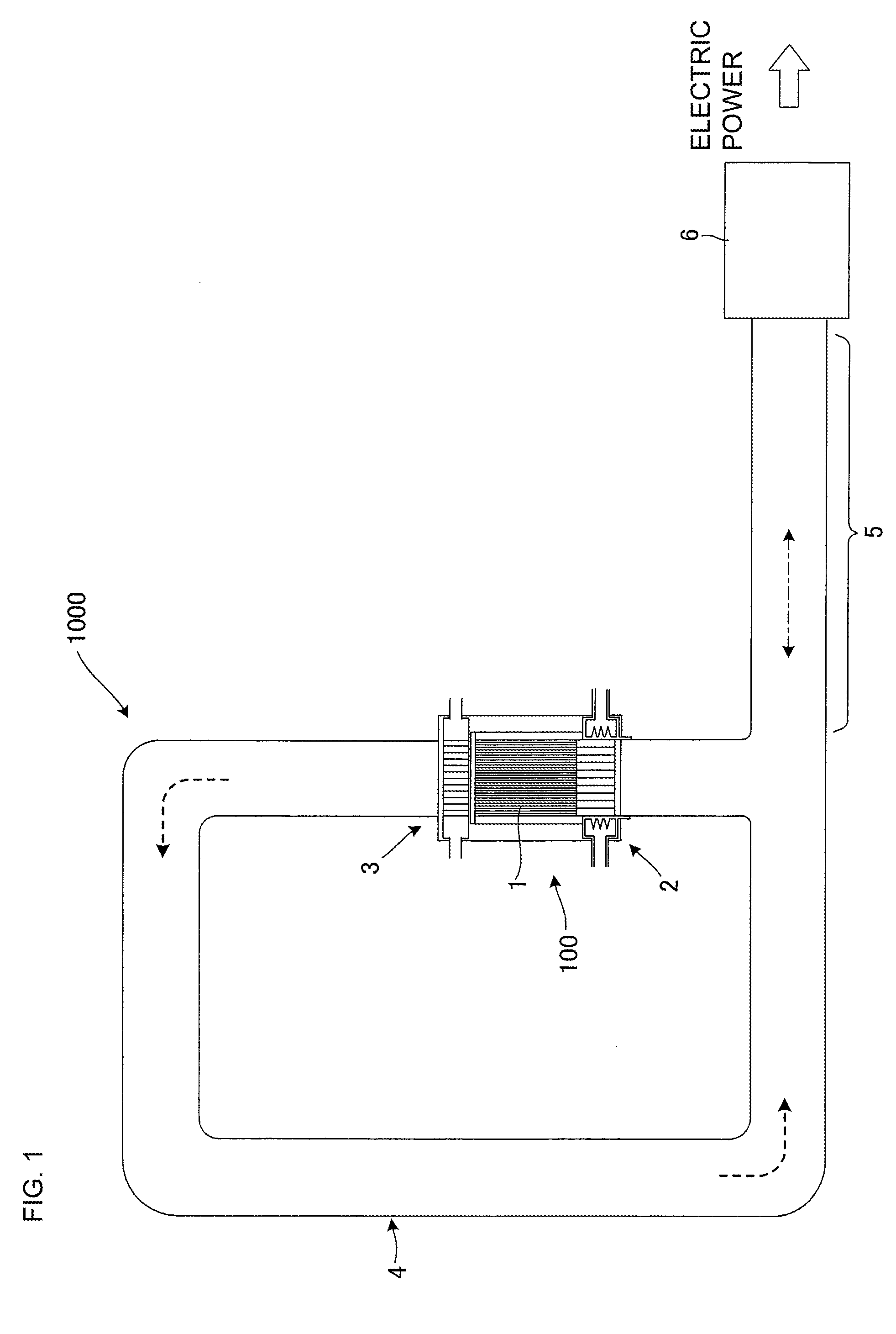

Systems and methods for energy storage and recovery using gas expansion and compression

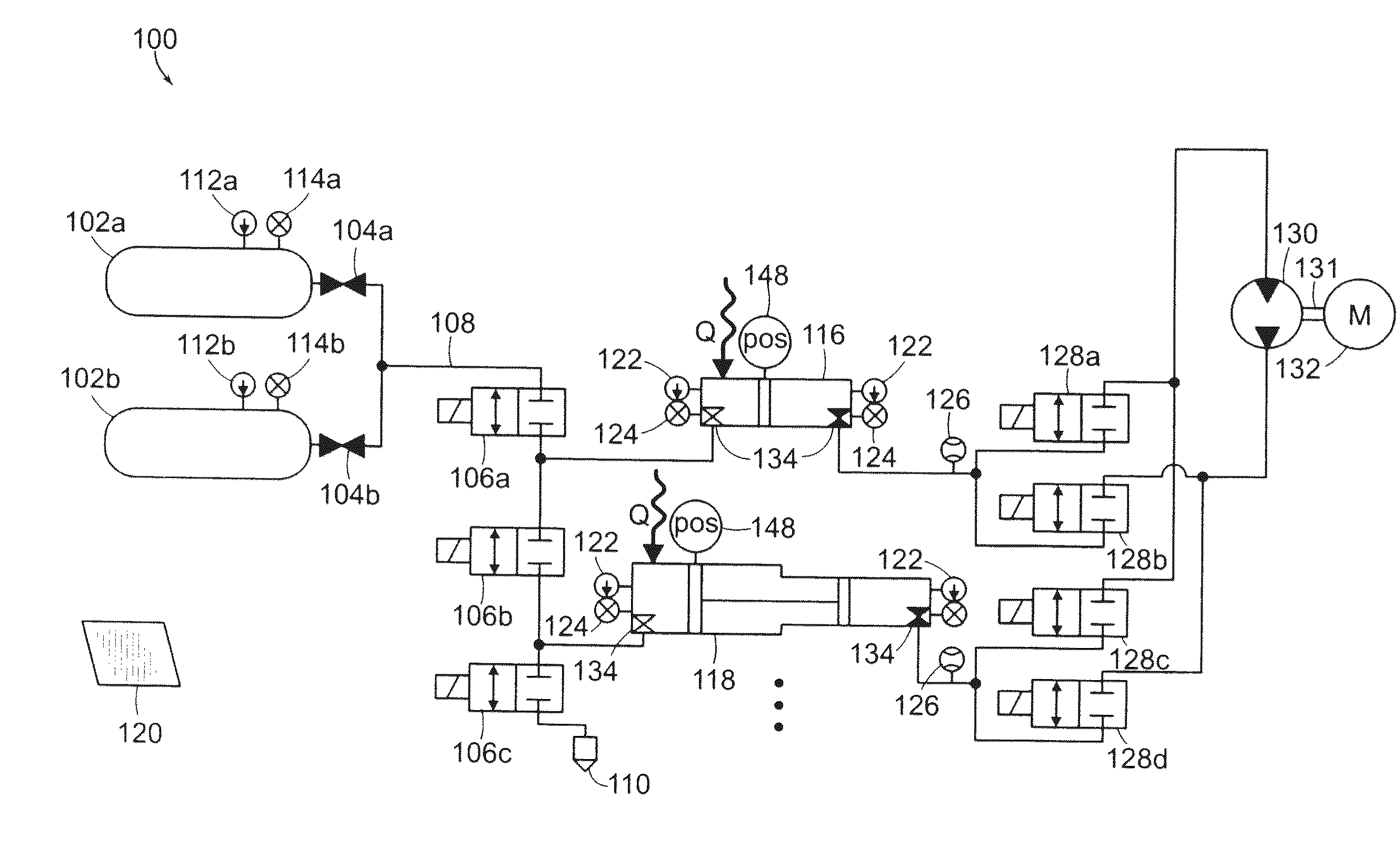

InactiveUS20110296823A1Increase energy densityElectrical storage systemFluid couplingsEngineeringAtmospheric pressure

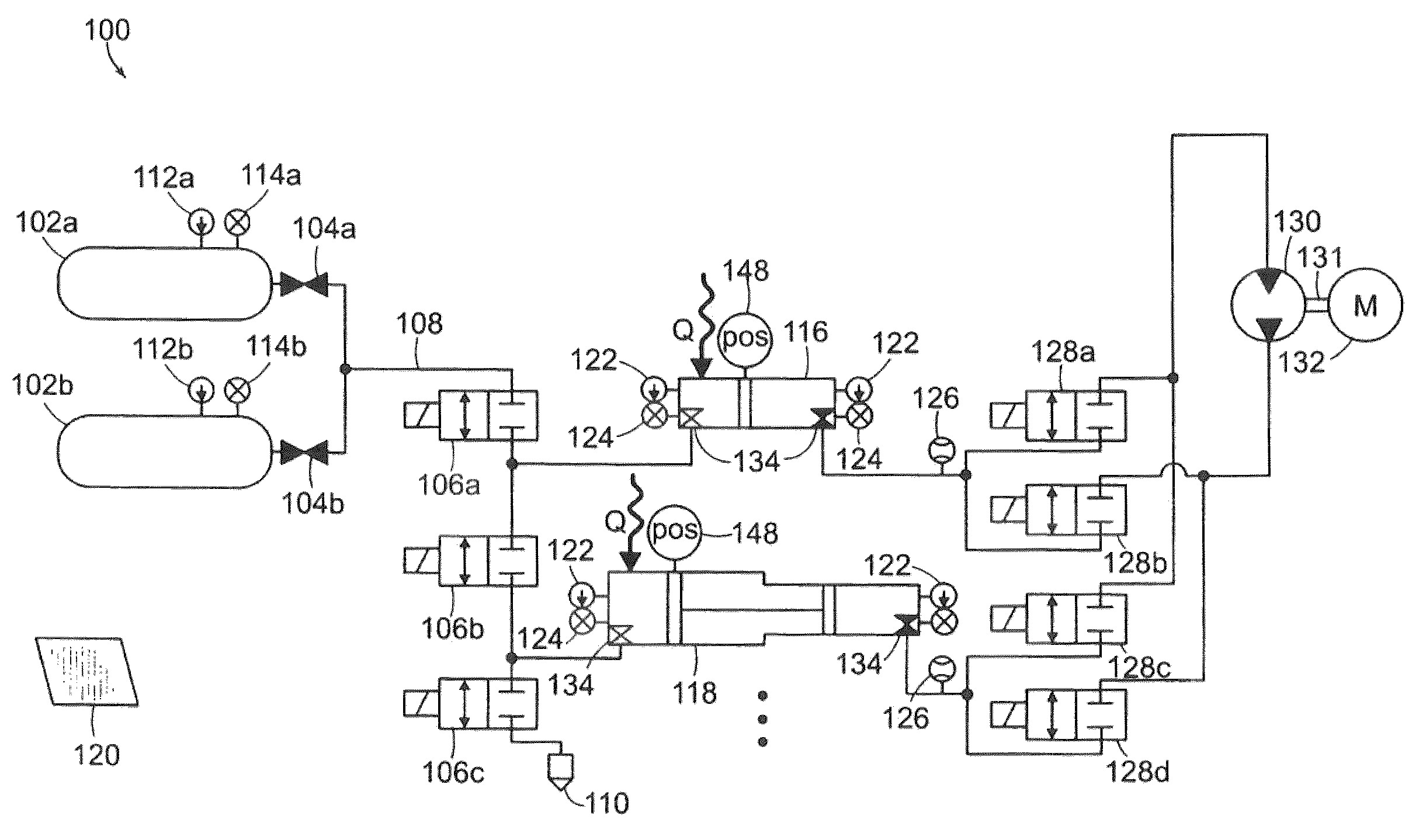

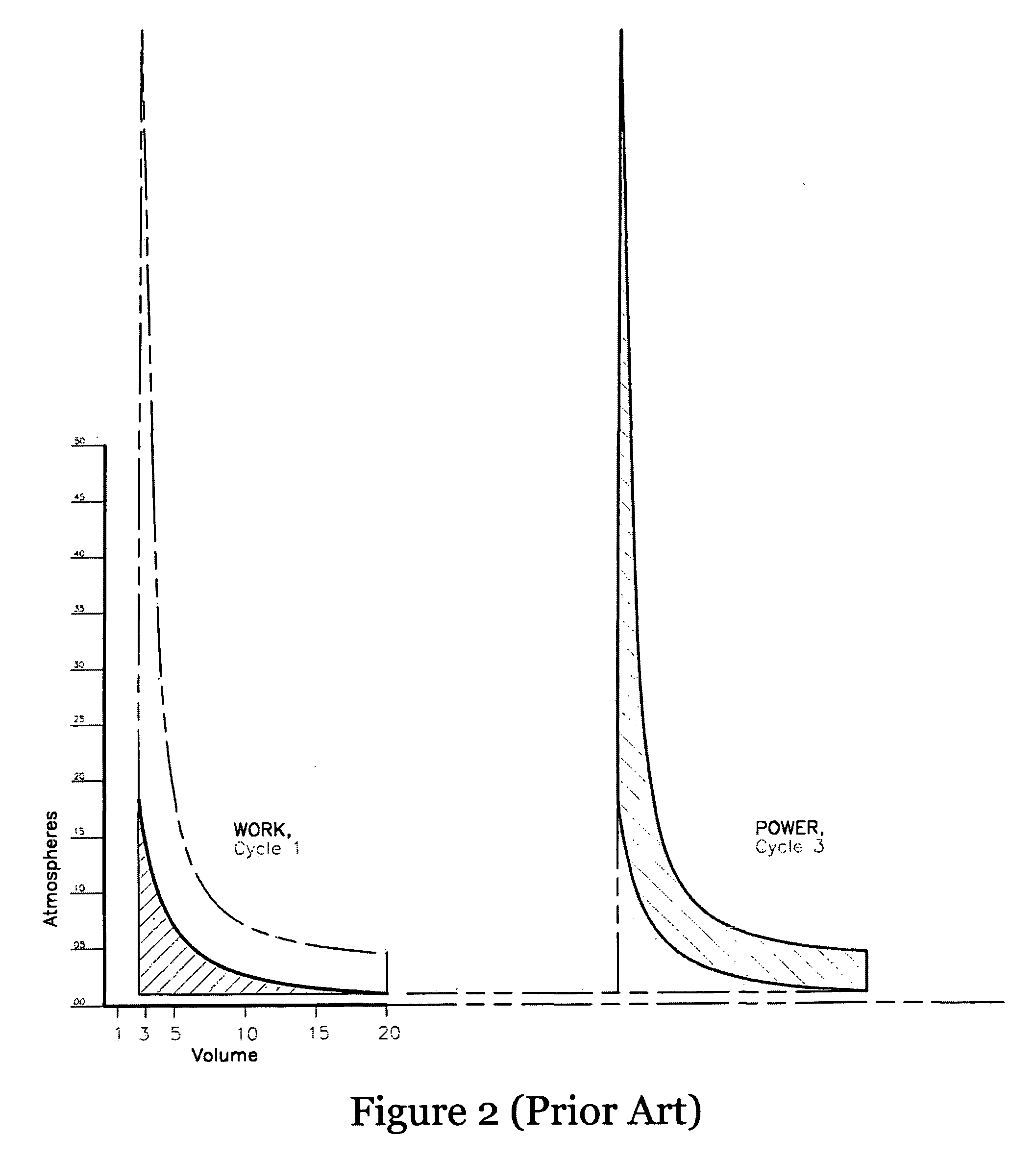

In various embodiments, energy-storage systems are based upon an open-air arrangement in which pressurized gas is expanded in small batches from a high pressure of, e.g., several hundred atmospheres to atmospheric pressure. The systems may be sized and operated at a rate that allows for near isothermal expansion and compression of the gas.

Owner:SUSTAINX

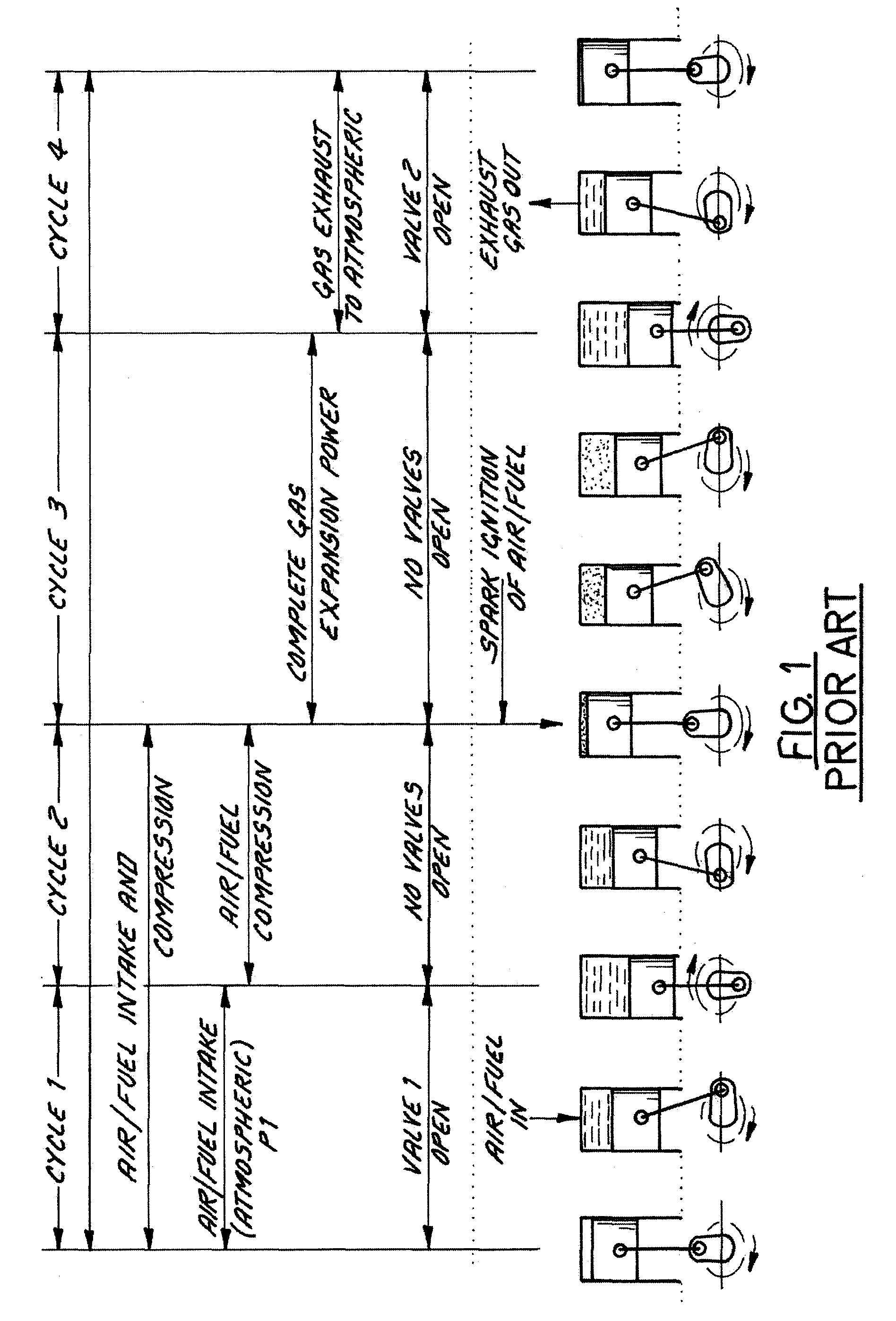

Internal combustion engine and method

InactiveUS20060243229A1Easy to operateReduce the amount of fuelInternal combustion piston enginesGas turbine plantsCombustion chamberEngine efficiency

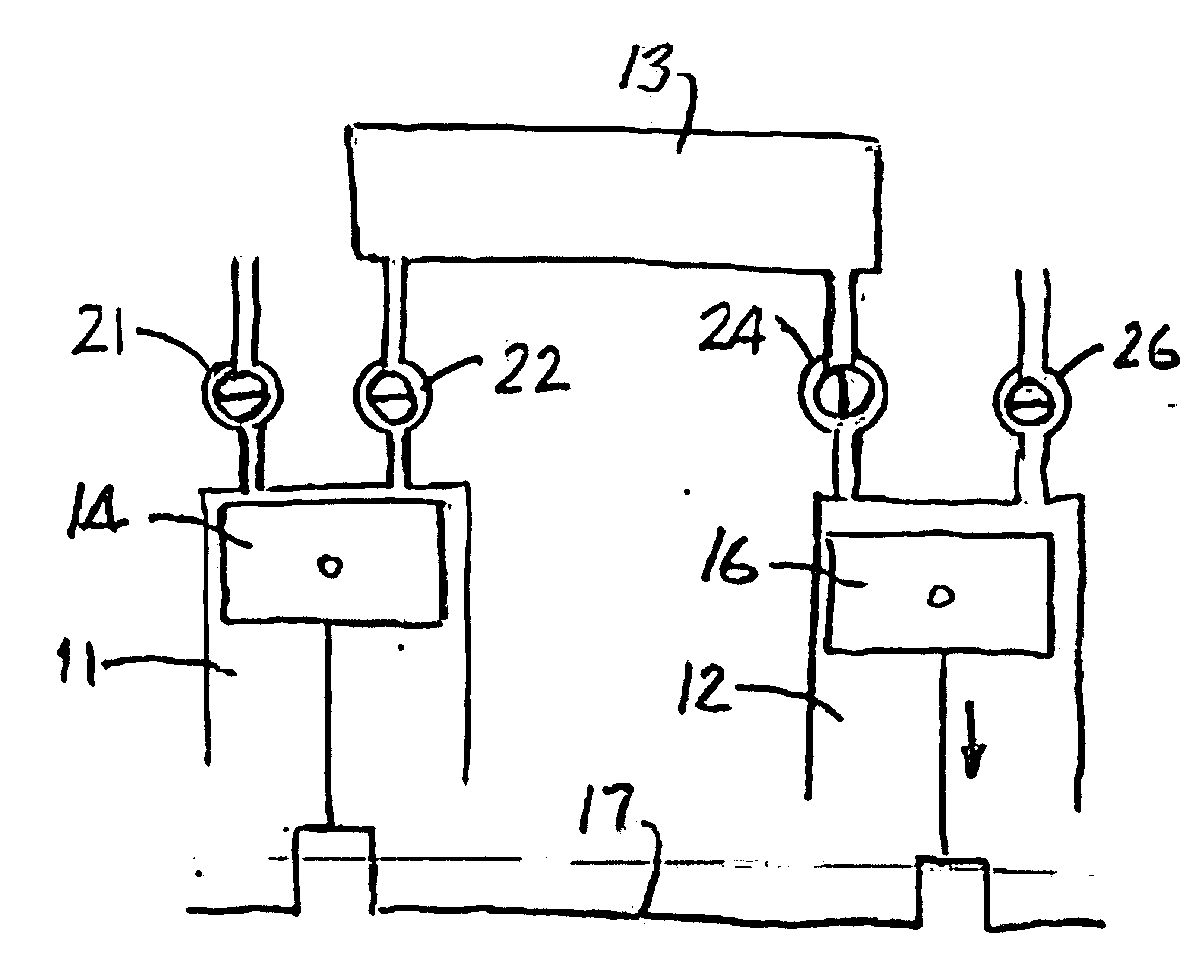

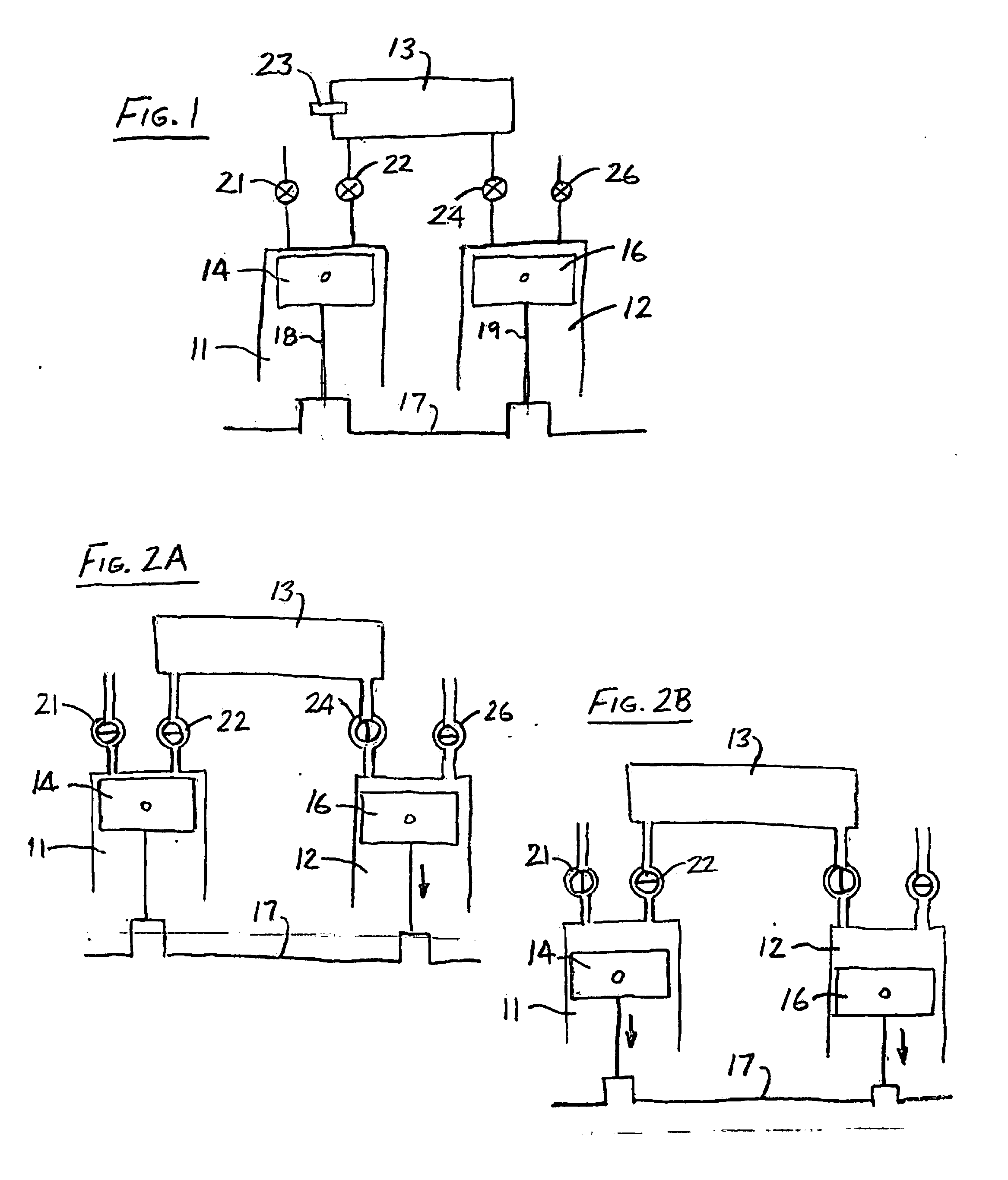

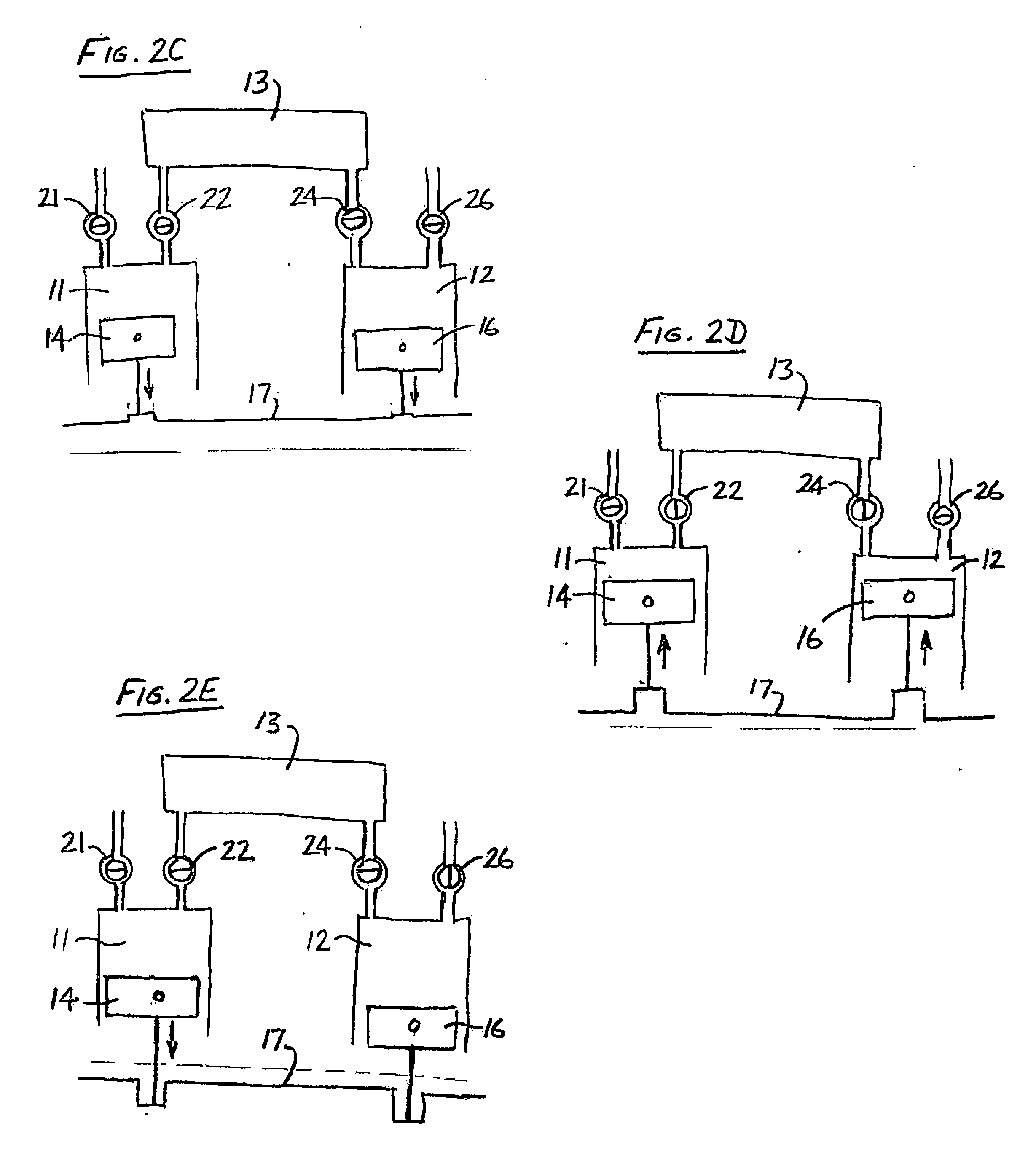

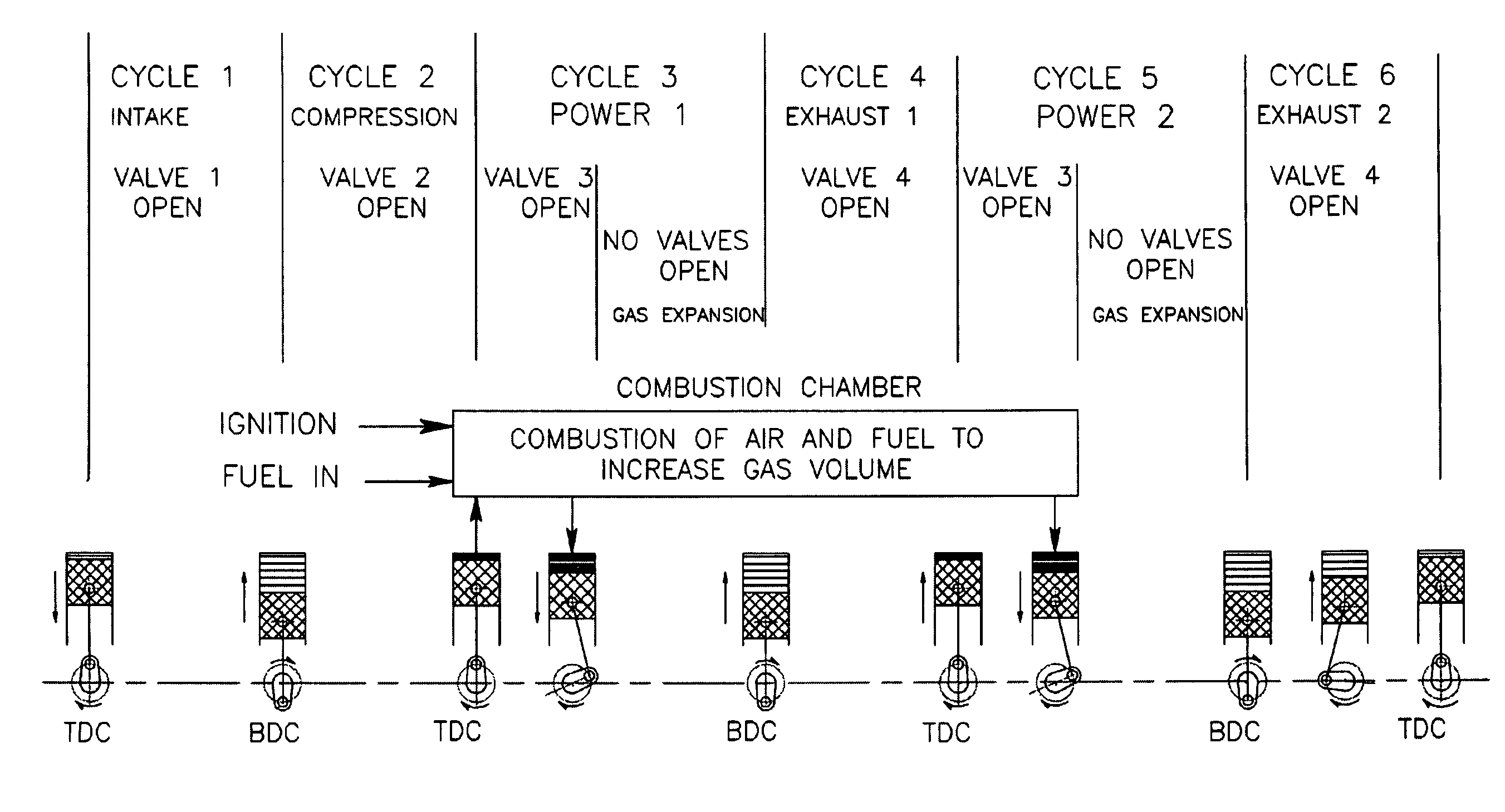

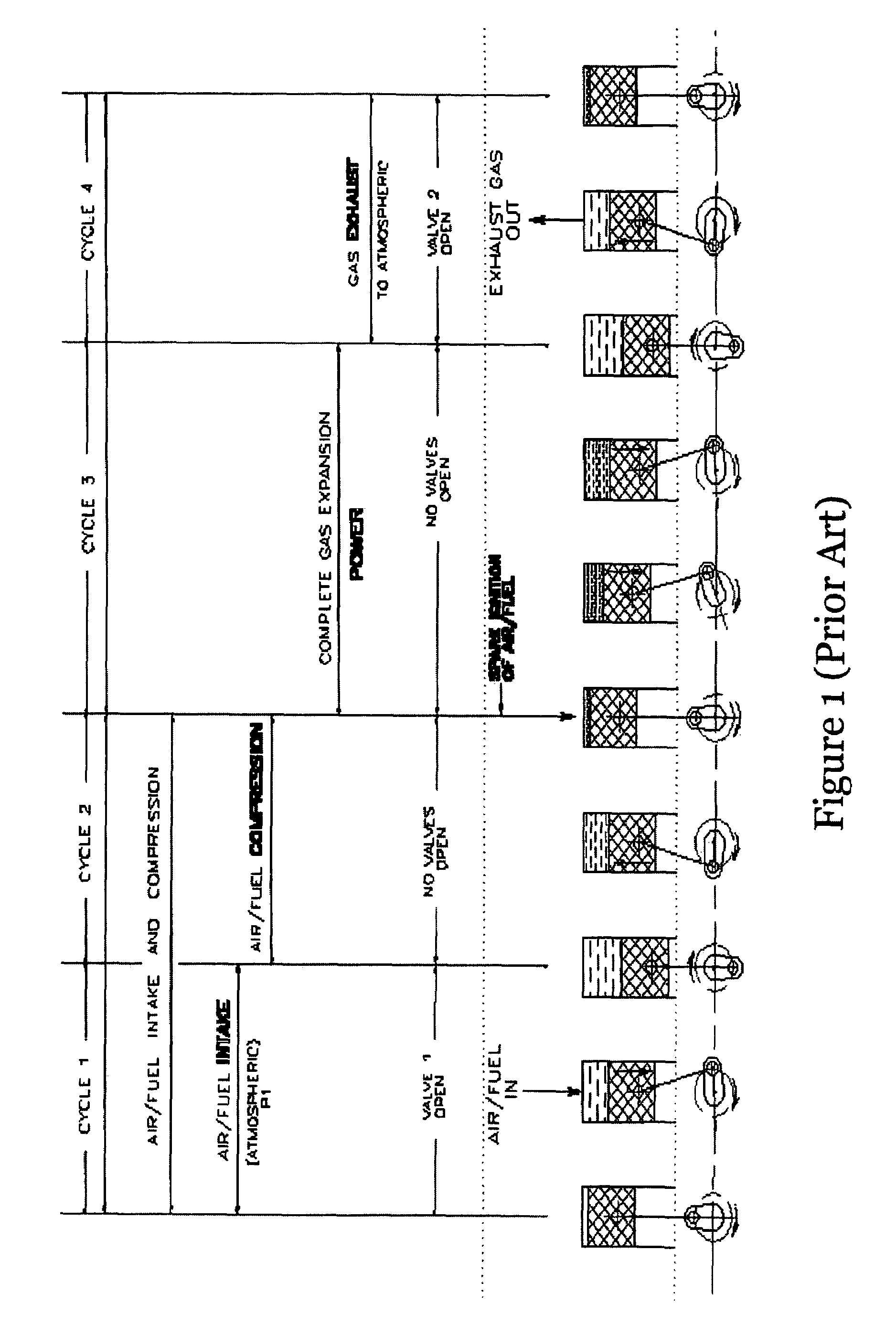

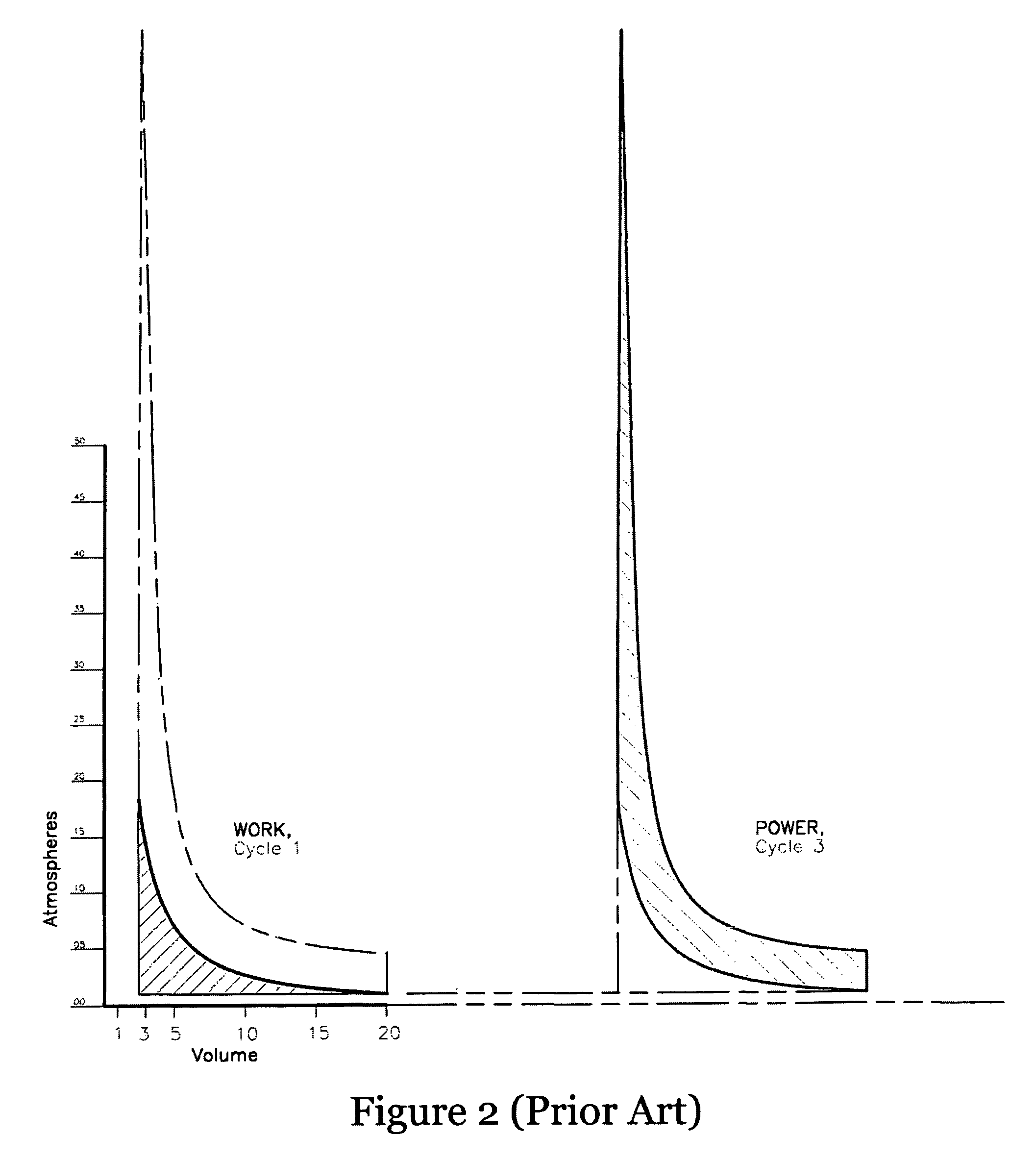

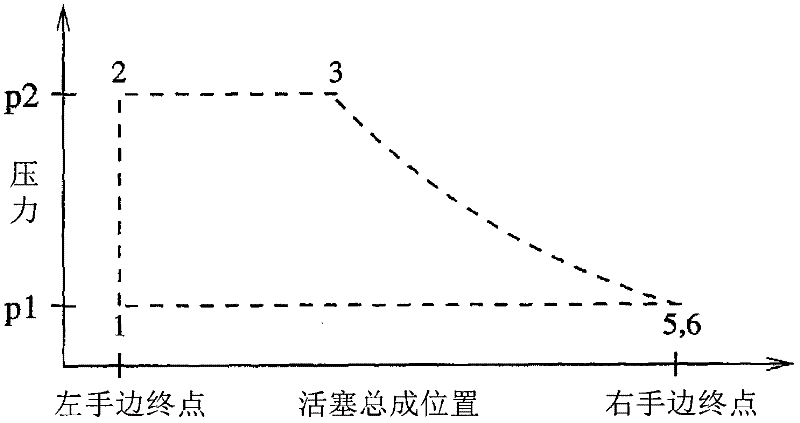

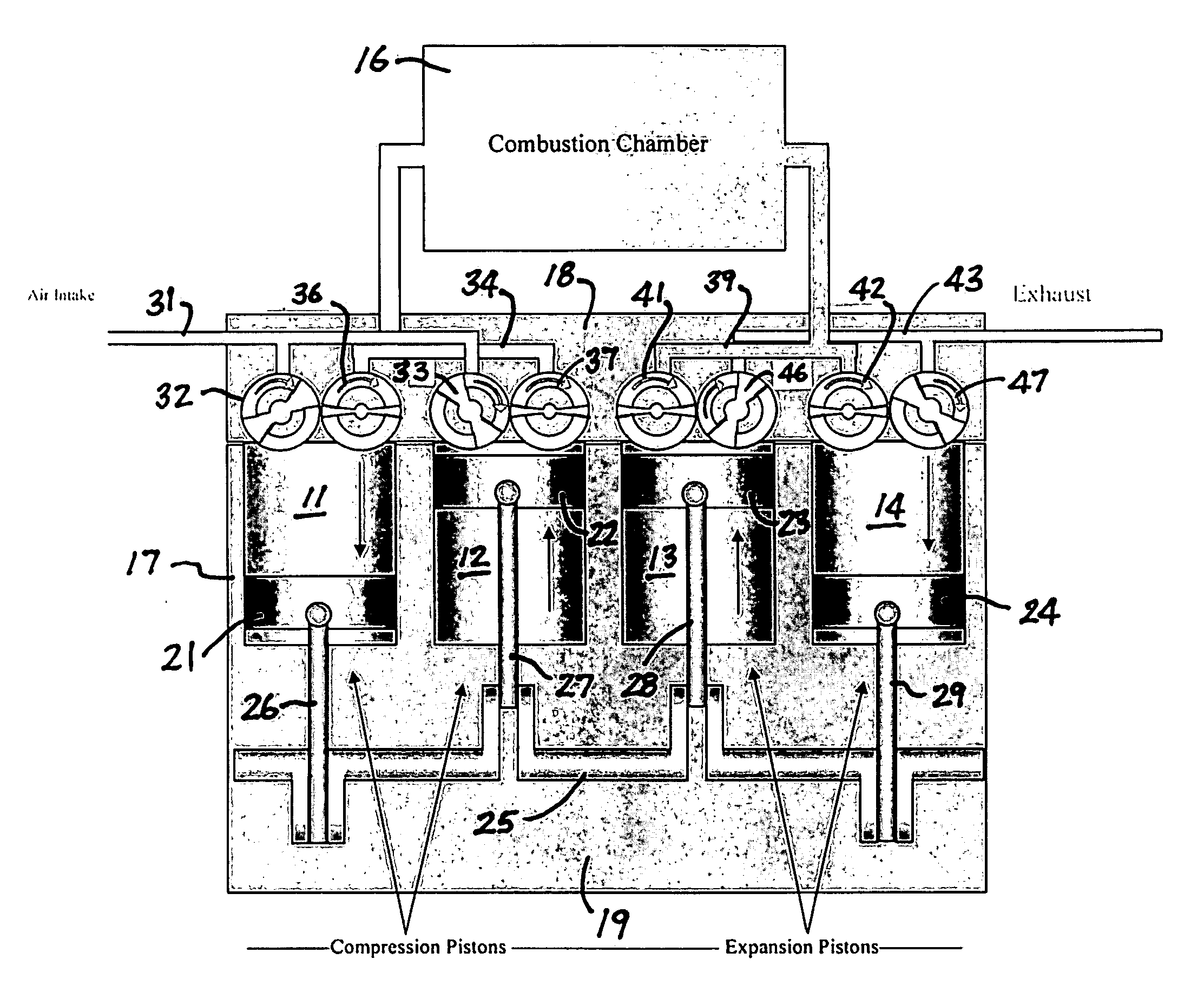

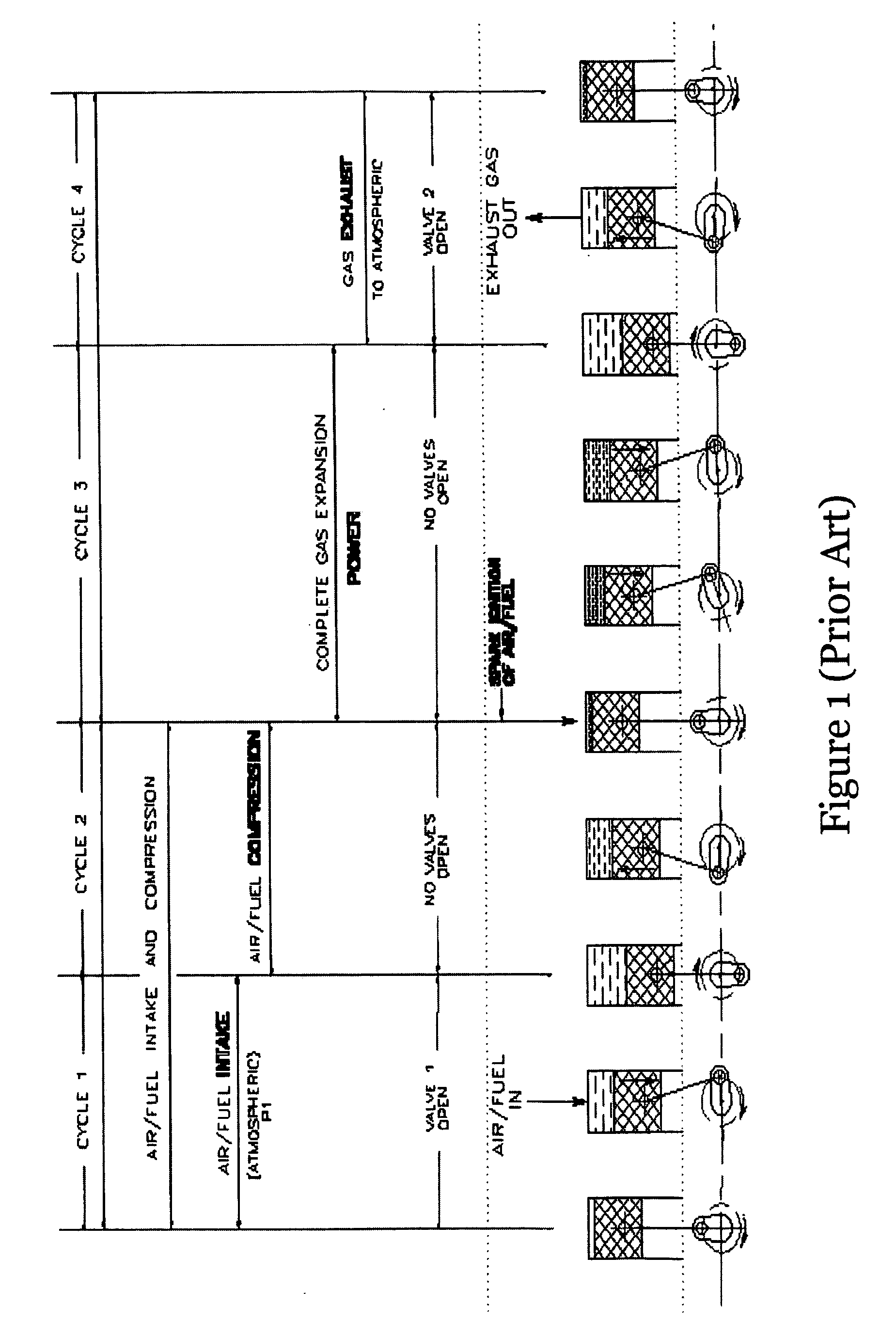

Internal combustion engine and method with compression and expansion chambers of variable volume, a combustion chamber, a variable intake valve for controlling air intake to the compression chamber, a variable outlet valve for controlling communication between the compression chamber and the combustion chamber, means for introducing fuel into the combustion chamber to form a mixture of fuel and air which burns and expands in the combustion chamber, a variable inlet valve for controlling communication between the combustion chamber and the expansion chamber, a variable exhaust valve for controlling exhaust flow from the expansion chamber, means for monitoring temperature and pressure conditions, and a computer responsive to the temperature and pressure conditions for controlling opening and closing of the valves and introduction of fuel into to the combustion chamber to optimize engine efficiency over a wide range of engine load conditions. The relative volumes of the compression and expansion chambers and the timing of the valves are such that the pressure in the combustion chamber remains substantially constant throughout the operating cycle of the engine, and exhaust pressures are very close to atmospheric pressure regardless of the load on the engine. The engine runs so quietly and burns so cleanly that in some applications it may not require a muffler and / or a catalytic converter.

Owner:ZAJAC OPTIMUM OUTPUT MOTORS

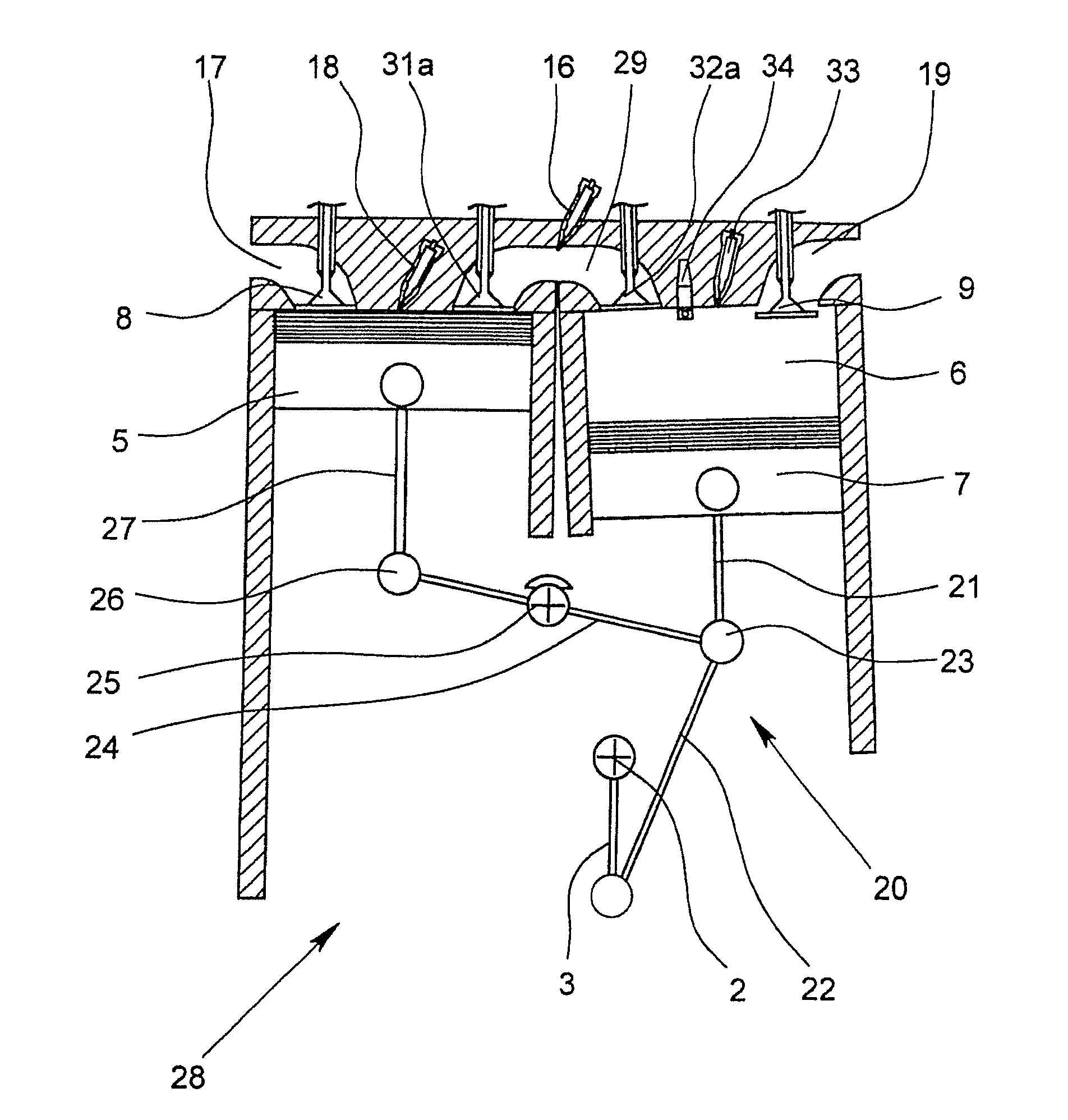

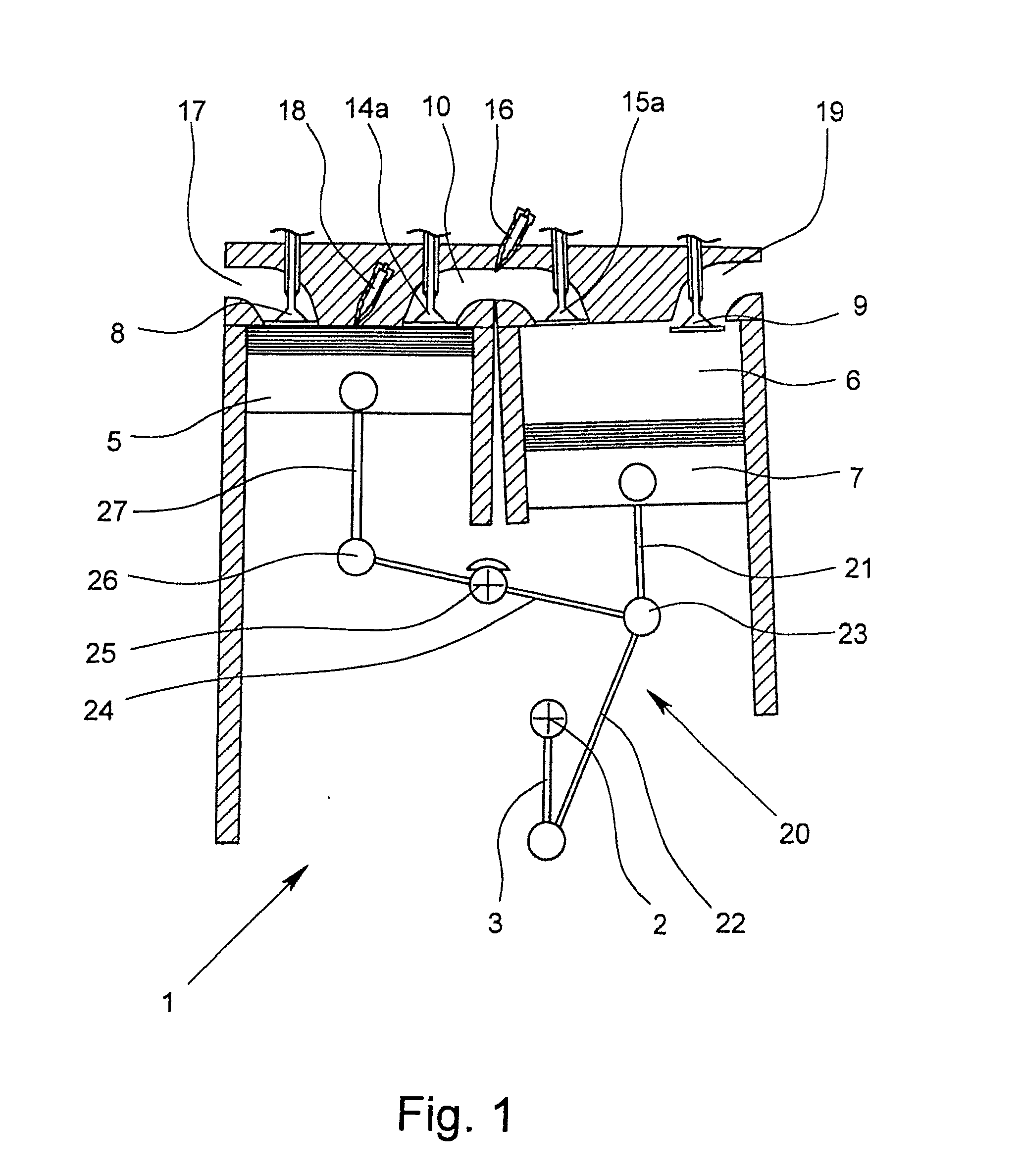

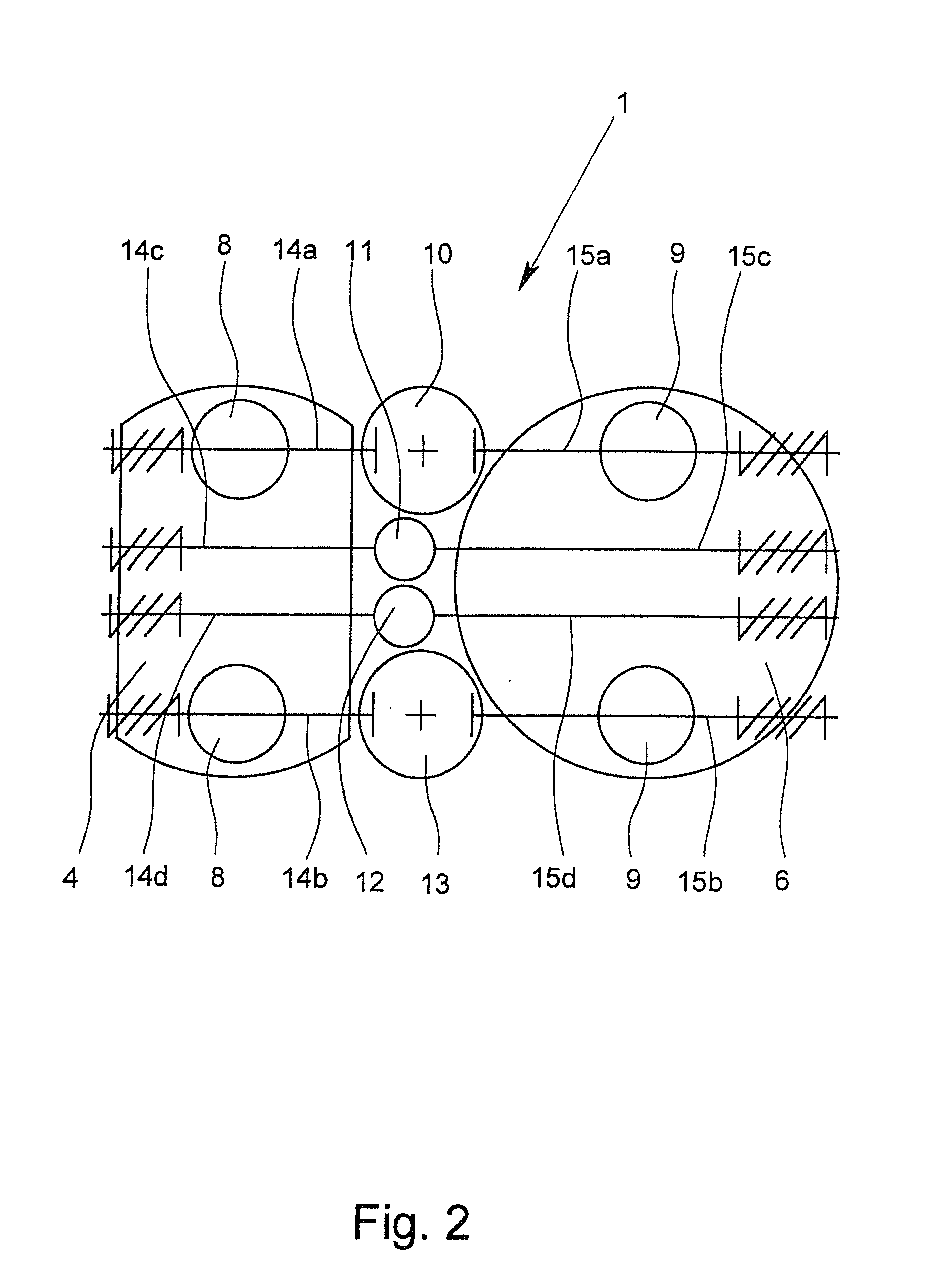

Heat engines

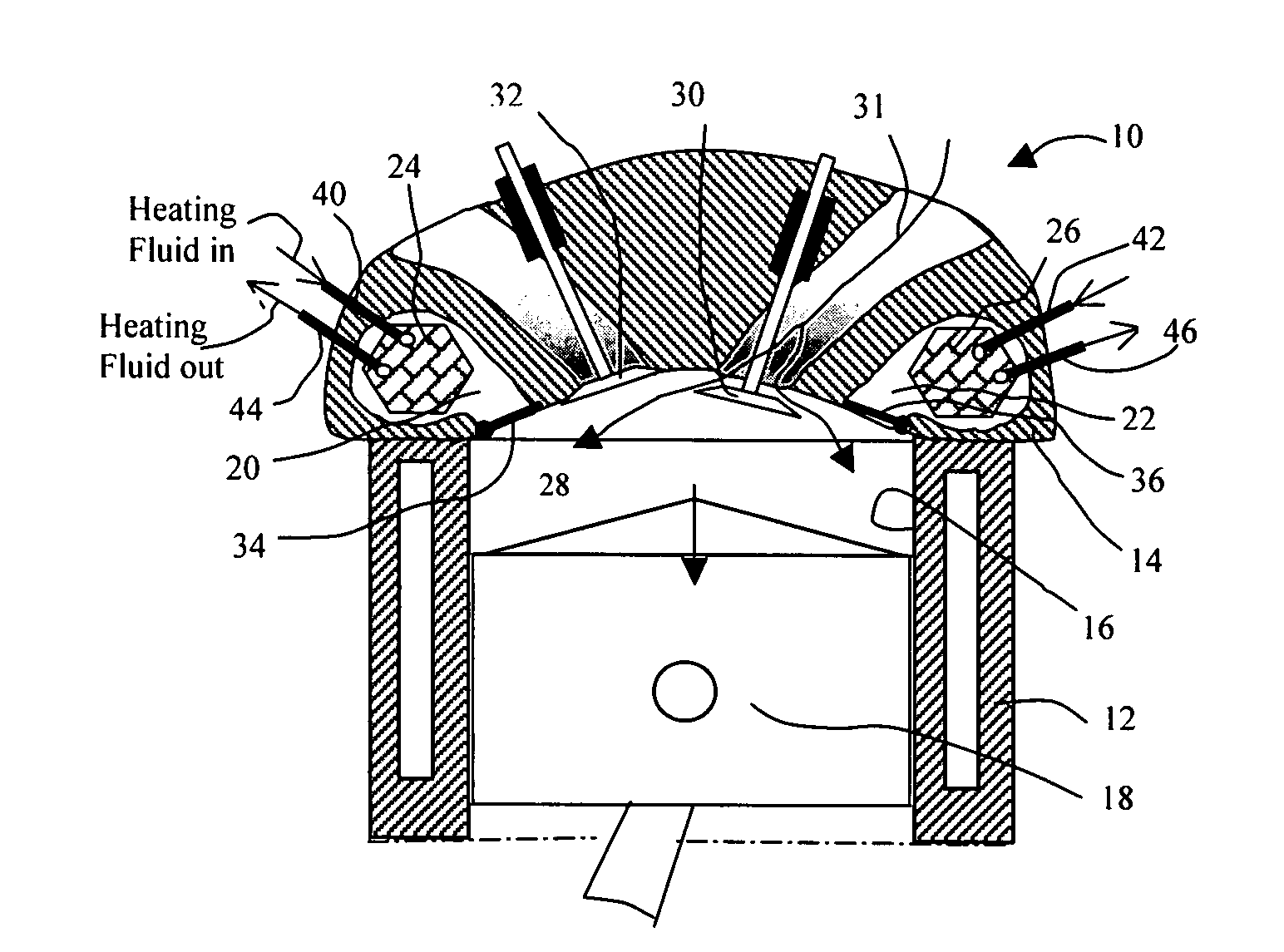

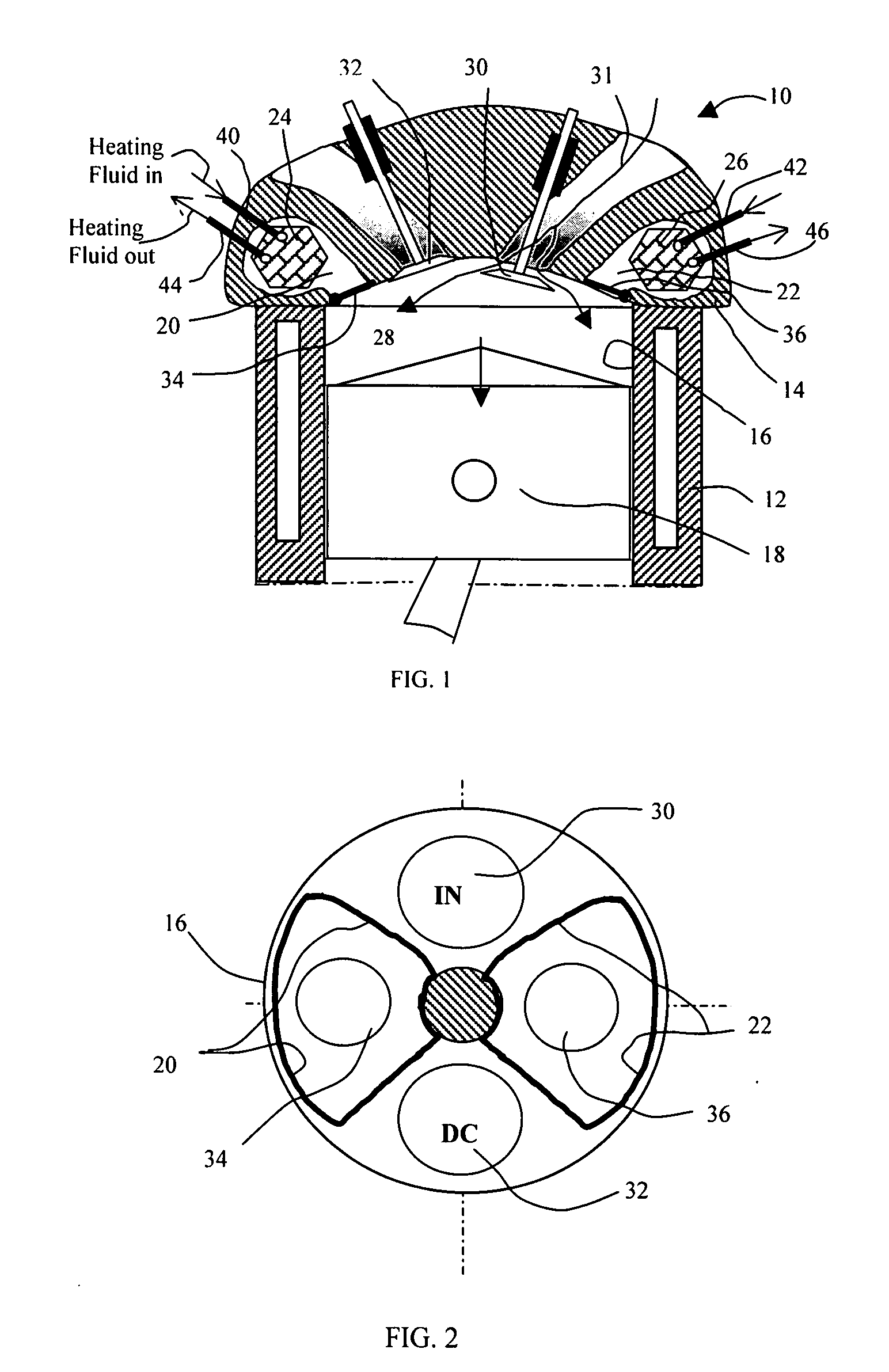

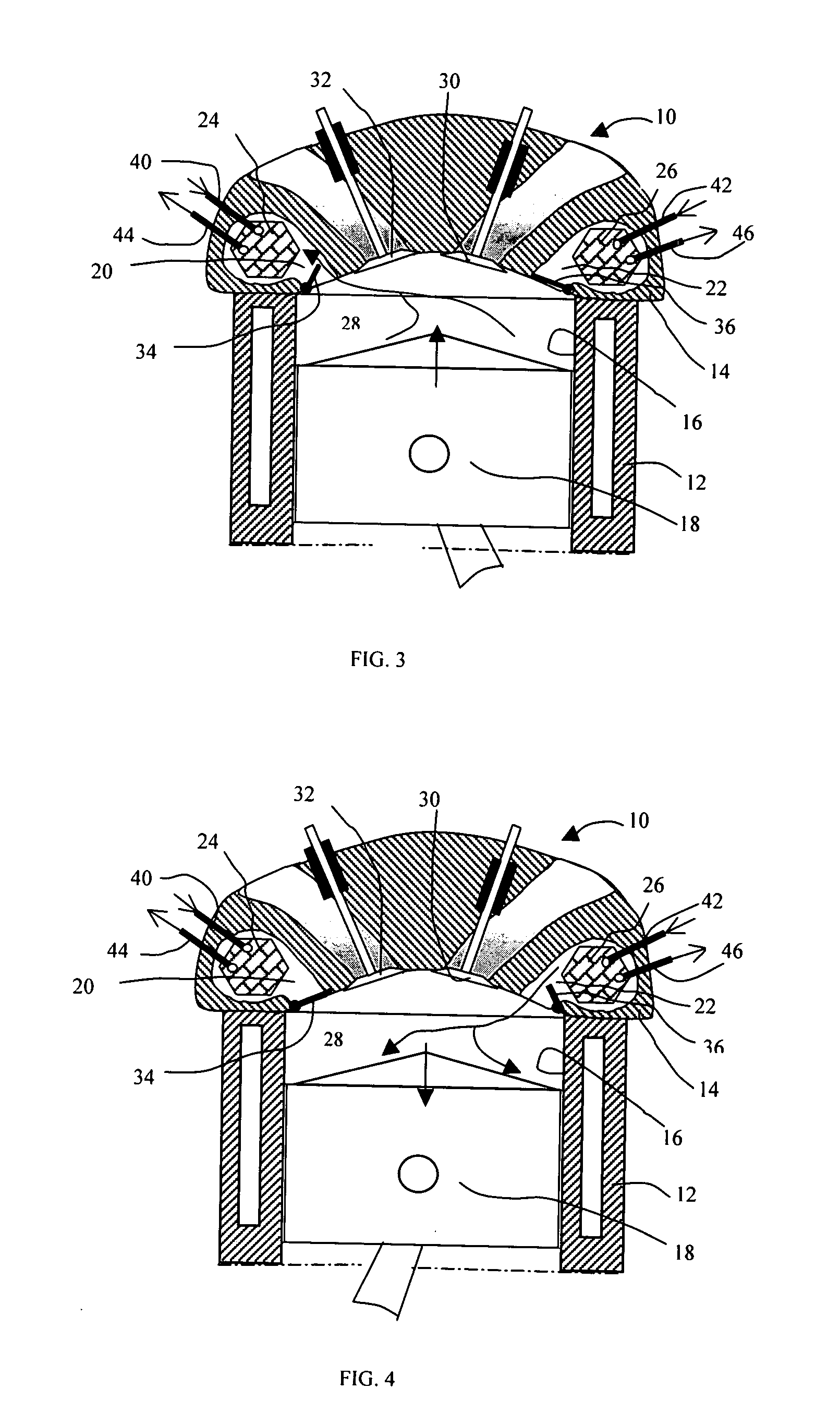

InactiveUS20080148731A1Extended durationImprove heat transfer performanceAuxillary drivesInternal combustion piston enginesWorking fluidCombustion

This invention provides a heat engine based on the well-developed structure of internal combustion engines. The heat engine comprises at least a piston and cylinder assembly and at least two heating chambers associated with said piston and cylinder assembly to provide a significantly increased time period for heat transfer from a heat source to the gaseous working of the engine without increasing the number of strokes per power stroke in a cycle. Each said heating chamber has therewithin a heat exchanger unit that facilitates heat transfer from the heating source to the working fluid, such as air, substantially under a constant volume, a port leading to said cylinder space, and a heating-chamber valve, said valve opening or closing the port to establish or block communication between said heating chamber and cylinder space. For a heat engine utilizing intake and discharge strokes respectively for intake and discharge purposes, each said heating chamber in a cycle has an associated intake stroke, a compression stroke, a power stroke, a discharge stroke, and between said compression and power strokes a time period of 4(n−1) strokes available for heat transfer from the heat source to the working fluid enclosed within said heating chamber while the piston serves the working fluid associated with another heating chamber, where n is the number of the heating chambers per piston / cylinder assembly. For a heat engine utilizing a scavenging process for intake and discharge purposes, each said heating chamber in a cycle has an associated scavenging process to facilitate the discharge and intake of the working fluid, a compression stroke, a power stroke, and between said compression and power strokes a time period of 2(n−1) strokes available for heat transfer from the heat source to the working fluid enclosed within said heating chamber while the piston serves the working fluid associated with another heating chamber, where n is the number of the heating chambers per piston and cylinder assembly. Additionally, a heat engine based on a rotary internal combustion engine as well as the techniques using heat pipes to cool a rotary engine is disclosed.

Owner:CAO YIDING

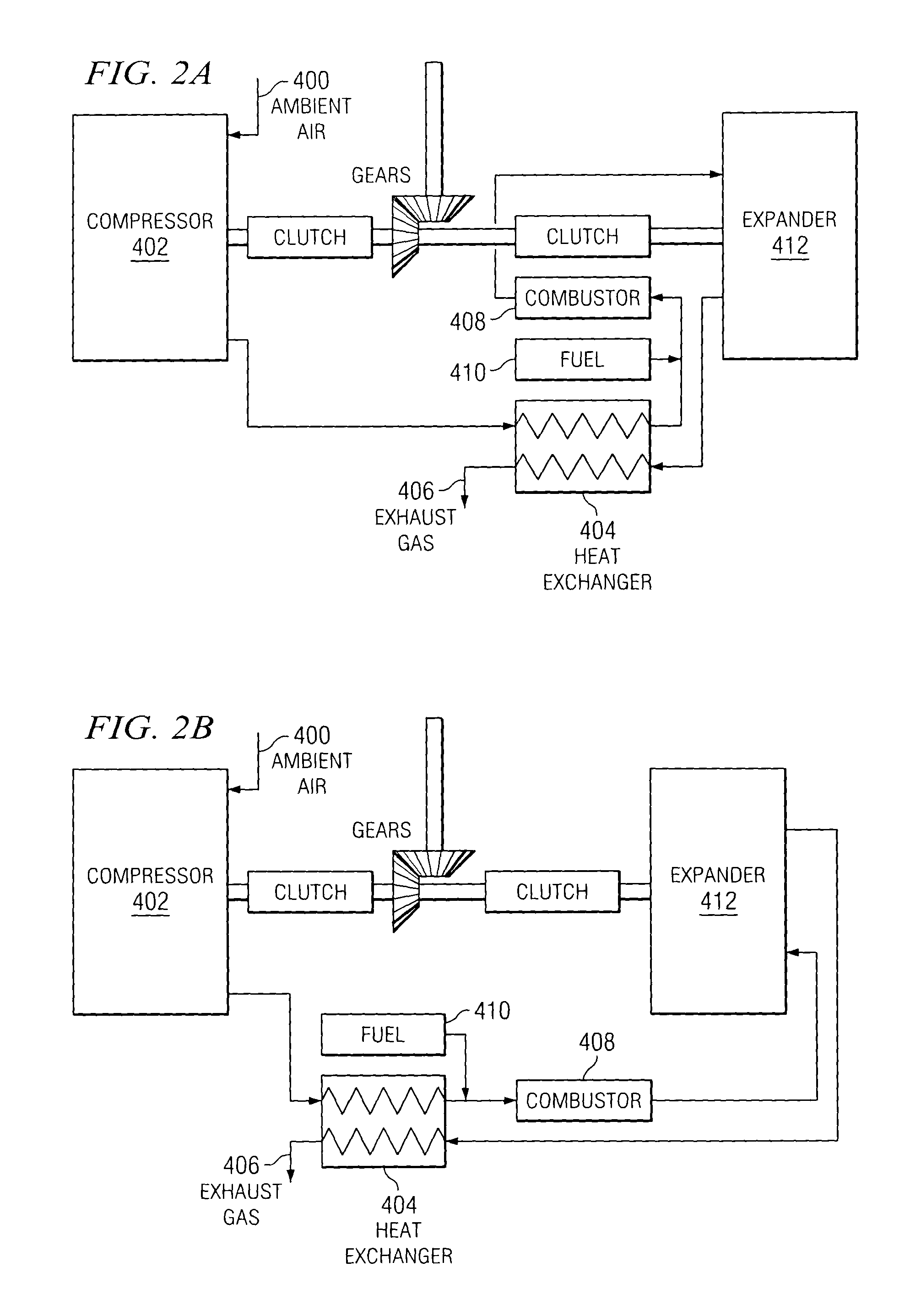

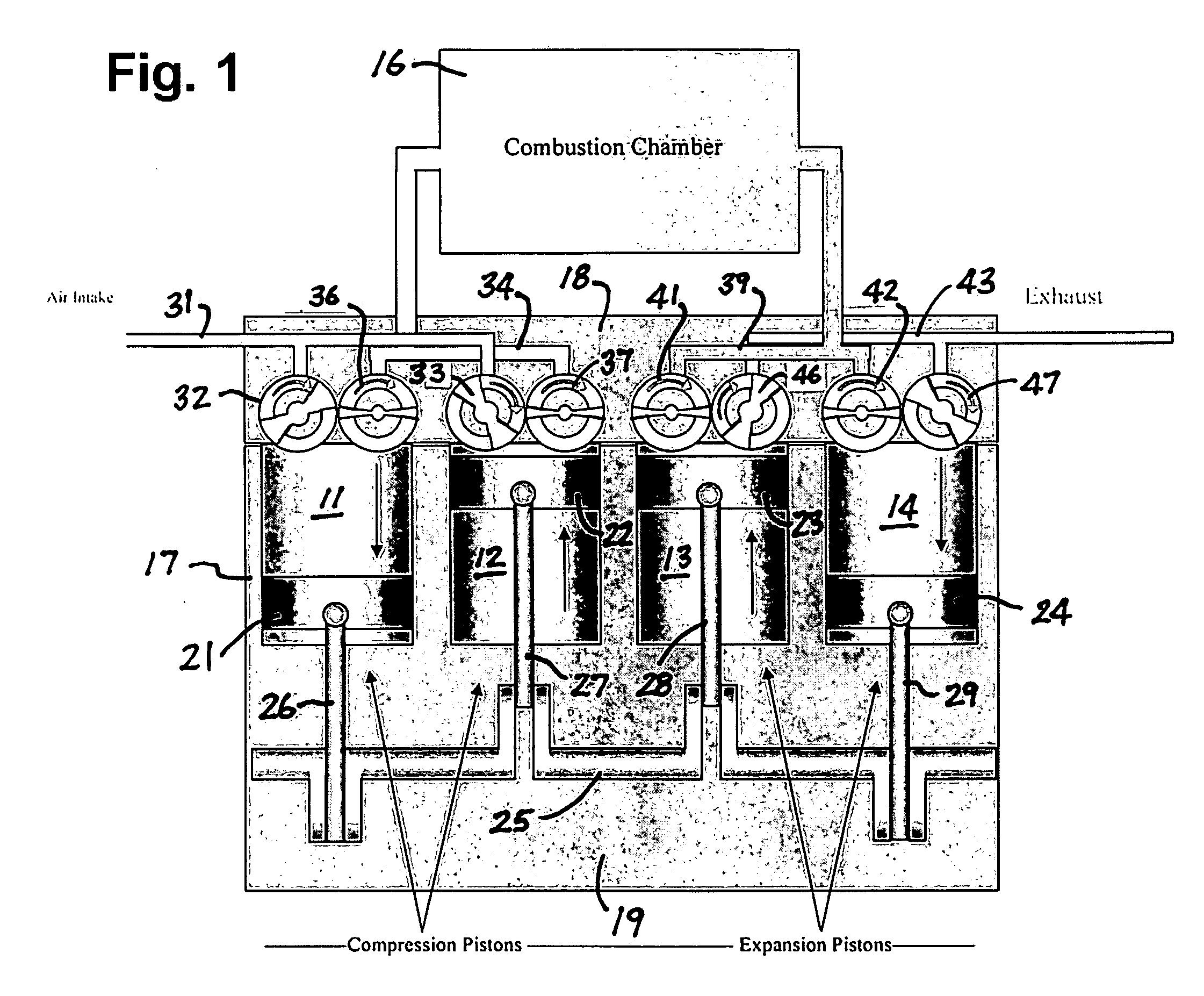

Quasi-Isothermal brayton cycle engine

InactiveUS20020014069A1Increase the turndown ratioHigh operating requirementsInternal combustion piston enginesCombination enginesBrayton cycleCombustor

An engine is disclosed. According to one embodiment of the present invention, the engine comprises a compressor, and combustor, and an expander. The compressor compresses ambient air. The combustor bums the compressed air, and produces exhaust gasses. The expander receives the exhaust gases from the combustor, and expands the exhaust gasses. The compressor may be a gerotor compressor or a piston compressor having variable-dead-volume control. The expander may be a gerotor expander or a piston expander having variable-dead-volume control. In another embodiment, an engine comprises a piston compressor, a combustor, a piston expander, and a pressure tank. The piston compressor compresses ambient air. The combustor bums the compressed air, and produces exhaust gasses. The piston expander receives the exhaust gasses from the combustor, and expands the exhaust gasses. The pressure tank receives and stores the compressed air from the compressor. In another embodiment, a gerotor compressor or a gerotor expander comprises an inner gerotor, and an outer gerotor. The inner gerotor and the outer gerotor are driven so that they do not touch. The gerotors may be cantilevered or non-cantilevered.

Owner:HOLTZAPPLE MARK T +1

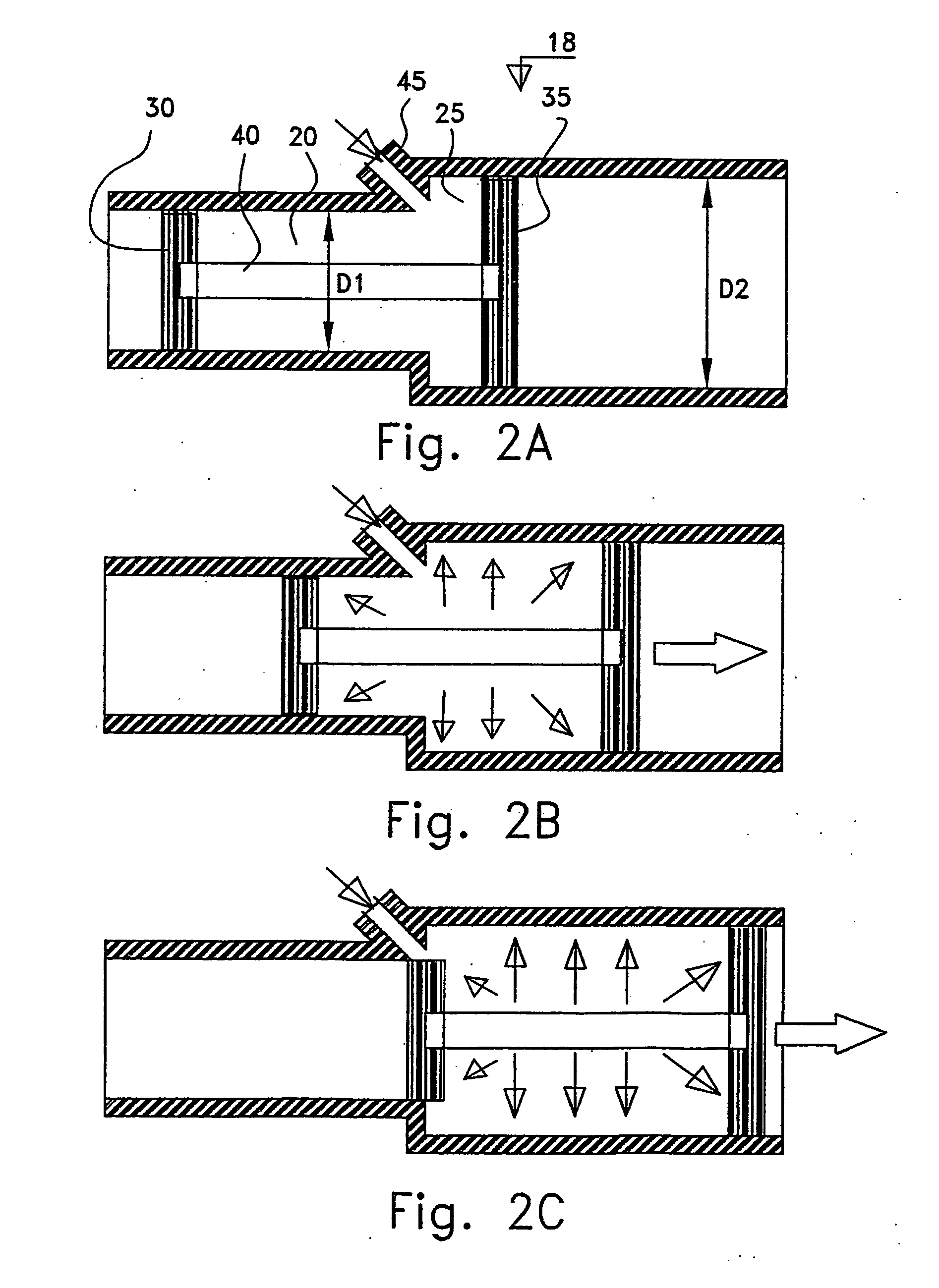

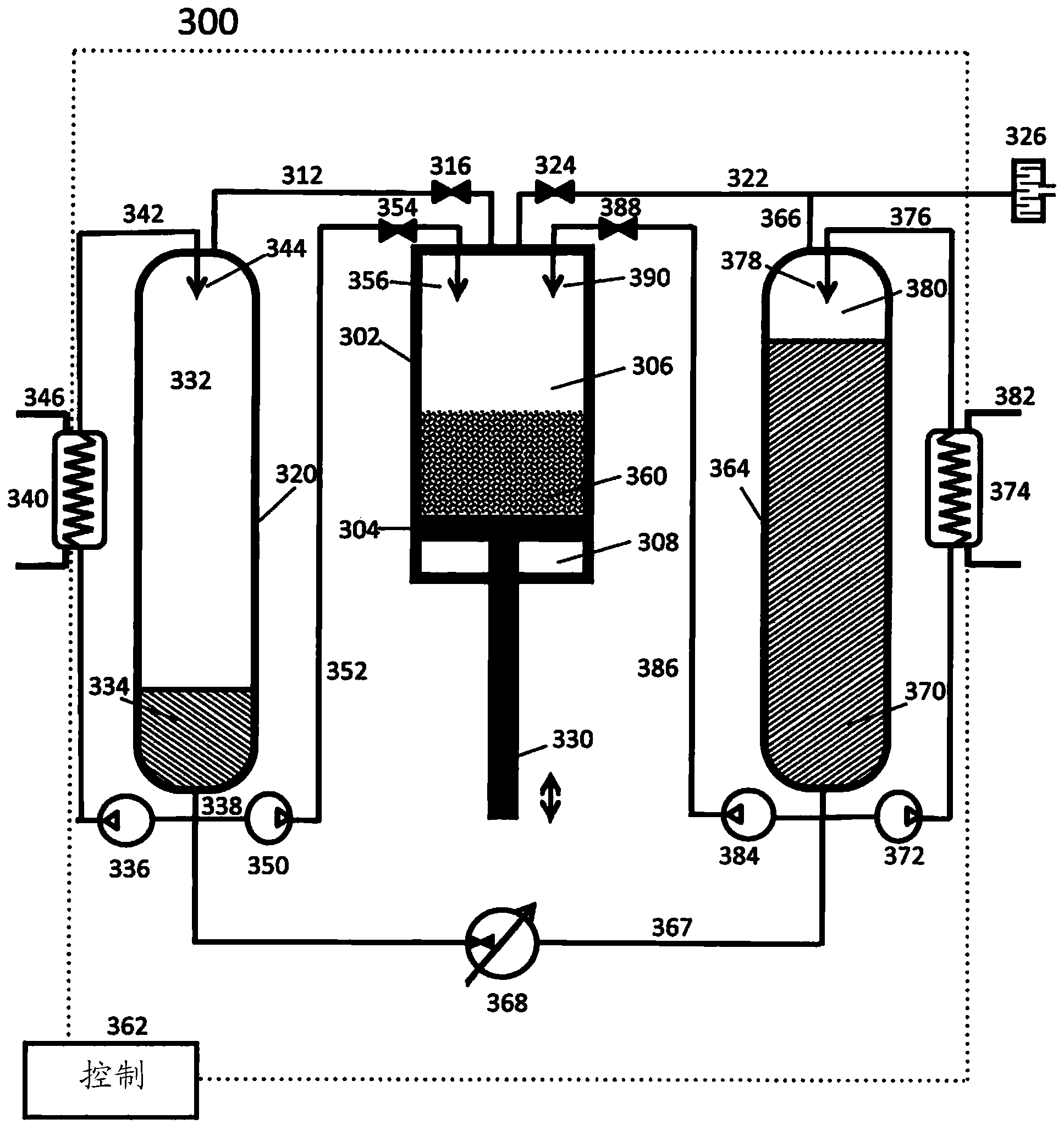

Compressor and/or expander device

An apparatus can include a pressure vessel that defines an interior region that can contain a liquid and / or a gas. A piston is movably disposed within the interior region of the pressure vessel. A divider is fixedly disposed within the interior region of the pressure vessel and divides the interior region into a first interior region on a first side of the divider and a second interior region on a second, opposite side of the divider. The piston is movable between a first position in which fluid having a first pressure is disposed within the first interior region and the first interior region has a volume less than a volume of the second interior region, and a second position in which fluid having a second pressure is disposed within the second interior region and the second interior region has a volume less than a volume of the first interior region.

Owner:GENERAL COMPRESSION

Internal combustion engine with regenerator, hot air ignition, and supercharger-based engine control

InactiveUS7004115B2Reduce the temperatureReduce heat lossInternal combustion piston enginesEngine operationsFour-stroke engineForced induction

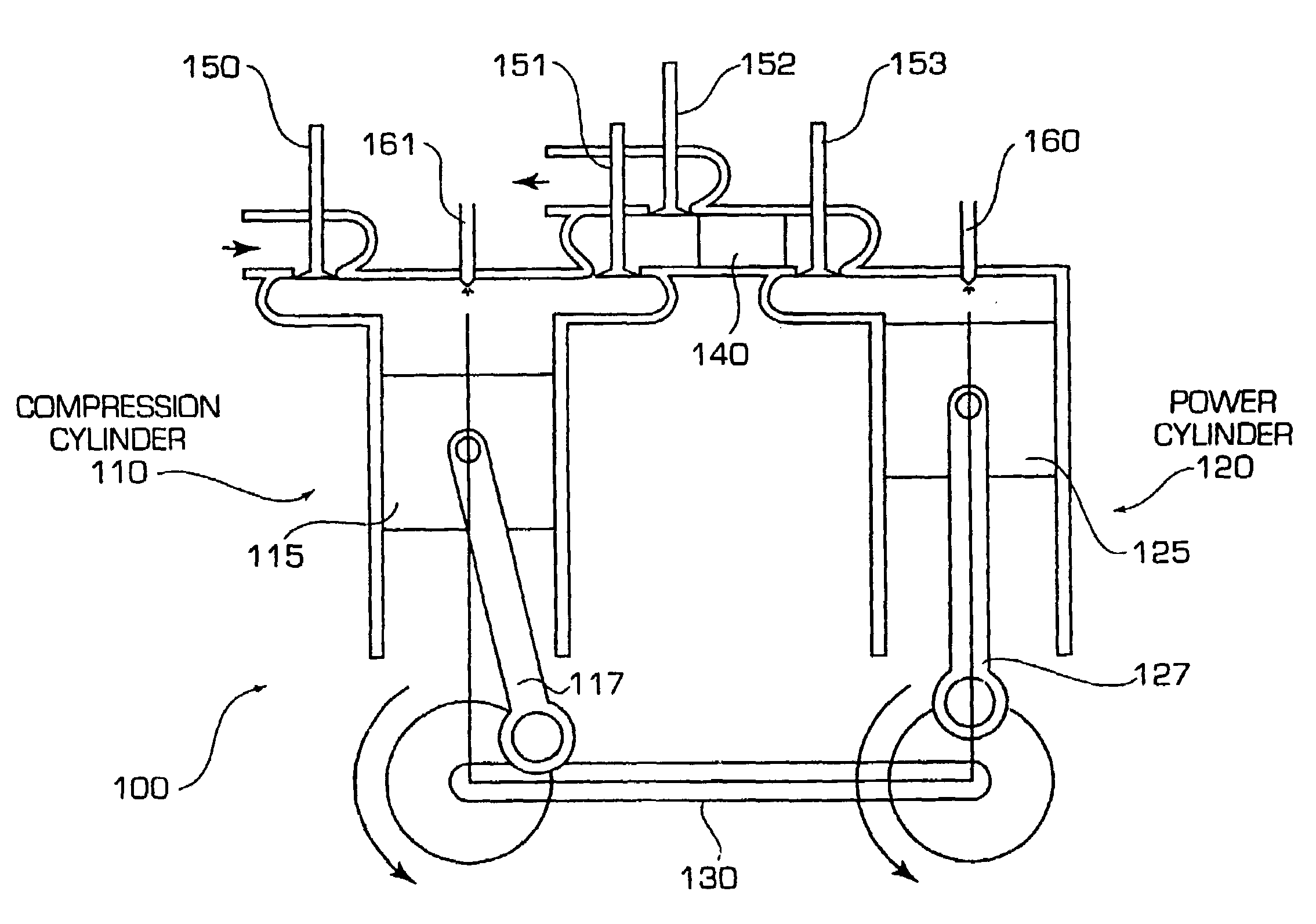

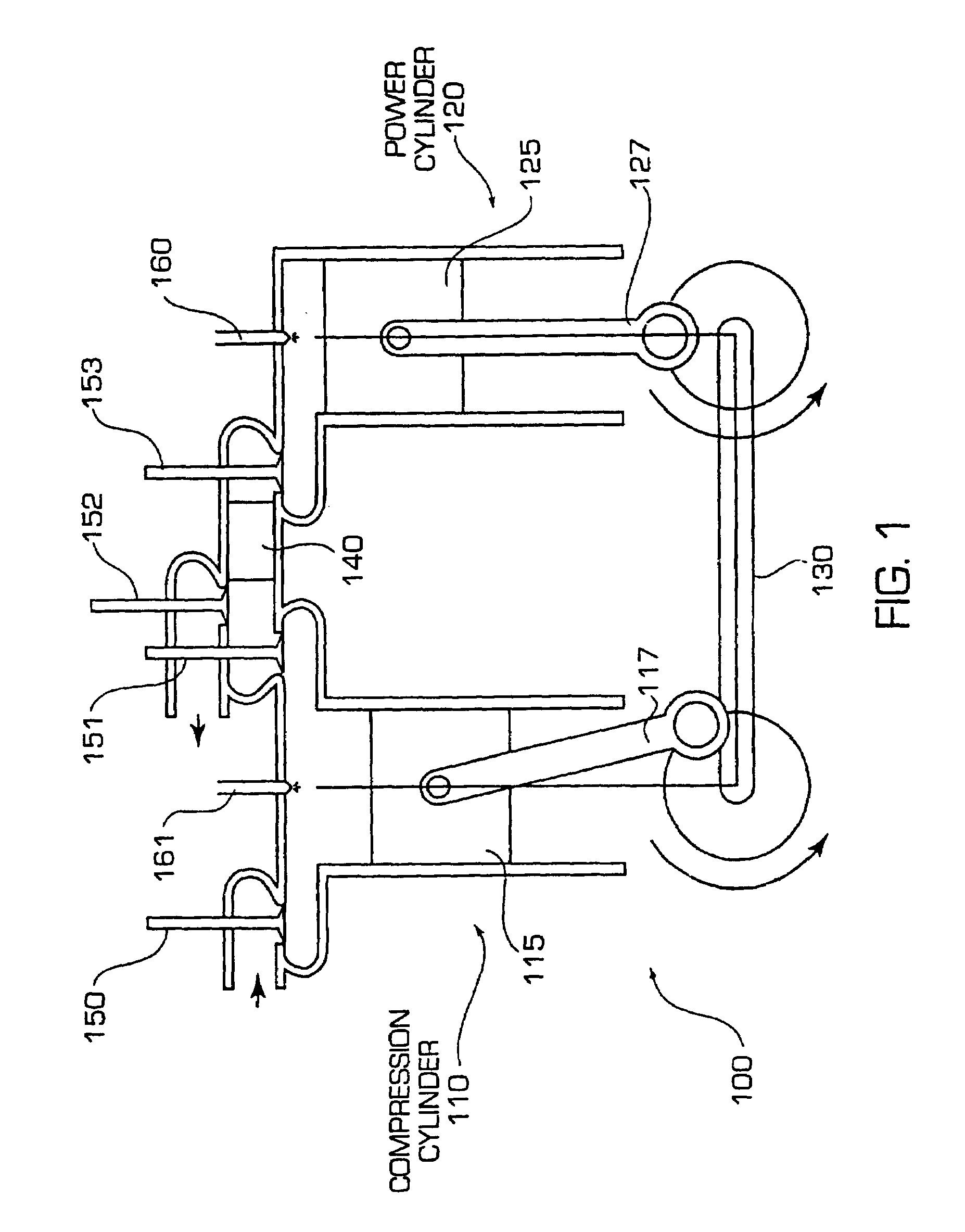

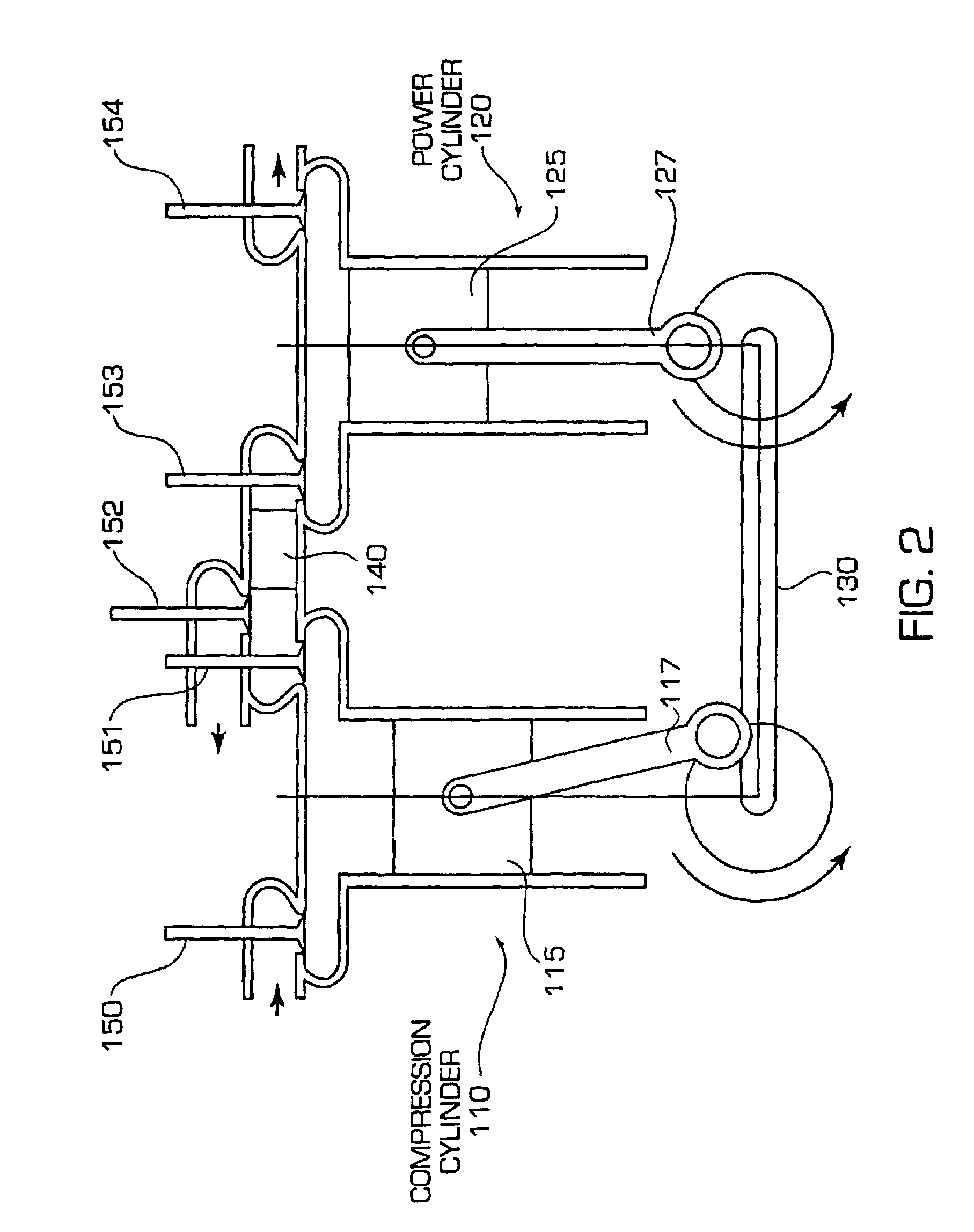

An internal combustion engine and method is disclosed wherein separate compression and power cylinders are used and a regenerator or pair of regenerators is mounted between them to provide heat for hot-air ignition. The single regenerator embodiment operates as a two-stroke cycle engine and the embodiment with an alternating pair of regenerators operates as a four-stroke cycle engine. Valving is provided for uniflow design and the system allows variable fuel ratios. The engine uses supercharging to control the engine.

Owner:PATTON RICHARD

Systems and methods for energy storage and recovery using gas expansion and compression

InactiveUS8448433B2Increase energy densityElectrical storage systemFluid couplingsEngineeringAtmospheric pressure

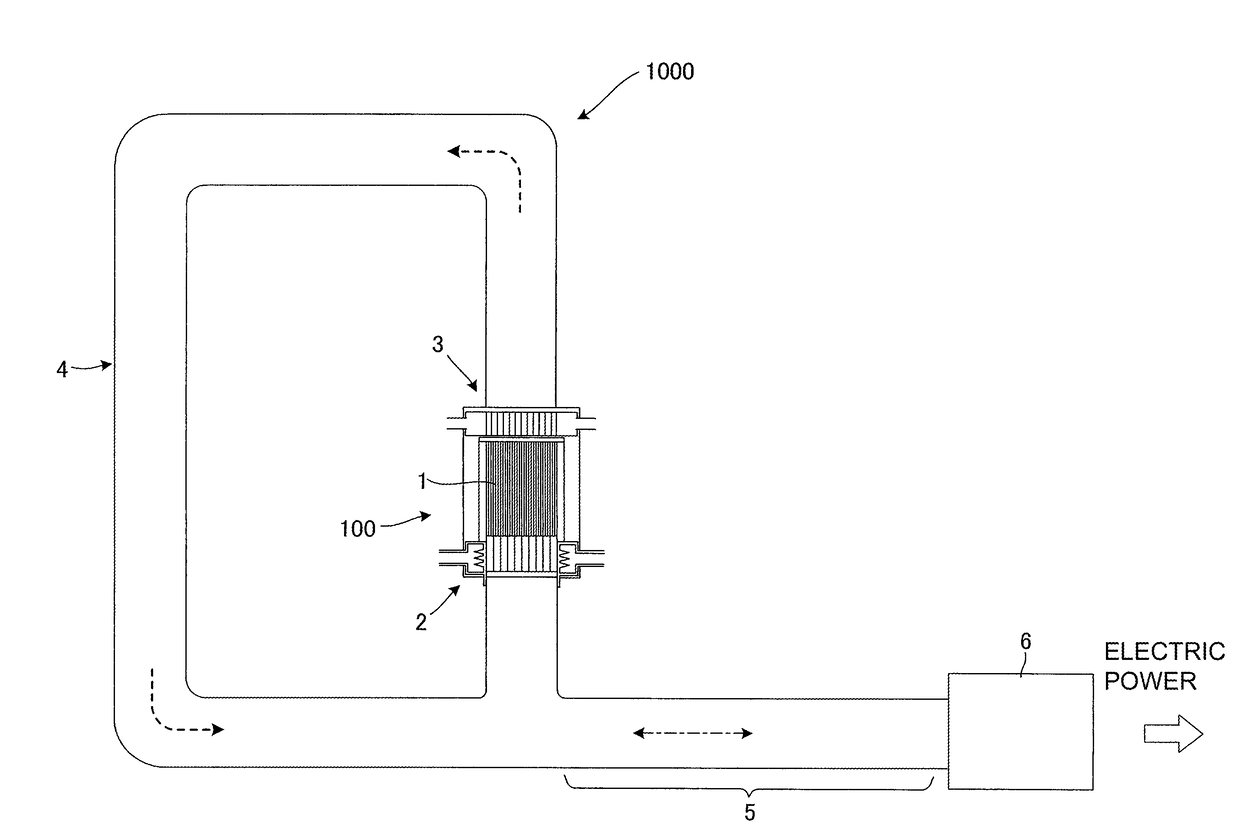

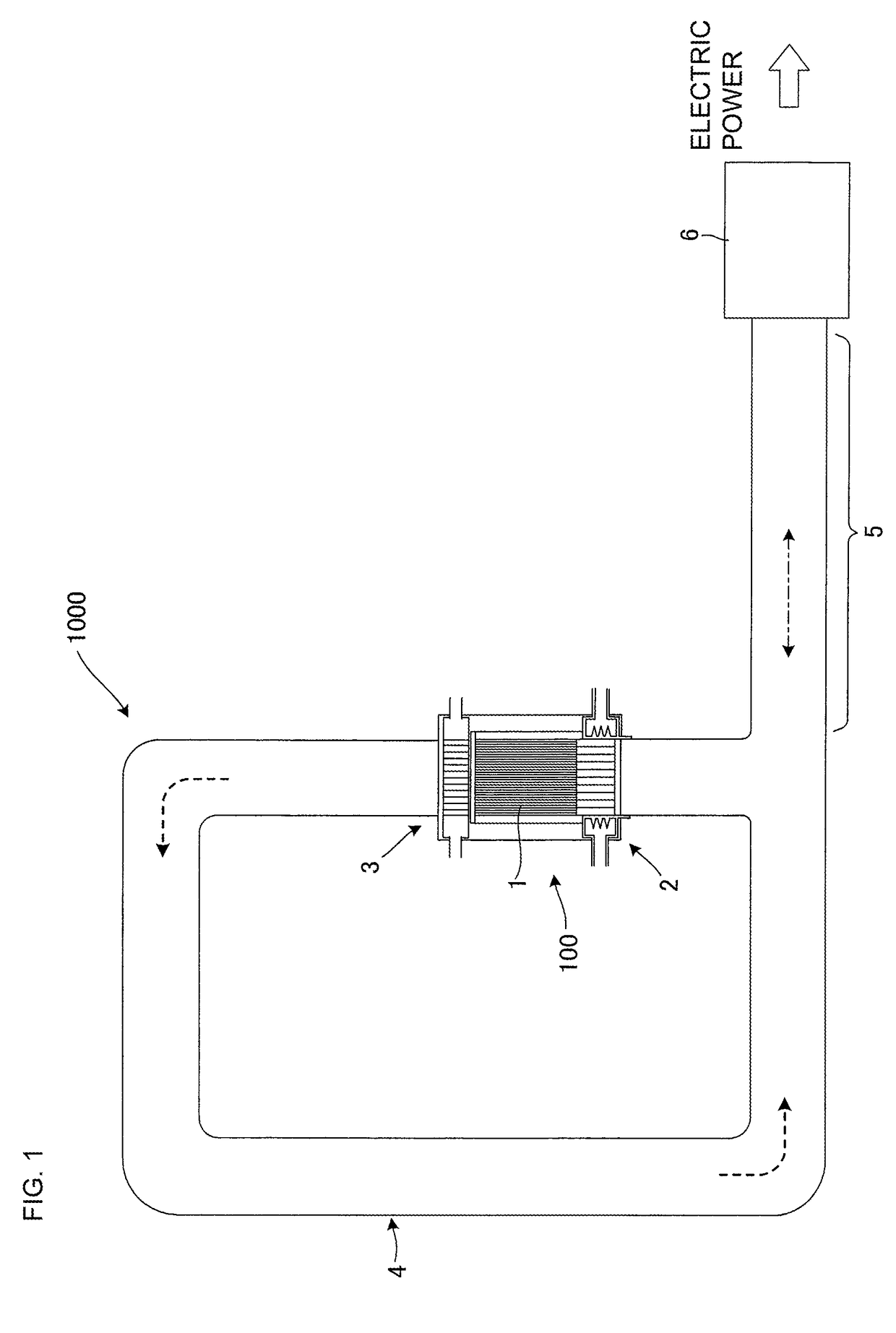

In various embodiments, energy-storage systems are based upon an open-air arrangement in which pressurized gas is expanded in small batches from a high pressure of, e.g., several hundred atmospheres to atmospheric pressure. The systems may be sized and operated at a rate that allows for near isothermal expansion and compression of the gas.

Owner:SUSTAINX

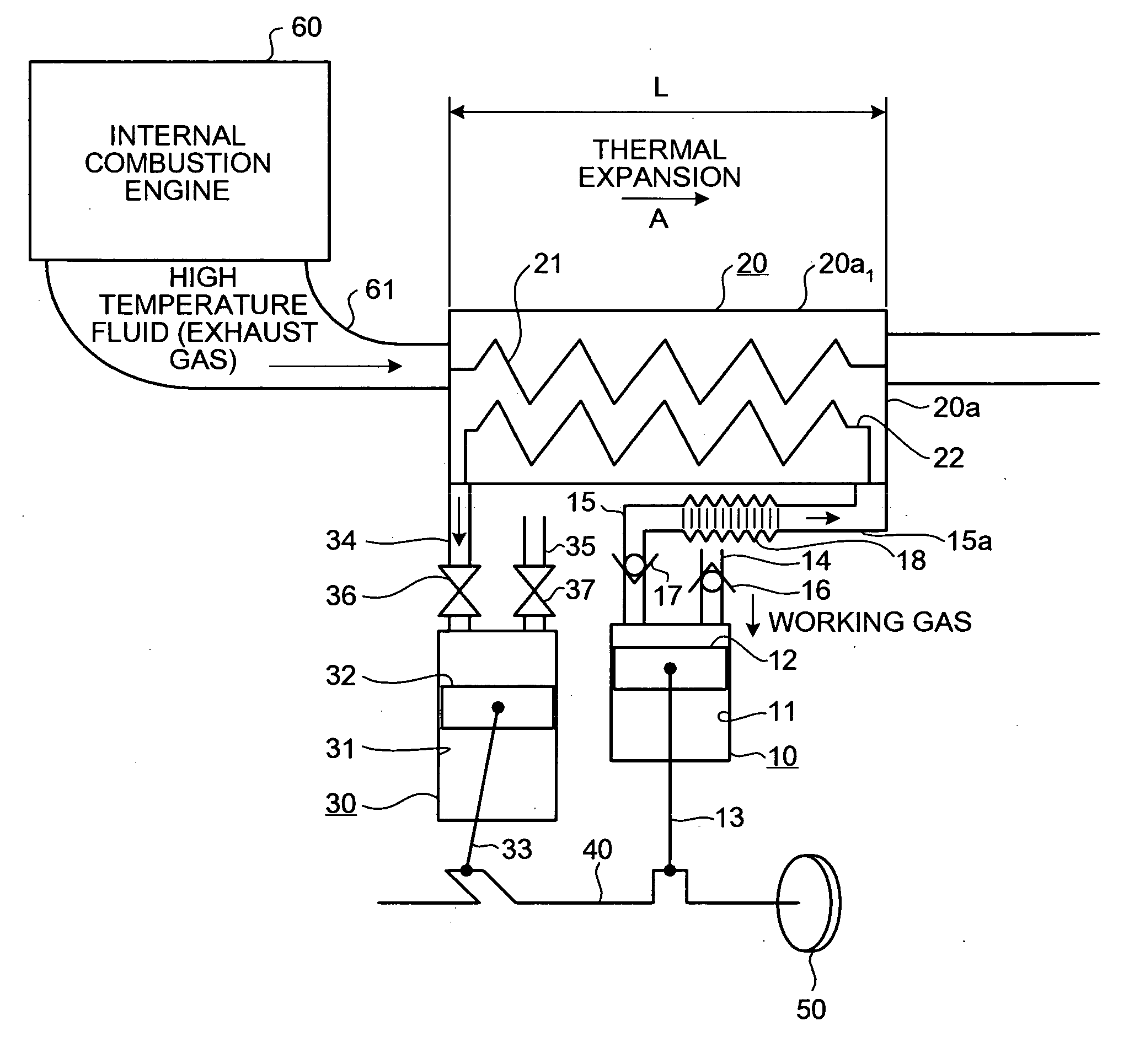

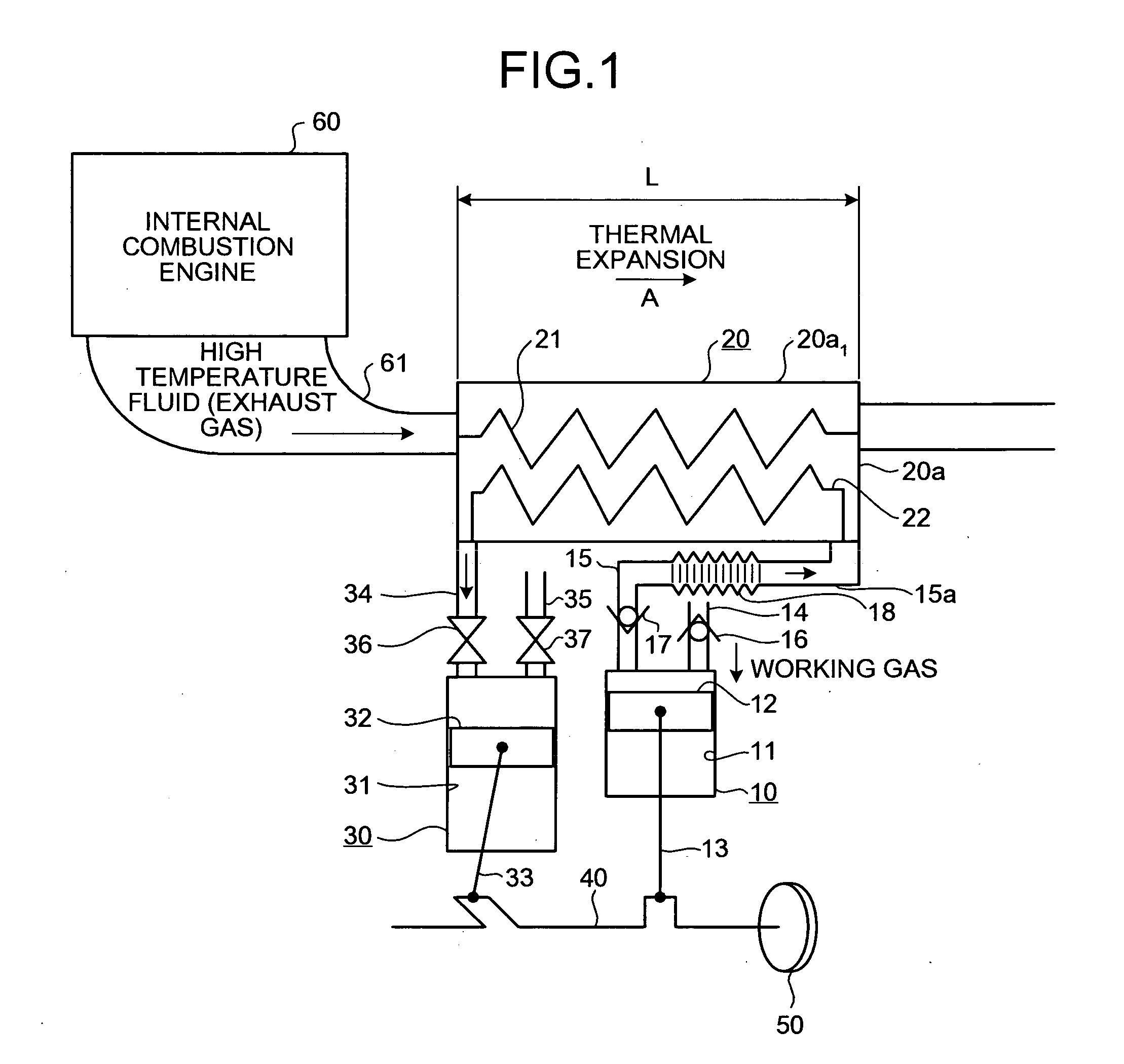

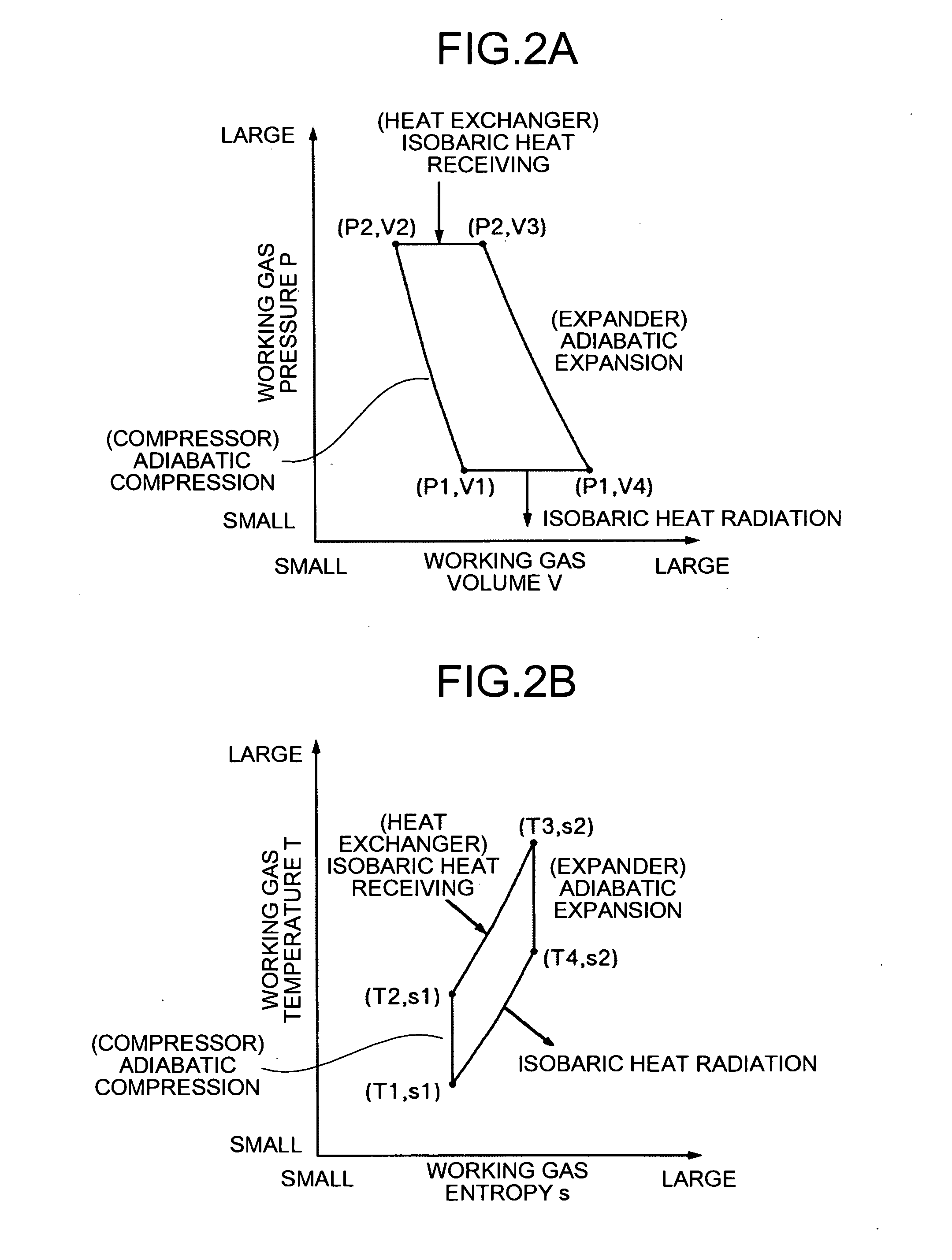

Heat energy recovery apparatus

InactiveUS20060218919A1Relieve compressive stressReduce tensile stressInternal combustion piston enginesEngine componentsEngineeringThermal expansion

A heat energy recovery apparatus includes a compressor; a heat exchanger; an expander; a working gas exhaust pipe which leads the working gas compressed by the compressor to the heat exchanger; a working gas exhaust path generally parallel to a direction of the thermal expansion of the heat exchanger; an extending unit extensible in the same direction as that of the thermal expansion when the heat exchanger expands thermally and tensile stress occurs in the working gas exhaust path with the thermal expansion of the heat exchanger; and a shrinking unit shrinkable in the same direction as that of the thermal expansion when the heat exchanger expands thermally and compressive stress occurs in the working gas exhaust path with the thermal expansion of the heat exchanger.

Owner:TOYOTA JIDOSHA KK

Internal combustion engine

InactiveUS20120031383A1Improve efficiencyImproved torque responseInternal combustion piston enginesGaseous engine fuelsCombustionExternal combustion engine

An internal combustion engine with a crankshaft, at least one compression piston which is housed in a compression cylinder, and at least one working piston which is housed in a working cylinder. Movement of the compression piston and of the working piston are coupled kinematically to movement of the crankshaft, so that the compression piston moves back and forth during a single revolution of the crankshaft in an intake stroke and a compression stroke and that the working piston moves back and forth during a single revolution of the crankshaft by a working stroke and an exhaust stroke. The compression cylinder has at least one inlet valve for drawing-in air into the compression cylinder during downward movement of the compression piston, and the working cylinder has at least one outlet valve for discharging combustion gases from the working cylinder during upward movement of the working piston.

Owner:WILLI FECHNER

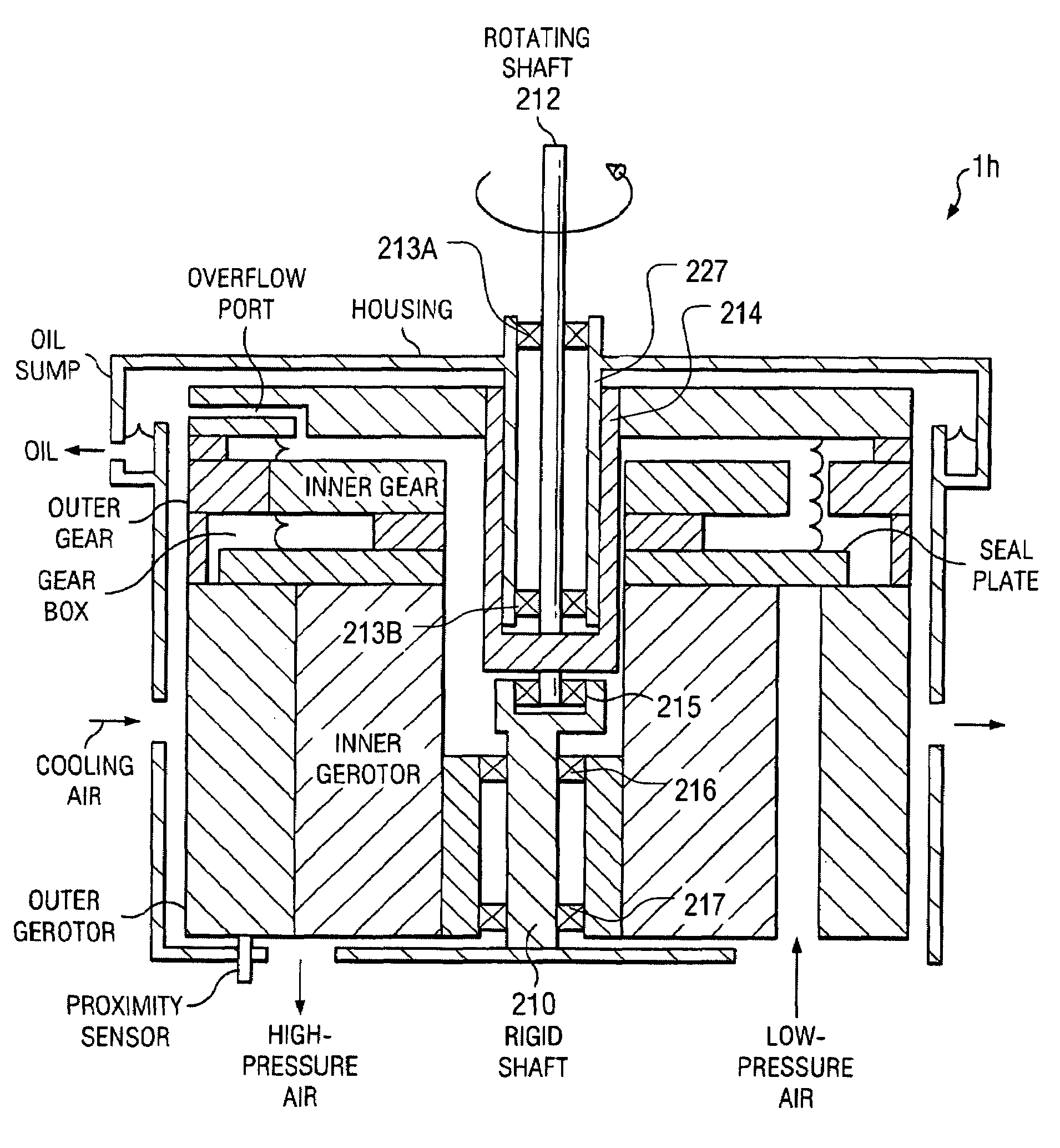

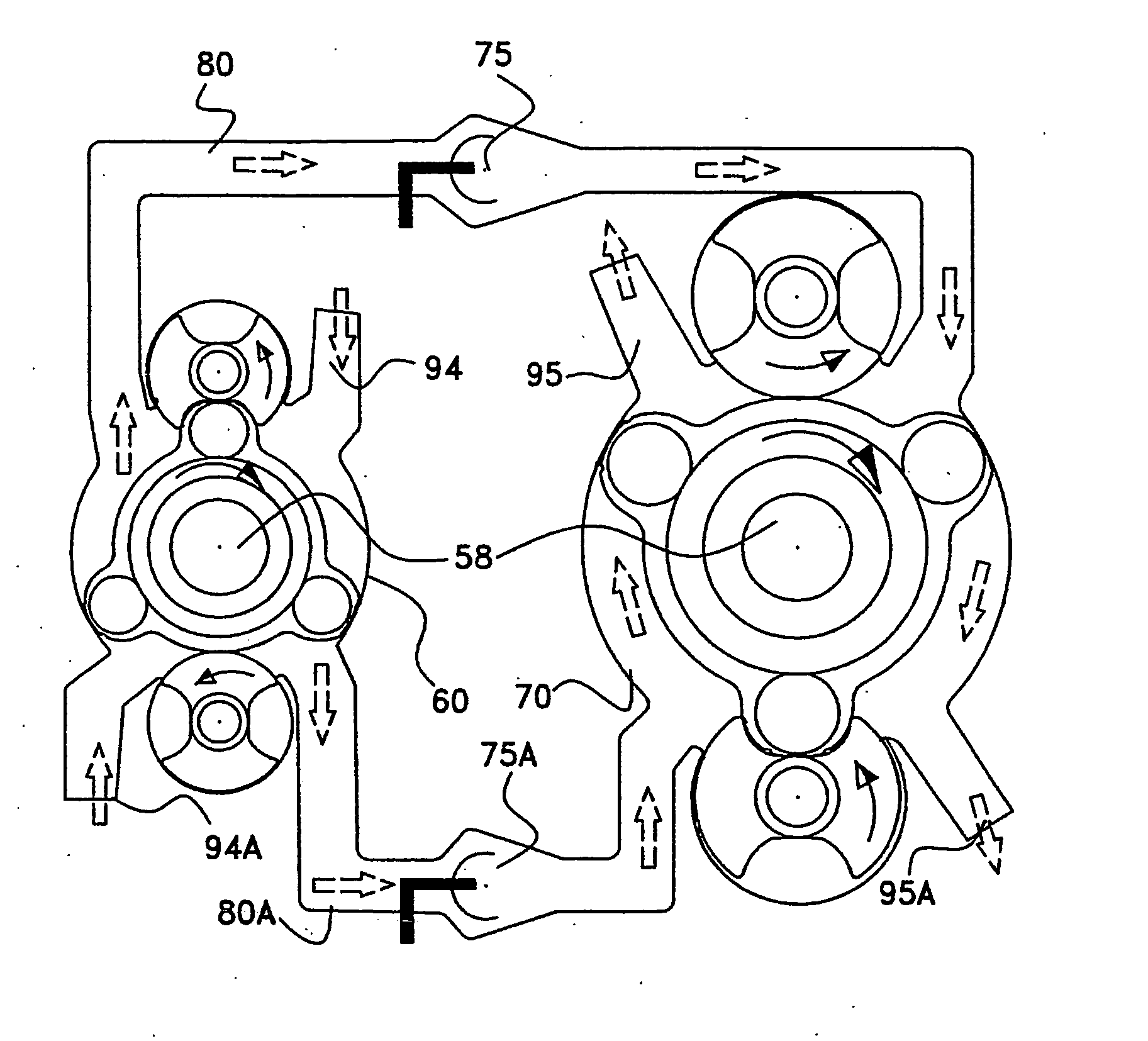

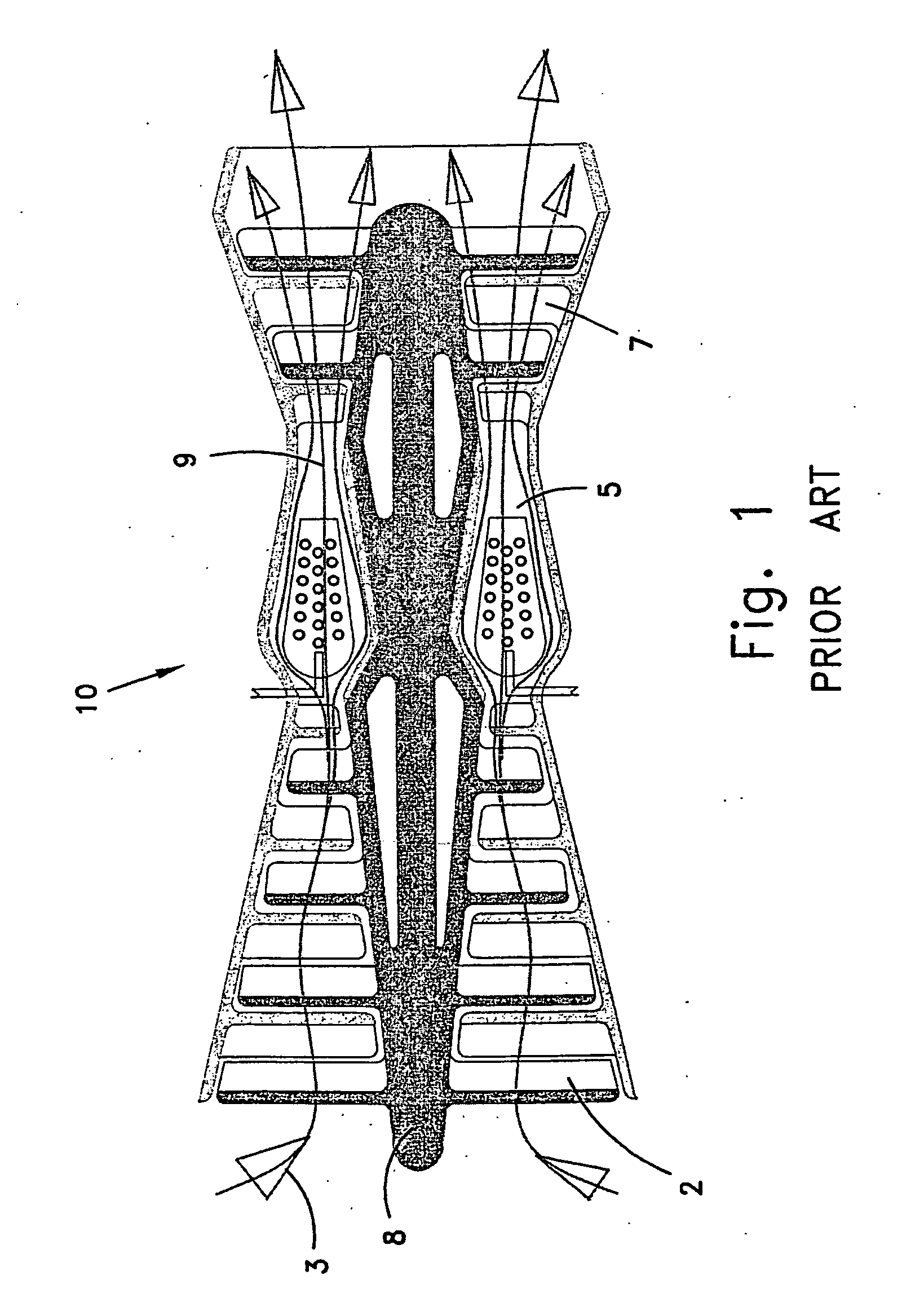

Gerotor apparatus for a quasi-isothermal Brayton cycle Engine

InactiveUS7186101B2Simpler gas flow pathLess loadInternal combustion piston enginesCombination enginesBrayton cycleCycloid

According to one embodiment of the invention, a gerotor apparatus includes an outer gerotor having an outer gerotor chamber, an inner gerotor, at least a portion of which is disposed within the outer gerotor chamber, and a synchronizing apparatus operable to control the rotation of the inner gerotor relative to the outer gerotor. The inner gerotor includes one or more entrance passages operable to communicate a lubricant into the outer gerotor chamber.

Owner:TEXAS A&M UNIVERSITY

Gas turbine engine system

InactiveUS20060101800A1Efficient combustionCost-effectiveReciprocating combination enginesInternal combustion piston enginesContinuous flowGas turbines

An engine system comprises at least a first volumetric device, and a second volumetric device in which said second volumetric device is larger in volume than said first volumetric device, in which, during continuous flow of a compressible fluid from said first to said second volumetric device work is performed.

Owner:NEWTON PROPULSION TECH

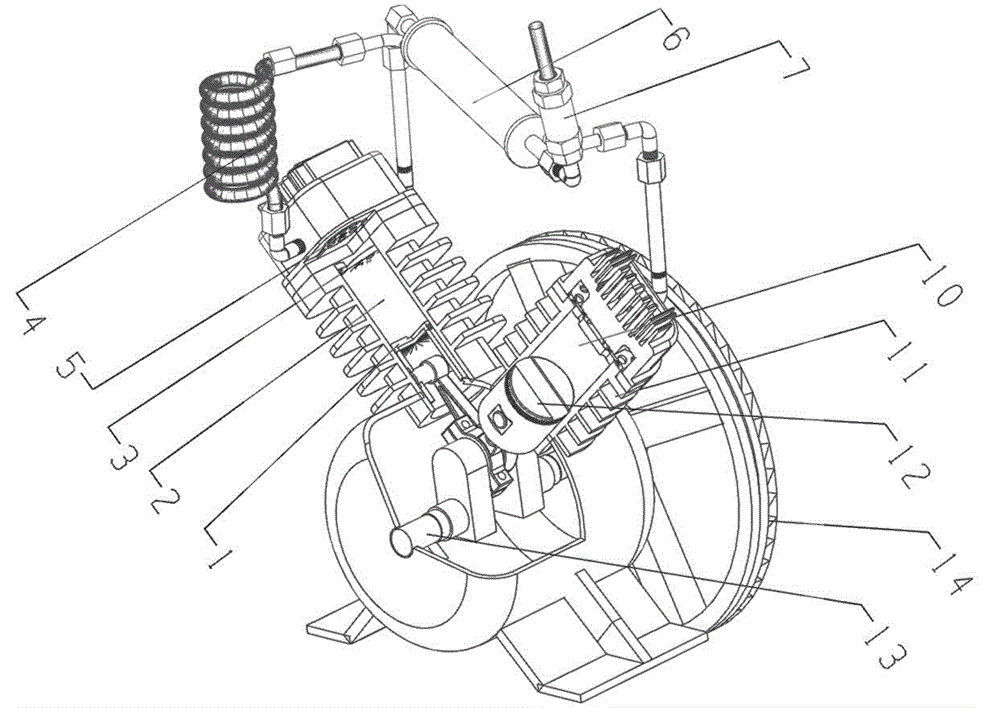

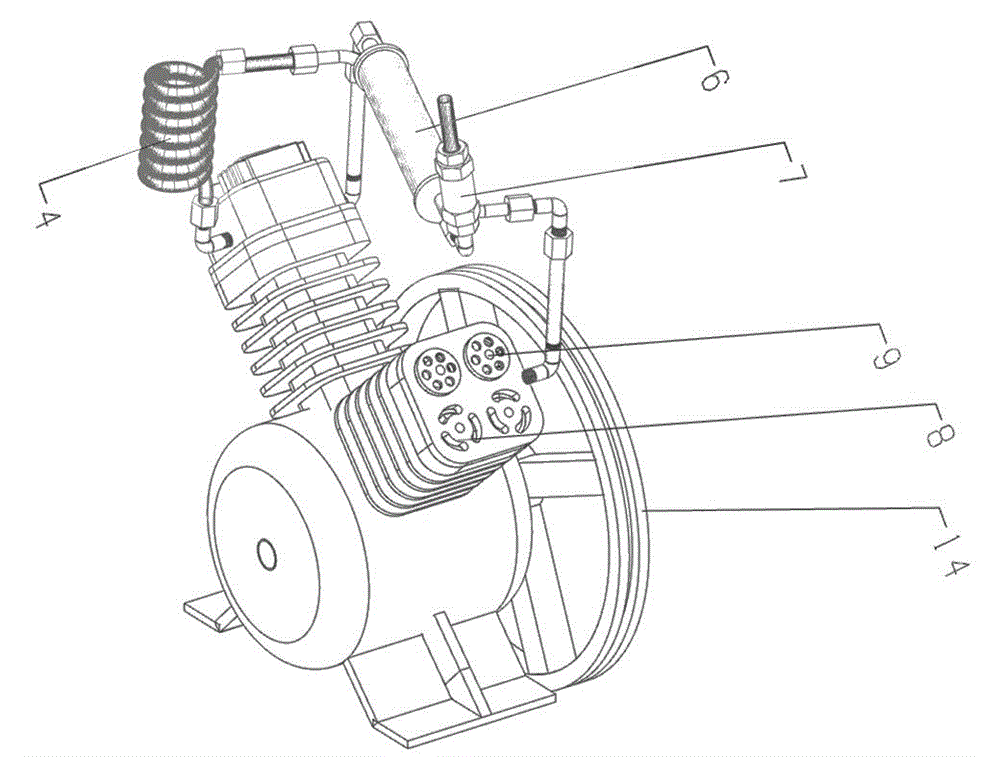

Combustion Engine

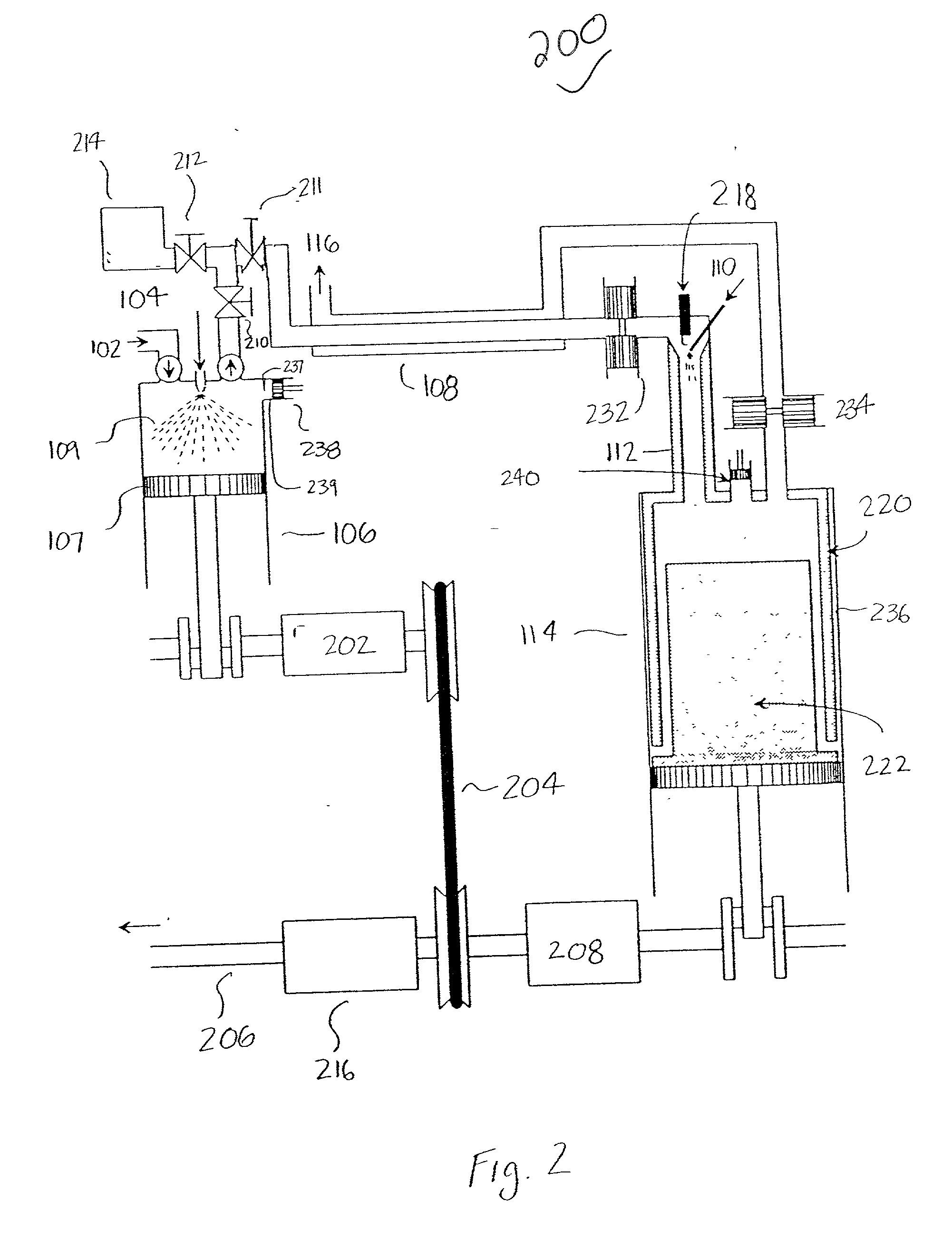

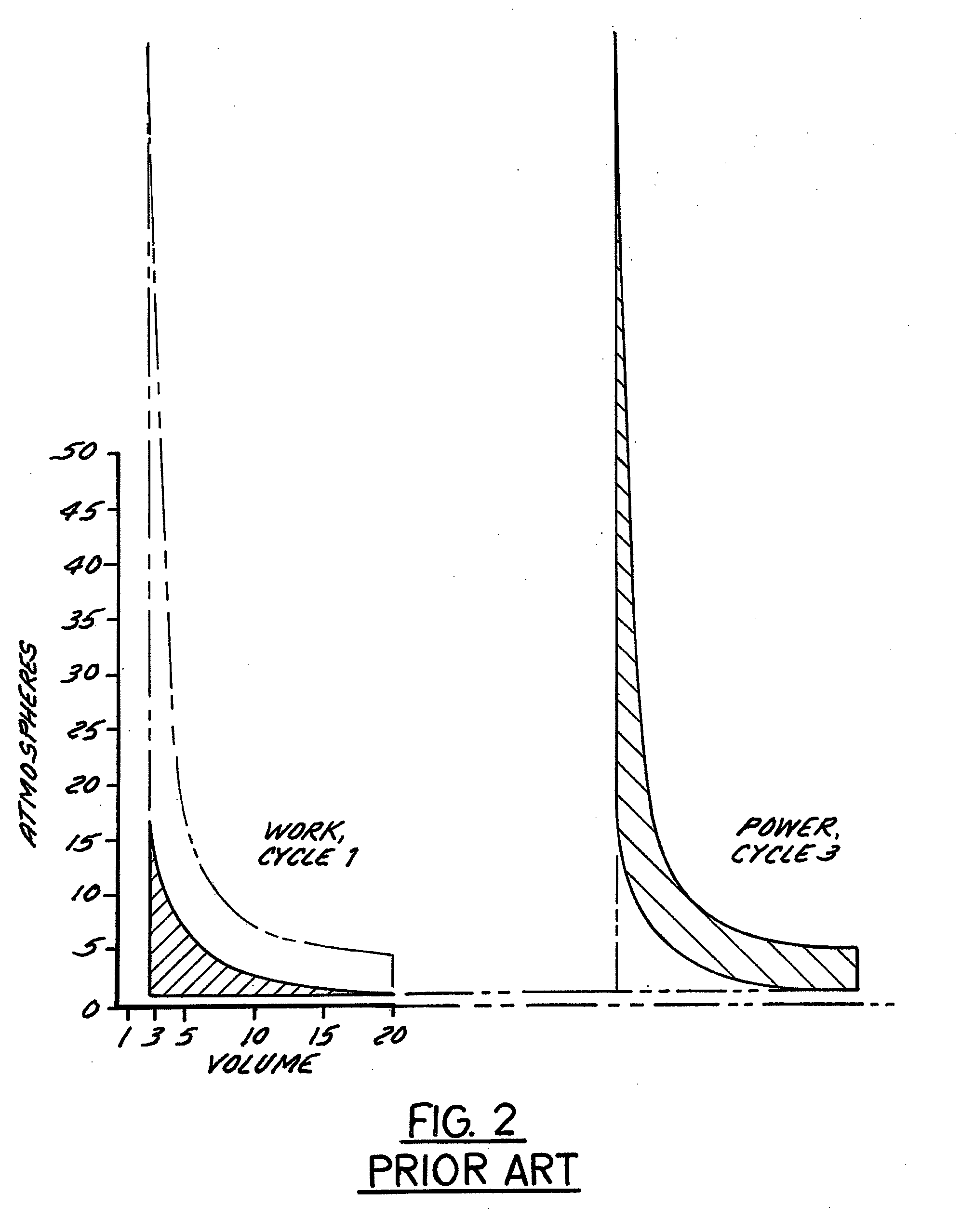

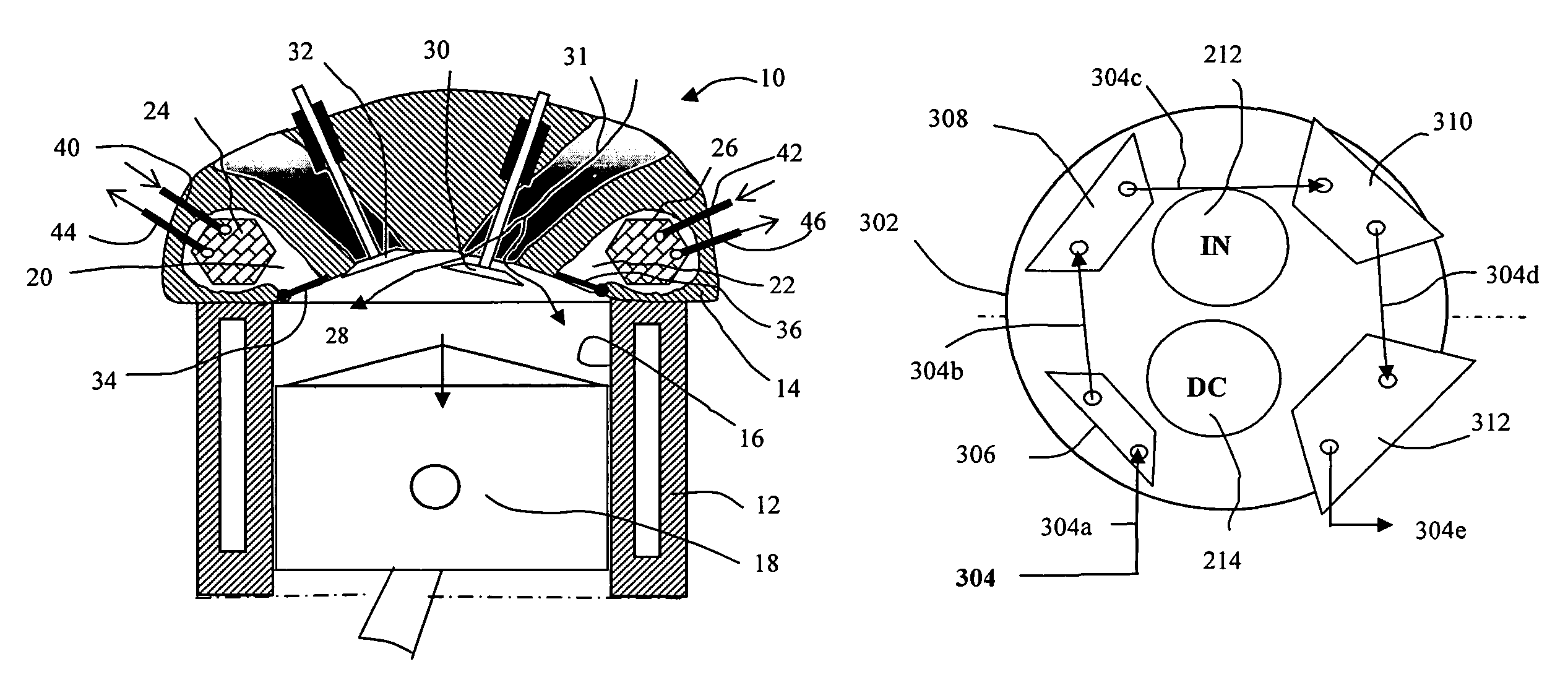

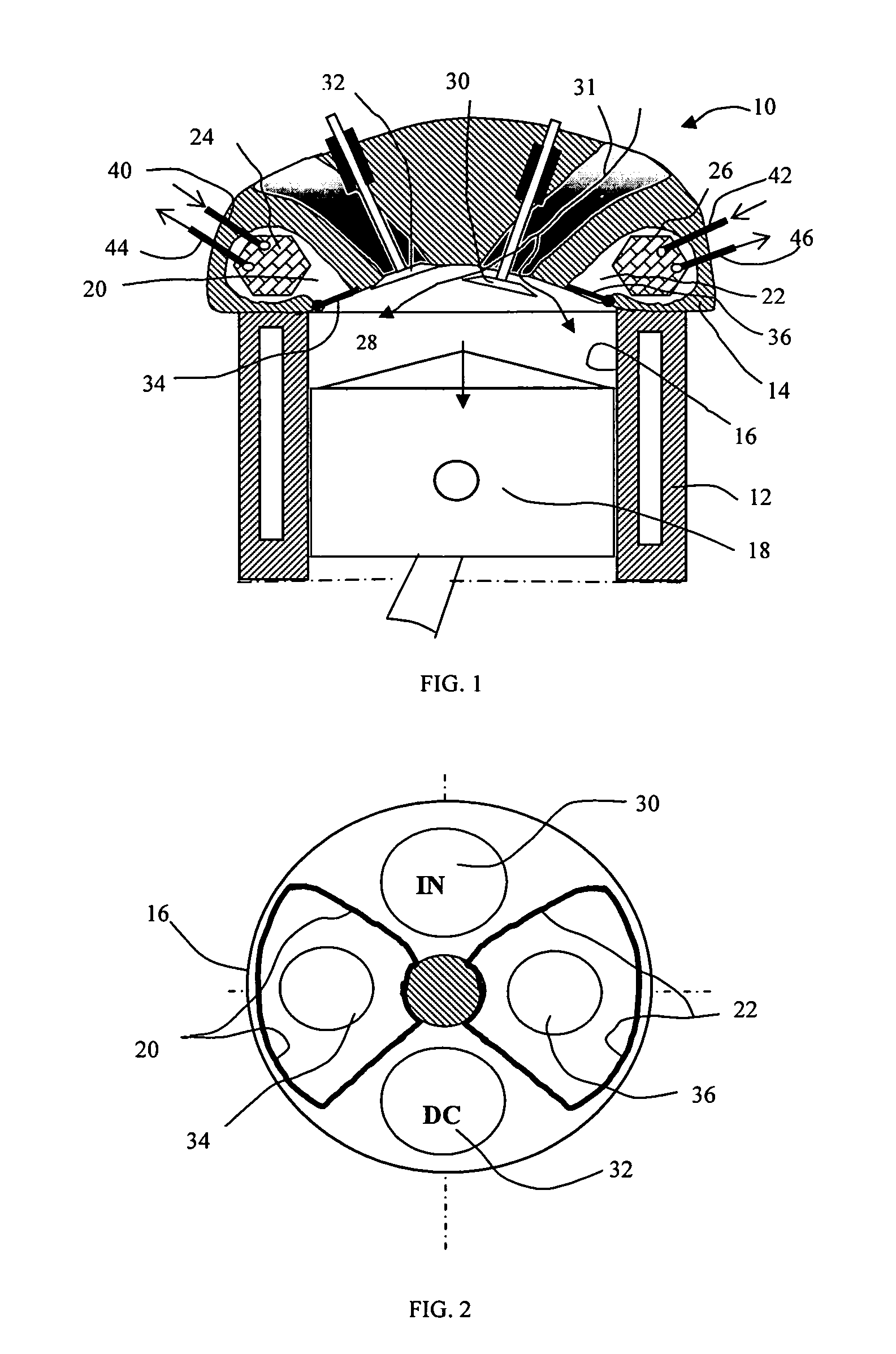

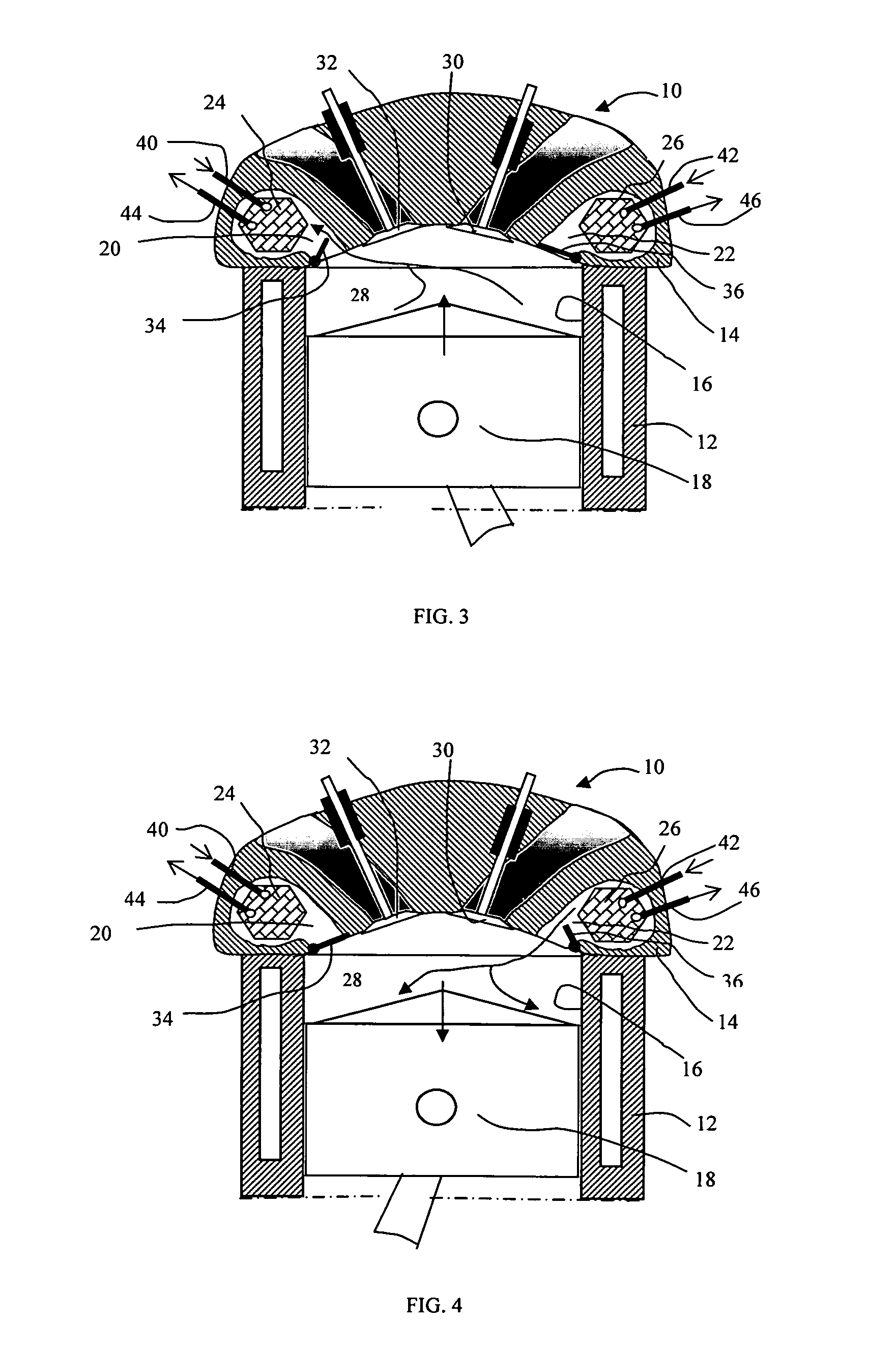

InactiveUS20070199299A1Fuel-type versatileEasy to startGas turbine plantsOpen-cycle gas positive displacement engine plantCombustion chamberPiston cylinder

A combustion engine that has at least a plurality of power strokes during a complete cycle of engine operation that is of compact packaging and Brayton cycle or modified Brayton cycle operable. In some embodiments, a piston-cylinder arrangement is used to compress air and deliver it to a combustion chamber where it is combusted along with fuel, while in some embodiments, at least some of the compressed air is delivered to and stored in a pressure vessel. The pressurized air stored in pressure vessel can be delivered to the combustion chamber or can pneumatically power various engine or vehicle accessories. Combustion gases are returned back to the piston-cylinder arrangement where they act on the piston to output power in a power stroke.

Owner:KASHMERICK GERALD E

Combustion engine

InactiveUS7765785B2Requires minimizationChanging compression ratio during engine operationTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionBrayton cycleCombustion chamber

A combustion engine that has at least a plurality of power strokes during a complete cycle of engine operation that is of compact packaging and Brayton cycle operable. In a preferred embodiment, a piston-cylinder arrangement used to compress air and deliver it to a combustion chamber where it is combusted along with fuel. The combustion gases are returned back to the piston-cylinder arrangement where they act on the piston to output power in a power stroke. A second power stroke can be implemented where additional combustion gases are available to extract additional power from. In a preferred embodiment, the same piston-cylinder arrangement receives the additional combustion gases from the combustion chamber in the second power stroke.

Owner:KASHMERICK GERALD E

Heat engine

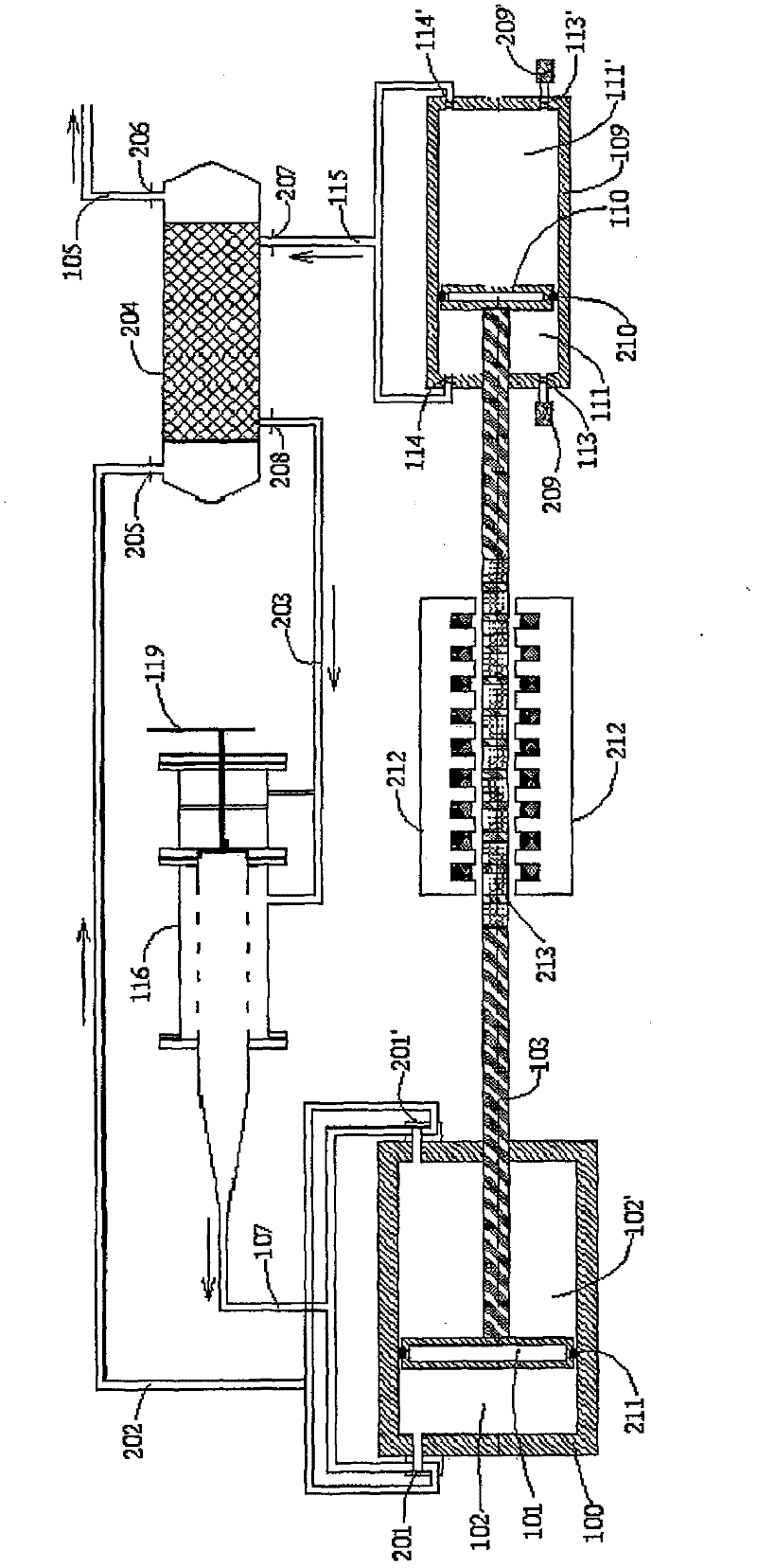

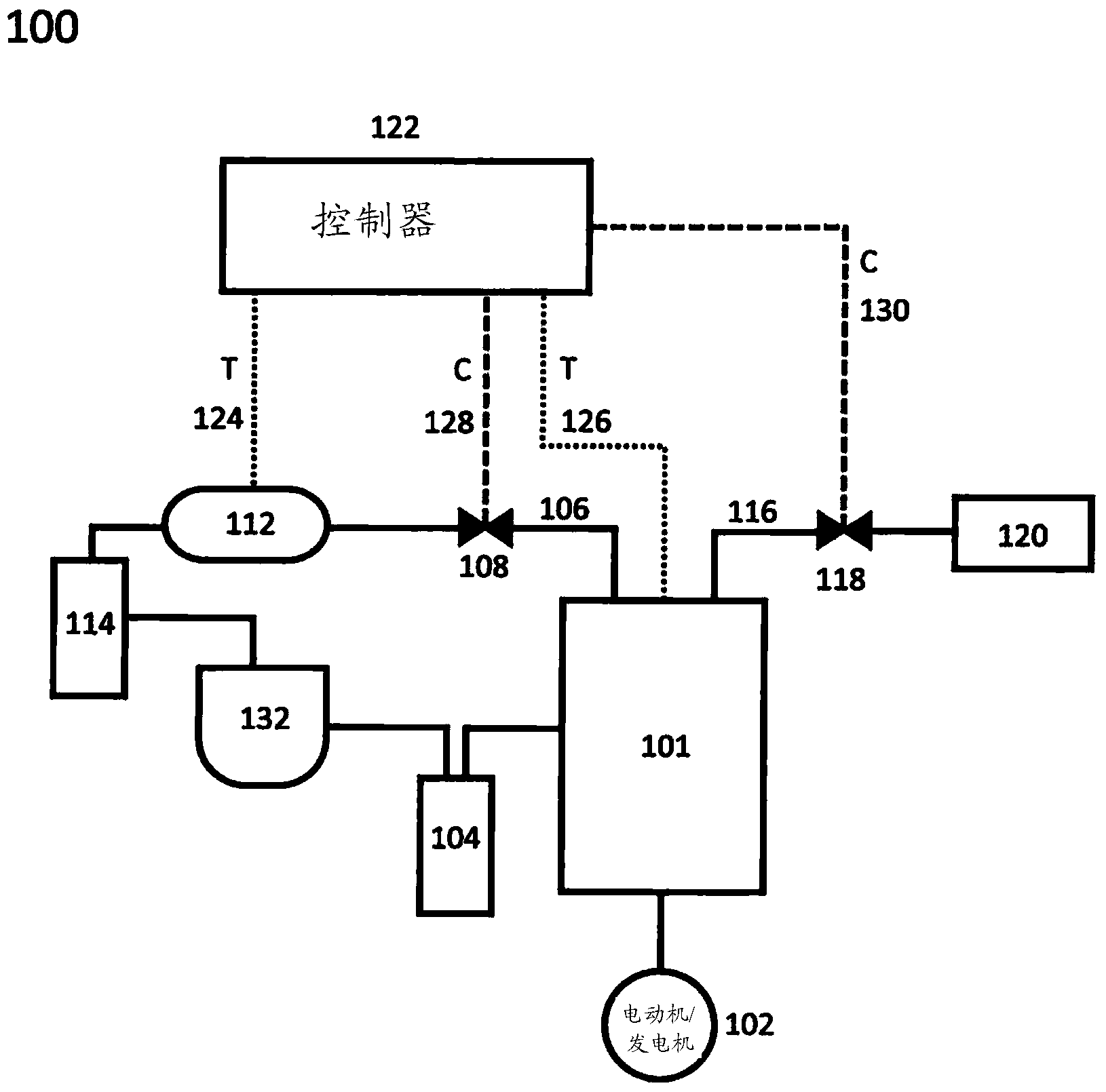

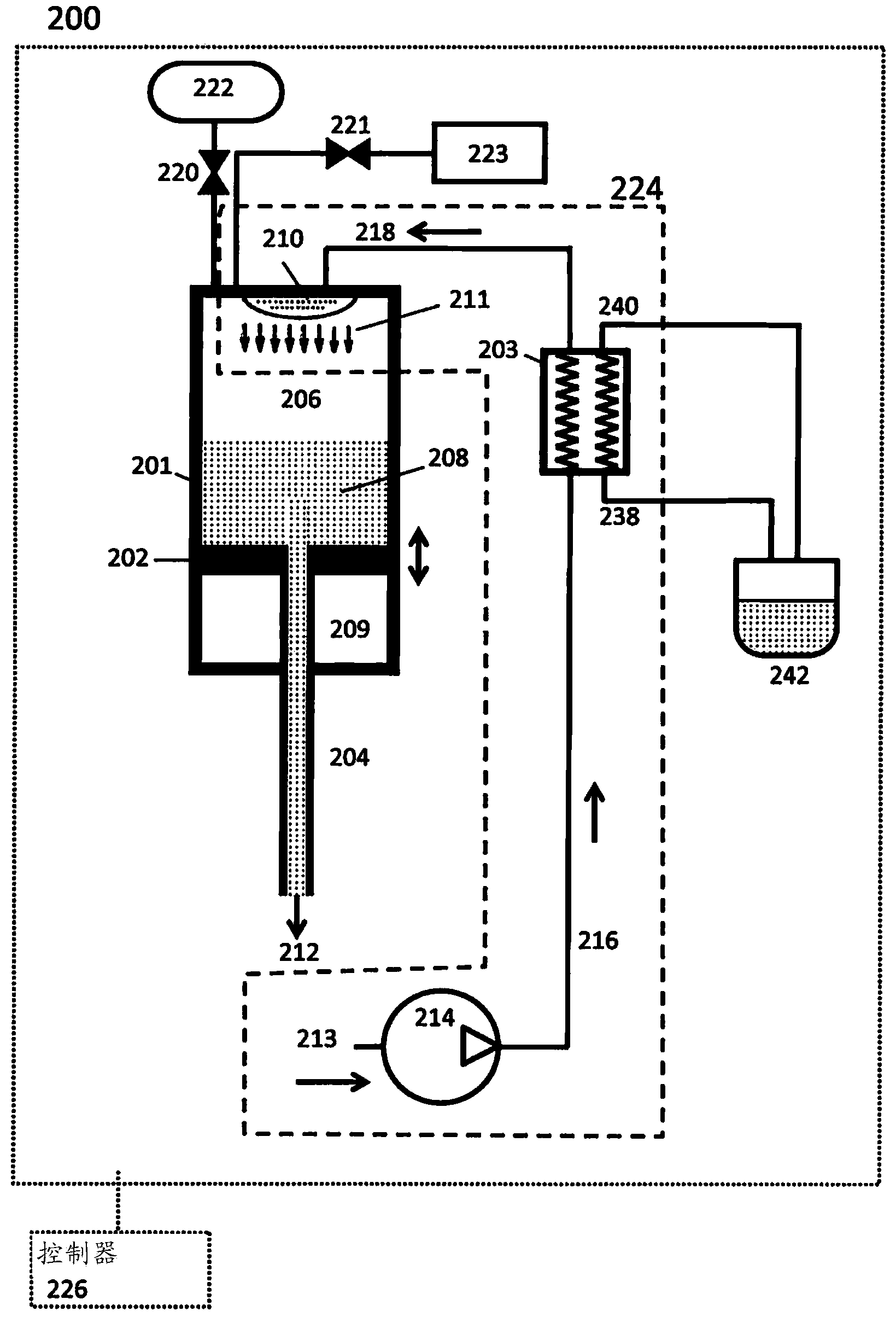

InactiveCN102449293AImprove fuel efficiencyAvoid damageOpen-cycle gas positive displacement engine plantElectronic controllerWorking fluid

Provided is a heat engine comprising compressor and expander displacement elements (210, 211) reciprocating in respective compression and expansion chambers (111, 111', 102, 102' ) and arranged in a linear, free-piston configuration, a combustor (116) separate from the compression and expansion chambers (111, 111', 102, 102' ), and a linear energy conversion device (212, 213) providing conversion of solid, liquid, or gaseous fuel into hydraulic, electric, or pneumatic energy by means of subjecting a working fluid to a thermodynamic cycle with substantially constant pressure combustion. The inlet and outlet valves of the compression chamber (102, 102') and the rate of fuel injection to the combustor (116) are actively controlled by an electronic controller to avoid engine damage, and to maintain thermodynamic efficiency over a wide range of loads.

Owner:UNIVERSITY OF NEWCASTLE

Energy conversion device

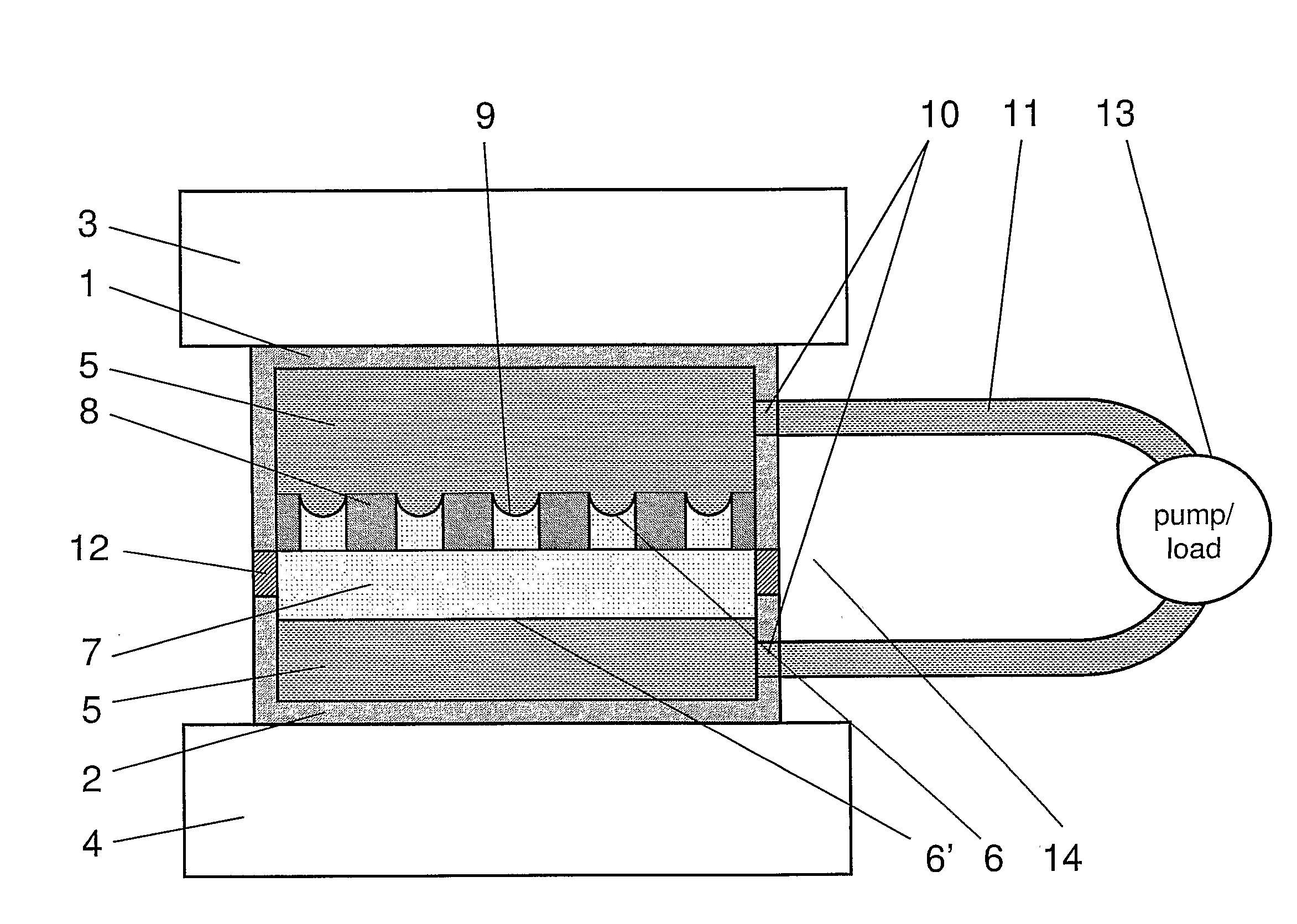

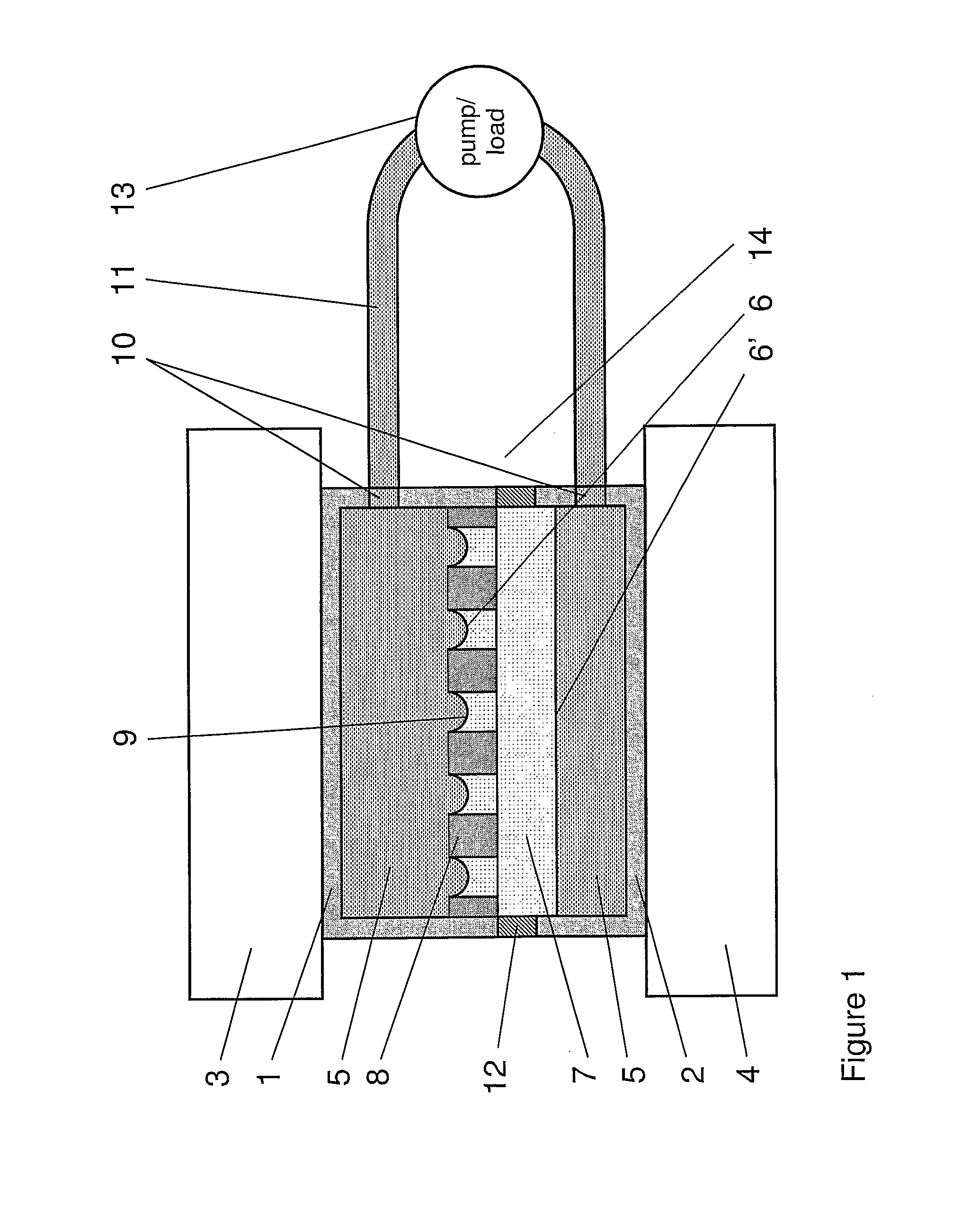

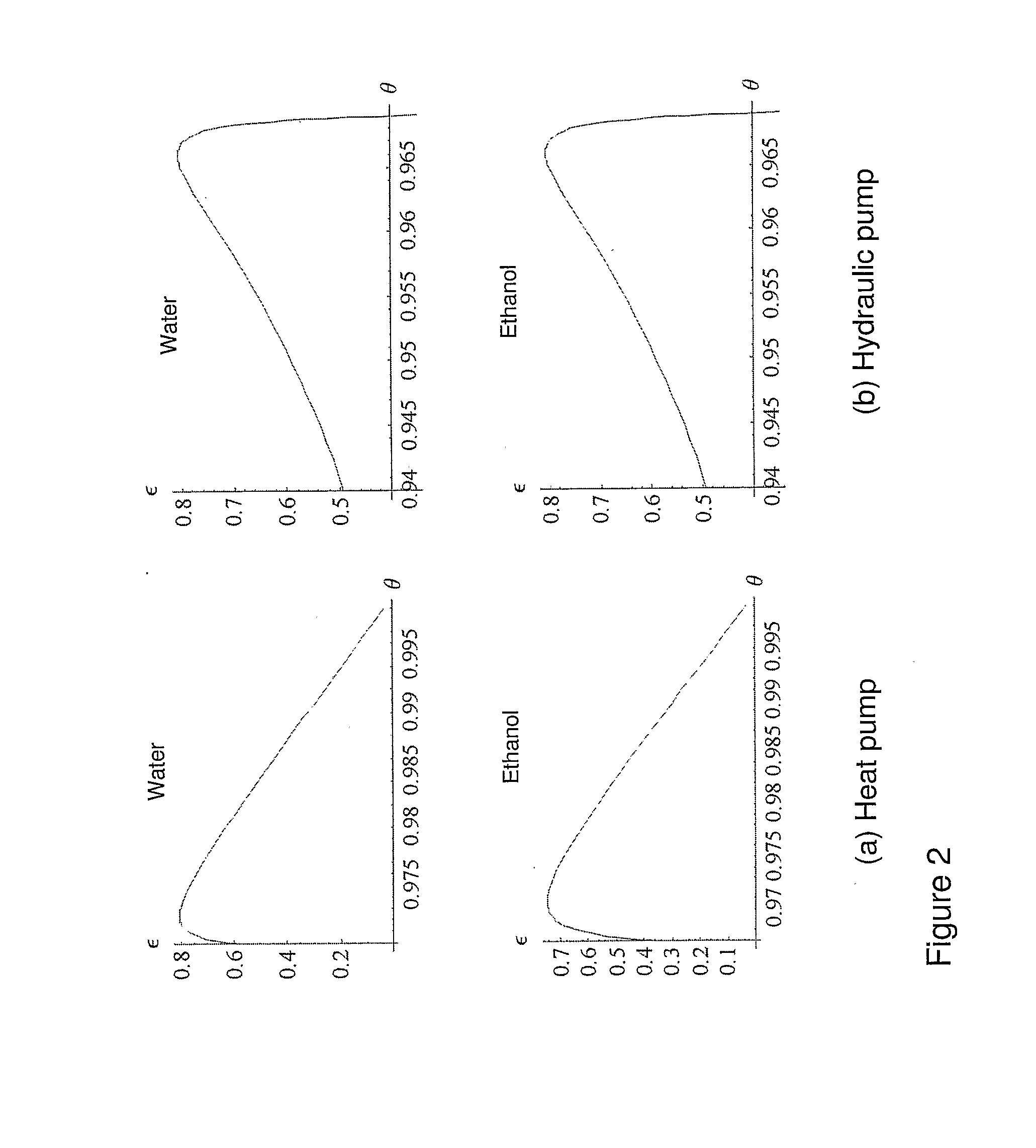

InactiveUS20100115977A1Improve efficiencyEasy constructionHeat pumpsPressure pumpsExternal combustion engineEvaporation

A thermodynamic energy conversion device (14) based on the effect of differential evaporation generated by a convex liquid surface and by a temperature gradient is constructed for the use either as a heat or hydraulic pump. In one arrangement the device (14) comprises two heat conductive containers (1) and (2); a working liquid (5) disposed in said containers with open surfaces (6) and (6′); a vapour (7) of the working liquid; a porous device (8) for creating at least one convex meniscus (9) on the open surface (6), of the working liquid (5) in one of the containers said convex meniscus having higher mean curvature than that of the open surface (6′); means (10) for connecting containers (1) and (2) to an external hydraulic circuit (11). An efficient external combustion engine using such a device (14) is disclosed.

Owner:THERMODYNAMIC NANOTECH

Systems and methods for efficient two-phase heat transfer in compressed-air energy storage systems

InactiveCN103930654AIncrease surface areaFast heat exchangePlural diverse prime-mover propulsion mountingSteam engine plantsEngineeringCompressed air energy storage

Owner:SUSTAINX

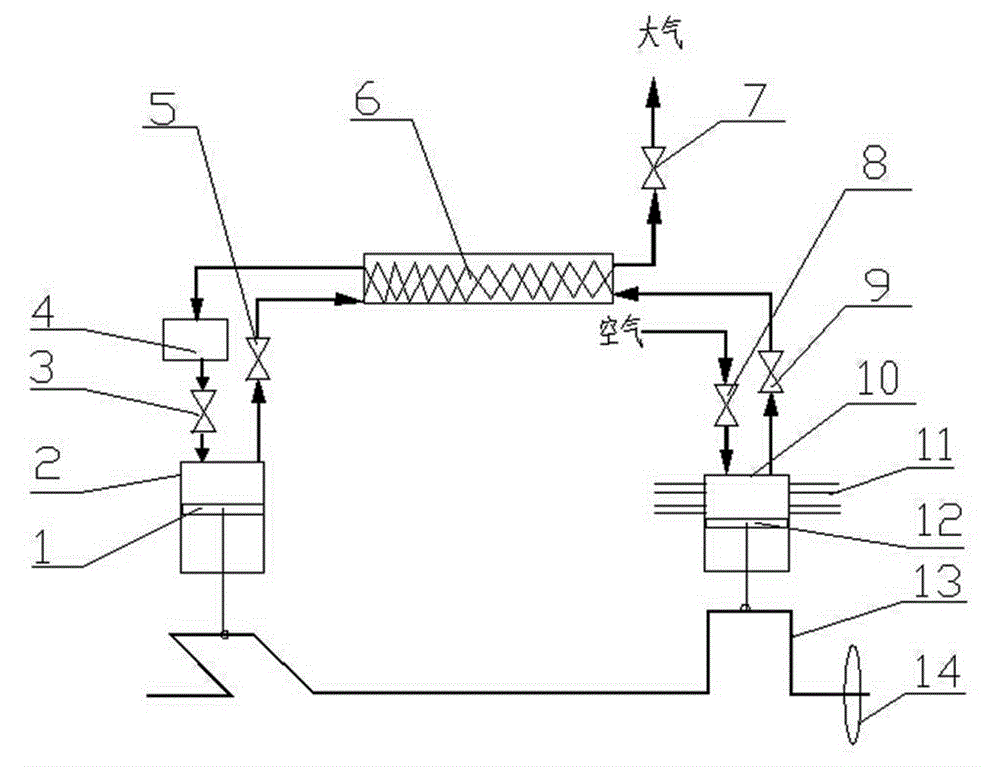

Opened circulating Stirling engine

InactiveCN104153910AHigh thermal efficiencyImprove reliabilityOpen-cycle gas positive displacement engine plantEngineeringPiston

The invention relates to an opened circulating Stirling engine comprising a hot-end cylinder, a hot-end piston, a regenerator, a cold-end cylinder and a cold-end piston. The regenerator is an one-way regenerator, the cold-end inlet and hot-end outlet of the one-way regenerator form a low-temperature medium channel, and the hot-end inlet and cold-end outlet form a high-temperature medium channel; the cold inlet of the cold-end cylinder is communicated with the air, and the cold outlet is communicated with the cold-end inlet of the one-way regenerator; the hot inlet of the hot-end cylinder is communicated with the hot-end outlet of the one-way regenerator, and the hot outlet is communicated with the hot-end inlet of the one-way regenerator; the cold-end outlet of the one-way regenerator is communicated with the air. The circulating medium adopts the one-way flowing manner, the heat exchanging manner is optimized, and the regenerating efficiency is improved; an absolute sealing device for a power piston and an expanding piston is omitted, the friction resistance is reduced greatly, and engine mechanical efficiency is improved; meanwhile, the medium is of the air, the operating pressure and temperature are low, expensive temperature-resistant material is omitted, cost is low, reliability is high, energy is saved, and environment is protected.

Owner:HEFEI UNIV OF TECH

Rotary valve system and engine using the same

InactiveUS20060254554A1Internal combustion piston enginesEngine controllersCombustion chamberReciprocating motion

Rotary valve system for controlling communication with a port in an internal combustion engine which, in one disclosed embodiment, has a crankshaft, compression and expansion pistons connected to the crankshaft for reciprocating movement within compression and expansion chambers, a combustion chamber in which air from the compression chamber is combined with fuel and burned to produce an increased gas volume. The valve system has an outer valve member which is rotatively mounted in a bore and has an opening which moves into and out of communication with the port as the outer valve member rotates, an inner valve member rotatably mounted within the outer outer valve member with an opening at least partly overlapping the opening in the outer valve member, a flange extending along one edge of the opening in the inner valve member and through the opening in the outer valve member for sealing engagement with the wall of the bore, and means for effecting rotation of the valve members to change the degree of overlap between the openings and thereby control the timing and duration of communication between the openings and the port.

Owner:ZAJAC OPTIMUM OUTPUT MOTORS

Engine having external combustion chamber

InactiveUS6988358B2Reduce power levelGas turbine plantsOpen-cycle gas positive displacement engine plantCombustion chamberCompressed natural gas

Provided is an engine having positive displacement chambers containing pistons and an external combustion chamber which utilizes the compression energy in compressed natural gas from a high pressure main line and compressed air in combination with the energy released during combustion of the fuel to drive the pistons. Energy expended compressing the natural gas and air are recovered. Also provided is an electrical generator driven by the engine.

Owner:MELCHER JEFFREY S

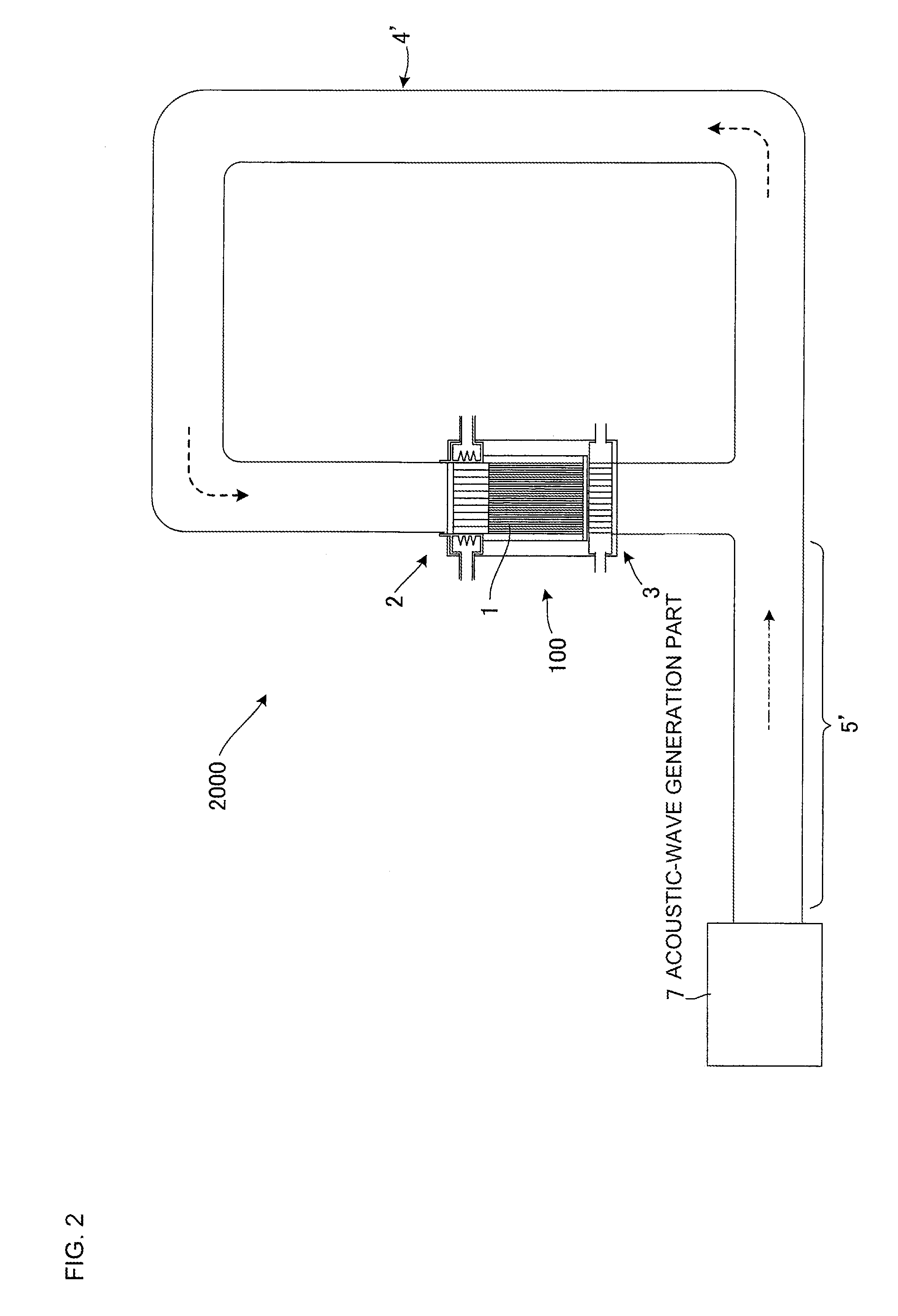

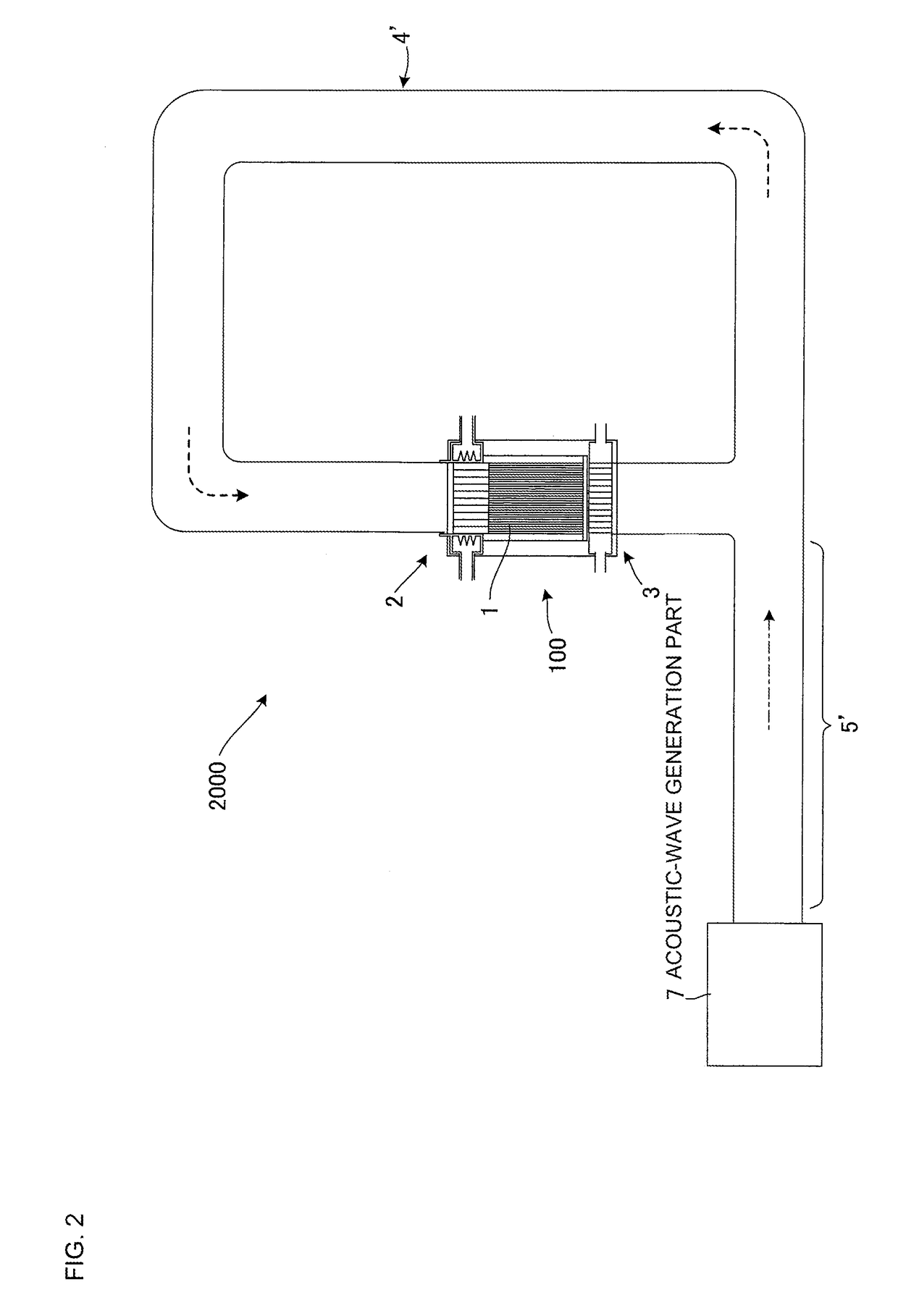

Heat/acoustic wave conversion unit

ActiveUS20160084198A1Improve conductivityImprove heat resistanceStirling type enginesCompression machinesEngineeringAcoustic wave

A heat / acoustic wave conversion unit includes a heat / acoustic wave conversion component and two heat exchangers. Hydraulic diameter HD of the cells in the heat / acoustic wave conversion component is 0.4 mm or less, and a ratio HD / L of HD to the length L of the heat / acoustic wave conversion component is from 0.005 to 0.02. One of the heat exchangers includes a heat-exchanging honeycomb structure and an annular tube that surrounds a circumferential face of the heat-exchanging honeycomb structure. The annular tube includes a structure body that is disposed in the channel to increase a contact area with the heated fluid, an inflow port into which the heated fluid flows, and an outflow port through which the heated fluid flows out. At least one of the heat-exchanging honeycomb structure and the structure body is made of a ceramic material that contains SiC as a main component.

Owner:NGK INSULATORS LTD

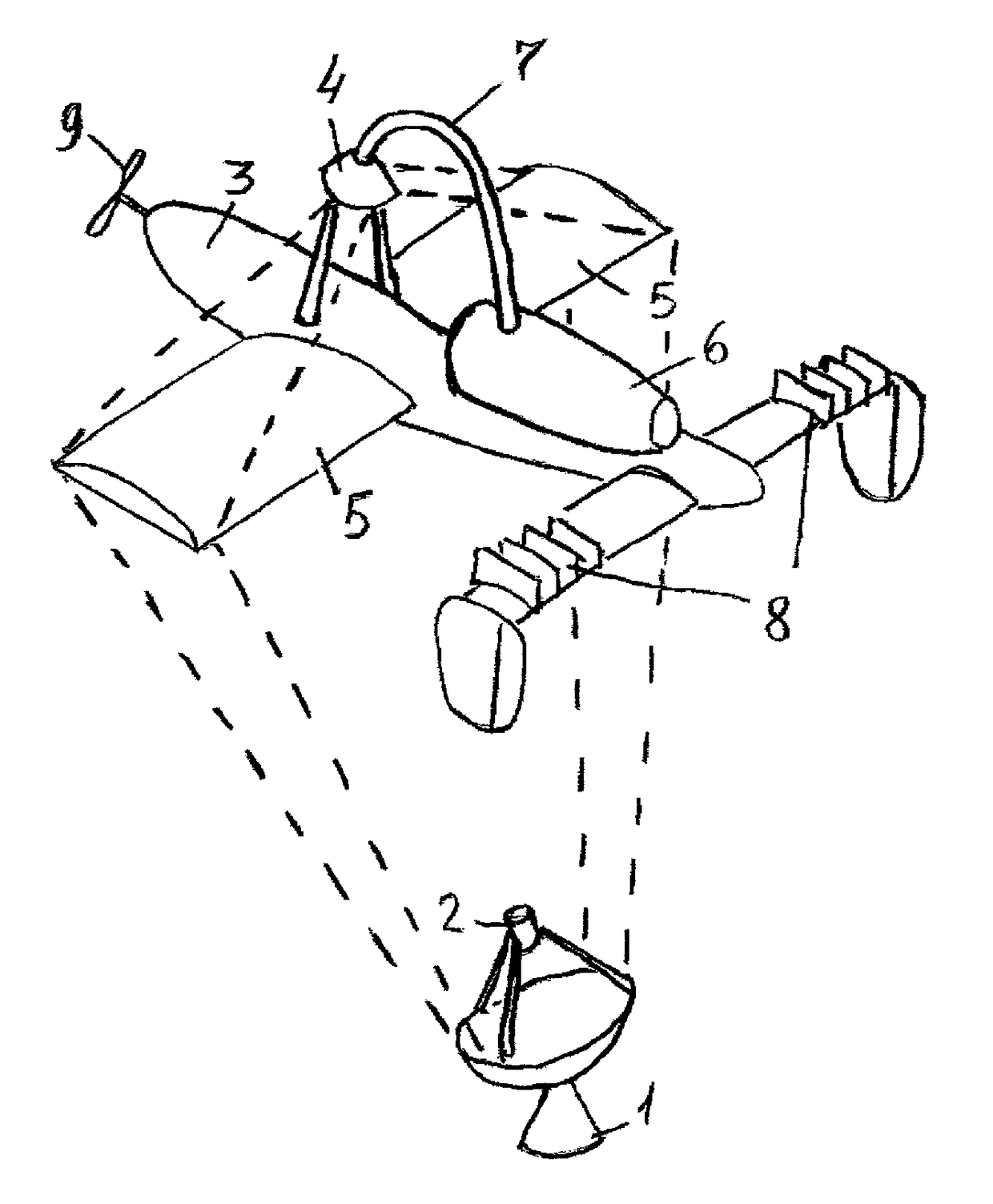

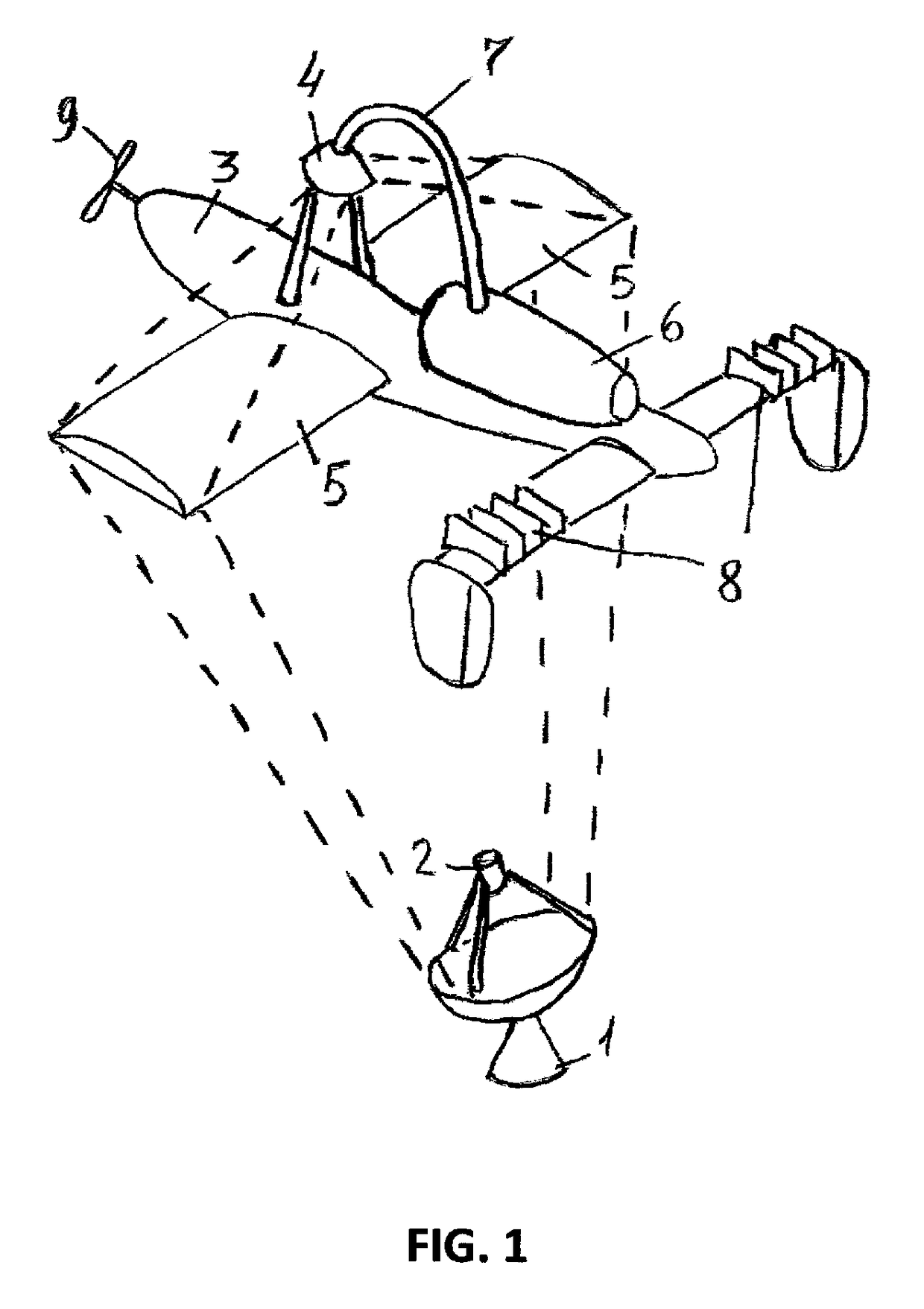

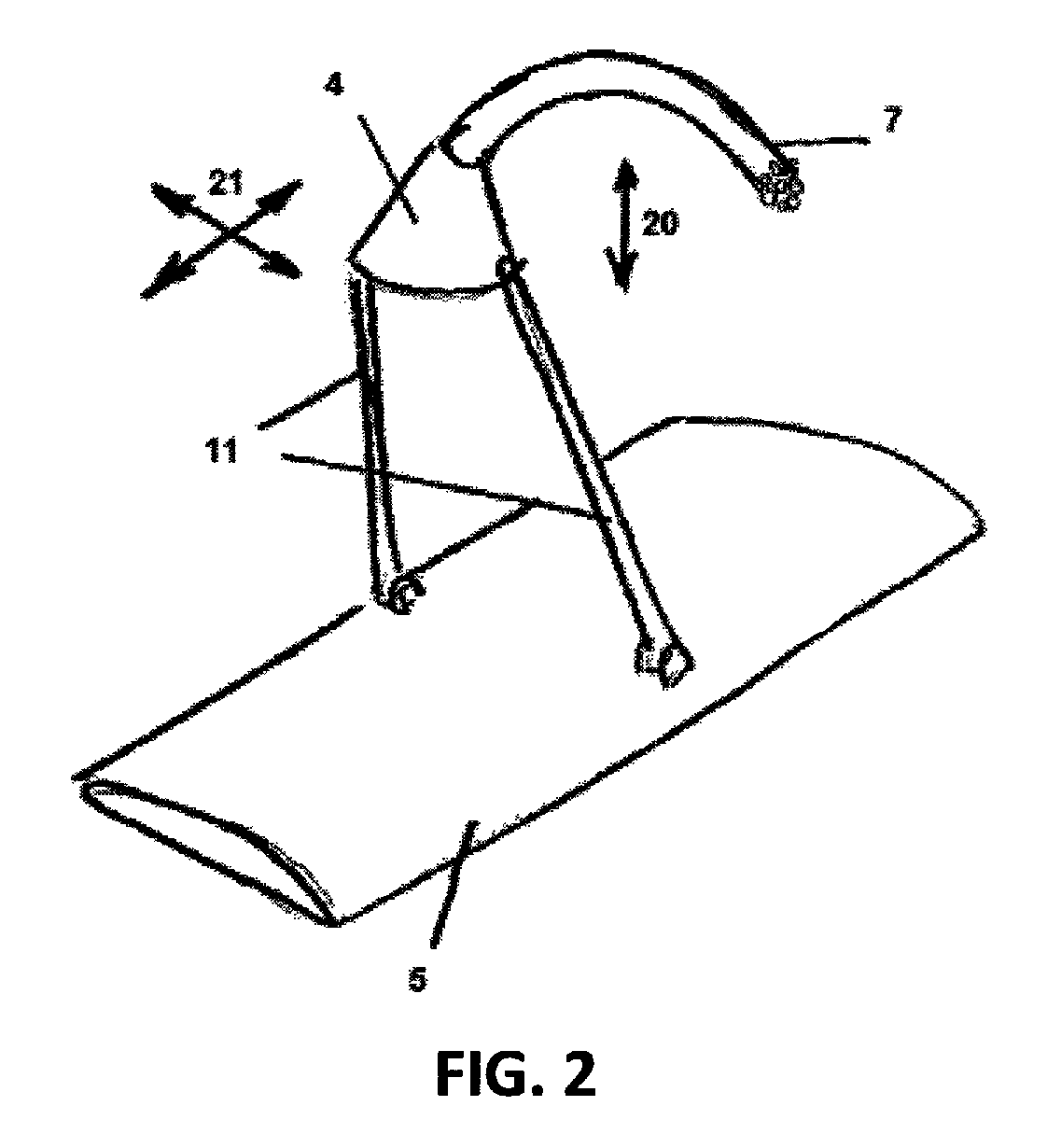

Methods of laser powering unmanned aerial vehicles with heat engines

Methods of laser powering unmanned aerial vehicles (UAV) with heat engines are disclosed. The laser powered heat engines are used in conjunction with devices for absorbing laser optical radiation, turning the laser optical radiation into heat, supplying the heat to a working fluid of the heat engine and harvesting mechanical work from expanding working fluid in the heat engine.

Owner:YAVID DMITRIY MR

Heat engines

Owner:CAO YIDING

Systems and methods for energy storage and recovery using gas expansion and compression

InactiveUS20130269330A1Increase energy densityElectrical storage systemRotary clutchesThermodynamicsAtmospheric pressure

In various embodiments, energy-storage systems are based upon an open-air arrangement in which pressurized gas is expanded in small batches from a high pressure of, e.g., several hundred atmospheres to atmospheric pressure. The systems may be sized and operated at a rate that allows for near isothermal expansion and compression of the gas.

Owner:SUSTAINX

Heat/acoustic wave conversion unit

ActiveUS9759157B2Improve conductivityImprove heat resistanceStirling type enginesCompression machinesAcoustic waveEngineering

A heat / acoustic wave conversion unit includes a heat / acoustic wave conversion component and two heat exchangers. Hydraulic diameter HD of the cells in the heat / acoustic wave conversion component is 0.4 mm or less, and a ratio HD / L of HD to the length L of the heat / acoustic wave conversion component is from 0.005 to 0.02. One of the heat exchangers includes a heat-exchanging honeycomb structure and an annular tube that surrounds a circumferential face of the heat-exchanging honeycomb structure. The annular tube includes a structure body that is disposed in the channel to increase a contact area with the heated fluid, an inflow port into which the heated fluid flows, and an outflow port through which the heated fluid flows out. At least one of the heat-exchanging honeycomb structure and the structure body is made of a ceramic material that contains SiC as a main component.

Owner:NGK INSULATORS LTD

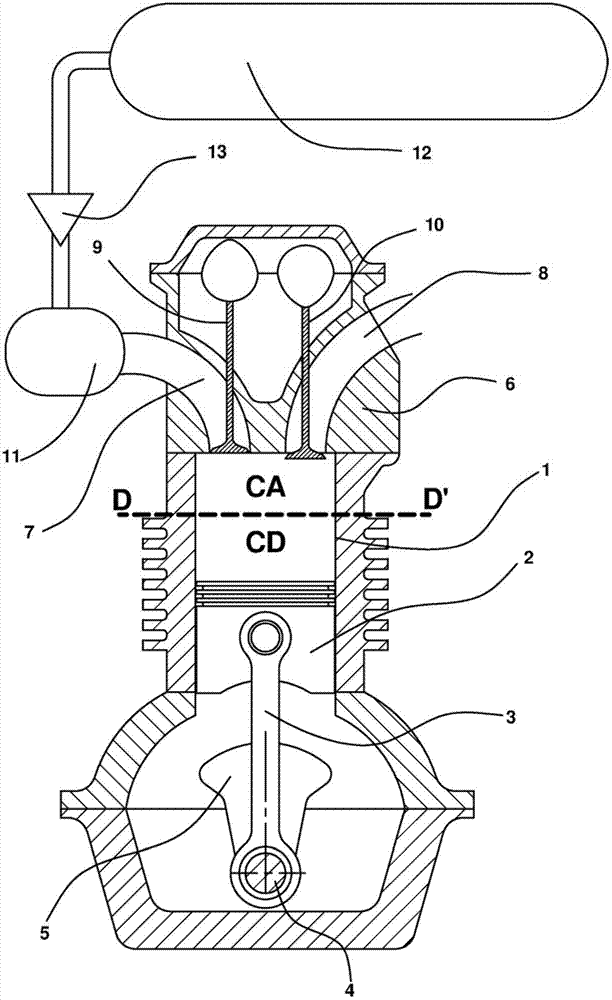

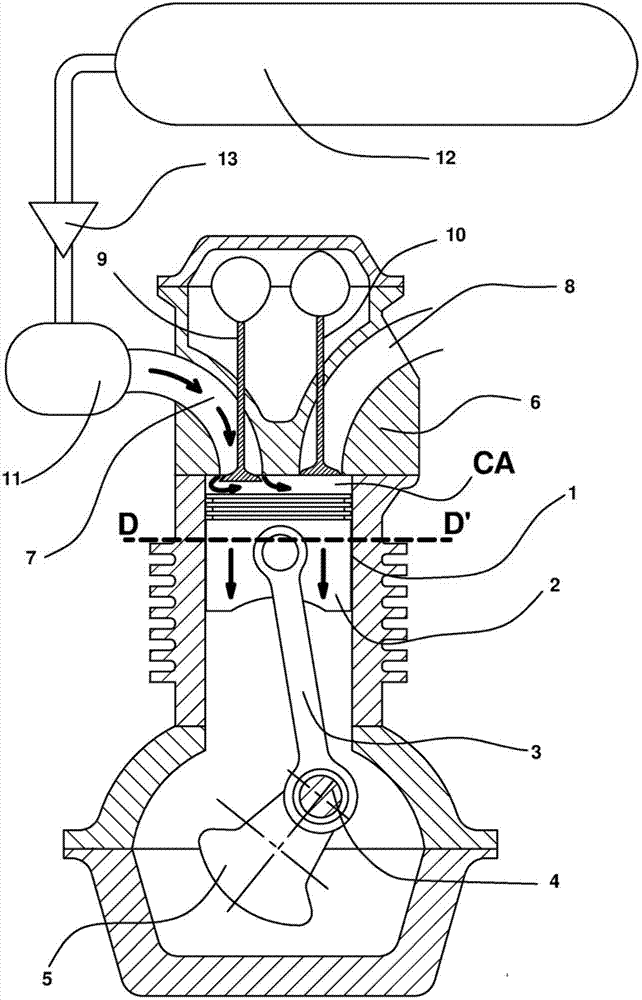

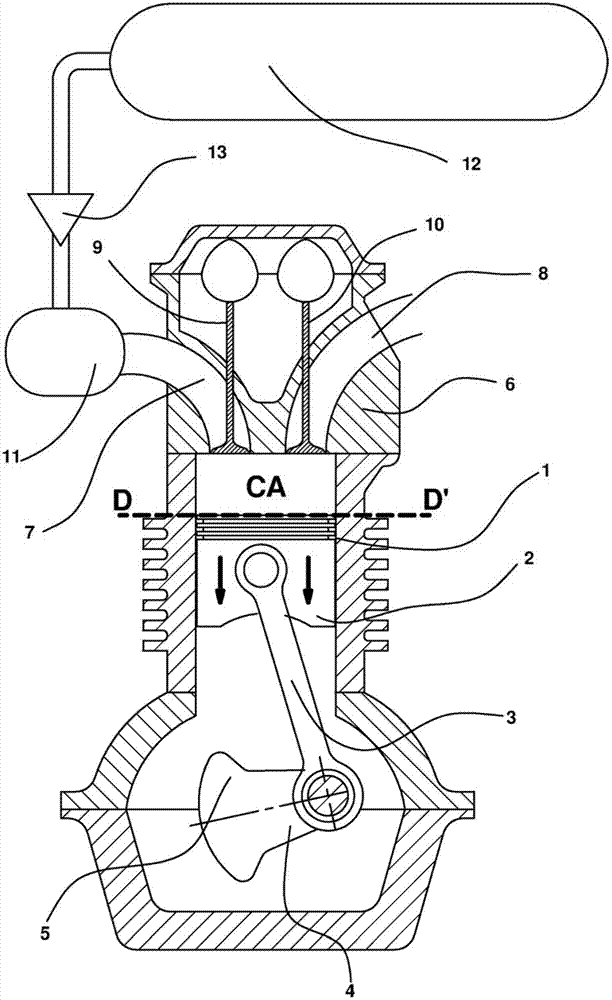

Mono-energy and/or dual-energy engine with compressed air and/or additional energy, comprising an active chamber included in the cylinder

InactiveCN103201457AIncrease mileageIncrease temperatureSolar heating energyInternal combustion piston enginesAmbient pressureDual energy

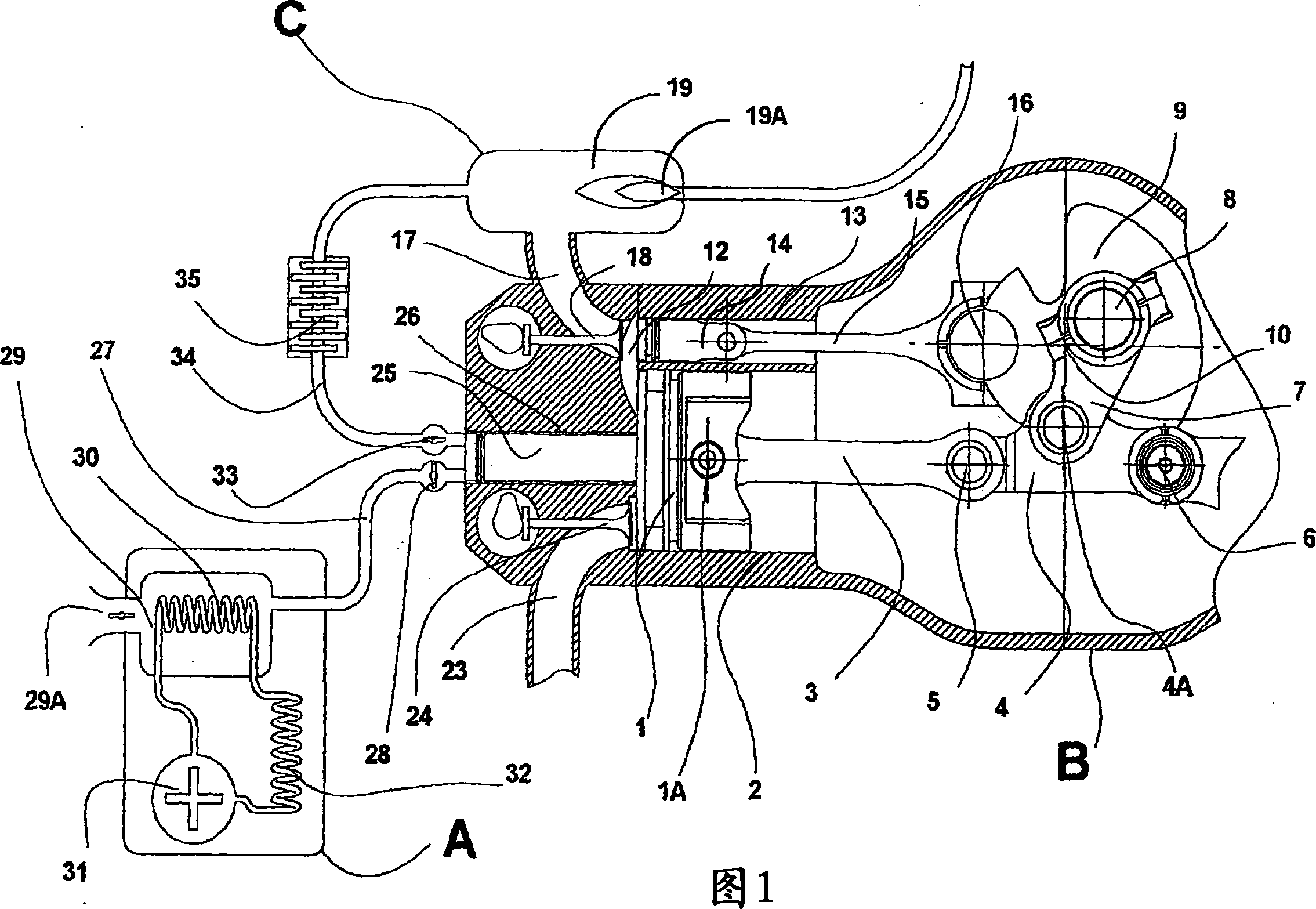

The invention relates to an engine with an active chamber, comprising at least one piston (2) mounted in a cylinder (1) in a sliding manner and driving a crankshaft (5) by means of a slider-crank device (3, 4) and operating according to a four-phase thermodynamic cycle comprising: an isothermal expansion without work; a transfer - slight so-called quasi-isothermal expansion with work; a polytropic expansion with work; and an exhaust at ambient pressure, preferentially supplied by compressed air contained in a high-pressure storage tank (12), through a buffer capacity, called a working capacity (11), which is expanded at an average pressure, called a working pressure, in a working capacity (11), preferentially through a dynamic pressure-reducing device (13), characterised in that the active chamber (CA) is included in the engine cylinder, the cylinder volume (1) being swept by the piston and divided into two separate parts, a first part forming the active chamber (CA) and a second part forming the expansion chamber (CD).

Owner:MOTOR DEVELOPMENT INTERNATIONAL

Combustion engine

InactiveUS20070044478A1Minimizing engine packaging requirementRequires minimizationTurbine/propulsion fuel supply systemsTurbine/propulsion engine ignitionBrayton cycleCombustion chamber

A combustion engine that has at least a plurality of power strokes during a complete cycle of engine operation that is of compact packaging and Brayton cycle operable. In a preferred embodiment, a piston-cylinder arrangement used to compress air and deliver it to a combustion chamber where it is combusted along with fuel. The combustion gases are returned back to the piston-cylinder arrangement where they act on the piston to output power in a power stroke. A second power stroke can be implemented where additional combustion gases are available to extract additional power from. In a preferred embodiment, the same piston-cylinder arrangement receives the additional combustion gases from the combustion chamber in the second power stroke.

Owner:KASHMERICK GERALD E

Low-temperature motor compressor unit with continuous 'cold' combustion at constant pressure and with active chamber

InactiveCN101233296AInternal combustion piston enginesCombined combustion mitigationAir compressionCombustion chamber

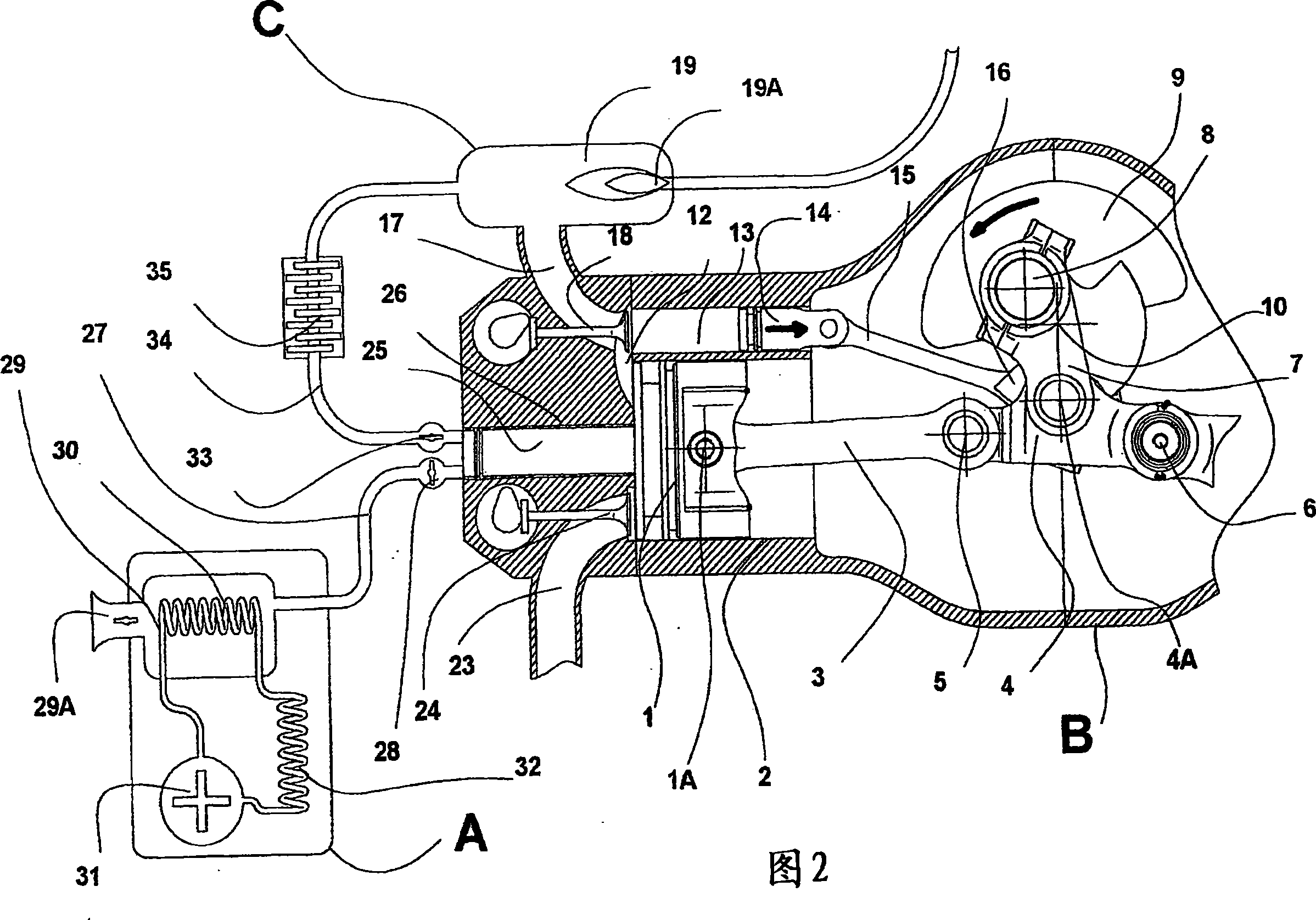

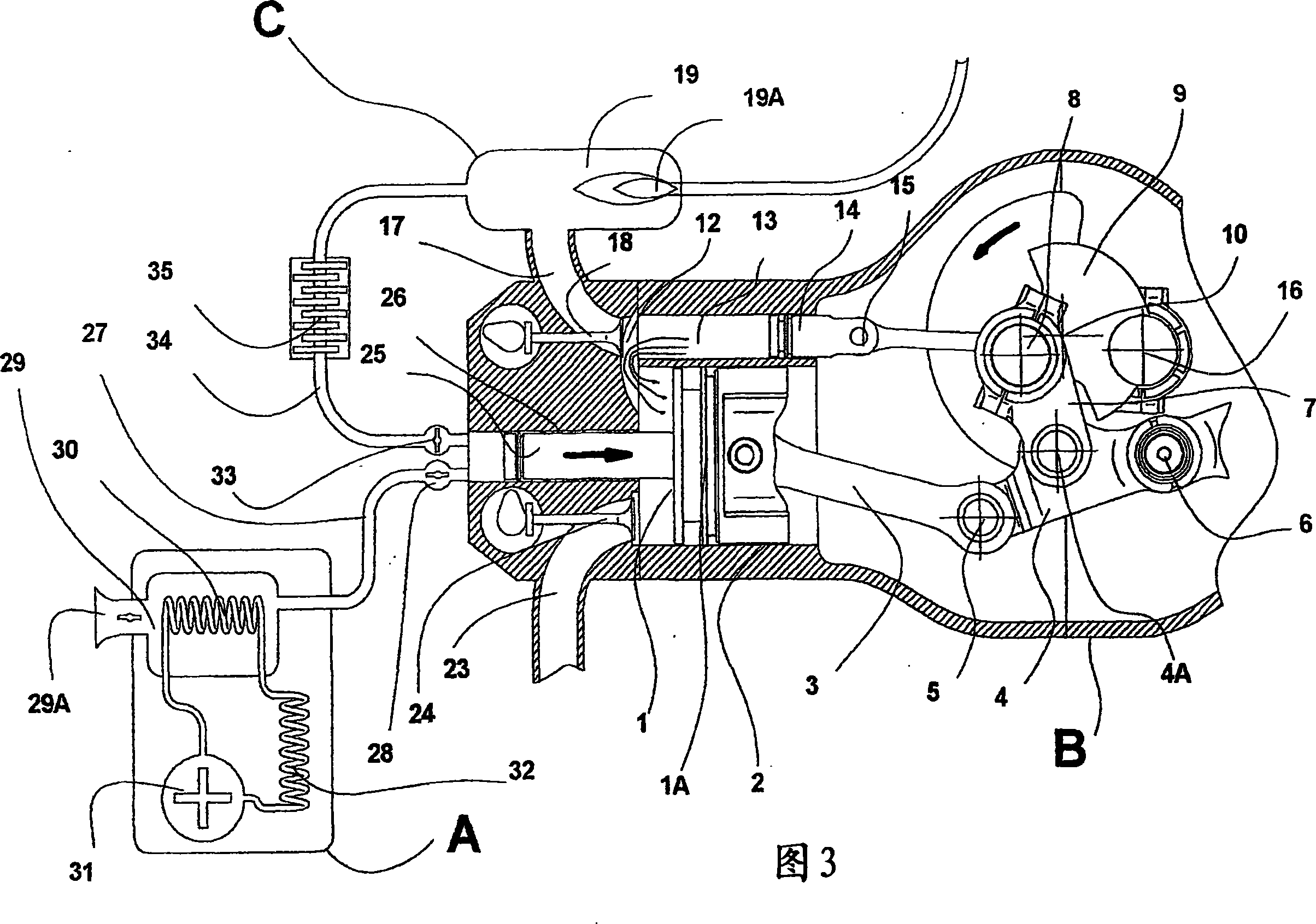

The invention relates to an active chamber type constant pressure continuous "cold" combustion type cryogenic engine-compressor unit, which works in particular with working compressed air and uses: a piston stroke control device and an active chamber with a cold chamber (29) which The atmosphere at the inlet (28) of the supply air compression device (28, 25, 26, 33) can be lowered to a very low temperature, which then compresses this working compressed air, which is still at low temperature, into the outer combustion chamber (19 ), the outer combustion chamber (19) is equipped with a constant pressure heating device (19A), and the working compressed air increases in volume in the heating device (19A), and then is transported quasi-isothermally to the active chamber ( 13), and then expand in the working cylinder (2) to do work again. The invention is applied to land vehicles, cars, buses, motorcycles, ships, airplanes, emergency power generation devices, household appliances, and stationary heat engines.

Owner:MDI MOTOR DEV INT SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com