Low-temperature motor compressor unit with continuous 'cold' combustion at constant pressure and with active chamber

A technology of compressor units and active chambers, which is applied in combustion engines, open gas positive displacement engines, variable displacement engines, etc., can solve the problems of materials, cooling and pollution emissions, and reduce the demand for heat energy supply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

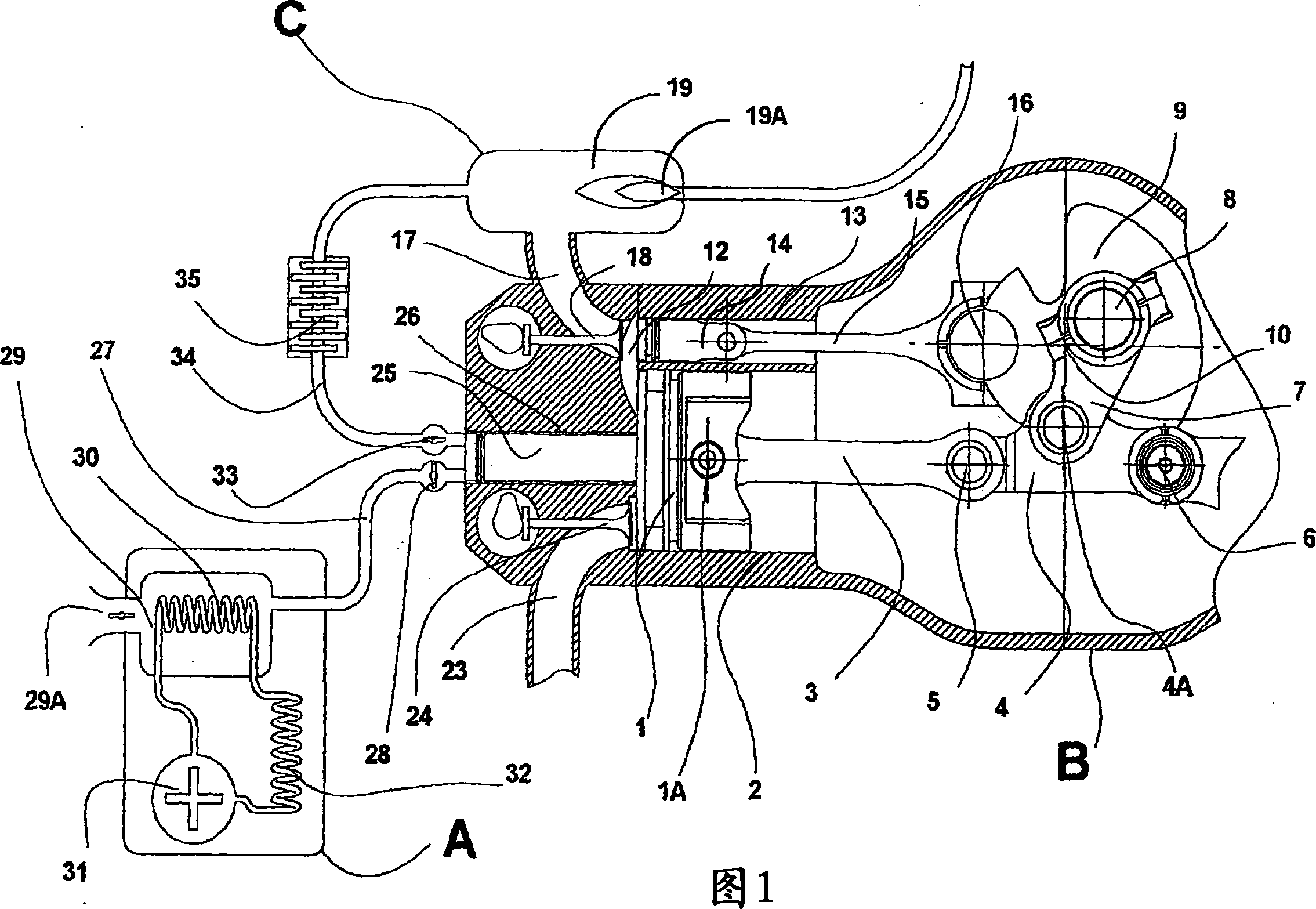

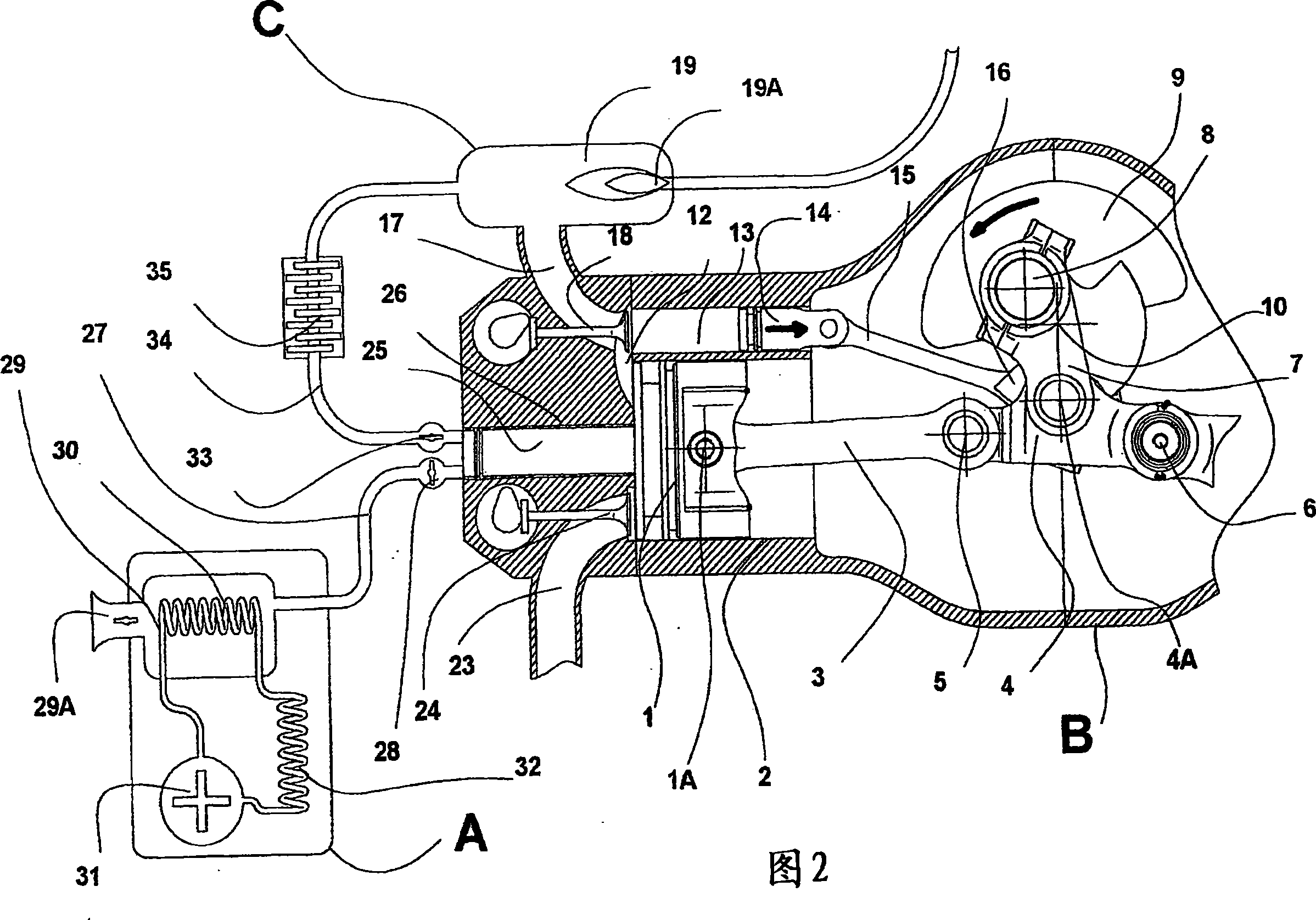

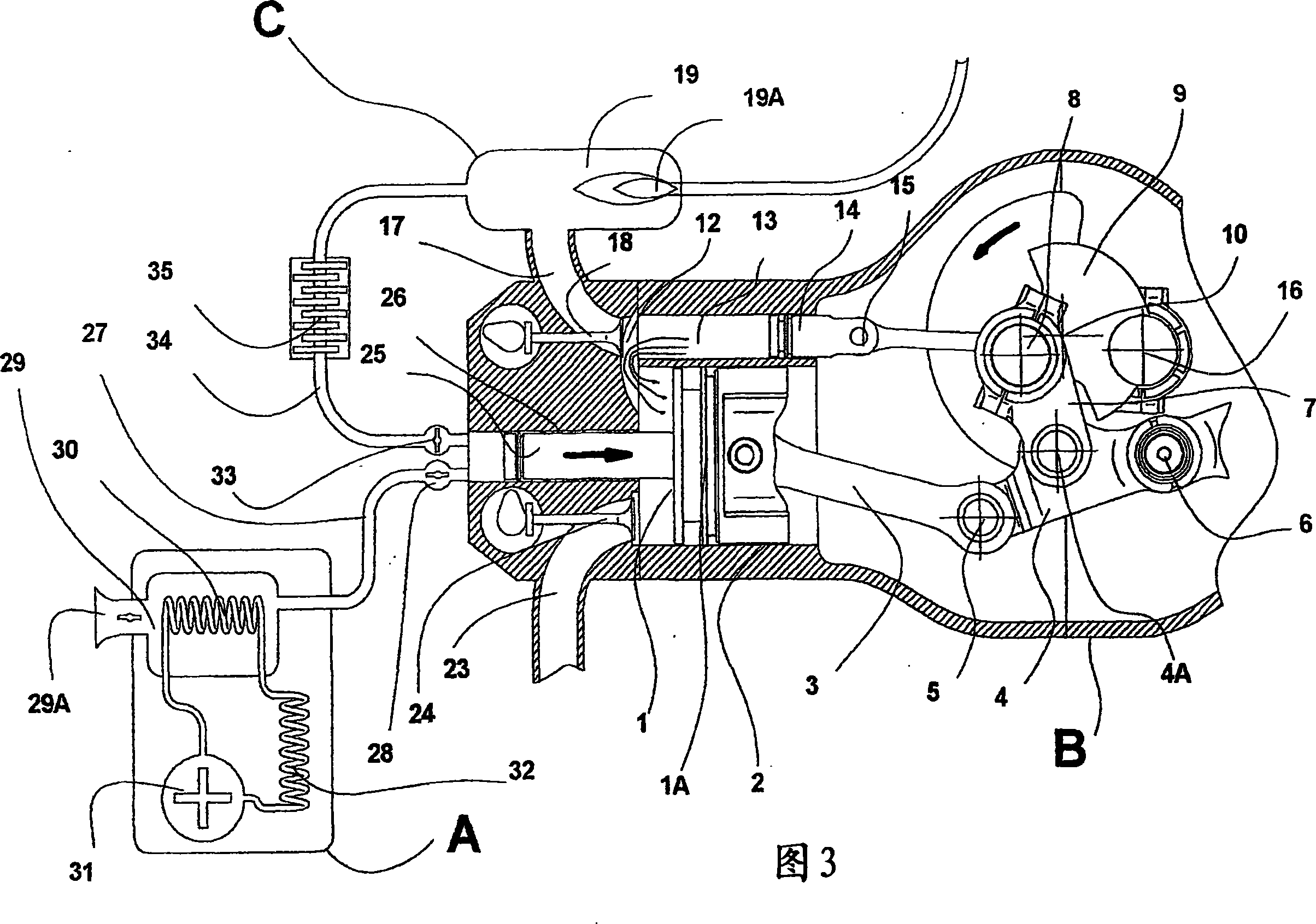

[0117] [117] Fig. 1 schematically shows in cross-section an active chamber cryogenic engine-compressor unit according to the invention, which has three main components: a cooling or refrigerating machine A, an engine-compressor unit B and an external combustion device C, Therein visible is the working piston 1 (shown at its top dead center) which slides in the cylinder 2 and is controlled by a pressure rod. The working piston 1 is connected via its shaft to the free end 1A of a pressure rod consisting of an arm 3 articulated on a common axis 5 to a further arm 4 , which is pivotally fixed on a fixed On the shaft 6, and the shaft 4A is basically arranged in the middle of the arm 4, and the control link 7 is connected to the shaft 4A, and the control link 7 is connected to the journal 8 of the crankshaft 9, and the crankshaft 9 Rotate on its axis 10. When the crankshaft rotates, the control connecting rod 7 exerts a force on the common shaft 5 of the two arms 3 and 4 of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com