Cushion material for packaging product therein and suspension air-packing method using same

a technology of cushion material and product, which is applied in the field of cushion material, can solve the problems of increasing the use of paper-based cushion material, reducing the resistance to another impact, and reducing the durability of the protruding piece for supporting the product to be packaged, so as to achieve the effect of effective absorption of shocks and vibrations, small storage space, and easy storag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

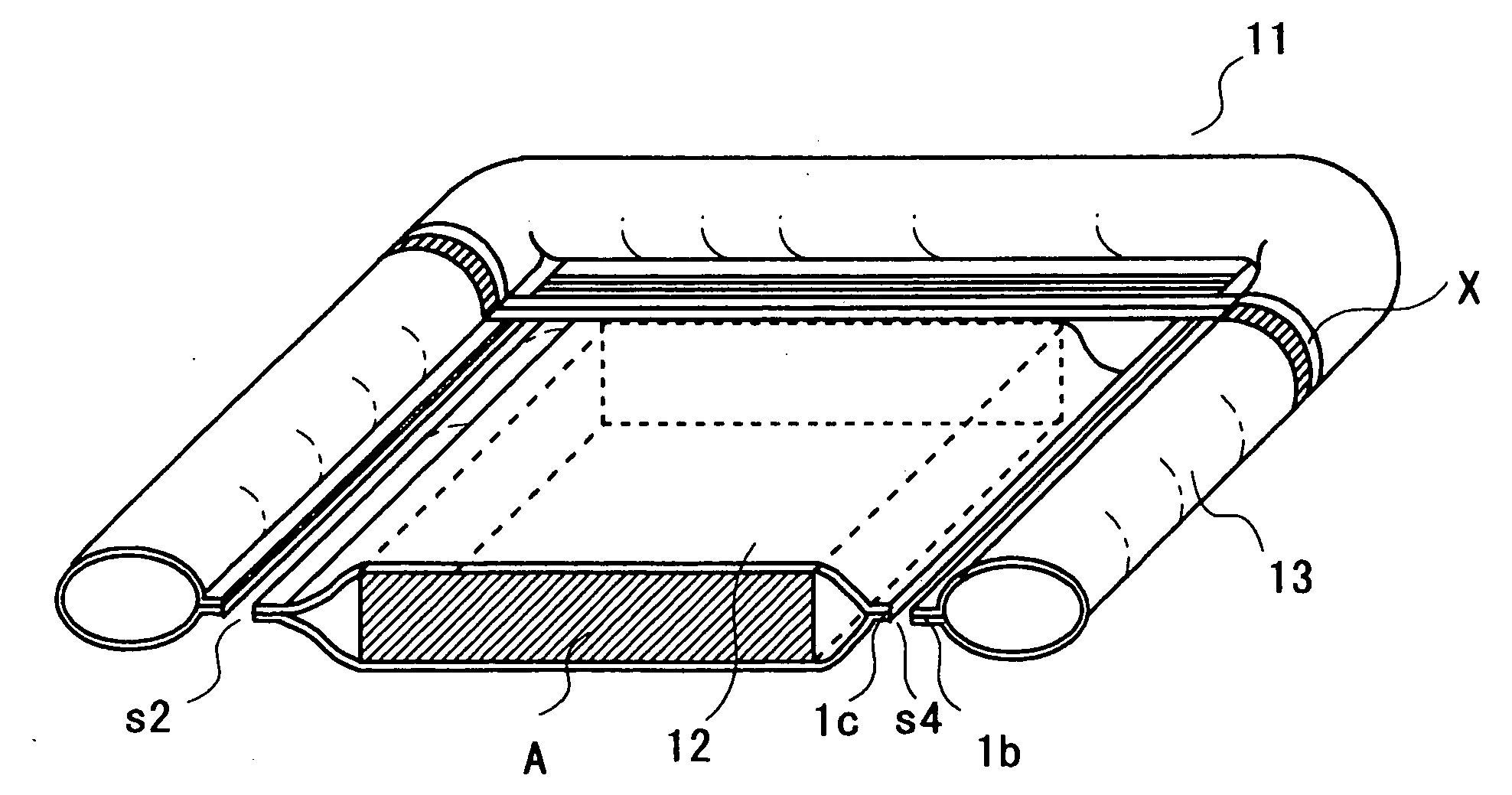

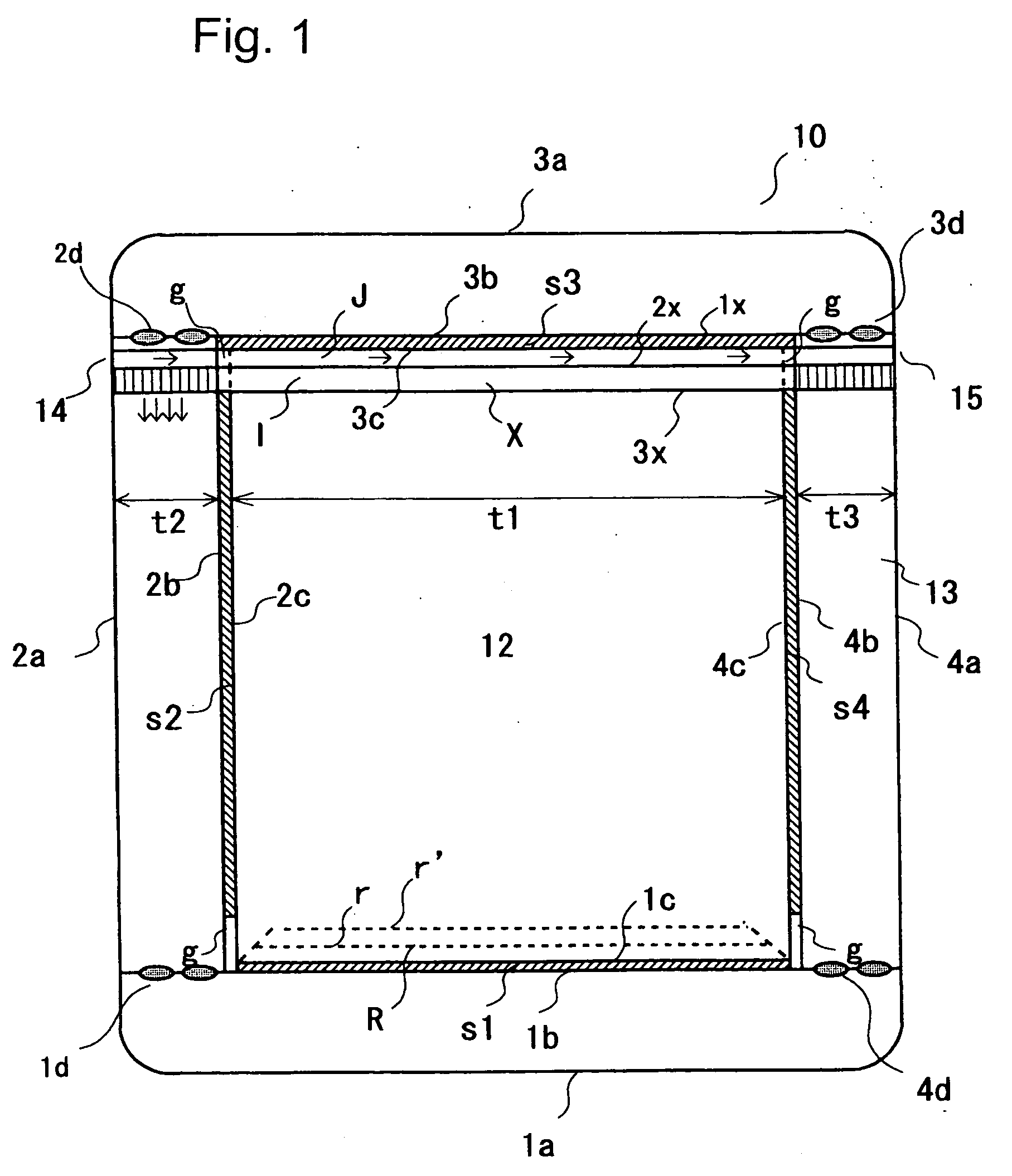

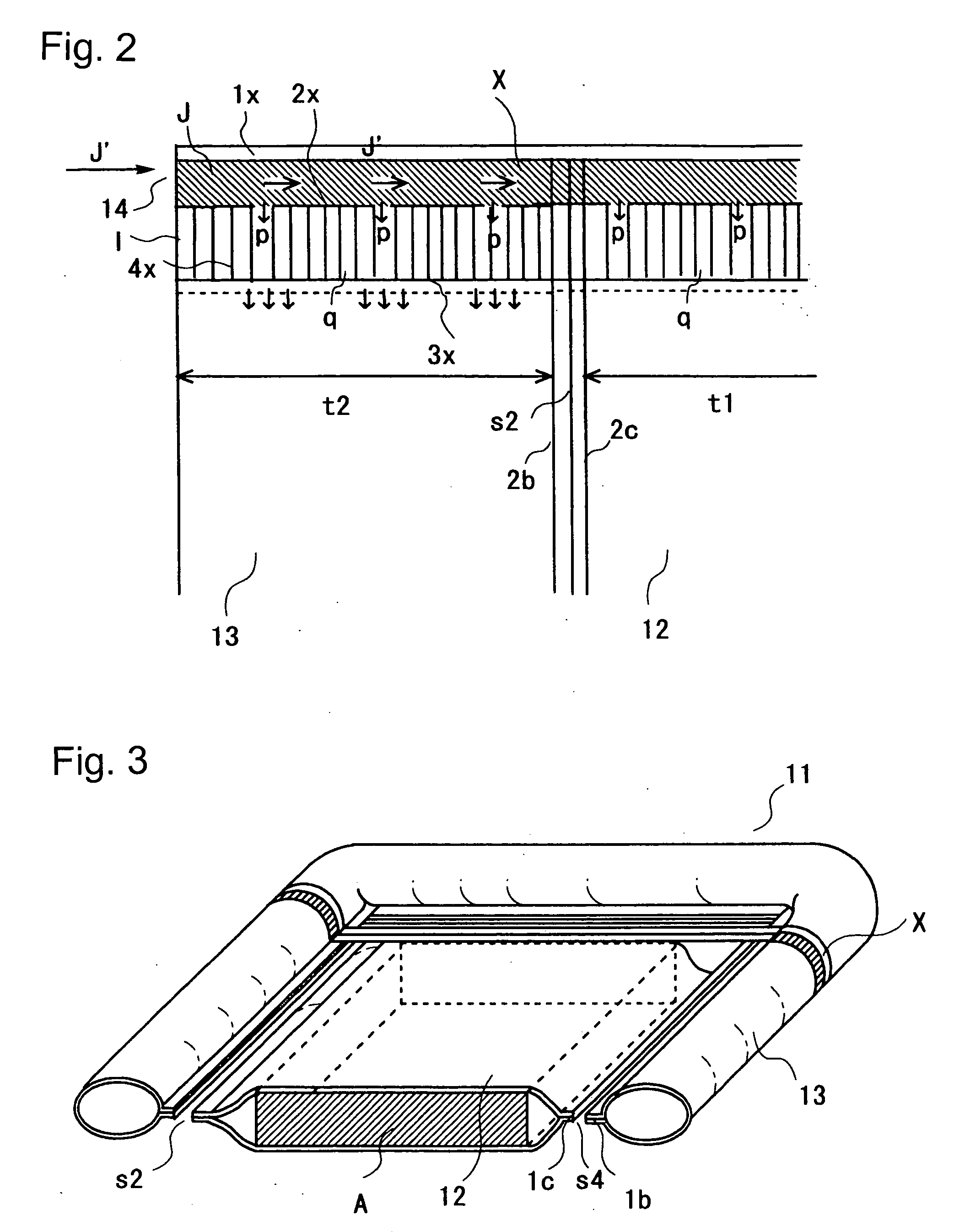

[0032] The embodiments of the cushion material related to the present invention will be explained below with reference to the accompanying drawings. FIG. 1 is a plan view showing a structure of the cushion material 10 of the present invention.

[0033] The cushion material 10 is comprised of a cushion material main body 11 which is formed with two flexible thermoplastic films (sheets) of the same shape and size that overlap with one another where the required parts are heat-sealed, and a sheet material X which is provided between the two thermoplastic films of the cushion material main body 11 to function as a check valve. The sheet material X also functions as an opening for injecting the air.

[0034] The cushion material main body 11 of the present embodiment is configured by a bag portion 12 for holding an object to be packaged therein, and a cushion portion 13 that will be inflated when it is injected with compressed air and established around the edges of the bag portion 12 (also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com