An electromagnetic heating FRP profile pultrusion machine

A glass fiber reinforced plastic profile and pultrusion technology, which is applied in the field of electromagnetic heating glass fiber reinforced plastic profile pultrusion machines, can solve the problems of rising ambient temperature, deteriorating working environment, unfavorable product process control, etc., so as to reduce maintenance costs and improve working environment. , Significant energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific embodiment:

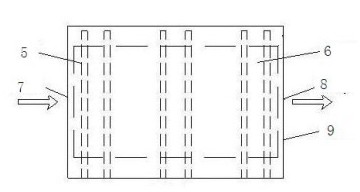

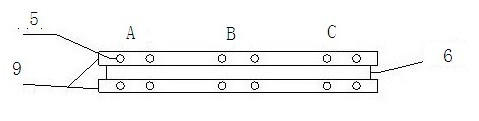

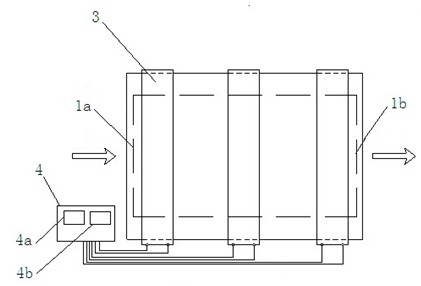

[0023] control image 3 as well as Figure 4 , an electromagnetic heating type FRP profile pultrusion machine, including a forming die 1, a die fixture 2, an electromagnetic coil 3 and a controller 4, the die fixture 2 includes two clamp bodies 2a, and the forming mold 1 is clamped between the two clamp bodies 2a, There is an extrusion processing space (not shown in the figure) inside the forming mold 1, and three sets of electromagnetic coils 3 are evenly set on the forming mold 1 and the mold fixture 2, corresponding to the three-stage temperature control and connected to the controller 4 respectively. The layer is wrapped with thermally insulating and nonmagnetic ceramic fiber paper (not shown in the figure), and the mold fixture 2 is made of non-metallic polyether ether ketone. Both sides of the molding die 1 are respectively provided with a material inlet 1a and a mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com