Differential thermodynamic machine with a cycle of eight thermodynamic transformations, and control method

A technology of thermodynamic cycle and process control, applied in the direction of hot gas variable displacement engine devices, mechanical equipment, special engines, etc., can solve problems such as not considering thermal machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] To facilitate understanding of this technology, formulas, descriptions supporting this patent, and diagrams and graphs to facilitate a full understanding of the principles will be provided.

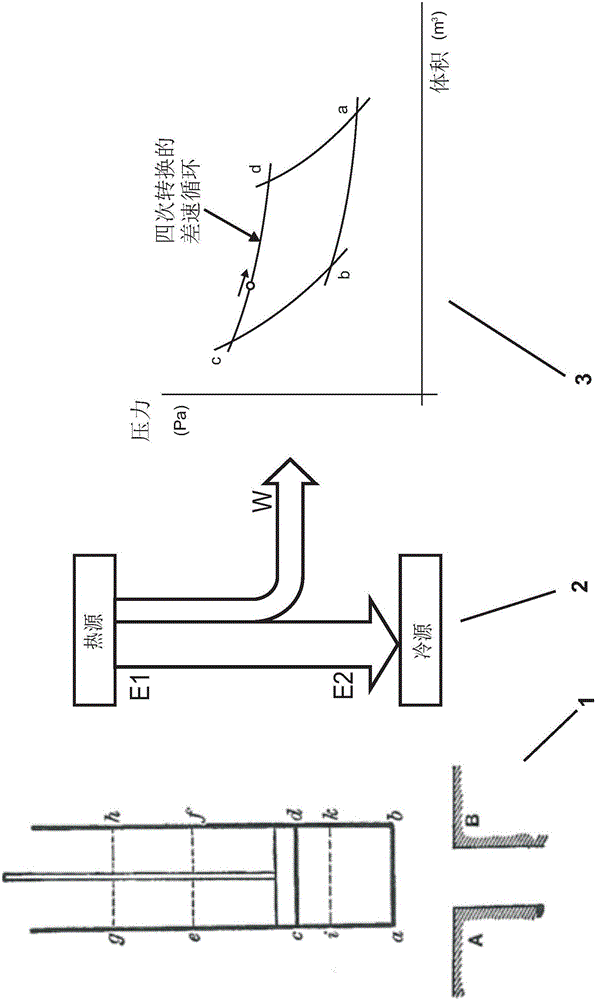

[0014] In Fig. 01 is depicted the Carnot primordial (1), the flow chart of the Carnot engine and other thermal engines operating in a four-step thermodynamic transformation loop (2), the cycle diagram of a Carnot engine with four transformations (3) .

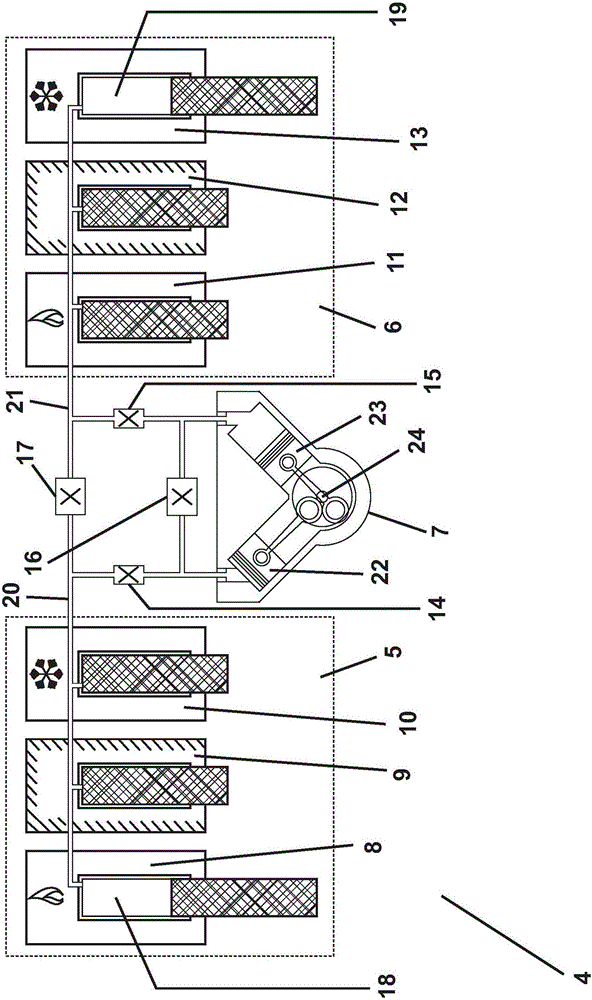

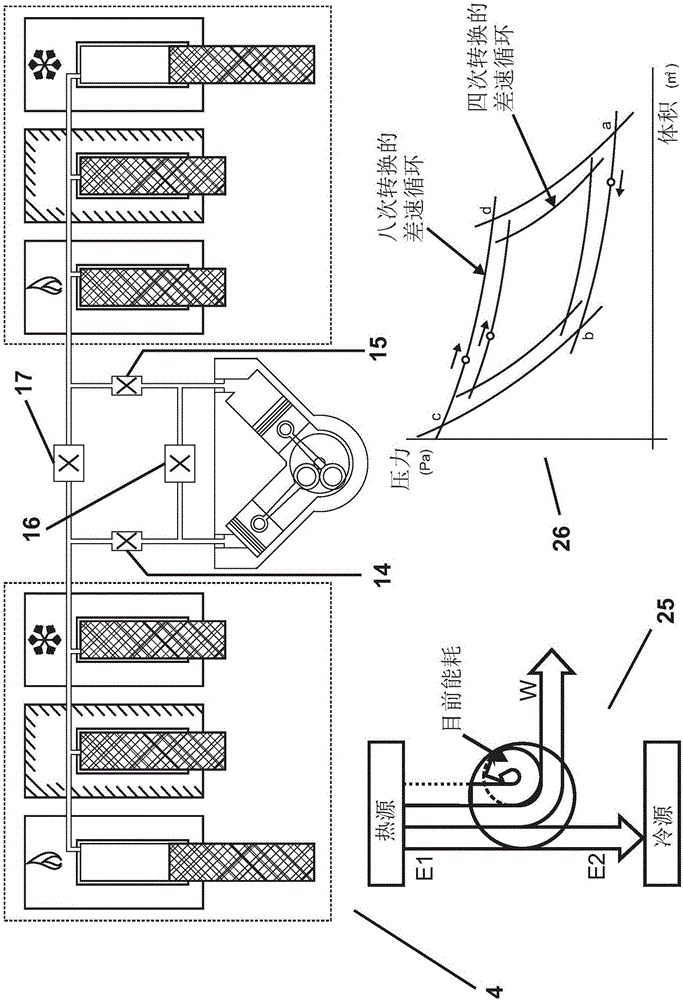

[0015] In Fig. 02 a differential machine (4) is depicted, which consists of two thermodynamic conversion chambers (5) and (6), each of which consists of three parts, respectively (8), (9), (10 ) and (11), (12), (13), each part includes a movable controllable piston, each chamber includes gas containers (18) and (19), passages (20) and (21) through which the working gas flows ), the gas mass transfer element (7), the control valve assembly (14) and (15), the inertia-operated valve (16) that releases the power drive unit, the power d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com