Correcting apparatus enhancing volume measuring accuracy of small size bell jar and correcting method thereof

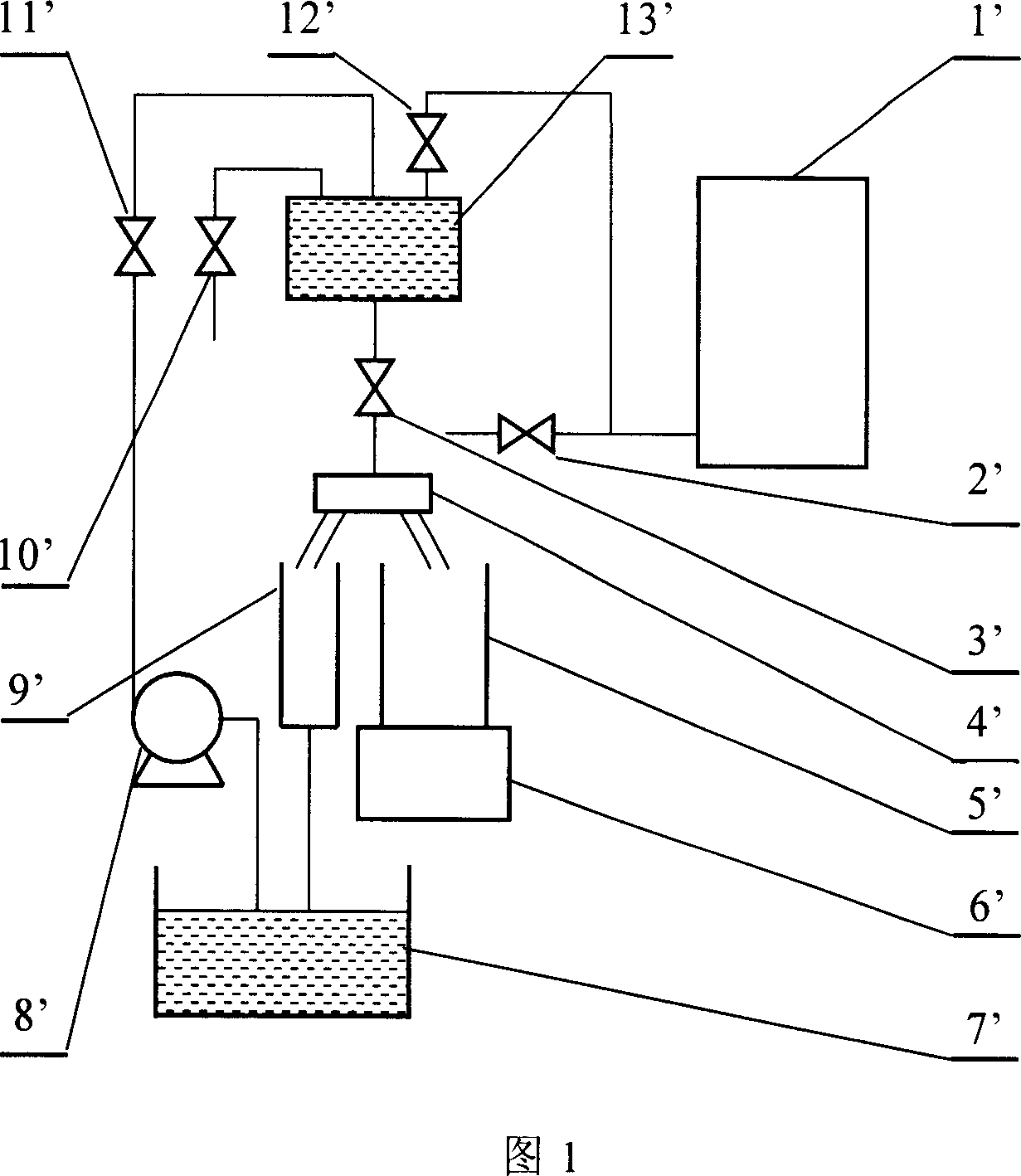

A technology for volume measurement and calibration device, which is used in testing/calibration devices, measuring devices, liquid/fluid solid measurement, etc., which can solve the problem that the accuracy level of the bell is difficult to achieve better than level 1.0, and the calibration method is difficult to achieve higher accuracy. It can improve the accuracy of volume calibration, improve the repeatability and stability of calibration, avoid unevenness and improve speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

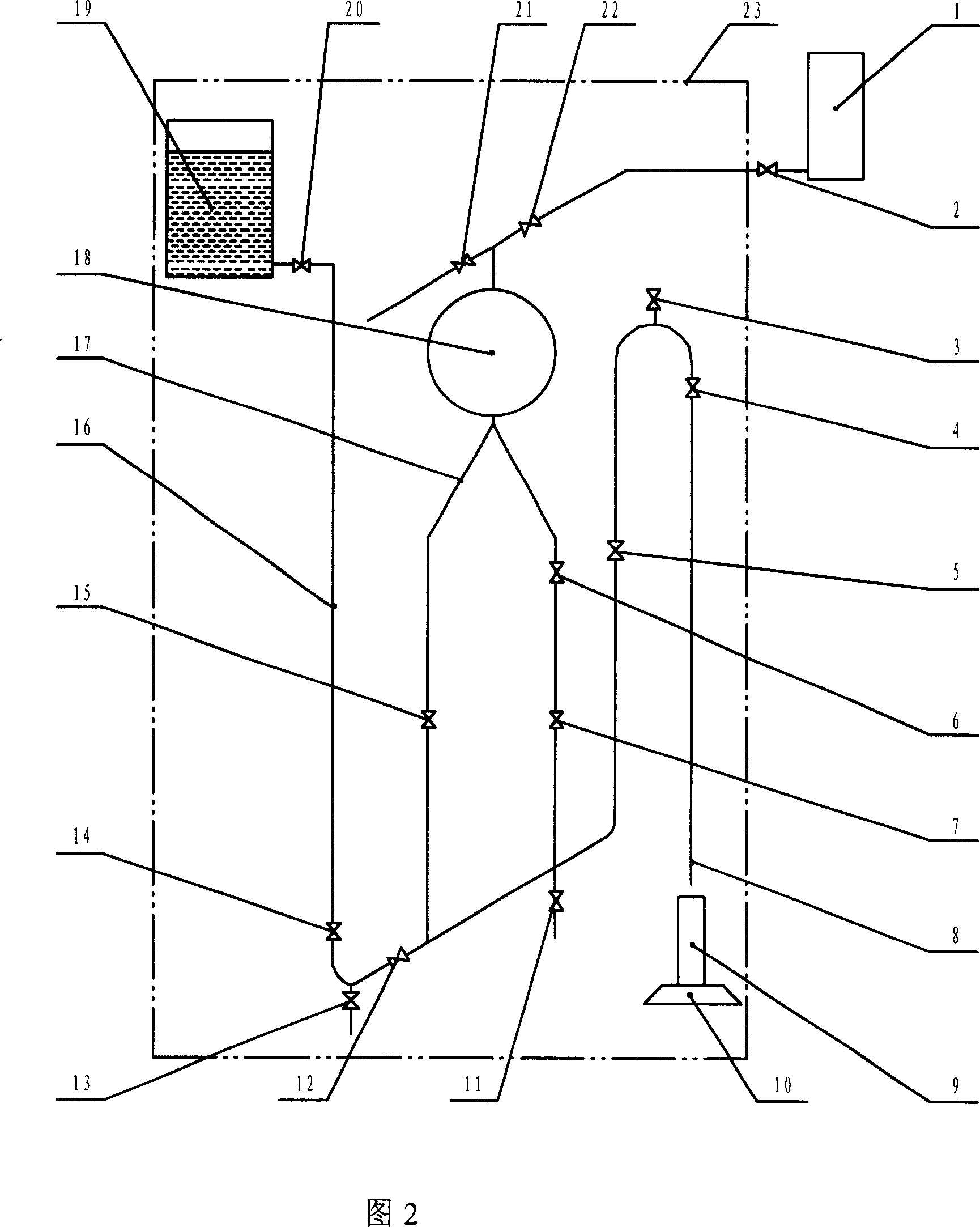

[0028] As shown in Figure 2, the present invention mainly consists of water storage container 19, 4 exhaust valves 3, 11, 13, 21, 8 glass stopcocks 4, 5, 6, 12, 14, 15, 17, 22, spherical A glass container 18, an electromagnetic stop valve 7, a silicone tube 16, a thin tube needle type drain pipe 8 and a small-diameter weighing cylinder 9 are formed, and the glass pipeline is the main structure of the whole device. When injecting water, the siphon principle of water is adopted, and the water in the water storage container 19 is controlled by the first cock valve 20 located at its outlet, and passes through the first cock valve 20, the silicone tube and the first cock valve 20 sequentially with the set flow rate. 16. The second cock valve 14 connected with the silicone tube 16 is connected to the third cock valve 12 after passing through the upward corner of the glass tube, and then divided into three ways after passing through the third cock valve 12, two of which go up through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com