Device and technology for laser auxiliary cutting and grinding machining of transparent hard and bristle material

A laser-assisted, hard and brittle material technology, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that the laser is easily blocked by the tool, the energy loss of the laser beam of the coolant, etc., and achieves convenient heating and enhanced precise control , to ensure the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

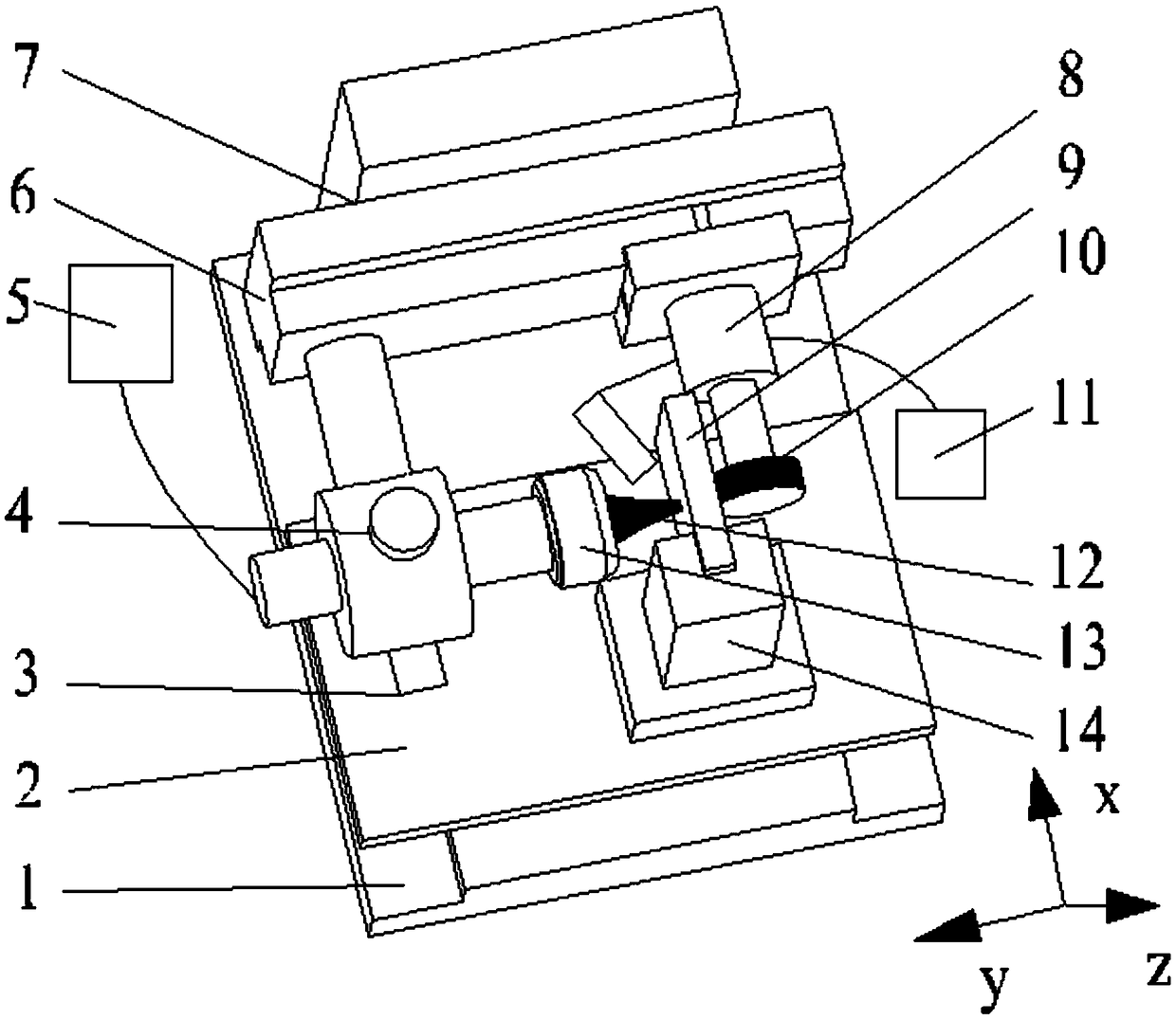

[0029] refer to figure 1 As shown, a laser-assisted cutting and grinding processing device for transparent materials includes a motion system, three linear axes x, y, and z control the feed movement, and a rotating shaft 8 controls the feeding or rotation of the cutting and grinding tool; the laser system includes Lasers, optical fibers, laser head devices; temperature measurement systems, including computers, infrared thermal imagers or infrared thermometers.

[0030] The laser head 23 and the rotating shaft 8 are fixed on the z-direction linear shaft 7 through the fixing plate 6;

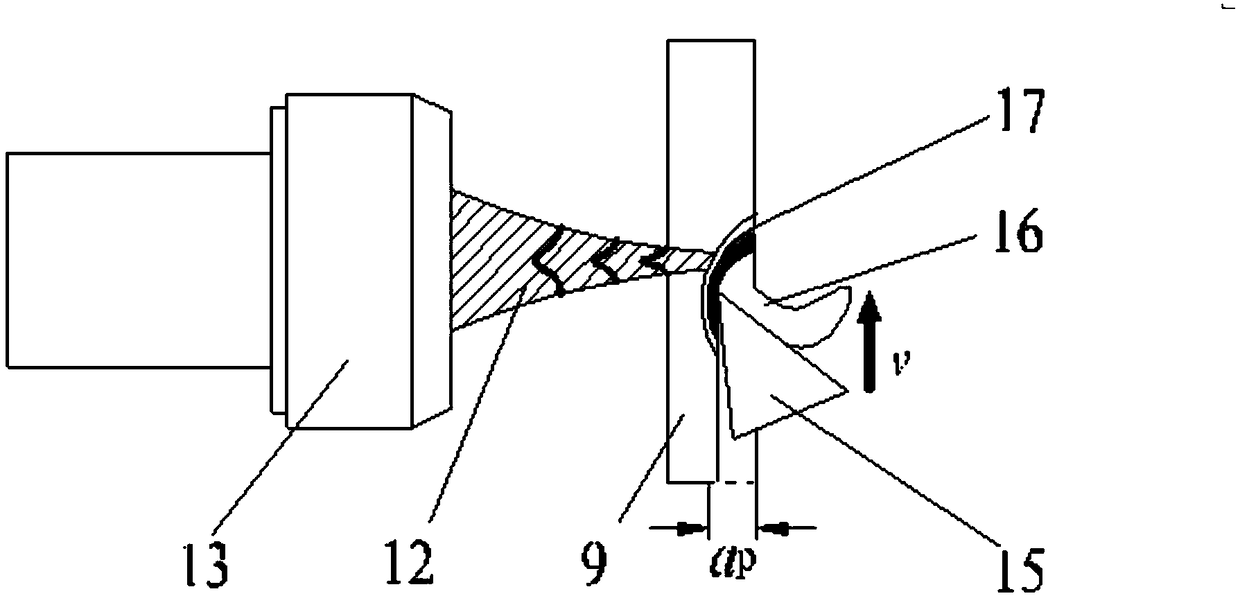

[0031] The position between the laser head and the transparent workpiece 9 is adjusted by the fine-tuning device, so that the laser is injected from the transparent workpiece to the other side of the workpiece, and the other side of the transparent material must be within the defocus range of the laser beam to ensure that the heating temperature is obtained. its softening;

[0032] The transpare...

Embodiment 2

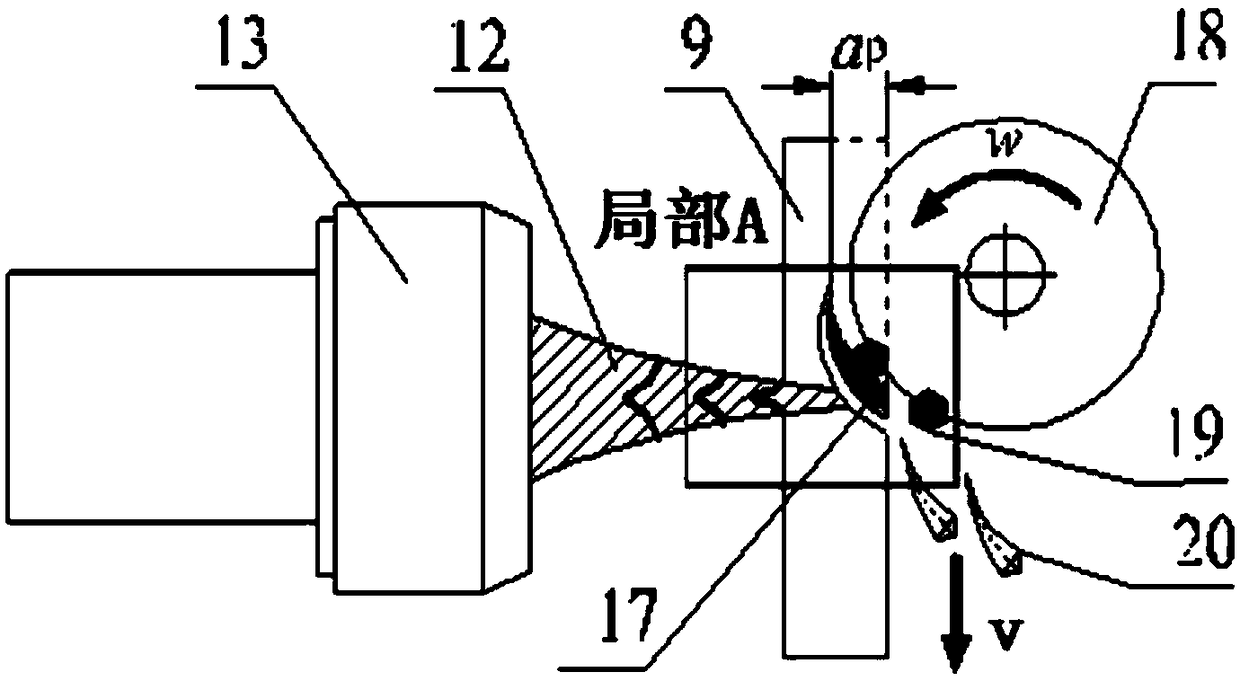

[0038] The cutting tool installed in embodiment 1 is replaced with superabrasive grinding wheel 10 in this embodiment, with reference to image 3 , because the transparent workpiece 9 is light-transmitting, the laser beam 12 can pass through the transparent workpiece 9 to heat the other side, the laser beam always heats the workpiece 9 at the front end of the area to be processed, and the laser heat-affected zone is consistent with the grinding arc zone of the grinding wheel. Under the action of the heat-affected zone 17, the workpiece material is softened to the maximum, and under the action of the grinding wheel abrasive grains 19, the softening depth is a p The softened layer is removed, forming wear debris 20.

[0039]On the one hand, this method can realize the ductile removal of hard and brittle materials and improve the surface quality of transparent materials. On the other hand, it can enhance the precise control of laser energy and defocus, and reasonably control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com