Mercury ion photo-electrochemical sensor working electrode and manufacturing method and application thereof

A working electrode and photoelectrochemical technology, which is applied in the field of chemical analysis and detection, can solve problems such as the difficulty in realizing the long-term stability of photosensitized materials and accurately control sensors, and achieve good development prospects, high selectivity, and good specificity recognition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

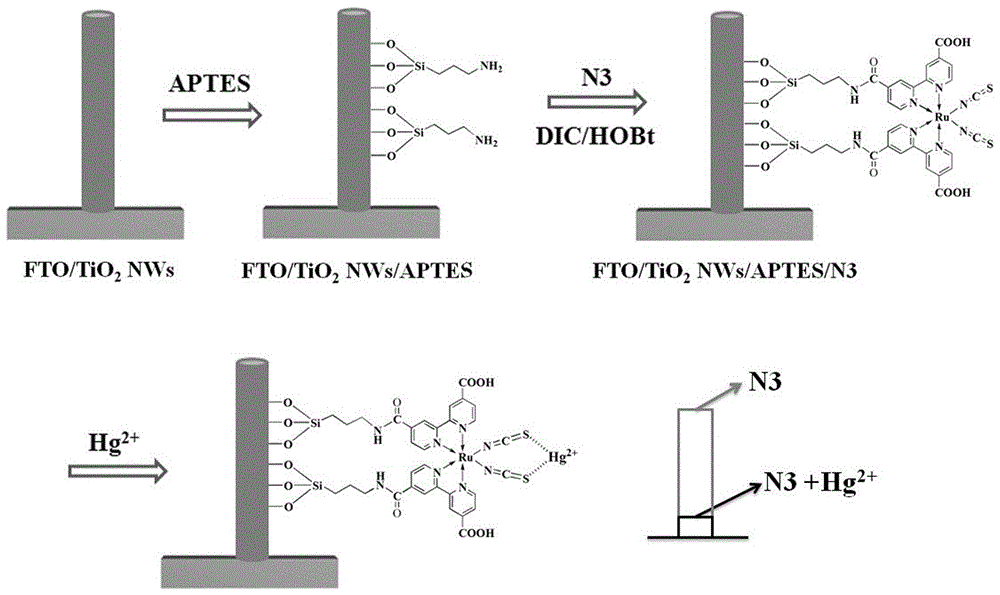

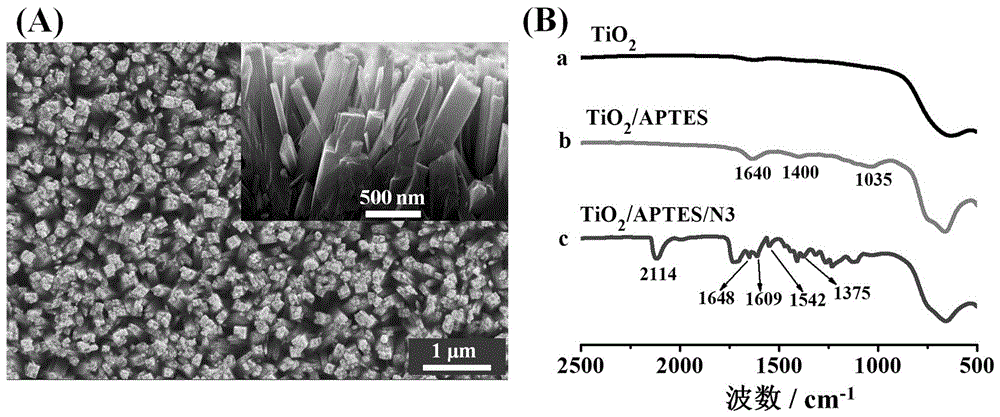

[0034] Embodiment 1: Preparation of photoelectrochemical sensor working electrode

[0035] Sonicate the FTO glass with acetone, isopropanol, ethanol, and deionized water in sequence, rinse with deionized water, and blow dry with nitrogen. Prepare the reaction solution for synthesizing titanium dioxide nanowires: 7.5mL deionized water, 6mL concentrated hydrochloric acid, 1.5mL saturated sodium chloride solution, 0.3mL n-butyl titanate. The reaction solution and the cleaned FTO glass substrate were placed in a muffle furnace and reacted at 180° C. for 12 hours to obtain a titania nanowire array. The prepared titanium dioxide nanowire array was placed in a solution of 100 μL of 3-aminopropyltriethoxysilane and 10 mL of isopropanol, and incubated at 100° C. for 1 hour to obtain an aminated titanium dioxide nanowire electrode. Then place the aminated titanium dioxide nanowire electrode in a DCM solution containing 0.3mM N3 dye molecules and equimolar amounts of DCC and HOBT, and r...

Embodiment 2

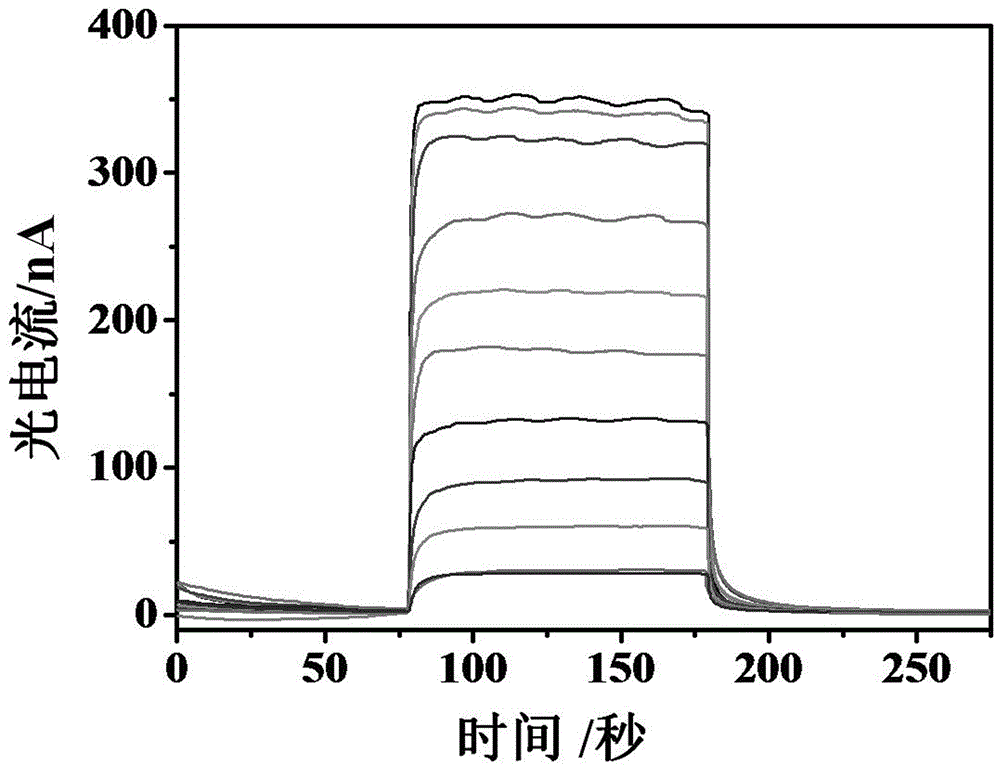

[0036] Embodiment 2: to the photoelectrochemical detection of mercury ion

[0037] The titanium dioxide nanowire array electrode modified by dye molecules prepared in Example 1 was used as the working electrode, the silver / silver chloride electrode was used as the reference electrode, and the platinum wire was used as the counter electrode to assemble a photoelectrochemical detection system for mercury ions. The working electrode was treated with different concentrations of mercury ion solutions, and its photoelectrochemical response was tested. The results are as follows: image 3 shown. The change value of photocurrent to Hg 2+ Concentration plotting, Hg 2+ Concentration at 0.5nmol·L -1 –50.0μmol·L -1 In the range, there is a good linear relationship between the two ( Figure 4 ), so Hg in this concentration range can be achieved 2+ quantitative detection. And the detection of mercury ions by the photoelectrochemical sensor is not affected by some other common cations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com