Servo-power four-station rotary plate mechanism

A four-station turntable and turntable mechanism technology, applied in the field of multi-material injection molding machines, can solve the problems of high energy loss, low production efficiency, low control precision, etc., and achieve the effect of rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

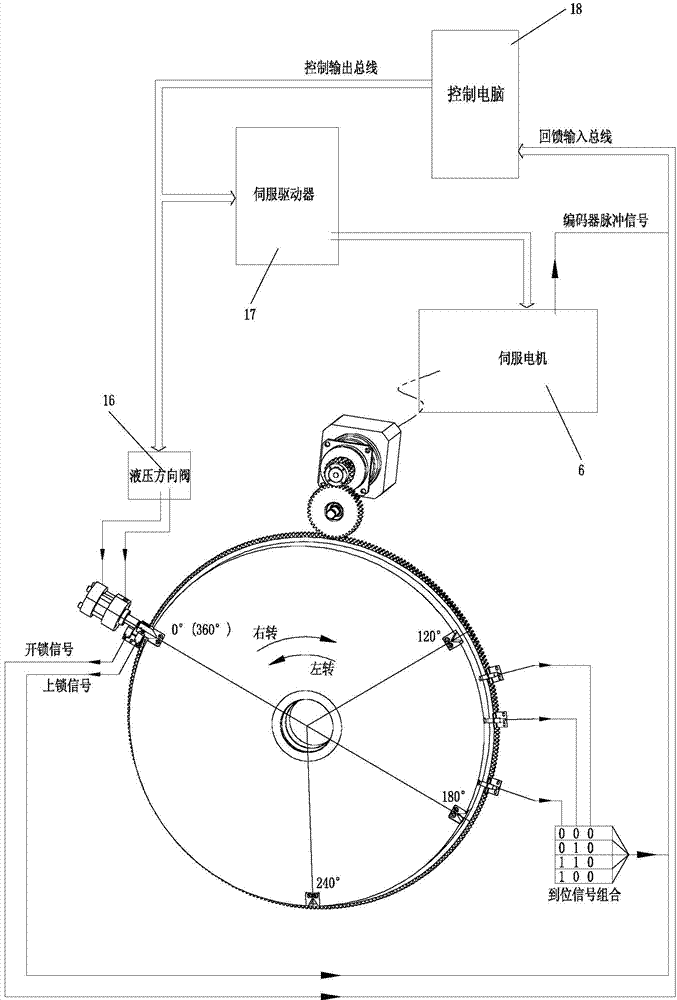

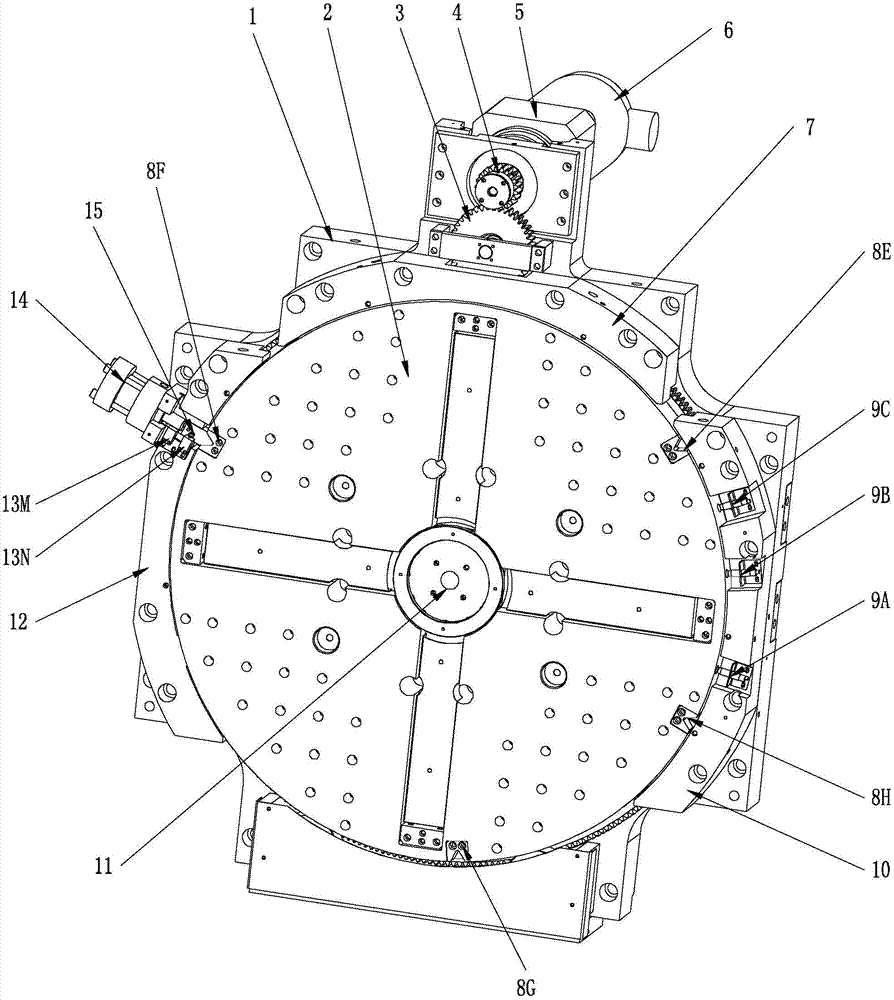

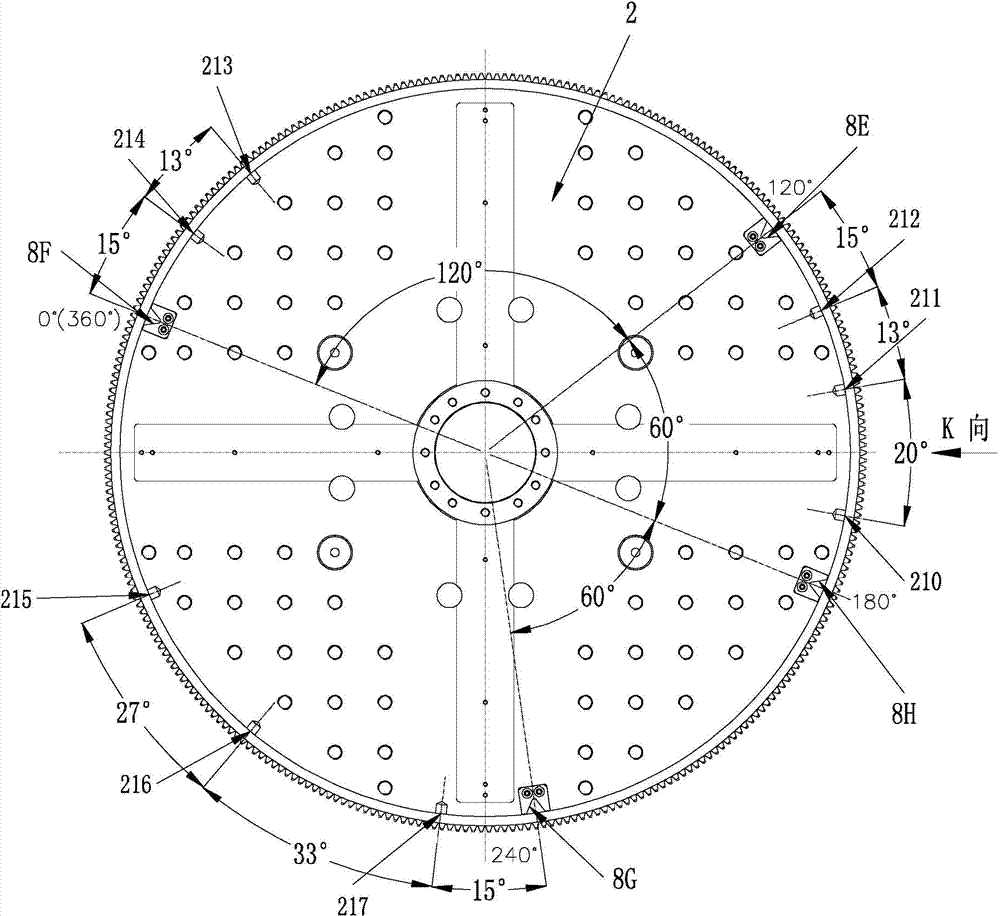

[0027] Such as Figure 1-8 As shown, a servo-powered four-station turntable mechanism includes a base plate 1, a turntable 2, a central shaft assembly 11 and a servo motor 6. The turntable 2 is positioned at the center of the base plate 1 through the shaft assembly 11, and the servo motor 6 is arranged on the base plate 1. The upper part of the gear box is installed on the input end of the gear box 5, through the action of the gear box 5, the speed is reduced and the torque is increased, and then the driving gear 4 installed on the output side of the gear box 5 drives the linkage gear 3 to mesh Acting on the teeth 202 on the periphery of the turntable 2, the rotating speed and torque are transmitted to the turntable 2, and the turntable 2 is driven to rotate around the central shaft assembly 11 on the plane of the bottom plate 1; The pressing block 10 and the left pressing block 12 form a certain closed space to protect the teeth 202 of the turntable 2 and prevent foreign matt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com