Motor intelligent power-saving protector

A protection device and motor technology, applied in emergency protection circuit devices, AC motor control, electrical components, etc., can solve the problems of large function expansion limitations, easy to burn power components, increase procurement costs, etc., to reduce operation difficulty and error. Operation probability, avoid mismatch of control parameters, convenient and quick function extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

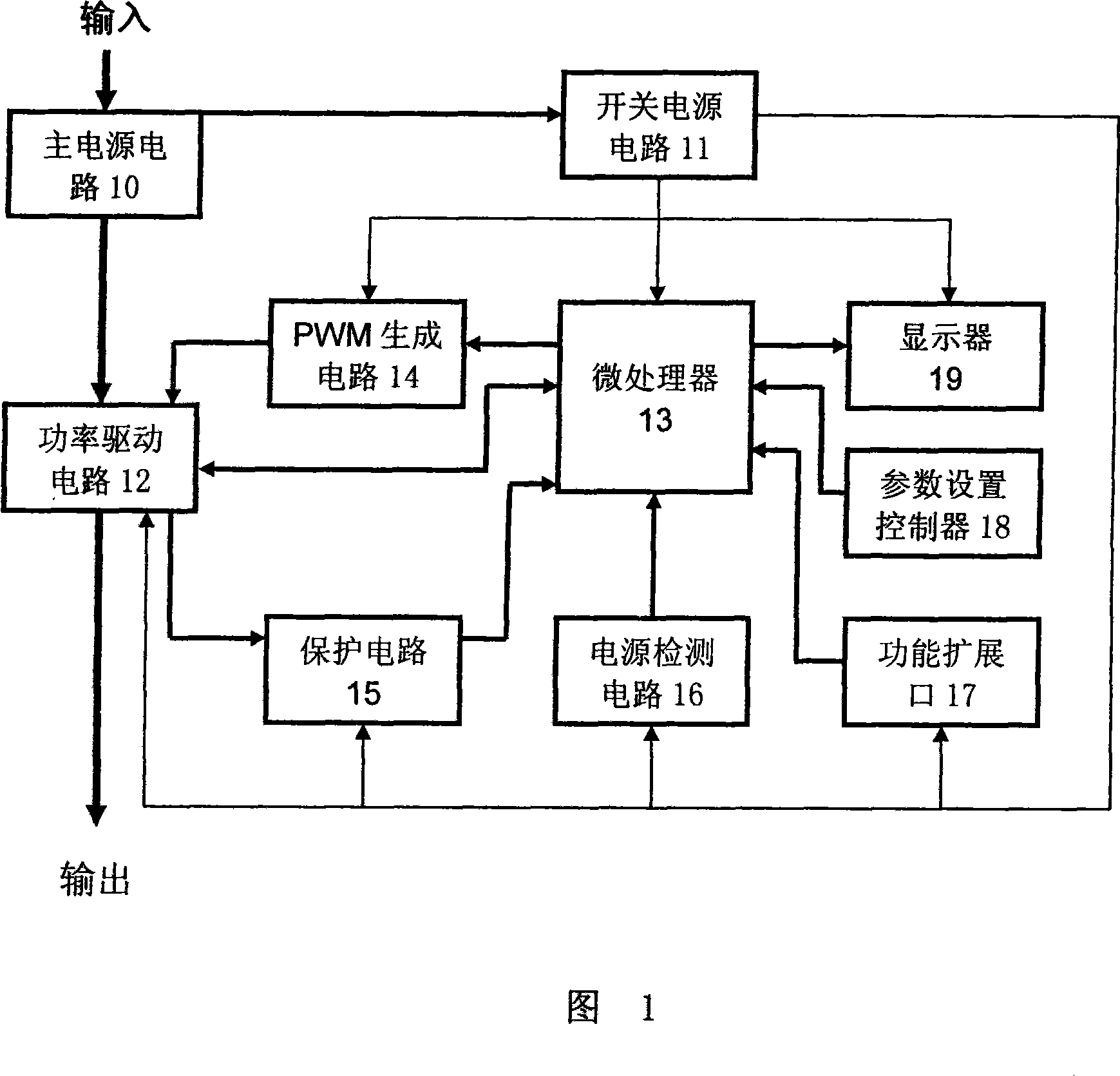

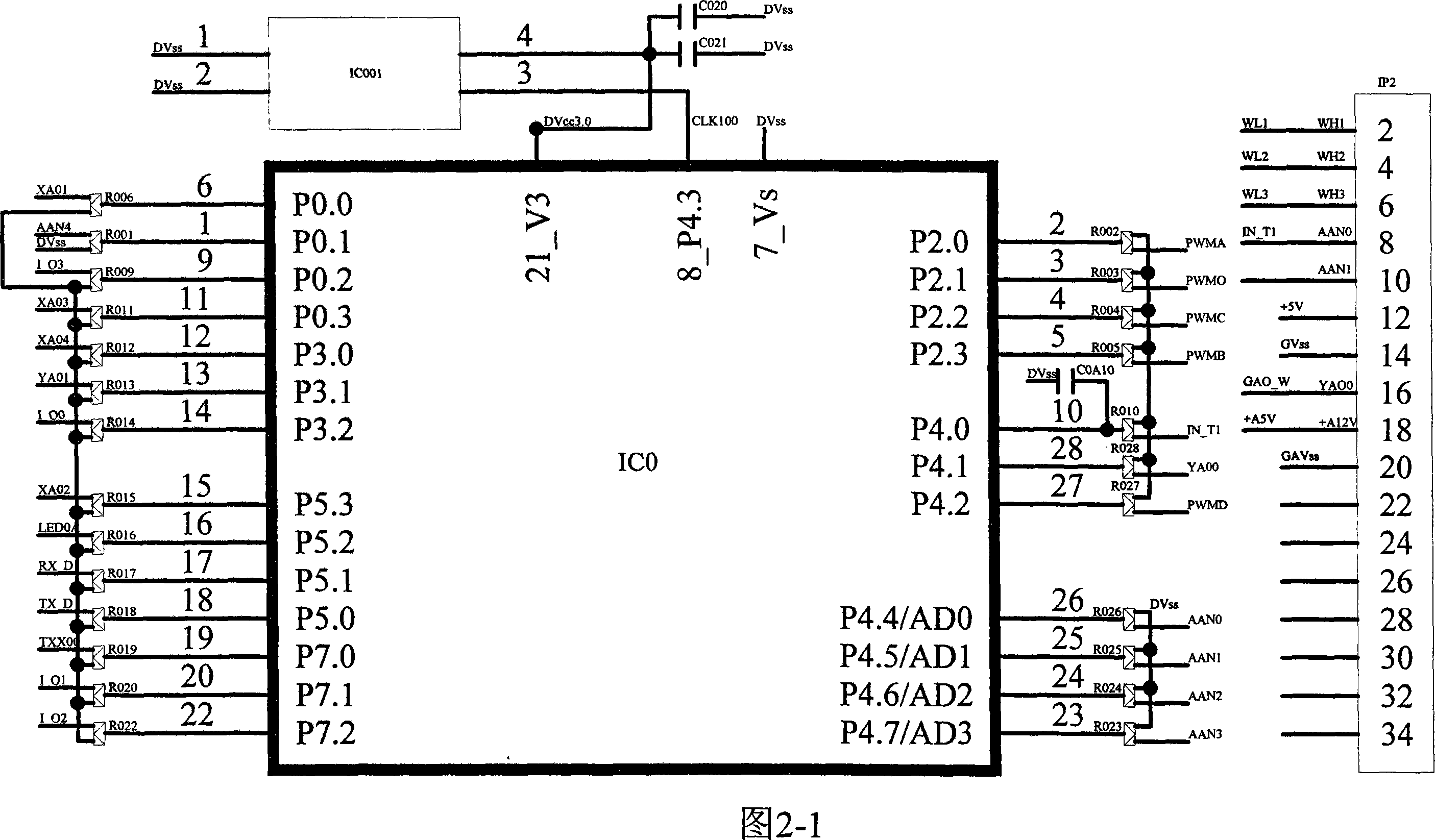

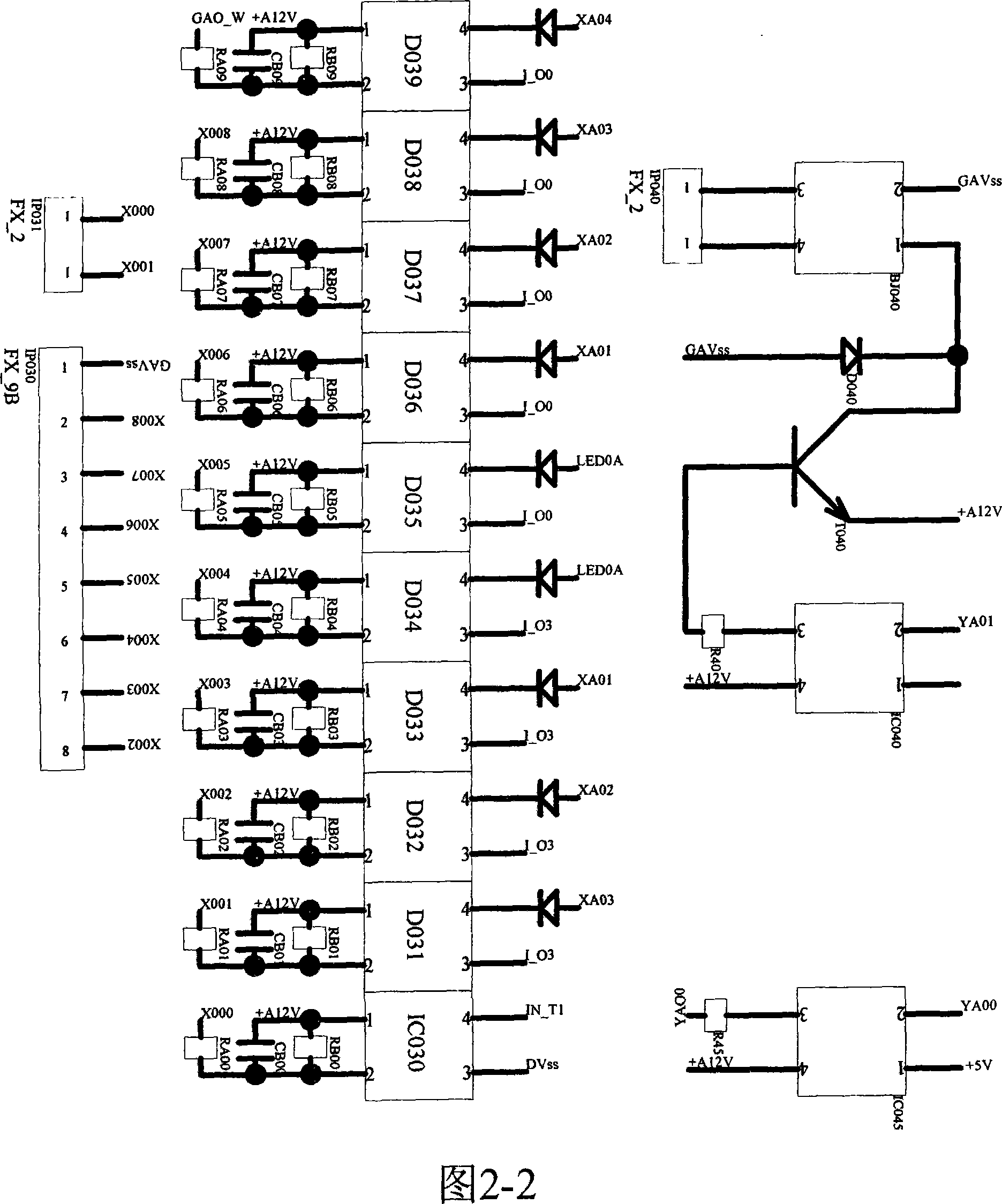

[0016] With reference to Fig. 1, present embodiment is controlled by main power supply circuit 10, switching power supply circuit 11, power drive circuit 12, microprocessor 13, PWM generation circuit 14, protection circuit 15, power supply detection circuit 16, function expansion port 17, parameter setting device 18, display 19; the output end of main power supply circuit 10 is connected with the input end of switching power supply 11 and power drive circuit 12 respectively; the output end of switching power supply 11 is connected with power drive circuit 12, microprocessor 13, PWM respectively. The input end of circuit 14, protection circuit 15, power supply detection circuit 16, function expansion port 17, display 19 is connected; connection, the output end is connected with the input end of the protection circuit 15; the input end of the microprocessor 13 is respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com