Product fatigue limit detection equipment

A technology for testing equipment and fatigue limit, which is applied in the field of product fatigue limit testing equipment, can solve problems such as untrue displayed values, and achieve the effect of improving the precise control of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

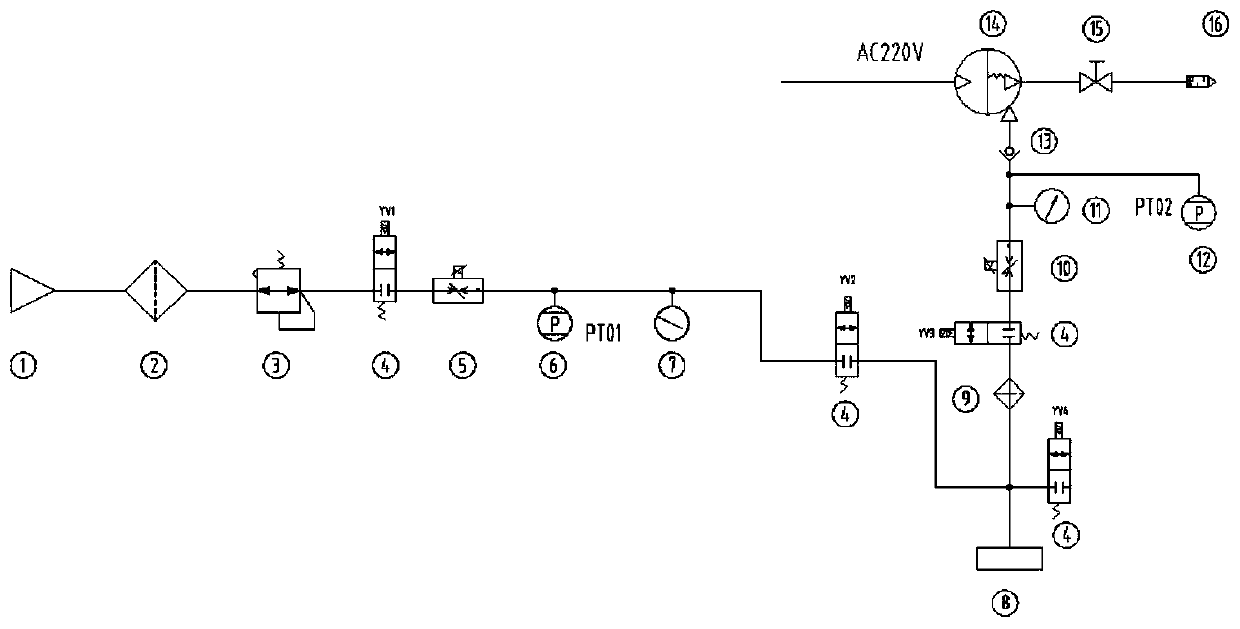

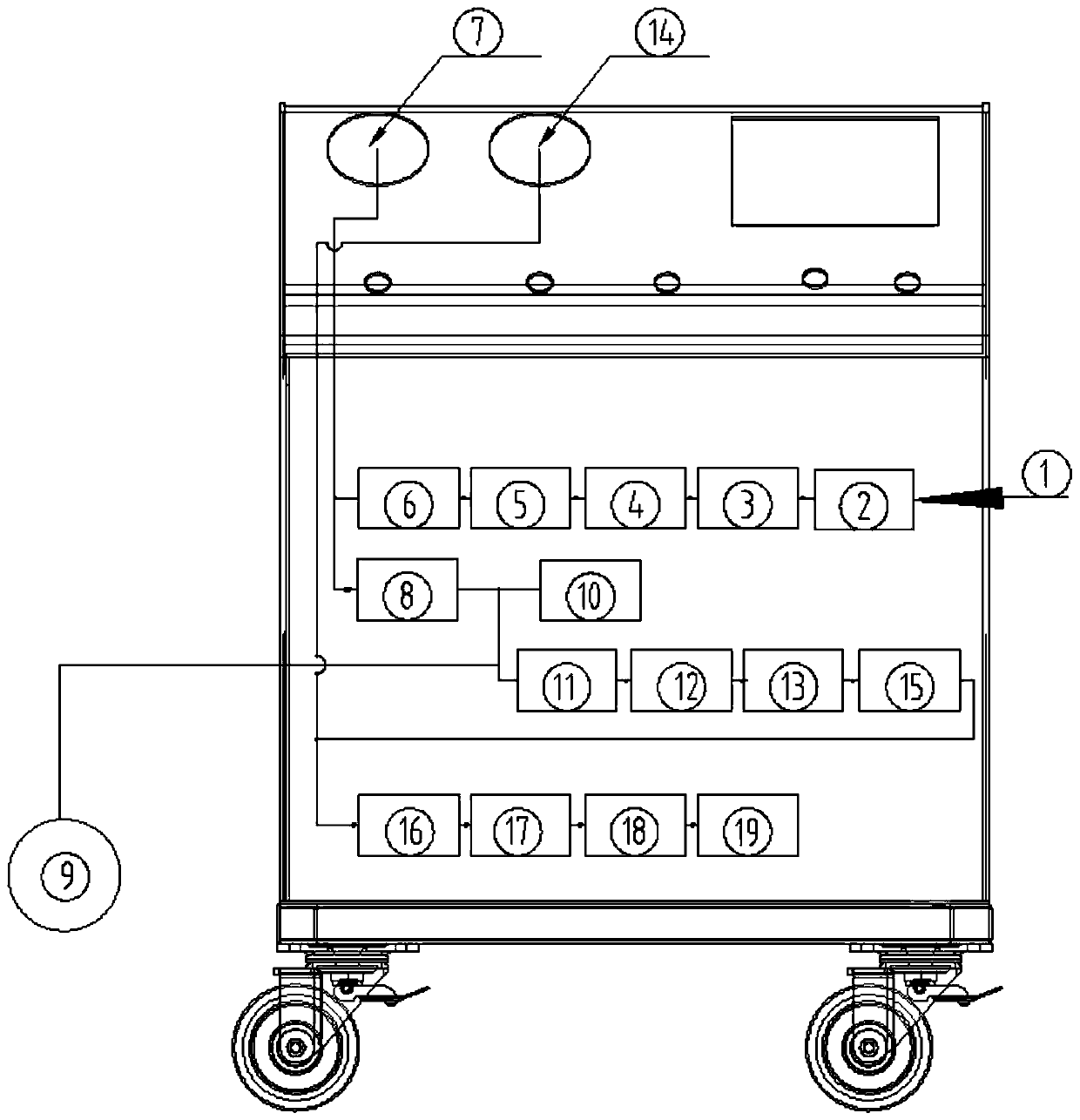

[0010] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0011] refer to Figure 1-2 , a product fatigue limit detection equipment, including air source 1, filter 2, pressure reducing valve 3, four two-position four-way solenoid valve 4, proportional flow valve 5, pressure sensor 6, digital display pressure gauge 7, the measured Product 8. Vacuum filter 9. Negative pressure proportional flow valve 10. Negative pressure digital display pressure gauge 11. Negative pressure sensor 12. Check valve 13. Vacuum pump 14. Stop valve 15. Muffler 16.

[0012] Air source 1, filter 2, pressure reducing valve 3, the first two-position four-way solenoid valve 4, proportional flow valve 5, pressure sensor 6, and digital display pressure g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com