Closed submerged arc furnace coal gas dry-process purifying and recycling system

A dry purification and recovery system technology, applied in furnaces, waste heat treatment, gas dust removal, etc., can solve problems such as clogging of washing water pipelines and equipment, failure to meet environmental protection emission standards, and lack of market competitiveness, saving operating costs. , avoid water pollution and sludge problems, avoid the effect of secondary cooling water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

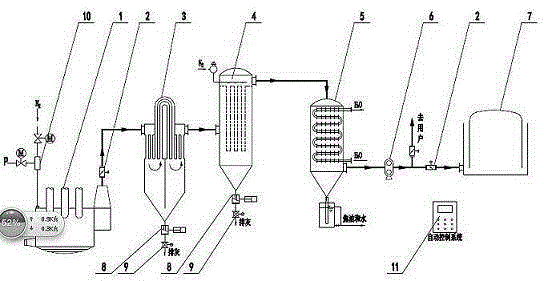

[0023] As shown in the accompanying drawings, the closed submerged arc furnace gas dry purification and recovery system provided by the present invention includes: closed submerged arc furnace 1, air natural cooler 3, bag filter 4, water-cooled condensation drainer 5, gas fan 6 , gas cabinet 7, automatic control system 11; closed submerged arc furnace 1, natural air cooler 3, bag filter 4, water-cooled condensation drainer 5, gas fan 6, and gas cabinet 7 are connected through carbon steel pipes in turn, in the closed mine The hot furnace 1 and the air natural cooler 3, and the connection pipeline of the gas fan 6 and the gas cabinet 7 are provided with a switching valve 2, and a furnace pressure measuring device 10 is installed on the furnace cover of the closed submerged arc furnace 1; the automatic control system 11 passes the signal The line is connected with the above-mentioned equipment and valves.

[0024] The 450°C high-temperature gas generated by the closed submerged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com