Pneumatic clutch actuating mechanism for automobile transmission system

A transmission system and actuator technology, which is applied in the field of automobile transmission system accessories, can solve the problems of low transmission efficiency, long response time, complex system, etc., and achieve the effects of wide output force range, convenient operation and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

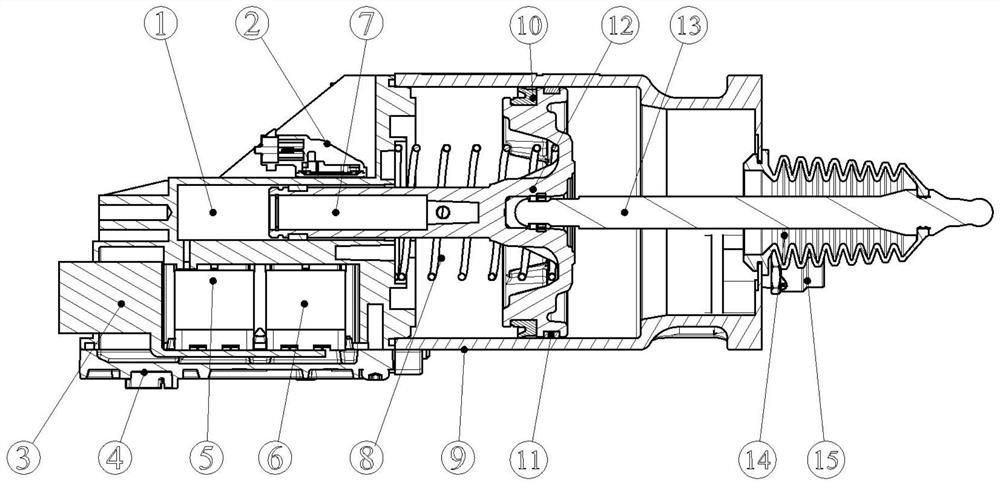

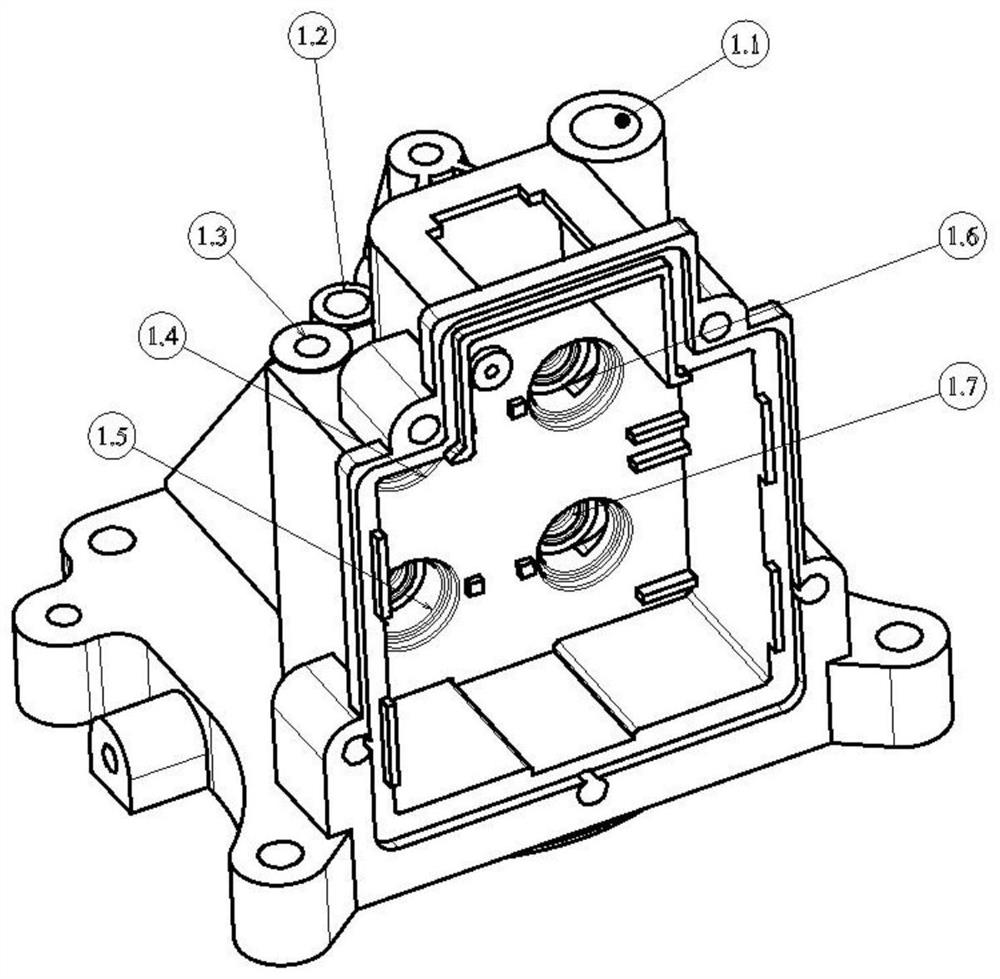

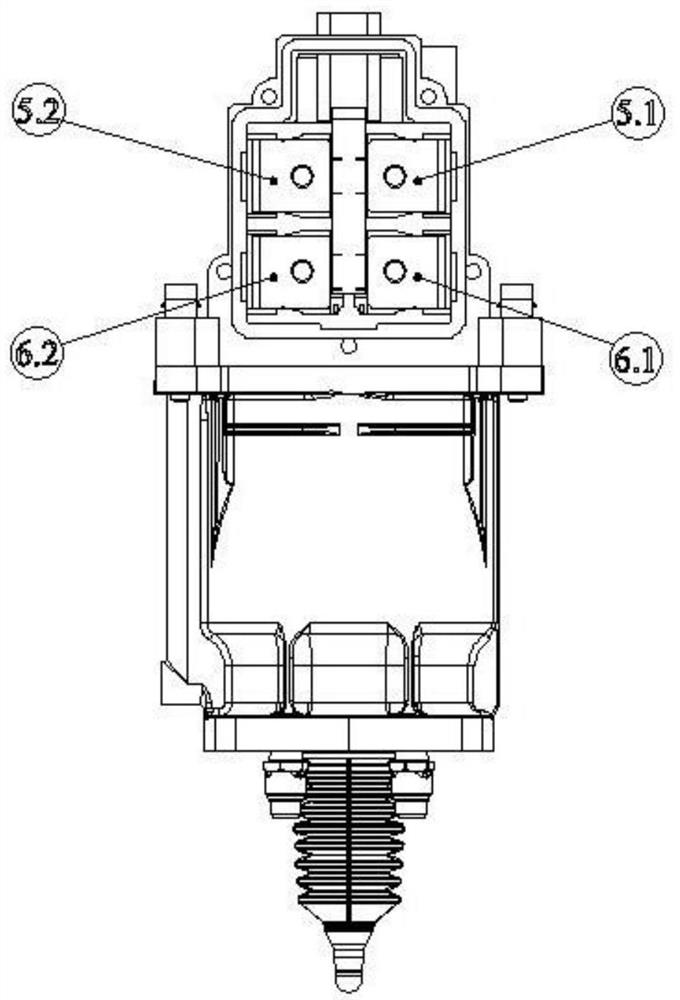

[0023] A pneumatic clutch actuator for automobile transmission system, comprising a valve body 1 and a cylinder 9 connected, the valve body 1 is provided with a plurality of solenoid valve installation holes for installing solenoid valves, the solenoid valve The valve is a two-position two-way solenoid valve, which is divided into two groups. The solenoid valves contained in each group have different aperture sizes. Multiple solenoid valves are set in two groups, respectively connected to the intake air path 1.1 and exhaust air path 1.2 of the valve body 1. connection, the solenoid valves in each group are connected in parallel;

[0024] As a preferred solution for the above-mentioned structure, this embodiment provides four solenoid valve installation holes in the valve body 1, refer to Figure 1 , are the installation hole a1.4 of the solenoid valve of the exhaust gas path, the installation hole b1.5 of the solenoid valve of the exhaust gas path, the installation hole a1.6 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com