High-precision automatic removing machine for back adhesive film of integrated circuit chip

An integrated circuit, high-precision technology, applied in the direction of circuits, electrical components, grinding racks, etc., can solve the problems of low product yield, difficult control of action accuracy, unsatisfactory cleaning effect, etc., to ensure the effect of glue removal and production The effect of high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

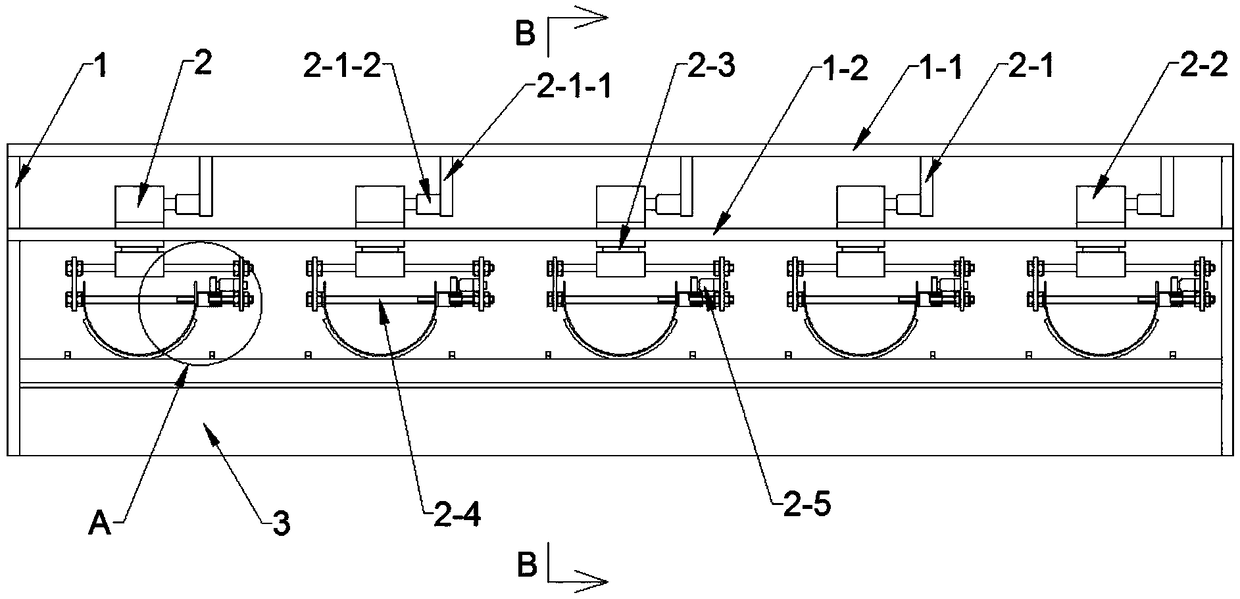

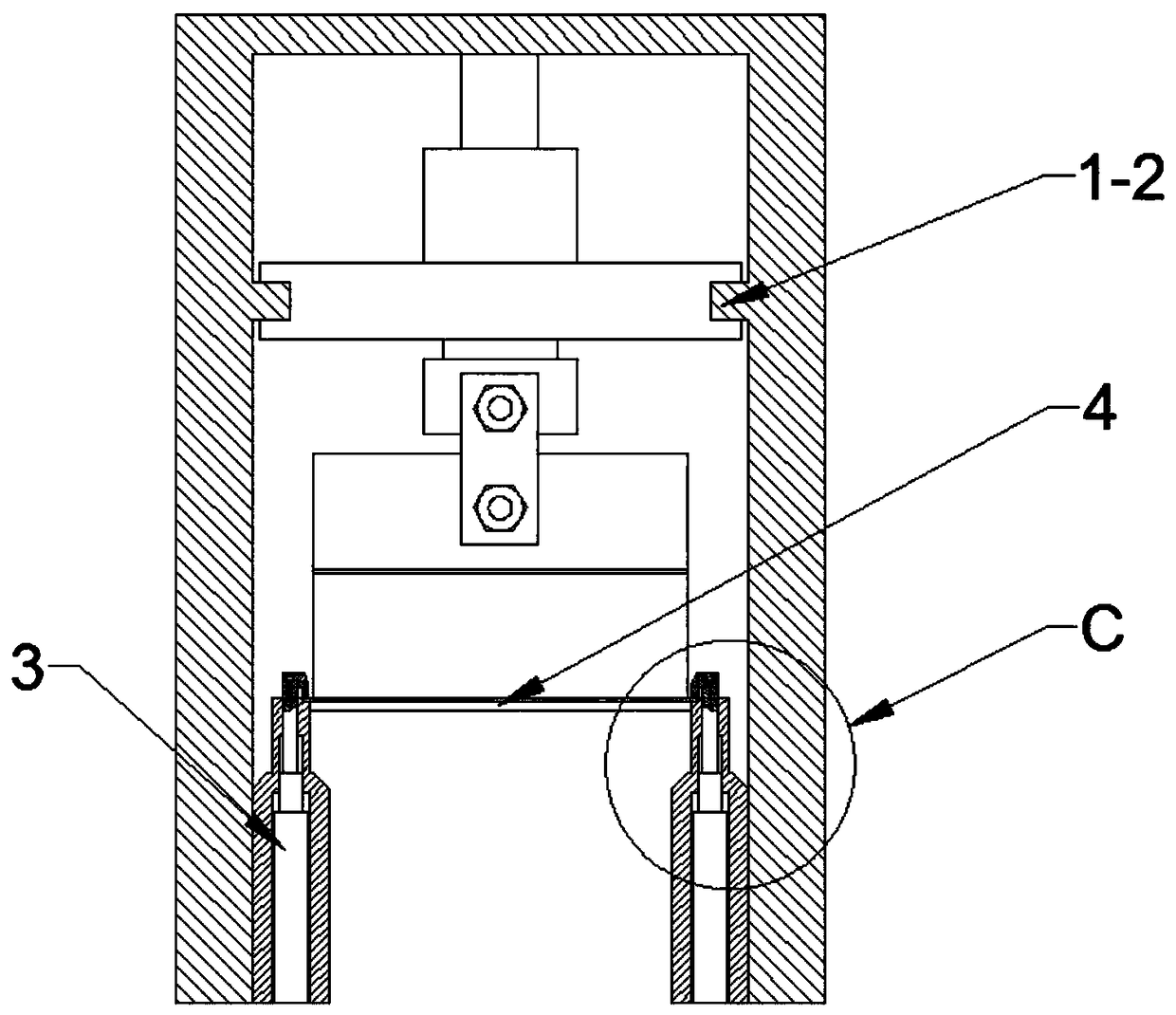

[0032] See Figure 1 to Figure 4 , the high-precision automatic cleaning machine for integrated circuit chip adhesive film of this embodiment includes a frame 1, a grinding mechanism 2 and a chip fixing mechanism 3.

[0033] The top of the frame 1 is provided with a beam 1-1, and the middle part is provided with a grinding guide rail 1-2. A plurality of grinding mechanisms 2 are equidistantly installed on the beam 1-1 of the frame 1. The chip fixing mechanism 3 is arranged on the inner bottom of the rack 1 , and the integrated circuit chip 4 is fixedly placed on the chip fixing mechanism 3 .

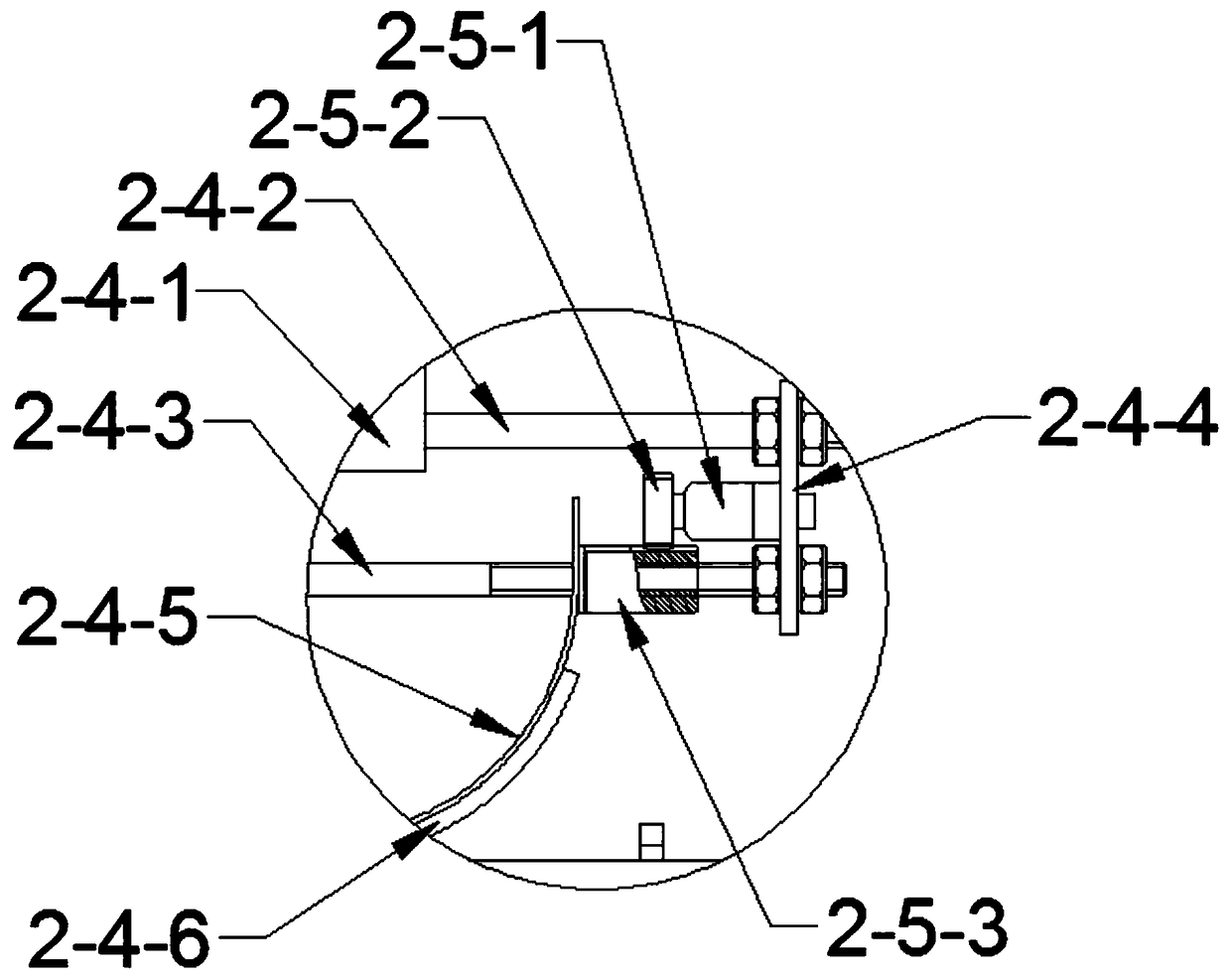

[0034] The grinding mechanism 2 includes a reciprocating drive device 2-1, a slider 2-2, a pressure sensor 2-3, a bow-shaped grinding assembly 2-4 and a fine adjustment assembly 2-5. The reciprocating driving device 2-1 is fixed on the crossbeam 1-1. The slide block 2-2 is slidably connected with the grinding guide rail 1-2. The reciprocating driving device 2-1 drives the slide block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com