Production apparatus and extrusion technology of novel clad pipe

A production device and composite pipe technology, which is applied to the production device of a new composite pipe and its extrusion process field, can solve the problems of difficult connection, high temperature resistance, flammability, etc., so as to improve control accuracy, increase accurate control, and promote generalized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described:

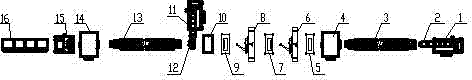

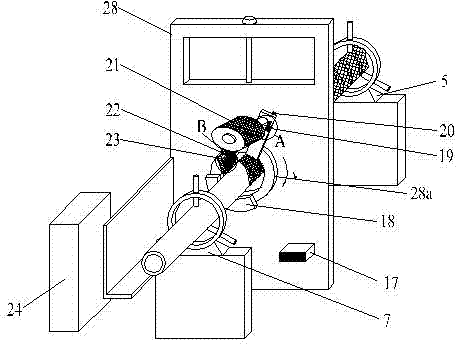

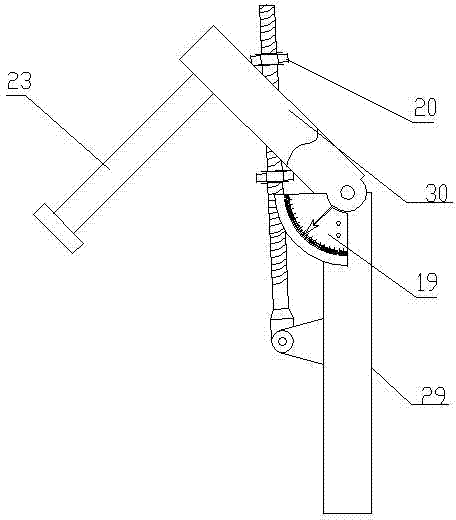

[0029] Such as Figure 1-4 As shown, a production device for a new type of composite pipe, including a coating double-layer extrusion line device for producing inner and outer layers of reinforced composite pipe, a winding machine for winding and preheating long fiber tapes, and a winding machine for controlling fiber tapes The center positioning frame that causes the inner tube to warp and the heating box for heating the inner tube wrapped with fiber tape, it is characterized in that the coating double-layer extrusion production line device includes an inner tube production line device, an outer tube production line device and post-processing device, the winding machine includes a first winding machine 6 and a second winding machine 8, which are sequentially arranged between the inner pipe production line device and the outer pipe production line device, and the central p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com