Air-injection vortex-spinning groove-shaped self-twist hollow spindle

A hollow spindle and groove type technology, applied in the textile field, can solve the problems of many details and low strength of air-jet vortex spinning yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

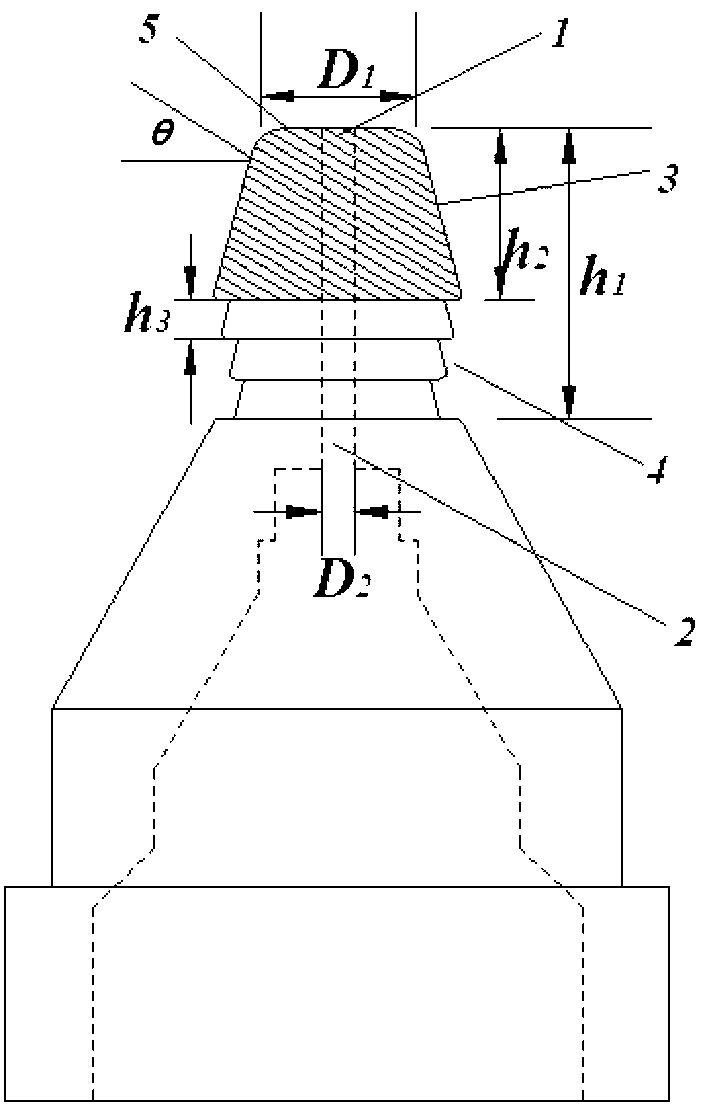

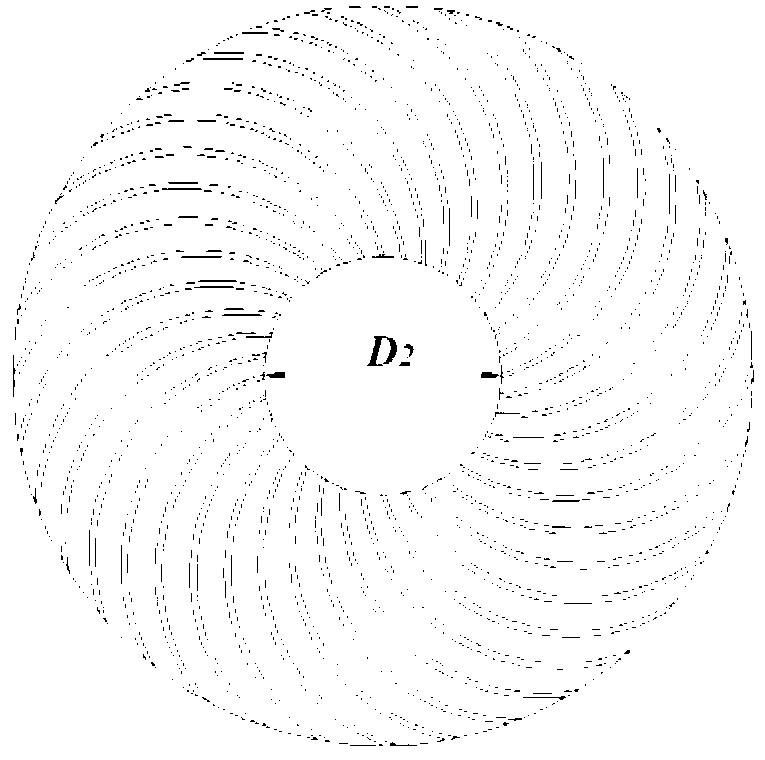

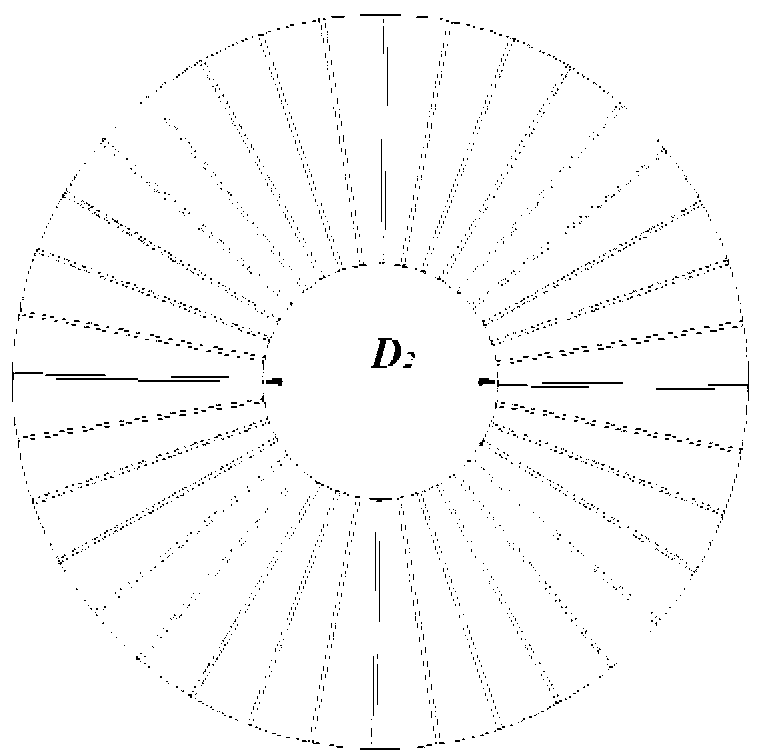

[0018] Such as Figure 1 ~ Figure 2 As shown, a grooved self-twisting hollow ingot for air-jet vortex spinning, including fiber inlet 1, yarn forming channel 2, wall spiral groove 3, circumferential stepped groove 4, cone top plane groove 5, diameter of hollow ingot cone top D. 1 , Yarn channel diameter D 2 , groove width D 3 , the height h from the top surface of the hollow ingot to the bottom surface of the circumferential groove 1 , The height h from the top surface of the hollow ingot to the top surface of the circumferential groove 2 , the height h of each step of the circumferential groove 3 , The spiral angle θ of the spiral groove on the wall surface, the main body of the hollow ingot. The number of steps of the circumferential stepped groove 4 is 3, the height of each step is 1.0mm, and the height from the top surface of the hollow ingot to the bottom surface of the circumferential groove is h 1 4.0mm; the cone-top plane groove 5 is 36, and the center of the yar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com