Self-resetting fabricated shear wall structure connecting device

A technology of structural connection and shear wall, applied in the direction of walls, building components, building structures, etc., can solve problems such as reduction, and achieve the effect of avoiding wet work, reducing bending curvature, and reducing earthquake resistance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

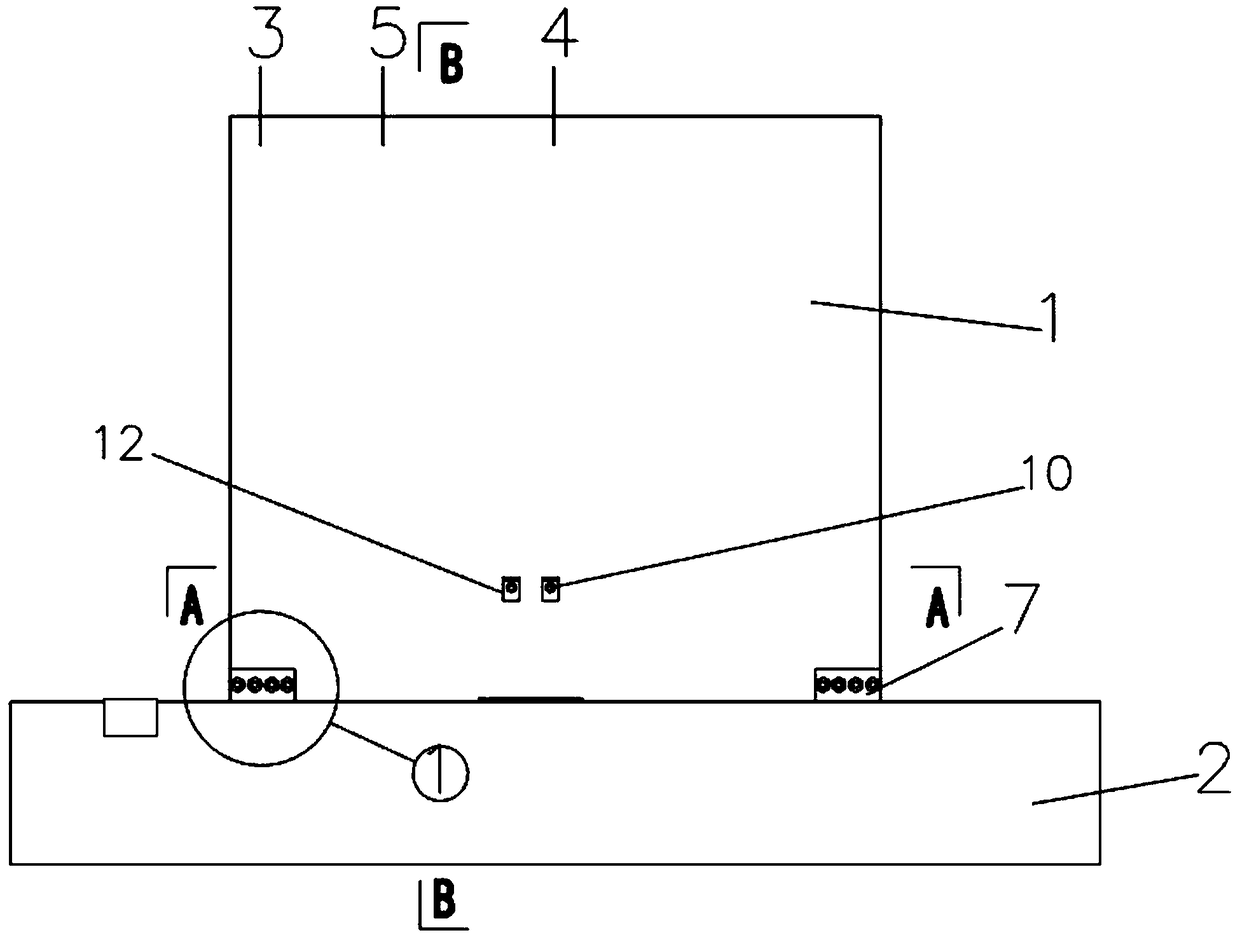

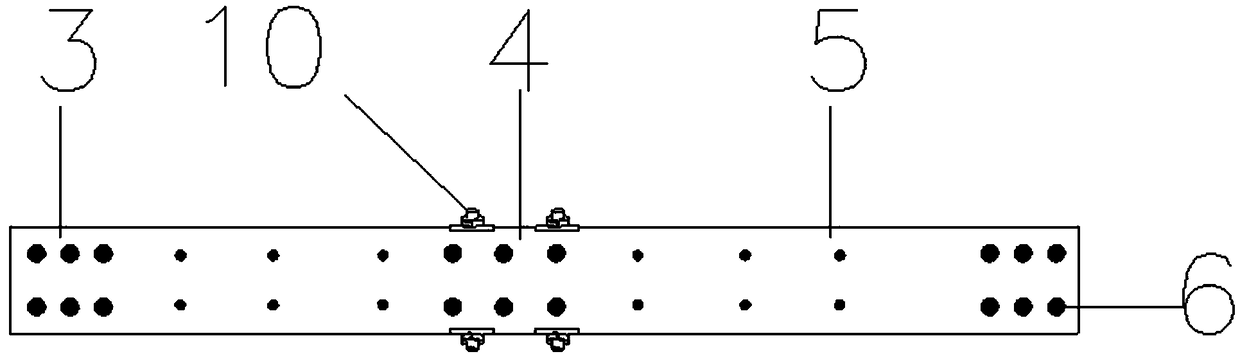

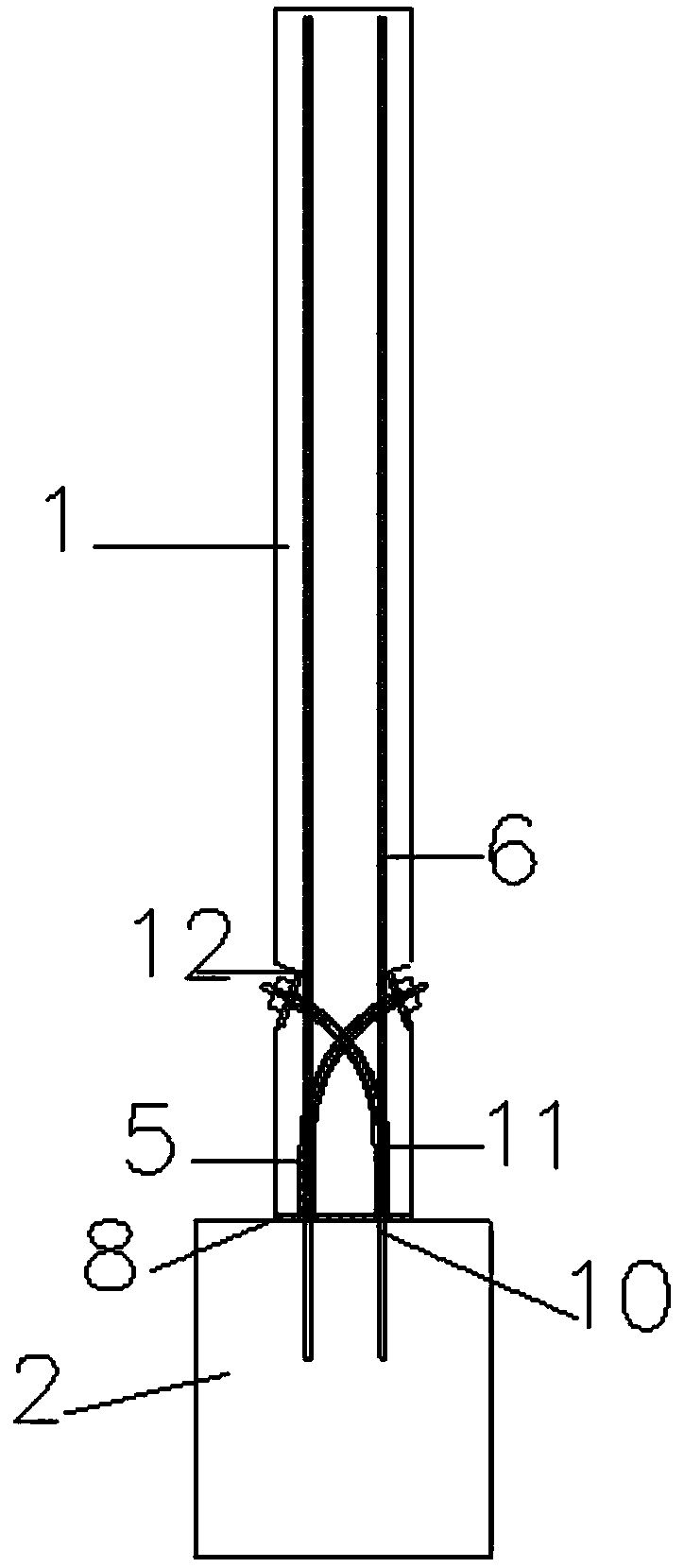

[0033] Such as Figure 1 to Figure 5 A self-resetting assembled shear wall structure connection device shown includes a prefabricated shear wall 1 and a foundation shear wall 2, and the prefabricated shear wall 1 is provided with a reinforcement cage and several longitudinal bars 6, and is characterized in that , the prefabricated shear wall 1 includes an end restraint area 3, a middle restraint area 4 and a distribution rib area 5, the middle restraint area 4 is located in the middle of the prefabricated shear wall 1, and the end restraint area 3 is located at At both ends of the wall of the prefabricated shear wall 1, the distribution rib area 5 is located between the end restraint area 3 and the middle restraint area 4; the lower end of the end restraint area 3 of the prefabricated shear wall 1 is sleeved with an end The longitudinal reinforcement connecting plate 7, the longitudinal reinforcement connecting plate 7 at the end is welded to the longitudinal reinforcement 6 a...

Embodiment 2

[0036]The rest are the same as in Embodiment 1, except that the long screw anchor backing plate 12 is provided with triangular grooves on both sides of the prefabricated shear wall 1, and the grooves are connected with the prefabricated shears below the grooves. The included angle of force wall 1 wall surface is 1°.

Embodiment 3

[0038] The rest are the same as in Embodiment 1, except that the long screw anchor backing plate 12 is provided with triangular grooves on both sides of the prefabricated shear wall 1, and the grooves are connected with the prefabricated shears below the grooves. The included angle of force wall 1 wall surface is 89 °.

[0039] The invention applies energy dissipation and shock absorption to the assembled structure. This connection method improves the energy dissipation capacity of the shear wall structure, and the shear wall has self-resetting ability under lateral load, which can reduce the anti-seismic requirements of the overall structure and improve the main structure. The anti-seismic performance of the structure; at the same time, it has the characteristics of easy industrial production, more efficient and faster, and avoids the inconvenience caused by on-site wet operations and energy consumption pollution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com